Design and principle of operation

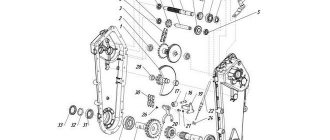

The gearbox is a complex mechanical transmission unit through which the axis of the motor-power unit transmits torque to the cartridge.

Two or three transmission stages are installed in the gearbox.

The design of the “household” dual-mode screwdriver assembly includes:

- The plastic case is a small drum that is mounted on a cartridge. The body itself is fixed motionless, and the chuck shaft is inserted into a clamp on one of the transfer plates;

- 2 or 3 transfer plates (carrier) - a round metal plate, on one side of each there are 3 protrusions for small gears. On the other side of one of them there is a clamp for the chuck shaft, and the other (or 2 others) has another so-called. a “planetary” gear that rotates three small gears;

- 6 or 9 small gears (three each: they can be of the same or different thicknesses) are the so-called “satellite” gears, which are installed and rotate freely on the projections of the transfer plates. With their teeth they interact with the sun gear located between them and with the ring gear, which is located on the inner surface of the housing;

- ring gear - a metal ring with teeth on the inside and small protrusions on one of the rings on the outside. It is placed on these protrusions and ball bearings on the inner surface of the housing.

The parts are lubricated, assembled in series and installed inside the ring gear, which lies inside the housing drum (it has a seal with recesses for ball bearings and gear lugs). After this, the surface of the open satellites is covered with a metal washer, in the center of which there is a hole into which the engine shaft enters with another gear attached to it.

During operation of the screwdriver, the gear wheel on the motor shaft rotates the upper satellites, and they, spinning around their axis and, along the ring gear, respectively, transmit movement to the next carrier. Depending on the number of plates and small gears, the rotation speed will decrease proportionally.

As can be seen from the design of the gear unit, they are divided depending on the number of transfer plates into:

- two-stage.

- three-stage. In this case, another plate with a “planetary” gear and 3 satellites is added to the design.

Another indicator by which gearboxes are divided is the material from which their parts are made.

In the production of satellite gears the following is used:

- plastic. Such structures are relatively lighter, but their reliability is lower than that of their metal counterpart;

- metal. They are durable and with proper care and lubrication they will work like a clock.

Causes of failure

Like any mechanical unit, when the gearbox operates, the parts are affected by frictional forces, causing them to gradually wear out or wear out and lose their “adhesion.” In order to avoid this, all parts of the assembly must be properly lubricated.

Therefore, the first reason for gear unit failure is a lack of lubrication (but there may also be an excess of it).

Also, the gearbox is affected by such a “scourge” of mechanics as dust. It settles on the parts and during operation heats up along with them. This is especially dangerous for plastic gears, since under the influence of heat from dust they are subject to deformation - which leads to failure.

Finally, another nuisance for the gearbox is the ingress of foreign particles into it. Clogging between the teeth, they jam them. Because of this, when the motor shaft rotates, an excessive load is created on other structural elements, which leads to their destruction.

Reference. If one of the reasons or force majeure has led to damage to an element of the gear unit (gears, bearings or shafts), it is often necessary to install a new gearbox as a whole, since not all manufacturers have on sale individual gearbox parts to make a replacement.

DeWalt Grease (DW 870889-02)

I bought it for the occasion. 150 rub. yellow-white tube, 100 gr. The lubricant is greenish in color, the smell is probably similar to something gasoline.

They said that it would be suitable for high-speed places (trimmer, grinder gearbox.) Is that true?

We have it for 130 rubles, I think it’s the same. On the packaging it says that it has a lot of uses, specifically for a rotary hammer. True, which part of it (perf) can be smeared with it, I couldn’t find it on the tube. I seem to remember there is a mention there of using it for lubrication of bearings. I didn’t like the color, IMHO it looks more like grease for drills, if not a complete “stick”. Perhaps dear DW will clarify this issue.

I addressed your question to our service center and received the following response

Therefore, if you don’t mind, could you post a photo of this tube.

It’s a good idea to start topics like this with photos. Otherwise you sit and wonder.

It spilled in more than one place" >

Darted

Not rich green, but rather faded and transparent. This is the right color!

Okay, at least not with chocolates. My astro forecast for the available 2 parameters is that the lubricant is not scorched.

Today I visited a store where I saw a possible lubricant like this for the fall, see below. post #2. As it lay, it still lies on the display case, the price has decreased slightly, 123 rubles. The tube in the window is so covered with hands that you can’t really read the inscriptions, the seller says they’re looking at it, a lot of people are looking at it, they don’t remember what they would take, like it’s expensive, the company and what they wanted. Lubricants are also available from other companies, prices start from 230 rubles. for 30 gr. tube. I ask him for another clean tube, I read it to refresh my memory. At the very top, on a black background in large yellow letters - DeWalt, below, as a heading: MULTIPURPOSE LUBRICANT. Article 870889-02, (there is no word article itself, just numbers). Further: it is intended for lubrication of chucks of electric hammers of all types, as well as bearings and gears. The tube is white plastic, with a yellow-white sticker on which all the information is written. The color of the lubricant (the inside of the tube is not packed with foil, they were allowed to squeeze out a little) is a little darker than lithol, a little thinner. Barcode - 40020703 (that’s it, no more numbers). At the very bottom of the sticker is the inscription (the only one in English): DeWalt, Idstein-Germany. e 100g.

Source

Lubricants from domestic manufacturers for bearings and gearboxes of angle grinders

With rising prices for foreign lubricants, lubricants from domestic manufacturers have become especially in demand.

Russian lubricant manufacturers have learned to produce high-quality lubricants suitable for any tools.

Lubricants have been developed for gearboxes of grinders, hammer drills, and drills.

Nanotech Metal Plak Electra products are especially popular. The range of lubricants produced by this company allows you to select the right lubricant for each unit.

Lubricant for angle grinder bearings

Three bearings are installed in the design of the angle grinder. Two bearings are mounted on the tool rotor, one bearing is mounted on the shaft of the driven helical gear of a larger diameter.

Angler grinders use bearings that are already filled with lubricant. But due to improper use or overheating of the tool, the lubricant leaks out.

How to choose the right lubricant for grinder bearings?

Bearing lubricant must meet the following requirements:

- increase sliding;

- reduce friction between components of parts;

- distribute heat evenly and act as a coolant;

- prevent corrosion;

- protect from dirt and dust getting inside;

- work in the required temperature range up to +150C;

The operating conditions of electric motor bearings differ from the operating conditions of gearbox bearings not only due to temperature requirements, but also due to operating modes, load conditions, frequency and rotation speed.

Lubricant for electric motor bearings must have protective properties that prevent dirt, dust and moisture from entering the bearing parts.

The Russian market offers a wide range of foreign lubricants intended for bearings operating under different conditions. But their cost forces us to look for cheaper, domestic lubricants that are not inferior in quality.

Among domestic lubricants, we recommend paying attention to lubricants Tsiatim-221, VNIINP-246 (GOST 18852-73), VNIINP-235. Lithium greases have proven themselves well. Lithium greases have proven themselves well

Lithium greases have proven themselves well.

Possessing high water-repellent properties, they have a wide temperature range. The role of a thickener in them is performed by organic and inorganic substances. For sealed bearings, it is best to use lubricants CIATIM-203, VNIINP-242.

Among pigment lubricants for electric motor bearings, blue grease VNIIMP-246 and dark purple ointment VNIINP-235 have become widespread. The first lubricant is less common than the second due to its high price.

In today's Russian market, domestic manufacturers of lubricants are represented in a wide range of products.

Lubricant for angle grinder gearbox

The lubricant for the grinder gear differs from the lubricant for bearings in the main feature - increased adhesion. It should hold firmly on the gear teeth when it rotates at high speeds.

In general, the process of lubrication of the gearbox in angle grinders occurs due to fine splashing of the lubricant and its suspensions. The gearbox operates as if in an oil mist. Therefore, the lubrication requirements for gearboxes are somewhat different.

In addition to increased adhesion, gear lubricant must have high heat resistance and not melt at elevated temperatures.

Do-it-yourself grease for the grinder gearbox

Is it possible to make a lubricant for the gearbox of an angle grinder with your own hands?

And there is an affirmative answer to this question.

Since the main technical characteristics of lubricants for angle grinder gearboxes are presented above, they can be taken as the basis for creating a lubricant with the required characteristics with your own hands.

The basis of a homemade lubricant for gearboxes should be a lubricant with high adhesion. It must hold tightly to the contacting parts.

Grease for CV joints has increased adhesion. A CV joint is a joint in a front-wheel drive vehicle that operates under conditions of increased dirt, shock loads, temperature fluctuations and humidity.

Taking the lubricant for CV joints as a basis, it is necessary to add liquid lubricant (MS-20) to give the mass the desired consistency. MS-20 oil should be added drop by drop, thoroughly kneading the mixture using a homemade mixer.

Good results are obtained from a mixture of Ciatim-221 and TAD-17 lubricants, where the base is Ciatim.

What and how to properly lubricate a drill?

For Soviet equipment, no better lubricant than Litol-24 has been invented; it must be put into the gearbox and lubricate the guides and gears in Soviet, and not only Soviet, equipment.

Naturally, before lubrication, you need to thoroughly clean and wipe the entire part dry (no need to wash with solvent, diesel fuel, or gasoline!), just clean and wipe dry.

Place and apply fresh Litol-24 into the gearbox and gears and assemble - that’s all!

Litol-24 lubricant will withstand high speeds and increased temperatures and increased loads and friction, it is put into the gearbox in quite a large volume, as the experts say - the excess will come out!, so its work is designed for a long time, and replacement is actually only during repairs.

In Soviet times, both people and technology were not spoiled by delicacies - they grabbed what they gave.

So you can treat your veteran drill with what remains from Soviet times - even simple grease.

Among modern lubricants for gear mechanisms, you can use CV joint grease (motorists know what it is), lithol. Bosch lubricants have proven themselves well in gear drives.

If you're lucky and come across this

buy without hesitation.

When servicing the drill, do not miss this moment: remove, as thoroughly as possible, all the old lubricant, because there will probably be metal particles from the gears and other dirt that have penetrated inside the tool.

There are a lot of types of drills, both by purpose (impact, hammerless, drill-mixers, etc.) and by type of power, these include manual, electric and pneumatic.

Drills also differ in power and in the number of revolutions it can produce.

Manufacturers are different, many manufacturers produce their own lubricants and recommend using only them.

In any case, in order to lubricate the drill (its gearbox), you need to get to it (the gearbox).

There are also a lot of options here, perhaps your drill needs to be “split” into two parts (I’m talking about the body, unscrew the screws that secure the body).

Before us is a gearbox

It is not necessary to disassemble it into its components.

They removed the old lubricant (although this is not always done), thoroughly cleaned it of the old lubricant (a rag is convenient), put in a new one, in general, that’s all, there are no difficulties here.

“Albina” always lubricated his “ancient” Soviet drill with Litol-24, there was no thought of switching to something more “advanced”, the lubricant was completely satisfactory.

Can the drill gearbox be lubricated with lithol?

Can the drill gearbox be lubricated with lithol? I know about the benefits of branded lubricants, but I’m wondering if non-branded lithol is suitable or not?

it means it’s a matter of its quantity - I recently laid it, and after three days there’s a metallic sound - I’ll add more

SergeyE wrote: it means it’s a matter of quantity

If you stuff too much in, it will crawl out of all the cracks and the gearbox will get hot

replacing lubricant in an old drill

SergeyE wrote: after three days there is a metallic sound

When metal “communicates” with metal, a metallic sound occurs. The gears spread the lubricant along the walls and the sound appeared again

Suitable, but with big reservations. This is rubbish.

scattered too quickly on the walls. What lubricant will be next in quality?

SergeyE wrote: what lubricant will be next in quality?

Buy specialized Makita lubricant for gearboxes (30g white tube with a red cap). This is the only thing that is freely available.

2Kvost, is this lubricant suitable for gearboxes of type 2450? And how much is needed? What is the price?

Lefty1 wrote: is this lubricant suitable for gearboxes of type 2450?

HZ. There is something yellowish in the perfs, but this one is black. That should also be changed.

Lefty1 wrote: And how much is needed there?

SergeyE wrote: it means it’s a matter of its quantity - I recently laid it, and in three days there’s a metallic sound - I’ll add it

And as for the metallic sound - you still need to listen, in fact, the wooden gearbox will not make a wooden sound even with any lubrication

and what do our manufacturers use – Interskol, etc. ?

2SergeyE Stop being provocative - get out of here, my dear.

SergeyE wrote: what do our manufacturers use – Interskol

It says that this is a lubricant for Li-based drills.

Solovushka wrote: Stop engaging in provocateurism - you should get out of here, my dear.

He doesn't know what he's doing. It’s just that for some reason, Soviet drills used to work with lithol (or even grease) in gearboxes for years, but then three days later a metallic sound appeared that got on the nerves. – this is the sound of a working drill, so it doesn’t sound suspicious. You must wear ear protection.

Kvost wrote: It says that this is a lubricant for Li-based drills.

Solovushka wrote: 2SergeyE Stop being provocative - you should get out of here, my dear.

Harsh.

Serg wrote: For some reason, before, Soviet drills worked with lithol (or even solid oil) in gearboxes for years

So before, the grass was greener, and the trees were taller, and the steel was harder, and the tolerances were tighter, and the roughness class was higher, and there were ball bearings, and Litol according to GOST.

READ How to lubricate the trimmer gearbox

Kamikaze wrote: the grass was greener and the trees were taller

Kamikaze wrote: the steel is harder, and the tolerances are tighter, and the roughness class is higher, and the ball bearings, and Litol according to GOST.

But Soviet drills were positioned as an industrial tool. Not even professional, and certainly not amateur.

Serg wrote:. But Soviet drills were positioned as an industrial tool. Not even professional, and certainly not amateur.

They were positioned as a tool that required maintenance every 80-100 hours of operation. (if memory is not lost).

Kvost wrote: They were positioned as a tool that required maintenance every 80-100 hours of operation. (if memory is not lost).

No, that's good. For comparison: Flex on its angle grinders recommends replacing the lubricant after 1000 (one thousand) hours of operation (as stated in the manual).

Serg wrote:. But Soviet drills were positioned as an industrial tool. Not even professional, and certainly not amateur.

Common IE1032-1 – for household use (according to passport). Despite the fact that the operating mode is long. Although in terms of execution, it probably corresponds to modern industrial ones. Okay, professional

Kvost wrote: They were positioned as a tool that required maintenance every 80-100 hours of operation. (if memory is not lost).

Due to the characteristics and suitability of the lubricant used for work in these units, this interval was determined.

Proper care of a drill with a hammer drill function

A hammer drill is a hybrid of two types of equipment used to create holes in various materials. In contrast to the classic hammer drill, such a drill has some design flaws, which makes its maintenance more difficult and not very convenient. Such disadvantages, for example, include:

- lack of a special container into which the lubricant is poured;

- the difficulty of servicing the cartridge due to the peculiarities of its structure.

The main care for a drill with hammer drill functions is that after each use, the drill of such equipment (in particular, not the tail part) must be thoroughly cleaned of drilling waste, and before inserting such a tool into the drill, a small amount of lubricant should be applied to its shank (regular grease is used). If the amount of lubricant on the shank is excessive, it will not harm the tool itself or the equipment not in use, but it may negatively affect the appearance of the surface you are drilling, since excess lubricant will splash out of the rotating chuck.

Gearbox lubrication

You, drills that have the functions of a hammer drill, are purchased for household use, since their price is quite affordable, and they cope quite well with the functions when performing simple repair work around the house. Despite the fact that these power tools are distinguished by the features mentioned above, caring for a hammer drill does not take up extra time and does not even cause problems even for not very experienced users.

Why do rotary hammer elements need lubrication?

Lubricant, particularly used for hammer drills, is a viscous substance, the use of which is necessary to reduce the coefficient of friction between mechanical elements moving relative to themselves. Thus, lubricant only reduces friction, but does not eliminate it completely, so the lubricant composition is gradually saturated with wear-resistant friction parts. metal dust. During the process, not only the viscosity of the lubricant composition changes, but also more intensive wear of the equipment.

It should be noted right away that viscosity is the most important parameter that needs to be followed when choosing a specific type of lubricant composition.

After some time, the lubricant becomes dirty and does not lose its properties

How to choose the right lubricant for a specific hammer drill model? First of all, it is necessary to take into account the recommendations of the equipment manufacturer, which necessarily indicates both the required type of lubricant composition and the frequency of its replacement. It is especially important to follow such recommendations, even though the warranty period for the hammer drill has not yet expired. Otherwise, if the device fails, you will not be able to benefit from the manufacturer's warranty.

Probably, after the warranty period has expired, the owners of rotary hammers begin to use not branded compounds for lubrication, but their cheaper analogues. litol as it is also called solid oil. These are lubricants that can damage the structural elements of the hammer drill, but when using them you should have them for the reason that they should be replaced more often.

Lubricant selection

While we are dealing with the question of what and how to lubricate a hammer drill, you should get acquainted with the means that are used to carry out such a procedure. You, the manufacturer, indicate the type or brand of lubricant that is optimally suited to the equipment of a certain model. In any case, such instructions are in the instructions for hammer drills produced under reputable brands. On the contrary, there are no such recommendations; you can ask the consultant in the store which lubricant is best suited for the hammer drill you are purchasing.

Service centers use branded lubricants that are difficult to find in stores; unfortunately, they order only knowing the product code

A universal, inexpensive lubricant that is used for most modern engines is the oil poured into diesel engines. Compositions based on graphite are not actively used to lubricate hammer drills. Such compositions, specifically, are used to lubricate open-type worm gears.

Litol-24 is also actively used as an inexpensive lubricant for structural elements of perforating devices. If you think about it, such a lubricating composition can cause overheating and braking of rubbing parts; even today, its effect does not last long.

Screwdriver "Makita"

Description, general information

produces various power tools, including screwdrivers. The company began its history at the beginning of the 20th century, and to this day it continues to delight consumers with its high-quality products. Let's look at the general features and characteristics of the models of this company.

Makita screwdrivers are very powerful. The average speed for various models is about 2300 rpm, which is a good indicator compared to other brands. The weight of most instrument models is within 1.5 kg. Its small mass means that such a tool will be comfortable to work with. The manufacturer also took care of the convenience of working in poorly lit rooms, making most models backlit with LEDs. Separately, it is worth highlighting the type of handle for holding these tools on weight. As a rule, they are made with rubber, and therefore they are convenient to hold in the hand, and accordingly, the work process is much easier.

The disadvantage of these screwdrivers is the strong vibration of the handle during operation, as well as their short-lived batteries.

In addition, the price of this company’s products is quite high, which is important for domestic consumers

Let's look at the design of a screwdriver on a specific model 6271D. The diagram of this model is presented in the figure below.

Scheme 1

The diagram shows:

- Shift lever

- Housing assembly

- Nameplate

- Screw

- Spring

- Reverse shift lever

- Start button

- Contact terminal

- Screw

- Keyless chuck

- Gearbox assembly

- Electric motor

- Screw

- Housing assembly

- Charging node

- Battery

A modern screwdriver is a high-tech device. Important design elements:

- Removable battery

- Rubberized handle grip

- Powerful electric motor

- Metal planetary gearbox

- Soft start button

- Reverse switch button

- Torque regulator

These are the main components of the screwdriver design, which are included in the basic package of any screwdriver model.

Disassembling a Makita screwdriver

To disassemble the screwdriver you will need a Phillips screwdriver and a little personal time. To disassemble the screwdriver completely, you need:

- unscrew the housing mounting screws;

- remove the composite start button mechanism;

- remove the electric motor together with the gearbox;

- disconnect the gearbox from the engine by unscrewing the bolts holding them together.

To disassemble the screwdriver battery, you need to unscrew the bolts connecting the case, or separate the adhesive-based connections of the case using a soldering iron. Inside the battery there are several nickel-cadmium batteries that have a certain capacity and carry a charge. If the battery is repaired, they must be replaced with new ones.

The cartridge is changed using a screwdriver and a hex key. First, you use a screwdriver to unscrew the mounting screw in the cartridge, rotating it clockwise. Then the hexagon is inserted, the reverse button is turned on, it is clamped, and then the cartridge gives in easily.

Equipment installation

The screwdriver can be equipped with drills or attachments for tightening and unscrewing screws. When the required attachment is selected, it is necessary to rotate the chuck sleeve counterclockwise until its jaws are separated enough to insert the shank of a drill bit or screw bit between them. Then clamping is done in reverse order. There are two types of cartridges:

- the clamp is made without a key, but only by rotating the cartridge sleeve by hand;

- requiring additional compression using a special key, which is inserted into a recess in the chuck and rotates it, resting on a toothed rim, for example, as in the Dnipro-M 1/2″x20 gear chuck.

How to remove the chuck from a screwdriver, for example, to lubricate it or replace it if it does not hold the attachment well. In modern models, the cartridges are screwed onto the shaft and secured with a screw with a left-hand thread for reliability. This is how the chucks are secured in Makita, Bosch, etc. screwdrivers. It is necessary to unscrew the screw and unscrew the chuck by rotating counterclockwise. Detailed instructions on how to do this are available in the documentation for the tool.

Lubricants recommended by foreign tool manufacturers

Foreign tool manufacturers, including angle grinders, recommend specially developed ointments as lubricants for angle grinders.

One of the most common foreign lubricants is the lubricant marked MoS2 NLGI 2 ISOL-XBCHB 2 DIN 51825-KPF 2 K-20.

- MoS2 – indicates the filler material, in this case molybdenum;

- NLGI2 - indicates the second viscosity class;

- ISOL-XBCHB 2 – belonging to ISO standards;

- DIN 51825-KPF 2 K-20 – lubricant manufactured according to German DIN standards;

- The numbers 51825 mean that the lubricant is type K.

Lubricants produced with such characteristics are quite expensive. There are imported, less expensive lubricants on the Russian market.

Every tool manufacturer, be it Bosch, Makita, Hitachi, DeWalt, Metabo, RedVerg, Interskol, E256, LEPSE, recommends its own lubricants. This is the manufacturer's policy. They insist that when performing maintenance, the lubricants specified in the instructions must be used. Moreover, failure to comply with these recommendations does not allow warranty repairs to be performed.

Lubricant for the Makita angle grinder gearbox is available in tubes. Its high cost is commensurate with its high quality and long service life.

Requirements for lubricating fluids for angle grinder gearboxes

The master decides for himself how to lubricate gearbox There is no universal remedy - you need to select your own liquid for a specific instrument. A properly selected lubricant must meet a number of requirements, including:

- be resistant to corrosion;

- consist of natural components - including ensuring that it does not harm the artist when inhaling vapors;

- reduce the friction force of gears, and, accordingly, the heating temperature of the tool;

- the consistency should be thick enough to stick to the parts, but with a viscosity not higher than 800 Pa s;

- the consistency must remain stable and not change, “melt” or flow out of the mechanism when the temperature rises - the minimum drop point is 120ºС;

- ensure the operation of the tool in the range of up to 150 ºС;

- The presence of metal impurities in the composition is not allowed;

- tensile strength of at least 120 Pa;

- be hydrophobic, have water-repellent properties;

- protect the “insides” from dirt and dust.

Review of lubricants for grinders

If you lubricate a working tool with lithol or grease, saving on materials, there is a high probability that, ultimately, the equipment will refuse to work properly, no matter how high quality it is.

Foreign companies recommend to craftsmen how to lubricate the grinder, offering specially developed ointments. The manufacturer strongly recommends the use of exactly the products specified in the operating instructions. They are indeed present on the Russian market, but at a fairly high price. In this regard, the question of high-quality lubricants from domestic manufacturers arises:

- if the original imported lubricant contained molybdenum, you should look for an analogue labeled “MoS2”;

- "NLGI2". for industrial tools and others operating on liquids of the second viscosity class (penetration 265-295);

- "ISOL-XBCHB 2" for ISO standard;

- "DIN 51825-KPF 2 K-20" for DIN standards.

DIY grease for an angle grinder

A self-made lubricant for grinder gears consists of a base and a diluent. The basis of homemade lubricant is usually a CV joint with molybdenum disulfide or Tsiatim-221. They have a second NLGI viscosity, so for use in an angle grinder gearbox, the base must be diluted. As a diluent, it is best to use simple mineral industrial oil, which, for example, is I-20 oil. To obtain a viscosity of NLGI 0, you will need to mix approximately 70 percent base and 30 percent thinner. The resulting mixture is thoroughly mixed and ready for application to gears and bearings of angle grinders.

Making your own lubricant

Timely maintenance of any electric tool is the key to its long-term and trouble-free operation. A properly functioning tool is also a guarantee of safety for the person using it. Using the tips given above, everyone can choose the right lubricant for the angle grinder gearbox and replace it without resorting to the help of expensive power tool service centers.

Source

Home workshop: how to repair a screwdriver gearbox?

Any tool, regardless of model and brand, will sooner or later break down. A screwdriver is no exception: individual parts and assemblies wear out over time, and without proper care or under force majeure circumstances they may fail.

The main functional load when operating the tool is distributed through the gearbox between the engine and the chuck, so if something happens to the gearbox, the work will stop. In order not to spend money on repair services, it is enough to use the advice of specialists to restore the operation of the unit yourself.

- Design and principle of operation

- Kinds

- Causes of failure

- DIY repair

- What and how to lubricate?

The choice of lubricant and the differences between them

It is not only the user who decides which screwdriver lubricant is best. Manufacturers Bosch, Makita, Metabo, Dewalt produce a large number of lubricants for construction tools. Recently they were joined by the Russian Zubr and Interskol.

The main condition for lubrication is the absence of solid fractions so that it does not destroy the tool parts. The oil should form a film that protects the elements from corrosion. And an important point - the lubricant must have a viscosity that allows it to adhere to the parts.

Which screwdriver gear lubricant is better - the differences lie in their consistency. For example, for a gearbox with a low rotation speed, soft lubricant from Metabo is used. For other parts, liquid or semi-liquid lubricant may be used.

Review of lubricants for grinders

It was previously said that there are many types of lubricants, both from foreign and domestic manufacturers. A good lubricant for power tool gearboxes is produced by Bosh. It’s called “Gearbox Lubricant” and is packaged in 65 gram tubes. One such tube is enough for several grinder maintenance.

Lubricant for grinder gearboxes of various brands

Of the lubricants intended for grinder gearboxes produced by domestic manufacturers, we can recommend products. It is called “Nanotech MetalPlak Electra” and is intended for tools that work under intense load. Also among domestic lubricants, CV joints or Tsiatim-221 are widely used, but they require preliminary preparation and, in fact, are a homemade lubricant.

Foreign lubricants

To decide what can be used to lubricate the grinder gearbox, you need to consider a number of expert recommendations. They argue that you should choose the oil that is produced by the equipment manufacturer. Such compositions are not cheap. However, they have a balanced set of additives that ensure long-term operation of angle grinders. If the equipment user purchases other lubricants to service the power tool, the equipment may not even be covered by the warranty.

However, if desired, you can replace the compositions recommended by the manufacturer with similar products. For foreign models of angle grinders, products that contain additives identical to those used by the manufacturer of the angle grinder are quite suitable.

If molybdenum was present in the lubricant, it is necessary to purchase a composition marked MoS2. For grinders that are serviced by consumables of the second viscosity class, the composition NLGI2 is suitable. Lubricants marked ISOL-XBCHB 2 comply with the ISO standard. If the product was manufactured according to German DIN quality standards, the new oil must contain the indication DIN 51825-KPF 2 K-20 in the marking.

Domestic lubricants

When considering what to lubricate the gearbox of a domestically produced grinder, it is necessary to pay attention to locally made compounds. Today, Russian companies offer a wide selection of such products.

They have an affordable price.

Modern domestic materials for lubrication of angle grinder gearboxes are characterized by high quality. They meet high foreign standards. They are used not only in grinders, but also in other types of power tools.

The products are especially popular. However, there are other types of maintenance compounds for any angle grinder unit, including the gearbox.

Homemade mixtures

Situations when there is an urgent need to lubricate the elements of an angle grinder are not uncommon. And at the same time, as luck would have it, there is no way to get a lubricant suitable for these purposes. Then the owner can try to make the product with his own hands from available materials.

To ensure the required level of adhesion, lubricant for automobile CV joints is used as a basis. In addition to its excellent penetrating properties, it can be used for operation in the following conditions:

- significant loads;

- high humidity;

- temperature fluctuations over a wide range;

- significant heating;

- exposure to solid pollutants.

To liquefy the material and obtain the consistency required for the gearbox, it is recommended to add MS-20 oil. The liquid is introduced into the base gradually, preferably in drops, with constant stirring of the resulting composition with a mixer.

No less effective is the use of homemade material based on Cythiam-221 with the addition of TAD-17.

Lubrication technology

First of all, it is necessary to completely remove the used lubricating fluid - usually, due to the presence of dust and dirt impurities, it darkens and becomes cloudy. Next, you should carefully check the tool parts for traces of lubricant, and the body cavities for foreign inclusions, including particles of broken parts. For more effective cleaning of the angle grinder, it is recommended to use liquids used to wash the motor and its parts. Kerosene and gasoline are suitable for this purpose.

New lubricant is added before it flows out from the reverse side - usually visually it occupies slightly less than half the volume of the gearbox. Masters believe that this is the only way to control whether the material is sufficiently filled.

If there is too much lubricant, it will not only find a place to “come out” during work at the most inopportune moment, but will also “interfere” with the tool. Power will decrease, and energy costs, on the contrary, will increase. However, as a last resort, you can always open the case and remove excess substance.

The situation is much more unpleasant if there is insufficient lubrication. In this case, there is a high probability of poor-quality operation of the gearbox and the tool as a whole. A characteristic “bad” noise is detected, indicating high voltage on the tool and gear friction.

Now you know what you can use to lubricate the gearbox of an angle grinder. Approach the choice of material for your instrument with all responsibility and care. In return, the equipment will repay you with long, uninterrupted service, and even expensive original lubricant will definitely pay for itself.

The angle grinder works in extreme conditions and under heavy load. Due to this, periodic lubrication of the grinder gearbox is necessary, since high lubrication requirements are placed on the moving components of the power tool. Otherwise, if there is a shortage of lubricant, increased wear occurs and the service life of the power tool is reduced.

The angle grinder gearbox is designed in such a way that the grease lubrication of a pair of gears moves to the housing walls under the influence of centrifugal force. A sign of “draining” of the gearbox is increased noise during operation of the grinder. When opening the gearbox housing, the problem becomes obvious. All the factory grease is on the walls of the housing, the helical gears are almost dry.

We check the degree of wear of a pair of gears and damage to the teeth. If necessary, replace the gears.

We clean the surface of the gears from mechanical dust. Lubricate the sealed bearings of the engine rotor and the working shaft of the gearbox with liquid motor oil. We rotate the rotor intensively to ensure uniform penetration of the lubricant into the bearing. Remove excess liquid lubricant with a clean rag. If this is not done, it will mix with the gear grease and make it thinner. Liquid lubricant will not adhere well to the gear teeth.

If the factory grease for the grinder in the gearbox is of normal quality, apply it to the teeth of both gears as thickly as possible. If there are signs of aging of the lubricant, wash the gearbox with kerosene or other penetrating liquid and replace the lubricant.

Regarding the question of how to lubricate the gearbox of an angle grinder, any high-temperature grease is suitable, for example, for lubricating CV joints and wheel bearings of a car. Do not forget to apply it to the shaft support bearing.

We assemble the gearbox, carefully tightening the fasteners. If you leave play in the gear pair, the gearbox may jam.

Also, when servicing an angle grinder, it is necessary to lubricate the second rotor bearing and check the condition of the motor brushes.

Depending on the intensity of use, a similar procedure (lubricating the grinder gearbox and checking the condition of moving parts) must be performed regularly. This will extend the life of your power tool.

Sometimes, in the midst of intensive mowing work, your trimmer begins to make unpleasant, grinding sounds. This complains about the lack of lubrication of the gearbox - the most intensively loaded unit of the device. And soon these “warnings” may be followed by jamming of the drive...

Diagnostics and troubleshooting of the electrical part of the screwdriver

If you have a battery-powered device, then the first thing you need to do is check the batteries in the battery pack by disassembling it. There are collapsible and non-dismountable blocks. In the second case, you will need to carefully insert a screwdriver into the place where the walls of the block are glued and, slowly, separate them.

Next, you need to measure the voltage on all “banks”. The voltage rating is indicated on the body of each battery. The voltage should be slightly lower than specified, but the same on working batteries. Faulty batteries will differ significantly from the rest in the voltage they produce - they will need to be replaced. New batteries can be purchased online.

If you are the owner of a networked screwdriver, then the verification algorithm is slightly different. First, you will need to unscrew the body of the device and remove one half of it. Take a tester and “ring” the power cord for a break. If the cord is working, you need to check the start button. With the button pressed, check whether there is a circuit at its output contacts. If the button is faulty, it will need to be replaced or repaired. How to do this will be discussed further. If the button is working properly, the problem may lie in the electric brushes or the motor.

Button repair

Below is an electrical diagram of a cordless screwdriver.

From the diagram you can see that 2 wires from the battery go to the button, and 2 wires come out of it to the engine. Also, 3 wires from the transistor responsible for adjusting the speed are connected to the button. To understand the structure of the screwdriver button, it must be disassembled. All wires going to this part do not need to be soldered. They will not interfere with disassembly.

Remove the push mechanism (red) from its seat. Do this with gentle rotational movements, while simultaneously pulling the part in the direction opposite to the button, making sure that the joke does not break.

Next, remove the button cover. In the places indicated by arrows in the figure, use a knife and a screwdriver to pry and push out the latches, and then remove the cover.

After removing the cover, you will see the reverse compartment. But the button mechanism will still be unavailable. Using a soldering iron, separate the 2 elements (indicated by an arrow in the following figure).

Carefully pull out element number 1, then remove the cover that covers the compartment with the device’s activation mechanism.

Holding the return spring, remove the mechanism from the housing.

In the faulty button you will see erased contact pads.

The contact pads wear out quickly due to the poor quality of the metal. Fine metal dust from actuated contacts accumulates between them and shorts out the pads. As a result, the device starts spontaneously.

Use cotton wool soaked in alcohol to remove metal dust. If this fails, you can scrape it off with a knife. After these steps, the spontaneous startup of the device will stop.

Replacing brushes

To check the condition of the brushes, it is necessary to disassemble the engine by bending the “antennae” located at the end of the housing.

Next, lightly tap the motor shaft with a hammer to knock the rotor out of the housing.

In this case, the cover in which the electric brushes are located will first be removed.

The next photo shows that the collector is black. This means that it will become contaminated with dust from the brushes. As a result of contamination of the commutator, as well as the grooves between its plates, engine power drops and the brushes spark. It is necessary to wipe the collector with cotton wool soaked in alcohol and clean the grooves with a needle.

The following photo shows what a clean manifold looks like.

If the brushes are worn out, they will need to be replaced. It is difficult to find original brushes on sale for some models of screwdrivers. But you can find brushes that are suitable in size, then use a sharpening machine to trim them and connect (solder) them to the brush holders.

To better understand how brushes are replaced, you can use the following video.

Engine brake repair

The engine brake is a device that stops the rotation of the armature when the start button is released. In screwdrivers, this function is implemented by closing the plus and minus of the motor when the button is released. As a result, a large self-induction occurs, and the spindle locks (with large sparks from under the brushes). If engine braking does not work, then the control transistor or start button will need to be replaced.

History of technology development

More than 150 years have passed since all additional details have been removed from the door since, back in 1851, a manual hammer drill began to be used in work for the first time. It was made for the needs of the mining industry and did not have the variety of modes that modern models currently have. But even then he significantly improved the work of workers. It is not without reason that this type of instrument has become widespread among craftsmen of various specializations.

Since then, the instrument has undergone significant design changes. One thing remains constant. the need for proper care. The device of the hammer drill is quite complex. Some of its parts can wear out quickly.

To prevent this from happening, the lubricant for the hammer drill must have a number of properties. With the development of the presented power tool, its additional materials were also improved. To understand how to choose a lubricant, you need to consider the design features of the equipment.