Sharpening of knives can be carried out using a whetstone, sharpening machines, mechanical and electric sharpeners. There are devices that are used not for sharpening the edge of a blade, but for straightening them - for example, with the help of musat you can “in no time” restore the cutting ability of a knife.

If you need sharpening of professional knives, surgical instruments, or hunting “arsenal”, then you should turn to professionals or use special devices. The price of sharpening one knife in workshops can range from 100-350 rubles.

Knife sharpening

Sharpening is required for any of the knives, regardless of what material the tool is made of.

| Causes of dullness | Explanation |

| Natural friction on the material | Microscopic changes occur in the blade, when it is impossible to determine them visually, but the need to apply more pressing force when working with the knife is clearly felt |

| Contact of the blade with solid particles of material such as grains of sand | Macroscopic damage appears on the blade, because when confronted with such an “obstacle,” the edge of the knife can either move it away or move away by crushing it |

| Inappropriate use of a tool - digging the earth, unscrewing/twisting fasteners, etc. | The blade deteriorates very badly, it can change its shape and completely lose its cutting ability. |

With constant load on the blade, not only the knife becomes dull. If it is made of high-quality steel, then its edge simply crumbles, and the softer metal begins to curl and deform.

Sharpening angle

The ideal sharpening angle for knives is 20 degrees, but for different types of this tool it is worth using individual parameters:

- hunting, folding/pen-pocket - to obtain maximum sharpness of the edge, the process is carried out at an angle of 30-35 degrees, and if you need to get a blade that is resistant to subsequent dulling, then the angle changes to 40-45 degrees;

- ordinary kitchen ones (not professional ones) - sharpen at an angle of 25-30 degrees, if they are made in Japan - 10-20 degrees;

- tactical (combat) knives – sharpening should be carried out at an angle of 35-40 degrees;

- professional chef's knives, for boning meat and cutting it into thin fillets - at an angle of 25 degrees.

When choosing the desired option, it is worth remembering two nuances:

- if the sharpest possible knife is required at the output, then the sharpening angle should be small;

- if it is necessary to maintain the cutting capabilities of the tool for a long time, the angle is made larger.

When sharpening, you need to maintain the selected angle throughout the entire process, for which it is recommended to work with smooth movements and slightly lift the knife handle while processing the bend of the blade. Movements must be carried out at a constant right angle relative to the cutting edge of the blade.

What to sharpen

You can sharpen knives with a variety of devices; even housewives can handle some of them:

- whetstone (touchstone);

- mechanical or electric sharpener;

- Musat;

- "Lansky".

Mechanical sharpener Oselok Musat Lansky

Sharpening machines are a professional tool that only a master can operate . They operate at very high speeds and have an increased risk of injury.

Touchstone (sharpening stone)

Sharpening stones are available with different surfaces, depending on the number of abrasive particles located per square millimeter of their surface. It is understood that to sharpen a knife you will need at least two whetstones - with maximum abrasiveness at the first stage of the process and with minimum at the last, when the final grinding of an already sharp blade is carried out.

Russian-made sharpening stones do not have any markings, so you will have to purchase them only by visually assessing the degree of abrasiveness of the surface. Imported whetstones have clear markings, according to which the choice will always be unmistakable.

Touchstone with handle

Mechanical sharpener

The simplest device for obtaining a sharp blade is used to “sharpen” kitchen knives. It is enough to run the blade along a special notch 2-5 times and its edge will become sharper. You cannot expect high quality from this method of sharpening a knife, but it is quite suitable for daily use and for kitchen knives.

It is strictly forbidden to sharpen hunting, sports and professional chef's knives with such a sharpener.

Mechanical knife sharpener KitchenIQ 50265

Electric sharpener

High quality knife sharpening can be achieved using an electric “tool”. The advantage of using an electric sharpener is that you can independently set the angle to get a perfectly sharp blade, and this is a built-in feature in most modern models of this device.

This method is used both in home kitchens and in public catering. The cost of the device varies, but to get better results, you should not save.

Electric sharpener SITITEK Mistress 31M

Musat

Not intended specifically for sharpening a knife blade, used only to maintain its sharpness. Visually, musat resembles a file with a handle and is included in most sets of kitchen knives. If you just need to “straighten” the blade, then this tool is perfect, but if the edge of the blade is dull, then you will need to use other types of sharpening tools.

You can maintain the sharpness of a knife blade with musat for a long time, for which you only need to constantly and regularly use it.

Sharpening a knife with musat

Sharpener "Lansky"

The Lansky sharpener is a complicated design and is suitable for processing only small and medium-sized knives. Structurally, it consists of a rod, a removable whetstone (sharpening stone) and two corners that are connected to each other. The latter work as a vice and securely hold the knife in the “machine”, and also have graduations on their surface - this ensures the correct setting of the sharpening angle.

The Lansky sharpener always comes with several sharpening stones (stones) with different levels of abrasiveness.

Watch the video about the Lansky knife sharpener:

Sharpening and grinding machines

Professional sharpening machines are used only in industrial production conditions and are designed for maximum precision sharpening of rotating shafts. But there are also machines with an electric drive, abrasive wheels, and grinding discs - they can be used at home, but only an experienced craftsman is allowed to work on them.

If sharpening is carried out incorrectly on such machines, the knife blade will be unsuitable for further use, and the likelihood of injury to the “sharpener” increases. This happens against the background of very high rotation speeds of the abrasive wheel (grinding disc) and high temperatures due to friction of materials.

Why does the blade become dull?

The knife blade becomes dull due to friction. You can quickly damage the tool by running the tip over a rough, hard surface, such as brick or concrete. The blade will be scratched by abrasive particles. The sharp edge will completely wear off, crumble and become dull. It will become impossible to cut with such a knife.

The products are much softer than brick. Therefore, the knife remains sharp for a long time. But gradually, particles of metal located on the very edge separate from the blade. If you cut chicken with bones or other hard foods, dulling will occur faster. The knife will get scratches. Jagged edges form along the edge. If you examine the edge of the blade through a magnifying glass, it has already acquired an oval shape. Now you have to put more effort into dividing into parts - pieces, products.

The degree of sharpness of a knife is most clearly visible when cutting a loaf. Under a sharp blade, the bread retains its shape, and the separated pieces have a smooth surface. The duller the blade, the more the loaf crumples, and the more difficult it is to evenly cut off the crispy crust.

A razor-sharp knife cuts onions without tears. The blade does not crush plant cells with caustic juice, but cuts them.

Types of sharpening

There are several types of knife sharpening:

| Types of knife sharpening | Description | Example |

| Lenticular | The edge of the blade is sharpened, and the bend of the blade can also be processed. With such sharpening, blades are distinguished by a high level of cutting ability; they are able to “work” even on thick material, and, if necessary, serve as a chopping or piercing tool. Lens-shaped sharpening is carried out exclusively by hand, therefore it is used only in the production of professional knives - kitchen, hunting, tactical. | |

| Razor sharpening (flat) | It is carried out at a minimum degree (10-20) and is suitable for processing only surgical instruments, razor accessories, and blades for fine cutting. In everyday life, such sharpening is done for hunting knives for special purposes - for example, skinning knives, fishing knives. | |

| Wedge sharpening | It is rarely used, because after it the cutting ability of the tool increases, but the strength of its blade decreases. During the process, the side surfaces of the blade must be grinded and polished, but at home this is quite problematic. | |

| Pentagonal sharpening | It is widely used for kitchen and travel knives; even household devices for this process often perform just this type of knife sharpening. After it, the blade slightly loses its tactical abilities, but its service life does not decrease. | |

| Double-sided asymmetric sharpening | Combines enhancing the tactical and physical abilities of knives. The result will be ease of cutting even the hardest products, flawless chopping of material without any effort. This type of sharpening is often used in the manufacture of Japanese kitchen knives, which are of high quality. A special feature of knives with double-sided asymmetric sharpening is that the edge of the blade does not enter the cut on the product, but is constantly held on top. |

There are many ways to sharpen knives, they will differ depending on the tool used for this.

The technology of sharpening at home with a whetstone by hand

At home, sharpening can be done in the simplest way - with a whetstone by hand, step-by-step instructions for the process:

- The block is placed on the table in such a way that it does not slip or move. To do this, place a kitchen towel or any other textile napkin under the stone.

- Moisten the surface of the bar with water. There is no need to fill it, just spread a few drops and this will help not only to easily sharpen the knife, but also to completely clean the block of metal particles at the end of the work.

- Place the knife across the block and begin to move it away from you, imitating the movements when sharpening a pencil. In total, you need to perform about 50 movements on one side to achieve a slight roughness (burr).

- Turn the knife over and do the “procedure” for the other side of the blade, also moving along the block at least 50 times until a characteristic burr appears.

It is important to remember two nuances:

- as you sharpen, you need to maintain the angle of contact of the blade with the block;

- You need to continue the process until (changing sides of the blade) until the formed burr completely disappears.

Only after the last condition is met can you stop sharpening and proceed to grinding. To do this, you will need a stone/block with a finely abrasive surface; the movements are the same as before, but to achieve the desired result, it is enough to repeat them 20 times on each side.

How often should you sharpen?

It is believed that knives need to be sharpened as they become dull, but experts recommend this “event” be carried out at least once a week. In this case, it will be possible to maintain the cutting ability of the tool, and the sharpening itself will take place quickly and efficiently.

If we are talking about manual/mechanical sharpeners with wheels or musat, then they can be used at least every day - the knife will be sharp, but not for long. These devices are needed for straightening the knife, and not for fully sharpening it.

Blade grinding using GOI paste

After we have sharpened the knife on a stone, the blade is polished using GOI paste. This procedure must be done, otherwise the knives will have to be sharpened much more often, the edge of the blade will be jagged, which will affect the deterioration of the cut. A knife with serrations will dull faster.

We take a board with leather and GOI paste, place a knife on it with the blade facing away from us and begin grinding. We carry it to the end, raise the blade, return it to its original state and start again. We do about 20-30 similar movements for one side.

Sand the other side. Periodically remove any remaining paste from the blade. After a good sanding, the edge of the blade should shine.

How to sharpen knives correctly

To properly sharpen knives, you need to remember the following:

- if the process is being performed for the first time, then you should not take up your favorite knives - there is no guarantee that sharpening will be successful the first time, and this will lead to damage to your favorite tool;

- Modern ceramic knives cannot be sharpened with ordinary whetstones, but if the stone is diamond coated, then it is ideal for the job;

- Damascus steel knives, as well as those with a wavy edge (“bread knife”) should not be sharpened at home at all - it is better to give them to professionals.

Watch the video about how to properly sharpen a knife:

On the grinding machine

In general, only those people who already have the skills to handle such a tool can work with a knife blade on a sharpening machine. If sharpening a knife is carried out for the first time (in independent mode), then you should give preference to less dangerous devices.

This precaution is associated with the following nuances:

- the grinding machine is a rotating axis with an abrasive wheel at the end and an electric motor;

- the rotation of the grinding wheel is carried out at high speed and if handled ineptly, it is possible to injure your hands, up to the complete cutting off of your fingers;

- when the knife blade rubs against the stone, the first one heats up, and holding it with your hands becomes problematic;

- During sharpening, beams of sparks come out from under the knife; they can cause burns to the skin and mucous membranes (for example, the eyes).

If the listed facts do not confuse you, then during sharpening you will need to frequently check the condition of the blade edge (so as not to miss the moment of formation of the characteristic roughness (burr) and strictly maintain the angle of its contact with the stone.

Simple sharpener, with wheels

A simple sharpener with wheels is used to quickly sharpen kitchen knives; even an untrained woman can handle the job, because it is enough to insert the blade into the slot and pull it towards you with some effort; the movement is repeated 2-5 times. Such sharpening is not considered high-quality, because the durability of the cutting capabilities of the knife is minimal.

If you often have to cut meat, fish or hard foods with a kitchen tool, then you will need to use a wheeled sharpener almost every day.

What to remember when doing work:

- the knife is inserted into the slots so that the blade is slightly tilted to the left - first one side of the blade is worked, then the angle is changed to the right side;

- when approaching the tip of the knife while drawing, you need to slightly lift the knife by the handle in order to maintain the geometry of the kitchen tool;

- There is no need to wet the knife before sharpening, but wash it thoroughly afterwards - metal particles remain on the blade and can get into food.

Stone

You can quickly restore the sharpness of a knife on a hike, on a picnic, or in other unusual conditions with an ordinary stone: just take any cobblestone and run the edge of the blade along its surface as if the process was being performed on a whetstone. 5-10 movements on each side are enough - and the knife will become sharp again.

This sharpening can only be done as a temporary solution to the problem of a dull knife. Upon returning home, you will definitely need to sharpen, grind and polish the cutting tool to extend its service life.

On the sandpaper

Experts believe that sharpening with emery does not give a high-quality result and wears away the metal too quickly, making the blade too thin and narrow. But this method of sharpening exists and is even actively used at home. It is suitable for processing regular/standard quality kitchen knives.

To get the desired result you need to do the following:

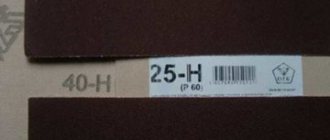

- Take two pieces of sandpaper - with a fine abrasive and a coarse abrasive surface.

- Fix them on a wooden block on two opposite sides - this can even be done with tape or tape.

- Lightly moisten the surface of the sandpaper and begin sharpening the knife, following the instructions for the process on the whetstone.

Fine grain

You must first wait for a burr (characteristic roughness) to appear on one side of the blade, then on the other, and with controlled movements make it disappear.

Knife on knife

It is quite possible to sharpen two cutting tools at once without any equipment - you need to rub the knife against the knife for 5-10 minutes. This method will not give a high-quality sharpening, but it will make kitchen tools much sharper.

After manipulation, be sure to rinse the knives under running water, because friction leads to the formation of a coating of tiny metal particles on the blades. They can get into food and even cause poisoning in particularly sensitive people.

File

You can also use a file to work with knife blades, but this method cannot be called high-quality sharpening; rather, it is straightening. It is better to select a tool for such work with medium-sized notches, which will prevent the formation of scratches, abrasions and roughness on the blade.

TOPEX metal files are designed for metal grinding

In general, a file should be used in extreme cases, when there are simply no other options at hand.

Electric sharpener

An electric sharpener is the most convenient option for sharpening kitchen knives:

- the sharpening angle is maintained automatically;

- the entire process takes no more than 5 minutes;

- You can sharpen tools with blades of any width.

This device is not suitable for sharpening Damascus steel knives; professional kitchen knives should not be subjected to similar “tests”.

What to do with dull knives?

If there are no problems with knives with replaceable blades (naturally, if these same blades are present), then a knife with a sharpened blade must be periodically sharpened. Typically, a special knife sharpening device is used for this.

Buying this now is not difficult. But not everyone prefers this solution to the problem. And the point here is not only the considerable cost of such devices. High-quality sharpeners cost a lot of money.

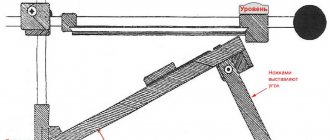

Many craftsmen will get great pleasure from a machine designed for sharpening knives, made by themselves. Although, even using an ordinary “bare” block, of course, you can sharpen knives with your own hands, but in order to sharpen a knife efficiently using only a whetstone, also known as a “block”, you need to have a certain skill and “steady” hands, because you will need to maintain the sharpening angle identical along the entire cutting edge, and this is not the easiest task. A special sharpener for knives is designed to make it easier, be it factory-made or made with your own hands.

But just to speed up sharpening, any sharpener, both factory-made and home-made, will help.

Kitchen knife sharpening angle

The sharpening angle of a regular kitchen knife should be 25-30 degrees, and this parameter must be maintained throughout the entire process. If sharpening is carried out independently, then you can understand exactly how to hold the knife in relation to the whetstone as follows:

- you need to cut an even square out of paper;

- fold it in half diagonally - this will be an angle of 45 degrees;

- fold the sheet in half again - you get the desired parameter.

This piece of paper, folded several times, just needs to be leaned against a sharpening stone and the knife blade aligned along it. Periodically, you can stop the sharpening process and check again that the angle is set correctly.

For hunting knife

A hunting knife should be sharpened at an angle of 30-35 degrees . This parameter must be maintained with any method of returning cutting abilities. Since a feature of hunting knives is the large width/thickness of the blade, it is worth using semi-professional tools for sharpening them, for example, a Lansky sharpener will be convenient.

About angles

Holding a knife at the desired angle while sharpening is not as easy as it might seem at first glance. And what is this corner like? For the vast majority of the inexpensive knives mentioned above, the sharpening angle is 20-30 degrees. There are many ways to “calculate with your hands” the desired tilt of the blade; The simplest one is to fold a sheet of thick paper into a triangle, one fold is 45 degrees, the second is half as much, 22.5. We place the resulting pyramid on the block, carefully press the blade against it and remember the tilt and position of the hands.

20-25 degrees is a good angle for a well-worn carbon OpinelFor the same purposes, you can use special wooden corners or several coins glued with superglue. Or simply buy a special clip for the blade, which will prevent the edge from being too “collapsed”.

True, if the steel is completely “plasticine”, they try to increase the angle as much as thirty-five degrees - cutting such a product will be quite lousy, but it will take a long time. Here you can also play with a sheet of paper, but you will have to fold it not in four, but in three - as a result you will get a corner with a working side close to 33 degrees.

For soft steels there is another trick: the angle is maintained around 30 degrees, but one side of the cutting edge is smoothed almost “into a mirror”, and the other is sharpened on a rough, coarse-grained whetstone. This method is popularly called “gypsy”; at the industrial level, it degenerated into the notorious “laser-sharpened knives” (although, of course, there was no smell of laser there).

Small teeth on one side, a smooth surface on the other, and even the top layer of steel is carburized to increase hardness - it cuts well until it gets dull. For cheap domestic stainless steels such as 40X13, 65X13 or the favorite of Chinese manufacturers 420J2, this method works well - try it yourself.

Professional sharpening of knives: how and what is better

While elementary, simple sharpening devices can be used for kitchen knives, professional sharpening of office knives, bread knives and surgical instruments requires a more serious approach. Most often, special devices are used for this manipulation, which are selected individually for each type of knife.

Hunter knives

In the field, hunting knives are best sharpened with mechanical pocket sharpeners, which can have different shapes and sizes, but are always of high quality materials. It is enough to run the knife several times along a special cut - and “at the exit” the edge of the blade will become sharp again.

Manufacturers of professional sharpening tools also offer hunters round or flat rods on a plastic/wooden handle - they are used for emergency knife sharpening. Round sharpeners are made of ceramic, flat ones have a diamond surface.

Among stationary tools, it is better to give preference to a case of sharpeners for hunting knives, which has a special clamp, numbered sharpening angles, and several stones with varying degrees of abrasiveness. Additionally, oil is included, which allows you to bring the hunting knife to perfection in terms of sharpness.

Scalpel

Surgical instruments, including scalpels, are sharpened using whetstones, emery and carborundum wheels. The sharpening angle is 15 degrees, and it must be strictly maintained throughout the entire process.

It is important to follow two rules:

- make movements during sharpening only with the blade forward;

- Both sides of the blade are processed on the sharpening device simultaneously.

This means you don't have to go through 50 strokes to sharpen one side of the blade and then the other - the sides have to be constantly changing. Scalpels are made of high-quality steel, so no burrs (roughness) are formed on their surface. It is necessary to periodically monitor the process and check the surgical instrument for sharpness.

Watch the video about sharpening a medical instrument:

Serving knives

Serving knives cannot be sharpened because they are made of a special metal - an oxidized or complex composition (alloy), which often contains precious metals. This type of knives is designed for cutting ready-made dishes, and they are a priori distinguished by their softness and pliability.

Boning knife

Boning knives can be sharpened with any equipment because they are made of durable steel and can withstand aggressive external factors. Since such knives are used for a long time, in addition to the main sharpening, periodic editing of the blade will be required. This can be done with a mechanical sharpener with wheels, musat, and a small whetstone.

Stationery knife

Stationery knives are made of thin metal, so you don’t need to use any special tools to sharpen them. But it’s worth taking a closer look at the structure and design of the blade – they have notches at a certain distance from each other. And if you take the edge of the knife with pliers and simply break it along the notch, then “sharpening” will take place instantly - the edge will become sharp again.

Thus, it will be possible to restore the cutting ability of a stationery knife 5 times for one replaceable blade.

You can break off a piece of dull metal using the back cover, it is located on the handle . To do this, remove the lid, insert a blade into the slot up to the line and turn it to the side. It will break off along this line.

Round knives

Round knives are used in the kitchen (for example, for cutting pizza, dough), in sewing workshops (for cutting pieces of fabric). It is almost impossible to sharpen them at home, because this process requires a professional tool such as a sharpening machine for hairdressing scissors.

In general, craftsmen avoid working with this type of knives and recommend purchasing new cutting tools as the blade becomes dull.

Flat knives

Flat knives are those used on woodworking machines and include chisels and plane blades. They can be sharpened with a whetstone, following the instructions:

- The blade is mounted on a whetstone (grindstone, whetstone) at an angle of 30-40 degrees.

- The chamfer is pressed against the whetstone with one hand (fingers), and the other holds the blade in the adjusted position.

- Move the edge of the blade along the block until a burr forms on the surface.

- Replace the whetstone with the same device with a fine abrasive surface and remove the burr using the usual sharpening movements.

It must be remembered that flat knives are sharpened only on one side . You can check the level of sharpness obtained on a wooden block - you need to remove the shavings from it.

Bread

A bread (serrated) knife is sharpened with a cone-shaped rod - it is placed in the space between the teeth. It is better if this sharpening tool is made of ceramic. Before starting the process, you need to determine the beveled side of the cloves - this is what needs to be processed.

The rod is inserted between the teeth at such an angle that it fits snugly against the edge, the movements are performed away from you and slowly, only 2-5 “pulls” are required to obtain the desired result. All nicks are processed in this way.

At the end of the work, you need to run your fingers along the back of the knife - small scale and burrs should be clearly felt on it, which indicate that the sharpening was carried out correctly. They are removed with fine abrasive sandpaper.

Watch the video on how to sharpen a bread knife:

Peeler

You don’t sharpen a peeler yourself, because given the low cost of this kitchen tool, it’s easier to buy it again to replace an already dull one. If the vegetable peeler is expensive, then you should take it to a professional, although he will most likely refuse such a service - the cutting parts in this device are too inconveniently located.

Japanese knives

Japanese knives are sharpened on water stones; you need several such sharpening tools with different levels of abrasiveness - from the smallest to the coarse. Before starting the process, the stones must be soaked in water (it covers them completely) for 3-5 minutes; the instructions for them indicate that this manipulation is carried out until air bubbles stop coming to the surface.

Japanese knives are sharpened in the usual way, but without even the slightest effort. The concave sides of kitchen tools are not sharpened; they are only passed over the stone a couple of times - this is necessary to remove burrs.

What are the differences between abrasive stones?

Sharpening stones come in a variety of shapes, bar sizes, and grain sizes. The optimal size of the bar is considered to be one in which its length exceeds the length of the blade of the knife being sharpened by at least one and a half times. This allows you to work with such a bar much more comfortably than with a bar that does not meet this simple requirement.

As mentioned earlier, sharpening stones can have not only different sizes, but also very different grain sizes. There are five main levels of grain size for such bars:

- Grain size 200-300 Extra coarse. In English called Extra coarse. Such bars are not used for sharpening tool blades and knives in particular;

- Grain size 300-350 Coarse grain. In English called Coarse. With the help of such bars, damaged or very dull blades are sharpened;

- Grain size 400-500 Medium grain. In English called Medium. You can do without such a block in the household;

- Grain size 600-700 Fine grain. Called Fine in English, these whetstones are the most popular for sharpening tool blades in the home workshop.

- Grain size 1000-1200 Very fine. In English called Ultra fine. These bars are used for final processing of blades that need to be brought to a shine. Such bars can be used as a tool for a homemade knife sharpener.

How to dull a knife

You can dull a knife as follows:

- perform chopping movements on hard objects - bones, wood, plastic pipes, frozen meat, and so on;

- sandpaper or whetstone - you need to run them several times directly along the blade.

Special, targeted blunting of the knife may be needed as an experiment for further sharpening or to reduce the level of sharpness - this will ensure safety of use.

What did we get?

Having assembled the design according to the drawing, you will receive the simplest device for sharpening knives, however, despite its simplicity, this device will allow you to sharpen knives and any other blades quite efficiently.

In order to understand how to use such a device, just enter “video knife” in any search engine.

Did you manage to sharpen the knife? Hooray! You have successfully made a DIY sharpening machine.

We should not forget that any sharpening machine, even if it is made by hand, requires strict adherence to the rules and safety requirements!!!

Common Mistakes

So, we found out how to properly sharpen knives by hand. Let's list the common mistakes of inexperienced consumers to summarize. Definitely not worth it:

- Place the stone directly on the table, without a backing.

- Use only one water stone for sharpening.

- Wet the stone only once.

- Sharpen dirty and greasy knives.

- Apply excessive pressure on the knife while sharpening.

- Violate the factory sharpening angle.

- Finish sharpening ahead of time without removing the burrs completely.

Such actions can reduce the efficiency of your work or even lead to damage to the blade.

Did you like the article? Have you read to the end?! Using the promotional code Stone we give a DISCOUNT on your purchase in the cart!