Fuel briquettes, for the production of which sawdust and waste from processing various agricultural raw materials are used, are an excellent alternative to the usual types of solid fuel - firewood and coal. In order not to purchase this fuel in finished form and, accordingly, to make it even more economical, you can make your own briquette press and produce the required amount of euro-firewood from sawdust with your own hands.

Eurofirewood - fuel briquettes in the form of a multi-faceted beam with a hole for smoke removal

Today, two technological schemes are used for the production of briquettes for heating, which, if you have the appropriate technical devices, can be implemented at home. Naturally, to produce Euro-firewood in the required quantity, the presence of basic raw materials is necessary, which can be sawdust, shavings and larger wood waste. It is advisable to make a press for fuel briquettes with your own hands if the raw materials that will be used for briquetting are affordable and can always be obtained in the required quantity.

Production for sale

In order for the production of briquettes for sale to be profitable, it is necessary to find not only sales, but also markets.

In addition, it is advisable to purchase equipment without resorting to a loan, so at first you can take a used line.

It will cost 2-3 times cheaper than a new one.

The cost of such a used line is 1–4 million rubles, depending on performance and condition.

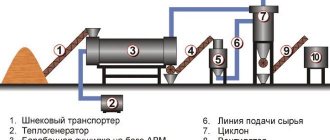

It includes all the necessary equipment, that is:

- press or extruder, depending on the type of briquettes;

- dryer;

- sawdust hopper;

- cyclone filter;

- Remote Control;

- conveyor.

For the production of briquettes, no special permit or license is required, however, it is necessary to obtain a sanitary and epidemiological certificate confirming the safety of transported and purchased sawdust.

This requirement was put forward by Rospotrebnadzor in order No. 776 dated November 21, 2005.

After this, you need to buy or rent a plot of land on which you will need to build all the necessary buildings. You can also find a site with ready-made buildings, which may be in good condition or require repairs.

Among other things, you will need workers, including:

- technologist;

- equipment setup specialist;

- accountant;

- driver;

- a loader with documents allowing him to operate a forklift;

- slinger;

- crane operator;

- workers.

After making fuel from sawdust, you will have to not only store it, but also immediately pack it in plastic film, which will protect the briquettes from moisture accumulation.

And given that large buyers take a batch of several tens of cubic meters, the size of the room must be appropriate.

To search for places of sale, you can use any media and conduct advertising campaigns on them.

Advertising in newspapers, radio and especially television is expensive, so for starters you can get by with advertising on such Internet platforms as:

- Avito.

- Flagma.

- Yandex Market.

- Regmarkets.

- Price pulse.

- Yula.

Another way to find a buyer for sawdust fuel is by posting advertisements on poles and notice boards.

This action will have the maximum effect in villages where there are many farmers, because the standard of living there is quite high, and gas is not always available everywhere.

Therefore, there is a high probability that someone will want to heat their house with European wood.

Briquette manufacturing technology

The process of producing heating material is labor-intensive and requires sequential operations.

If necessary, you need to prepare the raw materials before use:

- Crushing of material;

- Drying of crushed raw materials;

- Grinding (the better the components of the briquettes are crushed, the higher the heat transfer rates).

To make it yourself, the raw materials need to be mixed with a binder. Clay in accordance with 1 to 10 is quite suitable for this, where 1 kg of clay and 10 kg of crushed material are taken

The resulting mixture must be mixed with water to form a homogeneous mass, it is important that it is neither liquid nor solid

The resulting mass must be loaded into special equipment. During pressing, excess liquid is released and the product receives its final shape. If you use a homemade press, there is a possibility that a small amount of moisture will still remain inside the product.

An obligatory point in the manufacture of heating material is drying after pressing. You can dry it outdoors, in the sun and wind. The time of this stage depends on the volume of briquettes, as well as on the pressing technologies used.

After drying, the product must be moved to a special storage place or packaged.

Materials and available tools

To make a briquette press with your own hands, you need to stock up on some materials and available tools. In addition to the main component, you will also have to buy different types of rolled steel:

- channel;

- corner measuring 100x100 mm;

- a sheet 3-6 mm thick from which you will need to cut a punch. The thickness of the workpiece is determined by the diameter of the matrix.

It is also necessary to prepare a pipe with a cross-section of 25-30 mm for the manufacture of the punch rod, a thick-walled pipe for the matrix and a larger one for the body. In the absence of such material, the drum can be created from a sheet of tin. Also, galvanized steel is prepared for the upcoming work - trays are created from it.

The machine is assembled according to the following instructions:

- Equip the base of the device. It is created from channels using a welding machine.

- Based on the angle, four 1.5 m long posts are made. They are welded vertically with the same pitch.

- Next, a drum is created from a steel pipe or sheet of tin, where the feedstock will be mixed. If you have a broken washing machine in your house, you can remove the drum from it.

- The drum structure is then welded to the racks. If possible, it is better to equip it with an engine. If the power plant creates strong vibrations during operation and its rotation speed is too high, this can be solved using a gearbox.

- A tray is installed under the drum through which the raw materials will be fed into the matrix.

- At the bottom of the matrix there is a flange to which a removable bottom is screwed. It will require a steel sheet.

- Then you need to weld or screw the matrix to the base.

- A round punch is cut from a sheet of steel. Instead, you can use a regular disk of suitable diameter.

The briquetting press is designed for the production of fuel briquettes from soft and hard wood sawdust, sunflower husks and other plant waste

Useful tips

Although using a homemade press it is unlikely that it will be possible to produce a high-density briquette, it is quite enough for heating rooms in the cold season. The installation solves the main problem with a bang - the crumbly loose raw material becomes a solid brick or a cylindrical mass, which is then placed in a solid fuel boiler.

In order for the creation of a hydraulic press for the production of fuel briquettes to be justified, you need to take into account a lot of factors

First of all, it is important to make sure that the raw materials are available and cheap. You should also evaluate the weighted average volume of material received, the type of waste used and your own need for solid fuel

If heating with briquettes allows you to significantly save money, then making a press is a good solution with a long-term perspective.

Press selection criteria

Before installing equipment for the production of sawdust briquettes for personal use, it is necessary to evaluate the feasibility of the purchase. A machine for making Euro firewood from wood waste provides a number of advantages, but it is a rather expensive design, so you should focus on the following points:

- are there enough raw materials for production;

- the ability to sell surplus products;

- demand for this type of fuel.

Your own press is a profitable investment if you need to heat large areas, or you decide to sell European firewood for commercial purposes. Compressed sawdust can save you money if you have access to leftover products from the wood processing industry. And even with proper use of the press, its cost will pay off only after about 2 years.

Why are briquettes good?

Fuel briquettes are crushed wood and wood waste, compressed into a form convenient for transportation and storage.

As a result of processing on machines by pressing under high pressure, the finished briquettes acquire new qualities. Their use instead of conventional firewood in stoves, fireplaces and wood-burning boilers provides the following advantages:

- increased combustion temperature and, accordingly, better heat transfer;

- a higher density of briquettes leads to longer burning of the same volume;

- reduced formation of soot and ash residues;

- Briquettes are produced in various shapes - short cylinders, rectangular bricks. But in any case, they are convenient for storage and carrying.

When compared with conventional firewood, Euro-firewood will not be worse in any respect. The disadvantages include the fact that by the appearance of the briquette it is not always possible to determine the specific wood from which it is made. And if, for example, birch briquettes are required, then you have to rely on the integrity of the manufacturer.

Necessary equipment

As it becomes clear from the technology described above, to produce briquetted fuel you will need appropriate equipment, which is easy to make with your own hands. The main device is a press, which ensures the formation of a briquette from a crumbly raw material mass, characterized by a dense and uniform internal structure. A screw, lever or hydraulic mechanism can be used as a force body, with the help of which pressure will be applied to the raw materials used to produce fuel briquettes.

- drive mechanism, which, as mentioned above, can be screw, lever or hydraulic;

- a supporting frame on which all structural elements of the device are fixed;

- a matrix in the internal cavity of which a fuel briquette is formed from a loose raw material mass;

- a punch through which pressure is applied to the raw material mass;

- mixing drum (all components included in the raw material mass are mixed in it);

- trays designed for loading raw materials into the matrix and unloading finished products from its working chamber.

Scheme of a homemade impact machine with an electric drive

3D model of the shock-mechanical part of a press for the production of briquettes

To make briquettes from sawdust or any other suitable raw material, one press is not enough: this will also require auxiliary equipment:

- a crusher, with the help of which pre-cleaned raw materials will be crushed to fractions of the required size;

- mesh trays on which the finished briquettes will be dried;

- a ventilation unit necessary to remove the resulting dust from the raw material grinding zone.

Homemade biomass chopper based on an electric drill with a mixer attachment

You can produce Euro firewood yourself not only using screw, lever or hydraulic pressing equipment, but also using other types of technical devices. In particular, it is possible to use briquetting equipment of the impact-mechanical and extrusion type.

Like screw and lever type devices, briquetting equipment operating on the shock-mechanical principle belongs to the category of the least expensive in terms of self-production. When using such equipment, as when using screw and lever type devices, the produced fuel briquettes are not very dense, which makes them not very resistant to high humidity and significantly reduces their heat transfer level. In addition, such briquettes for heating, characterized by a rather loose internal structure, are unstable to mechanical damage, which eliminates the possibility of their transportation over significant distances.

Factory-made press VT60

The technology, which involves the use of extruder-type pressing equipment, is used primarily for the production of Euro-firewood in production conditions. A fuel briquette made using such equipment is characterized by a dense internal structure and, accordingly, high resistance to mechanical damage. When using extruder equipment, the pressure on the pressed raw material is exerted by a screw, which, rotating, moves the bulk mass to the holes of the matrix and pushes it through them. As a result, dense bars of cylindrical or hexagonal shape are formed.

Hydraulic press Green-440 for the production of briquettes RUF

To produce fuel briquettes using an extruder press, you do not need to add binders to the raw material. Such equipment, due to the peculiarities of its design, is capable of providing enormous pressure on the pressed raw materials, as a result of which the natural substance lignin is released from the latter, which acts as a binding component.

If you decide to make this type of pressing equipment with your own hands, keep in mind that this is a rather expensive undertaking, as it requires the use of expensive materials and special devices. That is why the option of independently manufacturing extruder-type pressing equipment is not often considered by home craftsmen.

Basic elements of the press

The most important element of the press is the mold. The press mold device has a simple design. Its cross-section is chosen arbitrarily; it depends more on the preferences of a particular person, since the shape gives an understanding of what the finished product will look like.

The elements of the device also include a piston and a mechanism that creates pressure. The minimum force that must be applied to obtain Euro firewood is 30 MPa. In this case, there is no need to add a binder, since lignin will bind the material quite firmly.

Industrial production

The first step in producing fuel briquettes in an industrial environment is grinding the material on special machines. Often the raw materials for making briquettes are wood processing waste - shavings, sawdust, wood chips. Large pieces of wood are crushed to sawdust no larger than 4 mm.

Then the wood is thoroughly dried. The specific humidity of the material is brought to 10% or even less. The drier the wood for subsequent briquetting, the better the quality of the finished fuel.

The final stage is obtaining the fuel briquettes themselves. To do this, the prepared raw materials are subjected to powerful pressure. The temperature rises, and a sticky component, lignin, is released from the wood pulp. Under high pressure and in the presence of lignin binder, wood pulp is formed into a single solid briquette.

The density of such a product exceeds the density of natural wood by 1.5-2 times, which provides briquette fuel with increased heat transfer and increases combustion duration. In the industrial production of Euro-firewood, two methods of compression are distinguished.

Pressing method

In pressing, the raw materials are pressed into prepared molds using a hydraulic press. The typical pressure in a machine for pressing the production of fuel briquettes is 300-600 atmospheres. The output is briquettes in the form of rectangular bricks or short cylinders, depending on the shape in which they are pressed.

Extrusion method

With this method, wood pulp is constantly squeezed out of the outlet of the working channel. The raw material is loaded into a hopper, from there it is fed into the working channel, where it is additionally heated. The channel is made in the form of a cone, tapering towards the exit. The supply of raw materials from the hopper and its compression in the working channel is carried out on the machine using a screw screw. Such a screw-based press provides pressure on the raw material mass of up to 1000 atmospheres. The compressed “sausage” coming out of the extrusion unit is cooled and cut into rods of the required size.

Homemade machine

There is information about the manufacture of homemade screw extrusion plants at home. But even the creators of such efficient machines for the production of fuel briquettes note that the devices require high-quality materials and the use of an electric motor. It is much easier to make a regular press instead of a complex machine.

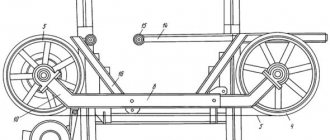

Hand press

Presses that use only manual effort come in two types: screw and lever. In screw versions, the rod, which compresses the raw material mass, is moved by tightening the screw. In lever presses, pressure is created by one's own muscular efforts using the length of the lever. With a screw installation, greater pressure is achieved and the quality of fuel briquettes becomes better. But tightening and unscrewing the screw takes time, so productivity is low. Lever presses are faster. You just need to think about the method or mechanism for pushing the finished briquette out of the pressing mold. The same form should have holes for water to escape when compressed, since during manual production the raw materials are soaked.

Shredders

An important step in the production of briquettes is the grinding of wood raw materials. Of course, you can do this manually, using simple cutters. But it will be more effective to mechanize this process. A rotary machine used for grinding plant matter in the production of fertilizers at home is suitable. Craftsmen also use old activator-type washing machines for these purposes. Knives are attached to the activator, crushing the loaded raw materials.

What are sawdust briquettes?

In an unprepared form, heating with sawdust is not profitable due to the low heat transfer efficiency. To increase efficiency, they are briquetted by compaction. Briquettes have a humidity level of 10 to 12% and a heat output of 4500 kcal/kg. This efficiency is 2-4 times higher than that of firewood. This is the reason for the popularity of the finished briquetted product.

The production of briquettes is popular among manufacturers due to the benefits and low cost of production. Woodworkers have the opportunity to achieve waste-free production.

Sawdust is pressed without additives. The compaction process releases lignin, a natural adhesive substance that provides high strength.

Briquetting Line Suppliers

| № | Name | Cost, pcs. | Provider |

| 1 | Imported new line-plant for the production of pellets from 1500 kg/hour | From 9 million rubles. | LLC RosIndKo (St. Petersburg) |

| 2 | Press Ruf for the production of fuel briquettes (volume not specified) | 180 thousand rubles. | LLC "Chernomorsky Trading House" (Krasnodar region) |

| 3 | Hydraulic press for the production of fuel briquettes Nestro, new | 600 thousand rubles. | Private person |

| Hydraulic press for the production of fuel briquettes Nestro, used | From 90 thousand rubles. | Private person | |

| 4 | Used briquetting press PB 400 kg/h | 390 thousand rubles. | LLC NGSBP (Krasnodar region) |

| 5 | Press for fuel briquettes from vegetable raw materials, 35-180 kg/h, made in Germany | 850 thousand rubles. | Agro-industrial technologies (Yurga, Kemerovo region, Russia +7) |

| 6 | Impact press for sawdust briquetting GC-1000 at 0.8…1 t/h | 3.25 million rubles. | LLC Eurasia-Vostok (Blagoveshchensk) |

| 7 | Dryer type AVM-650, new. | 150 thousand rubles. | Private person |

| 8 | Drying type AVM-650, used. | 90 thousand rubles. | Private person |

| 9 | Aerodynamic dryer SAD-0.6-1.2 with a capacity of 600 kg/hour | 1.3 million rubles. | LLC Stankostroitelny (Voronezh) |

| 10 | Chinese low power lines up to 250 kg/hour | 200 thousand rubles. (per unit of equipment in the line) | Private person |

| 11 | Chinese medium power lines from 500 kg/hour | 2.5 million rubles | Private person |

Types of presses

There are 4 types of press. The difference between them is the principle of operation and the cost of the device.

Kinds:

- mechanical impact press;

- Hydraulic Press;

- screw press;

- press granulator.

The operating principle of a mechanical impact press is based on impacts, under the influence of which chips are forced through a die. The advantage of this device is that in addition to wood waste, you can press the remains of MDF or coal dust. The device can operate for a long time without human intervention.

The hydraulic type sawdust briquetting press is similar in principle to the use of a hydraulic jack. The mold is filled with raw materials and pressure is applied to it by a hydraulic cylinder. The disadvantage of this model can be considered the low volume of products. To press sawdust and create euro-firewood in a hydraulic press, it is necessary to use a binder.

The production of pellets using a screw press is carried out under high temperatures. The chopped wood is fed to the auger through a die. Under the applied pressure, the raw material is pressed. Due to the high temperature, the wood loses its natural binder, as a result of which the pressed timber has sufficient strength. The briquetting line has similar features to the operation of a meat grinder, that is, the finished raw material is placed in a hole, mixed in a hopper and exits through a tapering channel.

Pressing sawdust using a granulator press is a fairly quick process. It will only be possible to produce small-sized products. A significant advantage of this product can be considered its cost and the availability of various additional devices that can improve the quality of the product.

To obtain fuel from sawdust, it is necessary to prepare it using any type of press. The moisture level of the raw materials should be in the range of 4-10%, and it must first be crushed into fractions measuring 25x25 mm.

Eurowood production process

First of all, it is necessary to understand industrial technology in order to further adhere to its principles.

First, sawdust, shavings, and larger wood waste are crushed. Then the raw materials are thoroughly dried until the humidity level is reduced by 90%. In addition to heating, they may include waste from the agricultural industry: grain husks, seed husks. If the briquetted sample consists of coal dust, it is better not to use it in everyday life.

After grinding and drying, the main production stage occurs - sawdust pressing. For this purpose, a briquetting press or an extruder is used, depending on the chosen method of forming the fuel. Extrusion and pressing - intensive compression of the raw material in order to obtain the binder lignin (a natural component extracted from wood). It replaces adhesives and preserves the environmental purity of fuel. With the first compression method, the hydraulic briquetting press develops a force of about 500 bar. Because of this, spontaneous heating of the raw materials occurs, the sawdust is knocked together into a dense rectangular brick.

Extrusion production technology is similar to the operation of a meat grinder. The source material enters the loading hopper and is pushed into a narrowed conical channel using a screw. A screw press for the production of fuel briquettes produces a force of 800–1000 bar. The result is a hexagonal briquette, additionally processed at high temperatures, cut into segments of equal caliber. The drawing shows the design of the screw unit in section.

Briquetting at home

Buying a press for the production of fuel briquettes is not entirely reasonable, even if you have available raw materials: the purchase is unlikely to pay off unless you start selling the finished product. Without a professional unit, it is impossible to withstand industrial technology and obtain lignin, which serves as a binding element. But there is a way to use wood waste by introducing various binding ingredients into the sawdust composition:

- wallpaper glue,

- clay,

- paper.

In order not to purchase professional equipment for drying and pressing chips, more affordable technology is used. Wood waste is soaked in water and combined with clay in a ratio of 1:10. Instead of clay, add soaked cardboard or wallpaper glue.

After mixing, the resulting mass is placed in the mold of a homemade machine for producing briquettes and squeezed tightly with your hands. The bricks are taken out and sent to dry.

Homemade device

The design of the sawdust press includes a mechanical screw drive. A perforated container installed on the briquetter, after filling with the prepared mixture, is placed under the frame. The screw is tightened by hand and pressure is created. It’s not difficult to make a device; you don’t need a diagram or drawings, just look at the drawing.

The screw device has low productivity. Working with it requires a lot of time loading the mold and tightening the screw. It is not very convenient to remove the briquette from the mold. An alternative is a homemade press, which includes a lever element and a special ejector for extracting the finished material. To optimize the production process, the frame is often equipped with not one, but two forms.

There is also a more advanced type of mechanized equipment. A home mini-press can be equipped with a hydraulic jack rather than a manual one, which can significantly increase fuel production. This briquetting machine requires some skill to assemble. But you should not count on providing the pressure necessary to squeeze out the lignin. It will not be possible to do without additional connecting components.

Do-it-yourself briquetting - pros and cons

It is possible to make a press yourself and set up the production of fuel briquettes. But this requires material costs, physical effort and time. It is also necessary to take into account that it is unlikely that it will be possible to achieve the quality of European firewood produced in factories. Of course, you can purchase a machine that is not much inferior to a production one, but the acquisition costs will be colossal.

You need to have a good idea of why you need your own production, what the conditions are for this, and what the costs will be. Maybe you shouldn’t give up regular firewood or it might be better to buy ready-made briquettes for heating.

pros

The positive aspects of homemade are as follows. Your own fuel briquettes will not provide the same combustion quality as purchased briquettes, but they will be more efficient than firewood.

If it is possible to obtain a large amount of wood waste - sawdust, small trimmings, shavings, bark - then it is more profitable to make compressed firewood from them. Sawdust and shavings in their pure form are of little use for combustion, but after processing on a sawdust pressing machine they produce good fuel.

You can use not only wood, but also any other combustible waste - straw, dry leaves, paper, cardboard. Separately, none of them are flammable material, but briquettes will be useful. Briquetted fuel is convenient for storage and loading into the firebox.

Minuses

But there are also disadvantages to keep in mind. Attempts to improve the quality of home-made European firewood can lead to the purchase of expensive equipment or the constant addition of existing equipment. As a result, it turns out that producing your own briquettes will not justify the costs.

Homemade fuel briquettes require space for proper drying. Drying in the sun is not always justified. A spacious, dry room is required. Homemade briquettes should also be stored so that they do not absorb moisture.

Homemade Bonding Materials

Using homemade machines, it is almost impossible to achieve the pressure at which lignin is released from wood pulp. Therefore, it is necessary to add materials to the raw materials for independent briquetting that will help bind and glue the raw materials into a monolithic briquette. Most often used for these purposes:

- clay. Volume proportion 1 to 10 wood raw materials;

- glue. Any will do, but, naturally, it’s better to take the cheapest one;

- shredded paper or cardboard. In addition to the fact that it is also a flammable material, paper contains lignin. And paper lignin exhibits its adhesive properties when soaked. True, then you will need additional time to dry the briquettes containing paper.

In order for binding additives to fully demonstrate their properties, they must be thoroughly mixed with combustible raw materials, and then this mixture must be soaked in water.

Note! In industrial production, the raw materials are thoroughly dried before pressing, and in homemade production, they are thoroughly soaked.

This is the main difference between homemade ones. Fuel briquettes are dried after pressing so that they harden, hold their shape and burn well.