Malfunctions. Repair.

If you decide to carry out repairs or adjustments yourself, make sure you have the necessary qualifications. Poor repair of gas equipment can cause a fire, explosion or poisoning. After completing the work and assembly, make sure that the device is tight and operates correctly. The tightness is checked by applying a soap solution to all joints. No bubbling indicates there is no leak. But you shouldn’t delude yourself. The tightness will need to be checked several more times (after a day, three days, a week of operation), and then checked regularly, since a leak may occur some time after the start of operation.

Main malfunctions: the gas pressure at the outlet does not correspond to the nominal value (reason: the spring is broken or deformed), gas leakage (reasons: the membrane is damaged, the tightness of the connection between the membrane and the housing is broken, the float valve is leaking)

Here is a selection of materials:

IN

Everything you need to know about heating and climate control Features of the selection and maintenance of boilers and burners. Comparison of fuels (gas, diesel, oil, coal, wood, electricity). Do-it-yourself ovens. Coolant, radiators, pipes, heated floors, circulation pumps. Chimney cleaning. Conditioning

If the float bypass valve leaks, then the leak may not occur in the reducer itself, but somewhere further, for example, in a gas stove, since in this case, in zero consumption mode (when the stove or some other consumer is turned off), at the outlet reducer and gas pipes, the pressure can reach the inlet pressure. Gas gradually leaks through the valve, and there is nowhere for it to go. If there is a gas cylinder at the inlet, the pressure can reach 15 bar, which is 500 times higher than the nominal one. Such pressure will definitely lead to leakage. At the same time, it is difficult to detect this malfunction, since when the stove is turned on, the pressure normalizes. There is no sign of overpressure (flame blowout). The fault can only be identified by measuring the outlet pressure in zero consumption mode. It can be no more than 20% more than nominal.

To repair, the gearbox must be disassembled. Only a dismountable gearbox with a spring can be repaired. Sealed gearboxes are not suitable for repair.

In the picture, the membrane is with the bottom side up.

An inspection will show if there are defects in the membrane or a broken spring. A torn membrane can be replaced. But it’s not worth it, it’s better to buy a new gearbox, since it’s quite difficult to hermetically connect the new membrane with the washers. A broken spring can be replaced. Most often, the spring does not break, but simply compresses a little over time. As a result, the outlet pressure becomes lower than nominal. This malfunction can be easily corrected by placing a gasket between the housing and the spring. Read about this below in the section on transferring to another pressure.

Membrane - top view.

If you have diagnosed problems with the bypass valve, then you need to inspect it. It is a tube with a thin hole. A piece of hard rubber mounted on a rocker arm is pressed against the end of the tube. The valve may not close for the following reasons: Firstly

, the mobility of the rocker arm is impaired.

Move it with your hands, make sure it moves freely. If there are problems, grind or replace the hinges. Secondly

, a piece of rubber was worn out and torn.

It can be removed with a sharp knife and replaced by gluing another one of the appropriate size in its place. Thirdly

, the end of the inlet tube may not be smooth, with damage and roughness. This prevents a tight seal. The end can be sanded with fine sandpaper.

Very often, a leak occurs due to a leak in the seal between the membrane and the lower part of the housing. Troubleshooting is easy. You need to lubricate the edge of the lower part of the case where the membrane fits with silicone sealant, let it dry a little (10 minutes), install the membrane, assemble the gearbox and let it dry a little more (2 hours).

During disassembly and subsequent reassembly, it is quite easy to break the tightness of the membrane. If you have disassembled the gearbox, then during reassembly in any case, even if there was no leakage, use silicone sealant. This will improve reliability.

Disassembling the Lovato gearbox - step-by-step instructions:

1. So, the gas supply is turned off, all safety measures have been observed, you can begin. The first step is to remove the gas supply hoses and dismantle the gearbox.

2. Then take the hexagon “H4” and unscrew the 6 bolts securing the top cover of the gearbox.

3. Remove the cover under which the first membrane is located. We pry off the membrane and remove it in the direction indicated in the photo.

4. You will now have access to the valve rocker arm. Unscrew the two rocker arm mounting bolts.

5. Unscrew the sensitivity adjustment screw.

6. Pry up the rocker arm with a screwdriver and remove it.

7. Using a hexagon, unscrew the 4 bolts, then remove the diaphragm and the spring located under the diaphragm.

8. Turn the gearbox over and unscrew the 8 mounting screws, remove the cover along with the spring located under it.

9. Next, using the same principle, remove the membrane.

10. After you have disassembled the gearbox, clean it, wash it, and also replace all the necessary rubber bands and seals. Allow all parts to dry before assembly. Assembly is performed in reverse order.

That's all for me, thank you for your attention and see you again at the HBO site.

Source: gboshnik.ru

Conversion to a different pressure

Sometimes it becomes necessary to obtain non-standard pressure at the outlet. For example, having bought a stove for natural gas, I wanted to convert it to a bottled one. The usual way is to replace the injectors and low gas flow screws, but there is another way - to use a 12 mbar reducer. Such reducers are commercially available, but they are rare and difficult to buy. You can remake the usual one.

I will say right away that not every reducer can be converted to any pressure. There are the following restrictions. The ratio of the areas of the membrane and the inlet port, multiplied by the rocker arm, should be one and a half times greater than the ratio of the maximum inlet pressure and outlet pressure. Otherwise, the force developed by the membrane under gas pressure will not be enough to reliably close the inlet valve. In practice, it is usually easier not to carry out these calculations, but to configure the gearbox experimentally. All the same, to carry out calculations it needs to be disassembled in order to measure the area and lever of the rocker arm.

For remodeling, it makes sense to buy a gearbox in which the mounting screws are accessible and not covered in paint. The modification comes down to changing the elasticity of the spring. Let's disassemble the gearbox. If the pressure needs to be made less than it was, then shorten the spring a little (by half a turn), if more pressure is needed, then place a spacer between the gearbox housing and the spring. When installing the gasket, be careful not to block the hole in the housing. We assemble and check the gas pressure at the outlet. Repeat until the desired pressure is achieved. If after the next shortening the pressure turns out to be less than necessary, then the spring can be stretched a little or a gasket can be placed.

If it turns out that the outlet pressure is too high, even in the complete absence of a spring, then the relationship described above is not observed. The selected reducer cannot be converted to the required pressure.

When the elasticity is selected, you need to finally assemble the gearbox by applying silicone sealant between the bottom of the housing and the membrane.

pressure regulator "Baltika". what is the operating principle of the BALTIKA regulator?

Reducer type "RDG" Reducer type "Baltika"

Typically, the design of the pressure regulator allows a one-stage reduction in pressure to the pressure level of the gas phase of liquefied gas (2.5 - 5 kPa) at the outlet of the cylinder.

The design of gearboxes is almost universal, but there are still a sufficient number of non-interchangeable cylinder valves and gearboxes. Therefore, in our country, two types of gearboxes, “Baltika” and “RDG,” are accepted for use by the relevant standards. This is due to the fact that in the cylinders used in Ukraine, either a valve is used as a shut-off valve, onto which an “RDG” type reducer is screwed, or a valve - in this case, a “Baltika” type reducer is used.

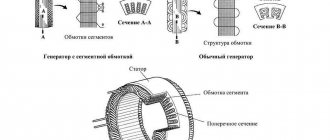

The principle used in all types of pressure regulators is as follows. 1 diaphragm; 2, 3 springs, respectively, regulator and return; 4, 10 holes, respectively, exhaust and inlet; 5, 6 caliper and diaphragm spindle; 7 lever; 8 building. 1 open switch /closed ; 2 outlet; 3 second stage diaphragm; 4 first stage diaphragm; 5 ball coupling.

A sensitive loaded diaphragm, under the influence of, on the one hand, excess pressure of the gas phase, and, on the other hand, a spring, opens or closes the valve inlet. The diaphragm is supported by a spring that regulates the pressure. Thus, the reducer can be adjusted to close at any pressure. Being adjusted to a certain output pressure, such a reducer will withstand it regardless of fluctuations in inlet pressure and changes in gas extraction.

How does a cylinder reducer work:

1 Direct gearbox

An ordinary simple gas pressure reducing device consists of two chambers with an area of high and low pressure, separated by a rubber membrane. In addition, the “reducer” is equipped with an inlet and outlet fitting. Modern devices are designed in such a way that the bellows connection is screwed directly into the gearbox. Increasingly, you can find a gas reducer with a third fitting intended for mounting the monomer.

After gas is supplied through the hose and then through the fitting, it enters the chamber. The created gas pressure tends to open the valve. On the reverse side, a shut-off spring presses on the valve, returning it back to a special seat, popularly called a “saddle.” Returning to its place, the valve prevents the uncontrolled flow of high-pressure gas from the cylinder.

Membrane

The second acting force inside the gearbox is a rubber membrane that divides the device into high and low pressure areas. The membrane acts as an “assistant” to high pressure and, in turn, tends to lift the valve from the seat, opening the passage. Thus, the membrane is between two opposing forces. One surface is pressed by a pressure spring (not to be confused with the return spring of the valve), which wants to open the valve, on the other hand, the gas that has already passed into the low pressure zone presses on it.

The compression spring has manual adjustment of the pressure applied to the valve. We advise you to buy a gas reducer with a seat for a pressure gauge, this way it will be easier for you to adjust the spring pressure to the desired output pressure values.

As the gas leaves the reducer to the source of consumption, the pressure in the working space chamber decreases, allowing the pressure spring to straighten. She then begins to push the valve out of the seat, again allowing the device to be filled with gas. Accordingly, the pressure creeps up, pressing on the membrane and reducing the size of the pressure spring. The valve moves back into the seat, narrowing the gap, reducing the gas filling of the reducer. The process is then repeated until the pressure equalizes to the set value.

It should be recognized that gearboxes for direct type gas cylinders, due to their complex design, are not in high demand; reverse type gearboxes are much more widespread; by the way, they are considered devices with a high degree of safety.

2 Reverse gearbox

The operation of the device consists of the opposite action described above. Liquefied blue fuel is supplied to a chamber where high pressure is created. The bottled gas accumulates and prevents the valve from opening. To ensure gas flow into the household appliance, you need to turn the regulator in the direction of the right-hand thread.

On the back of the regulator handle there is a long screw, which, when screwed, presses on the pressure spring. As it contracts, it begins to bend the elastic membrane to the upper position. Thus, the transfer disk, through the rod, exerts pressure on the return spring. The valve begins to move and begins to open slightly, increasing the gap. Blue fuel rushes into the gap and fills the working chamber with low pressure.

In the working chamber, in the gas hose and in the cylinder, the pressure begins to increase. Under the influence of pressure, the membrane is straightened, assisted in this by a constantly compressed spring. As a result of mechanical interactions, the transfer disk lowers, weakening the return spring, which tends to return the valve to its seat. By closing the gap, the flow of gas from the cylinder into the working chamber is naturally limited. Then, with a decrease in pressure in the bellows liner, the reverse process starts.

In a word, as a result of checks and balances, the swing can be balanced and the gas reducer automatically maintains balanced pressure, without sudden jumps and drops.

What is a propane reducer?

The design of all propane reducers is very similar. They all have:

- Sealed housing made of aluminum, brass or plastic.

- Inlet pipe for connection to the cylinder.

- Outlet pipe for connection to the consumer.

- High and low pressure chambers.

- Flexible membrane.

- Valve and stem.

- Return spring.

- Working spring.

In professional gas reducers, a pressure gauge, an adjusting screw or flywheel, and a threaded connection of the supply pipe are added to the design. The gearbox housing has a cylindrical shape, which is due to the use of a round membrane that bends inside the operating pressure chamber. The inlet and outlet pipes protrude from the housing.

Types of gas reducers

From the school course, the concept of non-flammable – inert gas – comes to mind. This broad group includes nitrogen, argon, helium, neon, etc. they do not support combustion and do not burn. It is widely used as a shielding gas during welding. On the other hand, there are flammable gases (butane, hydrogen, methane, propane, propylene, etc.), which either liquefy or compress and then move their cylinders. So, in order to prevent confusion, engineers, even at the production stage, suggested cutting versatile threads.

Thus, a gas reducer intended for use in the group of flammable gases is manufactured with a left-hand thread. The opposite thread turning to the right provides a gas reducer for inert gases. Among other things, manufacturers use color dyeing to promote brighter highlighting.

Before buying a gas reducer for a cylinder, we advise you to pay attention to the throughput of the device. The optimal solution would be to buy a 2nd generation gas reducer. Before making a purchase, you must make sure that the selected model meets the gas flow parameters sufficient for the consuming device.

Application

Gas reducers are widely used in households and private households. They are operated on all types of gas and are used in a wide variety of industries. Gas reducers can be found in agriculture, in the construction industry, in medical institutions, and simply in a country house.

For example, an oxygen reducer is used both in welding work and in providing medical care. As for acetylene gas reducers, you can find them in any mechanic shop.

Propane reducers are indispensable during construction work; you cannot do without them in activities related to laying roofing and bitumen materials. A gas reducer for a propane cylinder has become not a luxury, but a necessity; with its help, millions of housewives regulate the pressure coming from the cylinders to the gas stoves. A propane reducer often has a funny name, and if you ask in a store whether you can buy a frog reducer for a gas cylinder, then rest assured, the seller will perfectly understand your request.

Sequence of installation and use

A propane reducer of any type and design is considered a high-risk technique, therefore, when installing it, a number of mandatory requirements must be observed:

- The room (if the gearbox is mounted to an internal consumer) is thoroughly ventilated. Moreover, the window/vent must remain open throughout the entire duration of the initial start-up.

- The correct sequence for using the device is as follows: first, the valve on the propane cylinder opens smoothly. Then the valve of the reducer opens and only then the valve of the gas-consuming equipment. By rotating the adjusting screw handwheel, the required level of operating pressure is set. Disabling is done in reverse order. When extraneous sounds appear - clicks, hissing, etc. - the equipment is immediately turned off.

- After establishing a stable flow of gas through the reducer, monitor the readings of the pressure gauge needle, which should not deviate more than the pressure fluctuation values indicated in the passport. Otherwise, the use of the technology is stopped. A slow increase in gas pressure is considered especially dangerous.

- Once every 2...3 months, the tightness of all connections is checked, and if necessary, the threaded fasteners are tightened.

- If routine maintenance of the propane reducer is necessary - purge the valve - the device is disconnected from the gas main, after which the remaining gas is released from all working cavities of the device. All subsequent operations are performed only in special workshops that have test benches.

- After finishing use, the inlet valve on the gearbox is closed all the way. In this case, the binding of the spring is eliminated, and its performance increases.

- To comply with fire safety rules, it is advisable to provide flame extinguishing devices between the gearbox and the gas-consuming installation.

https://youtube.com/watch?v=lspIr9UNH7E

The use of bottled gas requires a thorough approach to ensuring safety and ease of use. We propose to consider the simplest example of connecting a propane cylinder to a gas stove: connection diagram, shut-off and control valves, organization of storage conditions.

Reducer for gas cylinder

Since we are choosing a reducer for a gas cylinder, we consider it necessary to touch upon the topic of the container itself. The technological process and widespread introduction of new innovative materials are bearing fruit. You can increasingly find new composite cylinders on the market, replacing the old generation. Modern models, unlike outdated predecessors, have less weight and offer a greater level of safety. The latest manufacturing technologies undergo multi-level testing; at testing sites, the composite cylinder is subjected to an explosion, but even after such tests you will not find small fragments.

What cars and gas equipment do we work with?

Our specialists will replace 1st, 2nd and 4th generation gas automotive equipment on both domestic cars and foreign cars, gazelles, passenger cars and off-road vehicles. Installation and replacement of a 4th generation gearbox on a car is carried out with a guarantee of 2 years from the date of installation.

Gas reducers for gas cylinder, price and types

Let's try to choose a reducer for gas cylinders, from those popular types that are in greatest demand among consumers. Let’s take a look at the gas appliance market and find out what the price for a gas reducer for a cylinder was at the end of 2017.

Household gas reducer RDSG for propane stabilization

The leading position in the market, and among consumers in the country, is occupied by the RDSG-1-1.2 “Frog” device with a threaded fastening. The RDSG-2 Baltika gearbox equipped with a threadless connection is not inferior in popularity. Both leaders represent the simplest design. As a result, they can offer the lowest possible cost. Specifications: — inlet pressure from 0.7 to 15.7 Bar; — the output pressure lies in the adjustment range from 30 to 32 mBar; — device weight 310 g; — permissible operation in the range from -30 to +45 ±3 °C; — gas throughput characteristic — 1.2 m3/hour. You can buy a gearbox RDSG 2-1.2 Baltika or RDSG 1-1.2 Frog for up to 350 rubles.

Specifics

As already noted, gearboxes can be domestic and industrial. Also universal models.

Consumer versions may not be customizable.

These are simple models. They are used in everyday life and outdoors. RDSG products are installed together with household gas cylinders. They have a very simple design. Due to this, gas can only be used in household stoves. These products are inexpensive and very reliable. There is also a Frog type gearbox, there is the RDSG-1 model. They should only be used in cylinders with a volume of 12 - 50 liters.

The class of universal, customizable gearboxes has a more complex design and greater potential. This is an excellent option for domestic use and for work in the home workshop. The products are attached to the cylinders using a threaded method and are fixed securely.

They have a pressure gauge and an adjustment screw that allows you to vary the functional pressure within the range of 0 - 0.3 MPa. Their highest throughput capacity is 5 m3/hour.

The category of professional models is created from the best wear-resistant materials. They have the highest build quality and settings: 0.4 - 1.6 MPa.

Some modifications have two pressure gauges. They reflect input and functional pressure.

Often, many summer residents and hikers ask questions such as: is a reducer needed for a gas burner? And is a gearbox needed for a gas stove in the country? Stable and safe operation of any gas appliances and in any conditions is always necessary. Even if there is no urgent need for gearboxes, it won’t hurt to be on the safe side. It remains to decide which gearbox is needed for the gas stove.

Since the stove and burner are propane based, a propane reducer is needed. You need to select these products by studying them and comparing their characteristics. The key ones are:

- Purpose of the device.

- Higher inlet pressure.

- Functional pressure.

- Higher gas consumption.

- Attachment method.

- Planned operational life.

- Price.

For example, if you plan to connect a desktop portable stove only on weekends, the gas consumption according to your calculations is 5 liters per month, then you need a 5 liter capacity and a Baltika RDSG-2 reducer.

For a static stove with an oven, a capacity of 27 or 50 liters is required. A suitable gearbox is the Frog RDSG-2.

Questions often arise here - what does a Frog gas reducer actually do? Why is it named like that? What is its purpose?

Why do you need a frog gas reducer? Its functions, like those of other gas reducers, are pressure stabilization, safety, etc.

Why frog? This device is direct. In it, gas flows through a fitting. The valve opens and is pressed against the seat by a spring. High pressure gas does not penetrate into the chamber. The diaphragm displaces the valve from this seat. The pressure gradually decreases to the operating values of the device to which the reducer is mounted.

The spring straightens. The valve is detached from the seat and does not interfere with gas flow. As the pressure increases, the spring presses the valve again, gas does not flow. This principle is reminiscent of frog jumping. And the device is similar in shape to it.

If it is necessary to connect a composite container to a thermal umbrella, it is better to use imported products with a KLF connector

The professional model BPO 5-3 Krass is optimally suited for gas welding in a home workshop. It guarantees a flow rate of a maximum of 5 m3 per hour and allows you to adjust the operating pressure to 0.4 MPa. And for this task it has a flywheel and a pressure gauge. Thanks to the latter, it is possible to scrupulously assign pressure to the needs of gas welding equipment.

Types of reducer for gas cylinder

Among numerous industrial inventions, the leading place belongs to shut-off valves used as valve-type regulators (reducers) for gas cylinders.

The purpose of the reducer for a household gas cylinder is to reduce and maintain the vapor pressure of liquefied gas coming from the cylinder within regulated limits.

The industrially manufactured gearbox NZGA RDSG-1-1.2 is a case-type regulator for constantly preset parameters of the gas mixture:

- the pressure of the supplied mixture at the inlet in a household gas cylinder is 0.07-1.6 MPa

- regulator pressure 2000-3600 Pa at outlet

- minimum gas consumption 1.2 m3/h.

The reducer is installed in a horizontal plane relative to the cylinder valve. The regulator has factory settings that ensure that the mixture parameters are maintained after filling household gas cylinders that are commonly used. The liquefied gaseous medium in the cylinder remains under a pressure of 15 bar. Using a propane reducer, the pressure is reduced to 36 mbar.

It is clear that any deviation from the specified parameters of the gas pressure reduction system can result in an accident. Helpful tips can help you avoid trouble.

Useful tips

The design of the NZGA RDSG-1-1.2 gearbox is simple. A single-stage round diaphragm reducer ø 52 mm without external adjustment elements and control pressure gauges measuring 150x105 mm is connected to a propane (LPG) cylinder of valve type VB-2 with a standard union nut with a left-hand thread.

Connecting dimensions are:

- inlet - nut SP 21.8LH 14/1″

- output - gas sampling fitting for DN 9.

It would seem that everything is simple to connect the regulator, daily adjustment and supply of gas to the consumer.

However, during the operation of gas equipment, malfunctions of the gas reducer cannot be ruled out. Most users repair the gas reducer using the services of gas services. You can troubleshoot problems yourself.

Area of application of devices

Wherever there is no stationary gas distribution, people use propane in cylinders. And each cylinder is connected to one or another reducer. The most popular applications are:

Using the gearbox for soldering and welding

- Household and portable stoves and grills.

- Gas water heaters and heat guns for heating rooms.

- Thermal umbrellas for heating recreation areas.

- Gas cutters and welding torches.

- Fuel for land and river transport.

In many countries, wide gas distribution networks have been created to ensure recharging and delivery of gas cylinders to consumers.

The gas cylinder reducer ensures safe and stable operation of gas consuming devices.

If you find an error, please select a piece of text and press Ctrl+Enter.

Liquefied gas, which is used to fill cylinders for subsequent use, is always under increased pressure. To lower it, it is necessary to install a special type of shut-off and distribution valves on the cylinder - a propane reducer. Subsequently, the reducer automatically maintains the specified level of gas pressure. According to safety regulations, the device is always painted bright red - the same color as propane cylinders.

Gas reducer malfunctions, repairs

Malfunctions of the gas reducer can be associated with a discrepancy between the pressure rating of propane or the gas mixture at the outlet, leading to deformation and damage to the internal elements of the regulator: membrane, spring, end of the bypass valve and gas leakage.

Naturally, determining the cause of the malfunction will require certain knowledge and skills. You can find out the cause of the malfunction and carry out independent repairs by disconnecting the fittings and disassembling the regulator body.

Let us tell you that to determine the pressure level it is recommended to use the following parameters:

- reducer diaphragm dimensions

- type and characteristics of the reducing spring

- mechanical force to close the bypass reducing valve.

Let us tell you that the “frog” reducer is an unregulated pressure option. More complex reduction systems are used for customized automotive systems.

membrane replacement

The NZGA RDSG-1-1.2 gearbox diaphragm is a round liner made of oiled rubber-fabric oil- and petrol-resistant fabric with a thickness of δ=3 mm, secured along the circumferential markings by the housing cover.

A possible cause of the defect is a violation of the tightness between the membrane and the housing. The malfunction is eliminated to create a better fit of the membrane by lubricating the edge of the lower housing with sealant. The above-membrane part of the body has an upper hole that provides communication with the environment.

replacing the reducing spring

The reducer for gas cylinders uses a long 1st degree reduction spring with parameters D=15.5, d=1.4, number of turns 12-14, balancing the force of the membrane and inlet valve in operating condition.

Precautionary measures

Household gas is very dangerous. The main threats posed by propane are:

Reminder about domestic gas

- Fire hazard.

- Unsuitable for breathing.

- Explosion hazard when the maximum concentration of propane in the air is reached, as well as when the temperature in a closed volume rises sharply.

- During a gas leak, the temperature drops sharply and frostbite is possible.

To preserve the life and health of people and their property, precautions should be taken:

Rules for using gas

- Avoid proximity to open flames and heat sources.

- Avoid the presence of other flammable materials in the work area.

- Eliminate the presence of nitrates and perchlorates near gas equipment due to their chemical activity.

- Do not use the reducer for a propane cylinder if it is damaged or leaking.

Installation features

As you know, gas should be handled with extreme caution due to its explosive hazard, because even a small leak or poor-quality connection can lead to extremely tragic consequences.

Connecting bottled gas to the stove should not occur in the absence of one of the following elements:

A stove designed for the use of liquefied gas (as a rule, when connecting equipment designed for pressure from a centralized network, the burners burn poorly with a characteristic yellowish flame color).

In this case, both a special stove for a summer house under a cylinder and replacement of the jets of the old tiles with special ones for liquefied gas are suitable.

Container with propane-butane mixture.

Gearbox. This unit is necessary to equalize gas pressure while gradually reducing the amount of mixture in the cylinder.

Gas hose made of flexible rubber or semi-flexible bellows hose. According to SNiP standards, the cylinder is installed no closer than 1 m relative to the stove or heating appliances.

In this case, the hose should be positioned freely, without tension. Therefore, you will need to purchase it about a meter more than required.

Connecting elements. Fittings and screw clamps for rubber hose.

In the case of using bellows hoses, use threaded adapters.

Soap solution to check for possible gas leaks after installation is completed.

Step by step guide

If you already have everything necessary for installation, then it’s time to tell you how to connect a gas cylinder to the stove with your own hands:

Step 1. Connect to the stove

The gas stove must already be installed in its place before connecting:

- We connect a hose to the outlet pipe of the stove, screwing it onto the pipe hole and tightening it with a clamp.

- In the case of using threaded adapters, it is enough to screw them tightly onto the pipe threads, having previously wound the non-metallic tape onto the threads.

- All manipulations are carried out without a connected cylinder, that is, the other end of the hose is not connected to it.

Step 2. Connecting the gas reducer

When using gas household appliances that receive fuel from a centralized gas supply system, the presence of this element is not necessary. However, the use of liquefied gas in cylinders requires a reducer to equalize the pressure of the outlet flow:

- The reducer is installed using an adapter at the outlet of the gas cylinder; the use of sealing fum tape is mandatory.

- A gas hose is installed at the outlet of the reducer, which is secured with a clamp.

Step 3. Installing the cylinder

The location of the cylinder must comply with all regulations and safety requirements. It can be installed either in the room where the stove is located, or in a neighboring one, or in a specialized box on the street or in a utility room.

To properly install the cylinder, the following conditions must be met:

- Do not install equipment in basements, basements, semi-basements, or buildings higher than two floors.

- The distance from heating appliances and gas stoves should not be less than 1 m.

- A metal cabinet for a cylinder located outdoors must protect it not only from precipitation and sunlight, but also from freezing, therefore it must be insulated and heated.

- The cylinder must be placed on a flat, clean, dry surface. If this is the floor in a special cabinet, then the cylinder itself is installed on a pallet or slats, not on the bottom itself.

Step 4: Check for Leaks

The connection of the cylinder to the stove is checked using a concentrated soap solution:

- Prepare a solution of soap and warm water, beat until light foam.

- Using a sponge or cloth, apply the solution to the junction of the gas hose and all elements.

- If soap bubbles appear, there is a leak. Otherwise, you did everything right.

If you can verify that the connection is tight, set the required pressure on the reducer and slightly open the cylinder screw to let gas into the system.

We turn on the burners and evaluate the color and quality of the flame: if it is bluish-green and even, then the pressure is normal.

You can connect a gas stove to several cylinders at the same time using a connecting ramp.

Useful tips

To ensure that the installation of a gas pipeline is as safe as possible, it would be useful to know some useful tips:

Frost-resistant gas mixtures

- can be refilled into cylinders stored outside or in unheated rooms (however, the price and demand during the season will be much higher).

The frost-resistant mixture does not require insulation and evaporates at air temperatures down to -40 °C

Recommendations

Comments 25

Replace the electronics too and you will be happy)

Thanks everyone, I'll try to connect

You can adjust it with a pressure gauge if you don’t have anywhere to connect.

Yes need. Set pressure and calibrate.

If the gearbox is like this, remove the cover from the old one and install it on the new one.

If you really can’t get to the adjusters, then you can remove the old gearbox and count the number of turns of the pressure screw before screwing it in all the way and tighten the screw on the new gearbox and unscrew it by the same number of turns - 0.5-1 turns, for example.

You can do the calculations, but there is no 100% guarantee that the pressure parameters will match...

If you really can’t get to the adjusters, then you can remove the old gearbox and count the number of turns of the pressure screw before screwing it in all the way and tighten the screw on the new gearbox and unscrew it by the same number of turns - 0.5-1 turns, for example.

Never matches ((((

At Lovato, if you unscrew it all the way, everything will match)))

If you set exactly the same pressure, there is no need. But for this you still need to connect...

I agree. And after 1000-1500 the pressure in the new reducer may drop, again it is advisable to connect.

If you set exactly the same pressure, there is no need. But for this you still need to connect...

Not necessarily. You can measure your blood pressure outside of the program. Pressure gauge. Or if it doesn’t exist, use a multimeter. But this is only if the old one is still alive.

How will he know what pressure the HBO is currently set to?

Why know? Using the pressure sensor you can set exactly the same pressure. How much is it in numbers - is it really important? It's like having a tablet and making the same one. You can of course try it on and mark the same one. Or you can draw and saw off right along this)

Ahhhh... Do you mean that you need to measure it on the old editor and set the same pressure on the new one? Well, yes, it’s possible...))

Not necessarily. You can measure your blood pressure outside of the program. Pressure gauge. Or if it doesn’t exist, use a multimeter. But this is only if the old one is still alive.

1) You need to check on an engine running on gas, because when running on gasoline, the gas that is in the ramp, hose and gearbox outlet is in a closed volume. On the one hand, these are closed gas injectors, on the other, a closed reducer valve, on the third, a diaphragm, which, through its movements, changes the size of this very volume, and therefore the pressure in it.

Stages of work

Before replacing automobile gas equipment, we will diagnose the car, identify the cause of the problem and determine the type of malfunction. Based on the data received, our technicians will repair or replace the car’s gas device with new equipment of the appropriate generation.

Our advantages

| Service | Price |

| replacement of 4th generation gearbox | from 6000 rubles |

| replacement of a traditional gearbox | from 5000 rubles |

If you are looking for where to repair and replace automotive gas equipment of 1-4 generations at an inexpensive price, call us at +7 (925) 470-79-47.

Source: power-gas.ru