The equipment for ultrasonic welding of plastics Telsonic Ultrasonic AG, which we offer, is already in demand by such global brands as BMW, Mercedes-Benz, Bosch, 3M, Tetra Pak, DuPont, Gillette, Philips, as well as large Russian enterprises - Aquaphor, Dimitrovgrad Avtoaggregatny ( water filters "Barrier") and many others. Quality, process optimization, savings - all play an important role in the success and stability of these companies. And the products of Telsonic Ultrasonic AG fully meet their high demands.

Ultrasonic welding of materials

Ultrasound can be used to weld various materials. The following ultrasonic welding of materials is possible:

- Various metals;

- Plastics;

- Ceramics;

- Leather;

- Textile;

- Glass.

Using ultrasound, you can not only join homogeneous metals, but also dissimilar ones. For example: using ultrasound you can connect metal to glass, and plastic to leather.

But not all dissimilar materials can be qualitatively combined with each other. Sometimes it is necessary to use an aluminum layer or other materials.

In any case, welding of metals and plastics performs best.

Ultrasonic welding of plastics

Working with metal parts

Due to its ease of use, ultrasonic welding of metals has recently begun to be used more and more often. It also has a number of advantages over contact and cold welding. It is also extremely useful when working with microelectronics.

This technology has some similar features to cold shear welding. The permanent bond of metals occurs due to the simultaneous influence of mechanical vibrations of high frequency and a low level of compressive forces.

Ultrasonic welding of metals can be performed at lower temperatures, which makes it possible to connect heat-sensitive elements without damage.

It allows you to weld together parts of different thicknesses and dissimilarities (for example, weld copper and aluminum, aluminum and nickel, etc.). The strength obtained in this way reaches about 70% of the strength of the material itself.

Metal products can also be welded with composite, ceramic, glass materials, and semiconductors. Refractory metals are no less successfully welded.

Ultrasonic welding of plastics

The process of ultrasonic welding of plastics can be divided into several stages:

The first stage includes the process of exposing the material to ultrasound. This process causes the movement of molecules, and therefore heating of the plastic. Heating occurs at the site of the future connection of two parts.

The second stage includes the cooling of the two parts. After this, a permanent connection is obtained.

This device comes in two types:

- Mechanical;

- Manual.

With the mechanical method, the device moves independently without the help of an operator. His task is to set the necessary welding parameters.

With the manual method, the welder must perform the welding process himself.

Depending on the thickness of the metal and the selected material, the ultrasonic wave can be:

- Continuous;

- Pulse.

A continuous wave always goes on continuously. The pulse wave is interrupted for a certain time.

According to the energy supply, the ultrasonic plastic welding device is:

- One-sided;

- Double-sided.

One-way energy supply is used to connect large cross-section structures.

Bilateral energy supply is needed to connect small plastic parts.

Advantages and disadvantages of ultrasonic welding of plastics

Ultrasonic welding of plastics has the following advantages:

- High-quality and tight connection;

- Possibility of welding plastics without preliminary preparation of parts;

- It is possible to weld various types of plastics;

- No additional filler materials are required;

- No radiation;

- High performance;

- Low cost.

The disadvantages of ultrasonic welding include:

- It is impossible to control the quality of the seam during welding;

- The quality is affected by equipment settings.

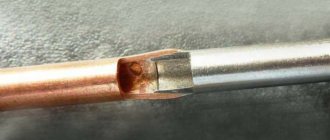

Ultrasonic welding of copper cable

Ultrasonic welding of metals

Ultrasound can be used to weld not only plastics, but also metals. Ultrasonic welding of metals occurs at low temperatures compared to fusion welding. Therefore, this method of joining metal is more preferable in cases where overheating of two parts is unacceptable.

Another advantage of ultrasonic metal welding is that it is capable of welding dissimilar metals. Especially those that do not weld well together: aluminum with nickel, aluminum with copper and other metals. Moreover, such a connection turns out to be quite reliable.

In addition to welding dissimilar steels, you can weld steel with plastic, ceramics and glass.

Ultrasonic welding machines

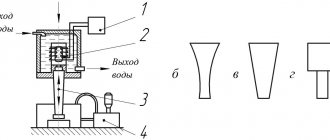

All ultrasonic welding machines can be divided into several types:

- Spot;

- Suture;

- Contour-transfer.

Ultrasonic spot welding performs a point-to-point connection between two parts. The operator, after applying a pulse to the desired location, moves the workpiece or equipment. After this, the pulse is applied again to the desired location on the product.

Despite this movement of the workpiece or equipment, the welder can quite quickly weld over a large area of the product. In this case, the distance between points can be controlled manually.

Suture ultrasonic welding is used to obtain a permanent overlapping connection of parts. This ultrasonic welding machine passes the workpiece between its rollers. It is through the rollers that the ultrasonic wave is supplied to the surface of the product.

Contour-transfer ultrasonic welding is more universal compared to seam welding. This ultrasonic welding machine is capable of joining products of any configuration. It is further divided into two types:

- Contour;

- Transfer.

Contour ultrasonic joint is used for overlapping thin sheet metal.

Transmission ultrasound is a more complex solution, as it is capable of generating an ultrasonic pulse at several points at once.

How to operate an ultrasonic welding machine

- First you need to turn on the ultrasound device itself.

- Assemble and display two parts. For convenience, you can use clamps or clamps.

- Lower the electrode onto the surface of the workpiece and release an ultrasonic pulse.

- Keep the parts under pressure for a certain time. The time is selected depending on the material being welded, the shape and thickness of the product.

- Remove the electrodes.

Depending on the features of the ultrasonic welding machine, the operations may differ slightly from each other. When seam welding, the rollers can automatically begin to rotate, thereby automatically delivering an electrical impulse.

With the manual welding method, the operator independently presses the electrode against the workpiece. This is usually ultrasonic spot welding. By pressing a button or trigger, an electrical impulse is sent to the electrode.

Possible defects

All welding methods may have certain defects. And UZS is no exception. Defects can be caused by many factors:

- Worn electrodes;

- Incorrectly set modes;

- Errors made by the operator or welder.

The following defects are possible:

- Lack of penetration . Happens frequently. The reason is incorrectly selected modes. Basically, lack of penetration occurs due to the low intensity of the ultrasonic wave and the time the electrodes are kept under pressure. This can happen if the two parts have different thicknesses. Because of this, it is not possible to heat up the thicker part.

- Lived . Occurs due to excessive operating conditions and poor cooling of the system. With high intensity of the sound wave and overexposure of two parts, burning can occur in any material.

- Undercuts . The reason may be wear of the electrode or excessively high pressure on the product. This usually occurs when welding plastics or any other soft materials. To prevent this from happening, you need to monitor the working surface of the electrodes. If necessary, change or sharpen them.

What can be produced on HDTV machines

HDTV welding machines weld materials containing PVC. They can be used to produce: medical products, packaging, inflatable products for sports and recreation, stretch ceilings made of film (including welding a harpoon), special. clothes, awnings, banners, tents, blisters, stationery. products, cases and much more.

HDTV machines are easy to use and pay for themselves in a few months. At the same time, as we see, they can produce a wide range of products. Also, the undoubted advantages of these machines are their reliability, versatility and compactness.

Unfortunately, only those thermoplastics whose dielectric loss factor is not less than hundredths of unity can be welded. Non-polar substances (such as polyethylene, polypropylene, polystyrene) are not suitable for high-frequency welding.

Specifics of the equipment used

Equipment used for welding with ultrasound is divided into devices that provide spot contour press, seam and seam-step welding.

The power of such machines ranges from 100 to 1500 W, and they most often operate at a frequency of 20,000 - 22,000 Hz.

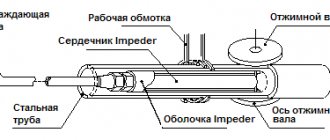

The key element of the equipment design is the electromechanical oscillatory system. Its main purpose is to convert electrical oscillations set by the generator into mechanical ones at a constant frequency. This system determines the level and method of energy transfer to the welding point and sets the speed of vibrations.

Converter

An important part of an ultrasonic welding machine is the magnetostrictive transducer. Usually it is made with two rods, using thin metal plates made of magnetostrictive material, which reduces losses.

The most optimal materials from which converters are made are alloys of iron and cobalt. Nickel is also often used to complete packages in magnetostrictive converters.

It has all the necessary properties for this (sufficient elongation, high strength, less susceptible to corrosion and easy to solder). Typically, running water is used to cool this element.

Transformer

The main function of an elastic vibration transformer is the process of matching the operating characteristics of the converters and the waveguide.

It allows you to increase the oscillation frequencies at the output of the waveguide. Most often, step transformers are used, which have a high gain (from 4 to 6). \

The waveguide tool amplifies the shift frequency of the output end of the transformer and transfers energy to the point at which welding work is carried out. Its working surface is made in the shape that is optimally suited for the part being welded and the type of ultrasonic welding used.

The material used to make the waveguide and transformer must have good elastic properties, a low degree of attenuation, and a good degree of machinability using cutting.

An equally important component of the ultrasonic machine is the support. It is used for the purpose of fixing parts during welding work. Sometimes it can be used as an element for heating and cooling, or in the form of a sensor for more precise control over the welding process. This piece of equipment must be able to move, for which an automatic drive is used.

Heat release

When carrying out ultrasonic welding, heat is generated at the point of impact of the device. This occurs due to the formation of friction between the surfaces of the materials in contact, as well as due to plastic deformations, without which any welding cannot be done.

The increase in temperature at the welding site is affected by the hardness of the material, its thermal capacity and thermal conductivity. The welding mode has a special influence on heating.

It is worth noting that an increase in temperature during ultrasonic welding does not greatly affect the quality of the connection. Practical studies have shown that the highest level of strength is achieved earlier than the maximum temperature in this process.

If you preheat the product, this will reduce the transmission time of ultrasonic vibrations and will lead to an increase in the strength of the joint obtained during welding.

Process Features

Ultrasonic welding helps create the necessary conditions for the connection. This is ensured by mechanical vibrations of the converter. Vibration energy creates complex shear, compression and tension stresses. Plastic deformation occurs when the elastic limits of materials are exceeded. Obtaining a strong connection is ensured by increasing the area of direct contact after the evacuation of surface oxides, organic and adsorbed films.

Advantages and disadvantages

When using this type of welding, a high level of productivity and a low level of costs are observed; voltage is not applied directly to the welding point, which avoids radio interference.

It becomes possible to make seams in a variety of conditions and on different scales, to combine several procedures (welding at one point and cutting at another). If you choose the right welding mode, the joint will be invisible; in addition, there is no need to use any additional reagents or devices.

Compared to the above advantages of ultrasonic welding, the disadvantages do not look so critical. Low welding power necessitates the use of a two-way energy supply method. There is also no way to control the quality of the seam at a sufficient level.

When performing welding work with your own hands, you need to use tabular data that indicates all the necessary parameters that are needed for high-quality ultrasonic welding.

Ultrasound power

Ultrasonic welding of plastic provides a permanent connection due to the combined action of high-frequency mechanical vibrations and a relatively small compressive force. This method has much in common with the cold method. The ultrasound power that can be transmitted through the medium will depend on the physical properties of the latter. If the strength limits in compression zones are exceeded, the solid material will collapse. In similar situations, cavitation occurs in liquids, accompanied by the appearance of small bubbles and their subsequent collapse. Along with the latter process, local pressures arise. This phenomenon is used when cleaning and processing products.

Preparation of products and mode parameters

Before performing ultrasonic welding, there is no need to carry out any complex measures with the surface of the parts. If desired, you can increase the stability of the connection quality. To do this, it is only advisable to degrease the product with a solvent. For joining ductile metals, a cycle with a delay of the pulse relative to the moment when the ultrasound is started is considered optimal. With a relatively high hardness of the product, it is advisable to wait for a slight heating before turning on the ultrasound.

Restrictions

The most important limitation that you should pay attention to is the size of the products welded in this way. It should not be more than 250 mm (length, width, height).

The size requirement is due to the fact that the output power of the sensor has its limits, it is not possible to produce too much power of ultrasonic waves, as well as problems in controlling the amplitude of oscillations.

Materials for which ultrasonic welding is used must be dry . In other words, the moisture content in them should be minimal, otherwise it is better to use vibration welding.

It makes no sense to use ultrasonic welding to fasten thick-walled parts. At least one of the elements being connected must be light, since it absorbs a large amount of energy.

Part thickness

It is limited by an upper limit. As the thickness of the metal workpiece increases, vibrations with a larger amplitude must be used. This will compensate for the loss of energy. An increase in amplitude, in turn, is possible up to a certain limit. Limitations are associated with the likelihood of fatigue cracks and large dents from the tool. In such cases, it is necessary to evaluate how practical ultrasonic welding would be. In practice, the method is used for product thicknesses from 3...4 microns to 05...1 mm. Welding can also be used for parts with a diameter of 0.01…05 mm. The thickness of the second product may be significantly greater than the first.

Specific behavior of the material

Tangential movements between parts and the stresses that are caused by them and act together with compression from the welding force ensure the localization of intense plastic deformation in small volumes in the near-surface layers. The entire process is accompanied by crushing and mechanical evacuation of oxide films and other contaminants. Ultrasonic welding reduces the yield strength, thereby facilitating plastic deformation.