What determines the consumption of shielding gas?

The main indicators during welding that affect the consumption of welding mixtures are:

- Current strength;

- Diameter of wire used;

- thickness of the metal being welded.

Many manufacturers indicate these values in the data sheet for a specific shielding gas, which greatly simplifies the calculation.

For example, the average consumption of an argon mixture used in TIG welding with a current of 100 A will be 6 l/min. When the current increases to 300 A, the flow rate increases to 10 l/min.

Table of the influence of current, arc voltage, welding speed on the size and shape of the seam

The same trend is observed with the MIG method - an increase in wire diameter from 1 mm to 1.6 mm leads to an increase in gas consumption from 9 l/min to 18 l/min.

Wire diameter is also important

The conditions in which welding takes place have a great influence. In an open space, or in the presence of drafts, the flow rate will increase, since more protective gas will be required to create optimal protection of the metal from the influence of extraneous factors. In this case, cylinders will be refilled more often than when working indoors. By the way, read about all the nuances of filling gas cylinders in the article: Filling with a gas mixture: how it’s done.

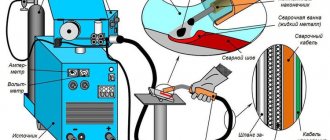

What gas mixtures are used for semi-automatic welding

Semi-automatic machines most often work:

- with steel alloys, cast iron;

- with alloy steels - stainless steel, various types of heat-resistant ones;

- with non-ferrous metals - aluminum, copper-containing: brass, bronze.

Working with other materials is difficult because there is no corresponding filler wire supplied in standard spools. Mixtures are created in accordance with TU 2114-002-45905715-2011.

The following are used as component gases:

- argon - GOST 10157-79 (highest grades);

- nitrogen - GOST 9293-74 (special purity 1st grade);

- carbon dioxide - GOST 8050-85 (highest grades);

- oxygen - GOST 5583-78 (technical, first grade);

- helium - TU 0271-135-31323949-2005 (grade “A”);

- hydrogen - GOST R 51673-2000 (first grades).

The use of ready-made mixtures is allowed, however, the content of components in the resulting mixture must comply with technical regulations.

Calculation of welding mixture consumption

There is a formula that allows you to find out the approximate consumption of the welding mixture during the welding process:

P = Ru x T

where, Ru – specific gas consumption declared by the manufacturer,

T is the main time spent on welding one pass.

The specific consumption of shielding gas depending on the wire diameter at average current values can be seen below:

- 1.0 mm – 9 l/min;

- 1.2 mm – 12 l/min;

- 1.4 mm – 15 l/min;

- 1.6 mm – 18 l/min;

- 2.0 mm – 20 l/min.

Table 1 depending on the parameters

Table 2 depending on the parameters

Based on the fact that a standard 40-liter cylinder contains 6 m³ or 6000 liters of welding mixture, you can easily calculate how long one tank will last during a continuous welding process.

For example, when using a wire with a diameter of 1 mm and combining argon with carbon dioxide, a 40 liter cylinder will be completely empty after 10-11 hours of continuous process.

Naturally, such calculations are quite rough, since they do not take into account gas consumption for preparatory and finishing operations during one pass. However, they allow you to see an approximate picture. When using flow meters and verifying readings, these calculations will be more accurate and objective.

Aluminum welding

The high electrical and thermal conductivity of aluminum, very low weight, combined with the excellent mechanical properties of its alloys, have made this material simply irreplaceable in many areas of human activity. As if to compensate for its advantages, the “winged” metal is very difficult to weld. The ability to weld aluminum with high quality is what distinguishes a highly qualified welder from an amateur welder.

Aluminum welding

Weldability

As already noted, aluminum is a difficult-to-weld metal. This feature is determined by a number of its properties:

- On the surface of parts made of aluminum and its alloys there is always an oxide film of Al2O3, which has a melting point of 2044°C, while the melting point of aluminum itself is about 660°C.

- The easy oxidation of aluminum leads to the formation of a refractory film on drops of molten metal, preventing their fusion into a monolithic seam. To prevent the formation of this film, reliable protection of the welding zone from air is required, which can be fully ensured by welding aluminum with argon.

- The high fluidity of the metal makes it difficult to control the weld pool and dictates the need to use heat-removing pads during welding.

- The tendency to form crystallization cracks and pores in the weld leads to weakening of the latter. Hydrogen dissolved in aluminum is responsible for the pores, tending to escape from the metal to the outside. Cracks are more typical for aluminum alloys; they occur when the metal cools due to the increased silicon content.

- Large shrinkage of the metal, caused by a high coefficient of linear expansion, leads to significant deformations during solidification of the weld.

- The high thermal conductivity of aluminum necessitates the use of a welding current that is 1.2-1.5 times higher than the current for steels, despite the fact that the melting point of the latter is much higher than that of aluminum.

- Additional difficulties in welding aluminum include the fact that in practice - especially when welding aluminum at home - you have to deal with various alloys of an unknown grade, which may require special materials and welding modes for high-quality welding.

Weld seam with inclusions and pores

Aluminum welding methods

There are many ways to weld aluminum using different equipment and different welding materials, with the welding zone protected by inert gases or fluxes. Three of them are most widespread:

- welding with a tungsten electrode in an inert gas environment (AC TIG mode);

- semi-automatic welding in an inert gas environment with automated wire feed (DC MIG mode);

- welding with coated consumable electrodes without the use of shielding gas (MMA mode).

An important condition for welding aluminum and its alloys is the need to destroy the oxide film on the metal surface. To fulfill this condition, an alternating or direct current of reverse polarity is required. Only in this case does the so-called cathode sputtering, which destroys the oxide film. Aluminum cannot be welded with direct current of direct polarity, since in this case the film is not subjected to cathode sputtering and remains undestroyed.

Preparing metal for welding

Regardless of the method used, welding must be preceded by careful preparation of the edges being welded, the purpose of which is to clean the edges from dirt and oxide film. Preparation consists of a number of operations:

- Cleaning and degreasing. The parts to be welded and the filler material are thoroughly cleaned of dirt, oil and grease before welding. Degreasing is carried out with acetone, aviation gasoline, white spirit or another suitable solvent.

- Cutting edges (if necessary). Welding of parts up to 4 mm thick is carried out without cutting the edges; for larger thicknesses, cutting is required. An exception to this rule is welding aluminum with coated electrodes, in which the edges are cut when the metal thickness is above 20 mm. For parts made of thin sheets (up to 1.5 mm thick), it is advisable to use flanging

Butt welding with flange

- Removing the oxide film. The edges of parts with a width of 25-30 mm are cleaned with sandpaper, a file or a stainless steel wire brush with a wire diameter of no more than 0.15 mm.

Welding aluminum with coated piece electrodes (MMA mode)

This type of welding is used mainly in the manufacture of non-critical structures with a metal thickness of at least 4 mm.

This welding method has significant disadvantages, including low quality of the weld (porosity, low strength), strong spattering of metal during welding, poor separation of solidified slag, which can cause corrosion of the metal. Coated electrodes can be used to weld both commercially pure aluminum and its alloys. Instead of the old brands OZA-1 and OZA-2, which have significant shortcomings, today more advanced electrodes for welding aluminum UANA and OZANA are produced, allowing the welding of all main types of aluminum alloys. In particular, for welding parts made of technical purity aluminum, OZANA-1 electrodes are used, parts made of aluminum-silicon alloys (AL-4, AL-9, AL-11) - OZANA-2.

Welding seam made with OZANA-2 electrode

Welding is performed with direct current of reverse polarity. The welding current is taken at the rate of 25-30A per 1 mm of electrode diameter.

To obtain satisfactory weld quality, heating is required - up to 250-300°C for medium-thick metal, and up to 400°C for massive parts. Heating and slow cooling make it possible to obtain sufficient metal penetration at moderate welding currents, avoid the occurrence of crystallization cracks and reduce warping. When welding large parts, local heating is advisable.

Welding with aluminum electrodes has its own characteristics due to the fact that they melt 2-3 times faster than steel ones. The welding speed must therefore be significantly higher. When the arc breaks, the crater and the end of the electrode are covered with a slag crust, which prevents the arc from re-igniting. In this regard, it is recommended to perform welding continuously within one electrode. Transverse vibrations of the electrode (as when welding steel) should not be done.

Immediately after welding, it is necessary to remove the slag from the seam, rinse it with hot water and treat it with a steel brush. The presence of slag in gaps and corners can cause metal corrosion.

Due to its shortcomings, aluminum welding with coated electrodes is not particularly respected among welding masters. Preference is given to argon welding of aluminum.

Tungsten inert gas welding (AC TIG mode)

This welding method is the most common.

It is used in the manufacture of structures made of aluminum and its alloys, the quality of which is subject to high demands in terms of strength and aesthetics. When welding, tungsten electrodes with a diameter of 1.6-5 mm and filler rods with a diameter of 1.6-4 mm are used.

Tungsten electrodes with blue color code

Filler rods for aluminum welding

High-purity argon or helium is used as a shielding gas. The arc is powered from an alternating current source, which ensures high-quality destruction of the oxide film. All necessary parameters - the diameters of the electrode and filler rod, the value of the welding current, the gas supply speed - depend on the characteristics of the equipment used. As a guide, you can take the values from the table below, which are correct provided that argon is used as a shielding gas.

| Connection type | Metal thickness, mm | Electrode diameter, mm | Diameter of filler wire, mm | Welding current, A | Argon consumption, l/min |

| With beaded edges | 1,0 1,5 2,0 | 1,0 1,6-2,0 1,6-2,0 | — | 45-50 70-75 80-85 | 4-5 5-6 7-8 |

| Butt without cutting edges, one-sided | 2,0 3,0 4,0 | 1,5-2,0 3,0-4,0 3,0-4,0 | 1,0-2,0 2,0-3,0 2,0-3,0 | 55-75 100-120 120-150 | 5-6 7-8 8-10 |

| Butt joint without cutting edges, double-sided | 4,0 5,0 6,0 | 3,0-4,0 4,0-5,0 4,0-5,0 | 3,0-4,0 3,0-4,0 3,0-4,0 | 120-180 200-250 240-270 | 7-8 8-10 8-10 |

The angle between the electrode and the horizontal plane should be 70-80°, between the filler wire and the electrode - about 90°. The arc length should not exceed 1.5-2.5 mm.

Position and direction of movement of the torch with electrode

The torch follows the filler rod rather than ahead of it. This provides better seam protection. The importance of this requirement is confirmed by the photo below, in which the seam on the left is made in the recommended way, and the seam on the right is made differently, in which the torch moved in front of the rod.

Welding seams when the rod moves in front of the torch (left) and behind the torch (right)

The filler rod is fed in short reciprocating movements, reminiscent of the movements of an artist's brush - it approaches, touching the edge of the bath with its tip, and is retracted back and up. Transverse movements of the electrode and filler rod are unacceptable.

TIG aluminum welding

TIG aluminum welding

The aluminum sheet must be placed on a steel or copper pad, which removes heat, acting as a radiator. This is especially necessary when welding thin sheets to avoid burn-throughs.

The dimensions of the weld pool should be minimal. The welding speed must correspond to the welding current and inert gas flow. Excessive consumption of the latter leads to air being sucked into the arc zone; if the gas flow is low or the welding speed is excessively high, high-quality protection will also not be provided.

The argon supply is turned on 3-5 seconds before the arc is ignited, and turns off 5-7 seconds after it breaks.

Aluminum welding with semi-automatic machines (DC MIG mode)

It is best to weld aluminum with a special pulsed aluminum welding machine, in which a high-voltage pulse, breaking the oxide film, drops to the base value. Each drop of molten electrode material is, as it were, “driven” into the weld pool, thereby ensuring high quality welds. However, such devices are expensive. However, as practice shows, it is quite possible to get by with a conventional semi-automatic machine, even one in which the aluminum welding mode was not initially set. True, in this case minor alterations may be required.

Inverter semiautomatic welding machine for continuous and pulsed welding MIG-MAG

The MIG welding process is three times faster than the TIG welding process, but the quality of the latter is higher.

In its principle, the semi-automatic aluminum welding technology does not differ from the steel welding technology. However, there are some technical features:

- Aluminum and its alloys cannot be welded with direct current of direct polarity - only reverse polarity (for the reason mentioned above).

- Aluminum wire is much softer than steel wire, so it tends to form loops with little resistance in the sleeve. To prevent this from happening, it is advisable to have a 4-roller feed mechanism, a short sleeve and a Teflon liner in it, which reduces friction resistance.

Collapse of aluminum wire in the automatic wire feeder

The liner should protrude as close to the rollers as possible

- Since aluminum expands more than steel when heated, the aluminum wire can get stuck in the current collector (conductive tip). To prevent this from happening, you can use a tip with a slightly larger hole diameter (for example, for aluminum wire with a diameter of 0.8 mm, use a tip for steel wire with a diameter of 1.0 mm). Also, special current collectors are sold for aluminum wire, usually marked “Al”.

Current collector (conductive tip) of a semi-automatic welding machine

- Aluminum wire melts faster than steel wire, so when welding it is necessary to ensure the required feed speed - higher than steel wire. Otherwise, you will have to frequently replace the melted tip.

The grade of welding wire must match the material. Before purchasing it, you need to study information about the types of aluminum alloys for which it is used for welding. An experiment will help compensate for the lack of information, which in any case cannot be avoided if you are trying to cook aluminum for the first time.

When using the content of this site, you need to put active links to this site, visible to users and search robots.

Literature

How can you reduce consumption?

The main indicator in the welding process is the quality and reliability of the seam. For this purpose, in fact, shielding gas is used. Therefore, it makes little sense to artificially reduce the consumption of welding mixtures, as this can lead to the formation of pores and other side effects.

Defective seam, low-quality welding mixture used

The quality indicators of the gas itself also play an important role. For example, when using the multi-component composition “Mixpro 3212”, consumption is reduced by at least two times, compared with the use of binary protective gases based on argon and carbon dioxide. In addition, in the case of Mixpro, the quality of the seam will be much higher.

By the way, you will find more information about welding mixtures in this section of the blog.

Application area

Due to its practical qualities, argon can be used almost everywhere. In the private sphere, it is quite rare, since it is often not profitable to maintain it, not to mention purchasing the appropriate equipment. In construction, where it is necessary to create critical load-bearing metal structures, gas is practically irreplaceable. Cost is not as important here as reliability and minimizing the likelihood of defects during operation.

It can also often be found in repair shops. It is used to connect parts in cars and products made of difficult-to-weld metals. Welding of stainless steel and aluminum often occurs with the help of this gas. Welding shops at various enterprises also cannot do without stations using argon, where they have to work with thin parts. In the utility sector, they can be used to weld pipes.

Brief description of gases used to create mixtures

Argon is a colorless, odorless, tasteless gas, non-flammable and non-toxic. However, any mixture of Ar with other gases can displace oxygen from the room, which can lead to suffocation of workers if the proportion of oxygen drops below 19% of the total volume. Argon is heavier than the air mixture and can accumulate in poorly ventilated areas near the floor.

Nitrogen is a colorless and non-flammable gas. Odorless and tasteless, non-toxic. However, the accumulation of a nitrogen gas mixture can cause oxygen deficiency and even suffocation when the oxygen concentration decreases to less than 19% of the volume.

Carbon dioxide is a colorless gas, non-flammable and non-toxic, with a specific sour taste. The maximum permissible concentration of the compound in the air of the working area is 9 g/m3 (which is equal to 0.5% of the volume). If the concentration becomes more than 5%, carbon dioxide can have a harmful effect on the physical condition of workers. Carbon dioxide is one and a half times heavier than the air mixture and can accumulate in unventilated rooms near the floor, in pits. When the oxygen concentration in the air drops below 19%, oxygen starvation and suffocation occur.

Helium is a colorless gas, tasteless and odorless, non-toxic and non-flammable, lighter than an air mixture, therefore it accumulates at the top of workshops.

Oxygen is a colorless, odorless, tasteless, non-flammable gas, although it itself is not toxic or explosive, however, being a strong oxidizing agent, it significantly increases the susceptibility of other materials to combustion. If oxygen accumulates in the air of workshops, it can cause fires and subsequently fires. It is important that the volume fraction of gas in working (production) areas should not be more than 23%.

Argon, carbon dioxide and oxygen

Carbon dioxide (5-20%) and argon (80-95%) are used to create permanent joints from steels: structural alloy and carbon. Pros: transfer is carried out by jet or drip. The arc burns stably. If you use a mixture with the addition of oxygen (2%), reducing the carbon dioxide content to 6%, then it will be easier for the welder to cope with thin alloys.

Argon and helium

The combination of helium (70%) and argon (30%) will allow you to work with any thick alloys:

- steel;

- cast iron;

- non-ferrous metals.

At the same time, the welding speed will increase due to the elimination of the operation of preheating the parts. The number of defects - porosity of seams, cracks - will be reduced to a minimum.

The disadvantage should be considered the high cost of such mixtures due to the high content of rare helium. Therefore, similar proportions are used when welding especially critical structures - when creating products for space or the military-industrial complex.

Argon plus helium (50% each) - the mixture is considered universally inert. Thanks to this, you can work with most alloys - both non-ferrous and ferrous. A composition of 70% argon and 30% helium, compared to pure argon, cools the welding zone better and is used for joining parts of medium thickness, if it is necessary to obtain seams with a minimum of defects. A mixture of 60% argon, 38% helium and 2% carbon dioxide is used for welding alloy and structural carbon alloys. At the same time, the arc is stable and the amount of splashes is reduced.

Argon and hydrogen

Used in production when working with austenitic (heat-resistant) alloys. The mixture allows you to improve the characteristics of the resulting seam and achieve greater elasticity . Often used when working during the creation of space and aircraft technology. The percentage of chemical elements content depends on the grade of steel.

Optimal carbon dioxide consumption during semi-automatic welding

Nowadays, in both small and large industries, you can increasingly find cylinders with protective gas. The use of shielding gas during welding improves the quality of the welded joint, speeds up work and does not allow oxygen to penetrate into the welding zone. In addition, a gas cylinder is inexpensive and, especially for home welding, manufacturers produce compact cylinders that easily fit into the trunk of a car.

If you are a home welder, then you simply purchase a compact cylinder in the store and use it without worrying about consumption. If the gas runs out, you can quickly buy another cylinder. But what if you are a welder in production and you are subject to rather strict gas consumption requirements? How to choose the volume so that there is exactly enough gas for the entire welding process? In this article, we tried to briefly tell you how to calculate the optimal carbon dioxide consumption when welding with a semi-automatic machine.

Tips for reducing consumption

The consumption of shielding gas during semi-automatic welding can be reduced. The following tips will help with this. The level of welding work depends on how high-quality and reliable the seam is. For these purposes, the use of protective gas will be required. Therefore, there is no point in artificially reducing the consumption of welding mixture. Otherwise, it may cause a situation where pores form and other side effects may occur.

To save money, the quality of the gas mixture is very important. For example, if you constantly use the Mixpro 3212 composition, which contains many different components, you can reduce your consumption by at least half. Compared to the situation where a binary shielding gas is used. Its base consists of argon and carbon dioxide mixtures. The use of the Mixpro mixture results in the highest quality seam.

Average indicators

Indicators of how much gas is consumed can be as follows:

| Wire diameter (cm) | Current (Ampere) | Average flow rates (liters per minute) |

| 0,8 – 1 | 60 – 160 | 8 |

| 1,2 | 100 – 250 | 9 – 12 |

| 1,4 | 120 – 320 | 12 – 15 |

| 1,6 | 240 – 130 | 15 – 18 |

| 2 cm | 280 – 450 | 18 – 20 |

Gas saving

We said above that gas consumption is also influenced by indirect factors that the welder has virtually no influence on. But he can still, if possible, minimize the effect of these factors, thereby saving gas.

The simplest thing you can do is to weld in a closed workshop with good ventilation. There should be no drafts or wind. It is also better to involve qualified, experienced welders who perform the work quickly and accurately. After all, for beginners, in any case, gas consumption will be much higher.

Many novice welders are interested in whether there is any other way to reduce co2 consumption during semi-automatic welding? For example, simply supply less gas to the welding zone. Our answer: no. By deliberately reducing the amount of gas used, you will deteriorate the quality of the seam, since oxygen will enter the welding zone.

But this problem still has a solution. Experienced craftsmen advise using multi-component gas mixtures in their work; thanks to them, consumption is reduced, while the quality of welding remains at a decent level. But be prepared for the fact that the cost of multicomponent mixtures is much higher than that of standard gas. So make sure that using such mixtures is cost-effective.