When performing repair work, it often becomes necessary to change the configuration of pipes in order to give them the required shape. This result can only be achieved using a special tool. But purchasing a device for the sake of performing only a few operations is impractical. However, every craftsman should make sure that he has a pipe bender in his arsenal, since bending a pipe product may be required at the most unexpected time.

In domestic conditions and for small volumes of work, manual pipe benders are used

General information

This instrument differs in its design by a number of features. It is thanks to them that it is possible to bend pipes, including metal ones, without any problems, giving them a given angular radius with minimal physical effort. Such equipment is divided into several types:

- manual pipe benders;

- hydraulic pipe benders. Models of this type can also be classified as hand tools;

- mandrel;

- spring.

But there are devices of other designs:

- electromechanical;

- segmental;

- crossbow

All of the above tools have positive and negative qualities, but each of them allows you to bend a metal pipe product with a round cross-section without significant physical effort and in a short time.

The easiest option is to go to the nearest specialized store, which has devices of this type in its assortment. But a person who has experience in making a wide variety of devices with his own hands will be able to create a manual pipe bender at home.

You can purchase a factory-made tool, but it is quite possible to assemble it yourself from scrap materials

A little about radii

A circular bend involves determining the radius value, which can be divided into three categories:

- Small radius - from 50 to 250 mm. A bend under such a radius can appropriately be called a knee. It is performed on round water pipes Ø 15–75 mm, or on square pipes 15–25 mm (decorative forging).

- The average radius is from 250 to 500 mm. It is often used for the manufacture of ring molds from a 40x3 strip, a pipe Ø 15–75 mm, a square (15–25 mm) or rectangular (up to 20x40 mm) profile - the rim of barrels, tanks.

- Large radius - more than 500 mm. It is used for the manufacture of arched elements - frames of greenhouses, canopies, ribs of welded structures. Usually this is a square (15x15, 20x20) or rectangular profile 20x40, 40x60 mm. Arches are usually not made from a round pipe - it is inconvenient to attach a distribution sheathing to them, but it is possible to bend a round pipe of a large radius with a diameter of no more than 75 mm.

The radius on thicker pipes is not done by bending, but by segmentation - when the elbow is cut into segments and welded.

Small radius bends are in most cases necessary on water pipes Ø 15–38 mm. Often the fact of bending at the desired angle is more important than its quality. There are two types of pipe benders used by craftsmen to perform this task - three-point and rotary.

Device. Operating principle

The type of pipe bender largely determines its design. However, each device includes a standard set of elements. The key operating component is the pressure nozzle (pressure) on which pressure is applied. As a result of its influence, the bending angle of the pipe changes.

A manual pipe bender is characterized by a design that includes a spring with a lock, while electric devices are equipped with electric motors. The pressure is driven by these elements.

Regardless of the type of pipe bender, the unit includes several shafts (templates/rollers). They perform the function of stabilizing and regulating the bending radius of the workpiece. The impact on the pipe involves its preliminary fixation between the pressure plate and the shafts. The amount of bending that can be achieved is controlled by the position of the shafts. For example, if it is necessary to form an acute angle, the shafts are placed close to the pressure and one to the other.

Good to know! In a homemade pipe bender, this option is most often absent due to the simplicity of the design.

The type of equipment also determines the way it acts on the pipe. The methods are as follows:

- rolling (rolling). It uses 3 moving shafts. Bending radius is a value derived from the location of the support rollers in relation to the central shaft, which also exerts pressure on the pipe;

- impact on the pipe blank with a rod (crossbow method). In this case, two stationary rollers serve as support, and the pipe between them is bent by a template on the rod;

- winding When winding, the pipe is pressed against a rotating roller with a special clamp. In this case, the roller winds the workpiece, pulling it between itself and the stop;

- running-in In this method, the pipe bender clamps the ends of the pipe, the template remains stationary, while the pressure roller moves and bends the workpiece.

You can adjust the bending radius of the pipe using templates of different diameters

It should be noted the versatility of this tool: it can be used to bend various types of pipe products:

- plumbing;

- gas;

- boiler rooms, etc.

The pipes themselves can be made from:

- metal-plastic;

- aluminum;

- copper;

- become.

The only limitation concerns the diameter of the pipes: the value of this parameter should not exceed two inches.

Types of devices

Manufacturers offer devices of different designs.

It can be argued that any of the devices is not difficult to use. Pipe benders are:

- crossbow type - looks like a sports crossbow;

- segmental - they are also break-in;

- spring - external and internal, always separately for each diameter.

Crossbow

A crossbow pipe bender is a device that has a fixed bending pattern for each diameter separately. It has the shape of a semicircle and allows you to bend the pipe at an angle of 90 degrees.

The principle of operation of the crossbow device:

- the section intended for bending is fixedly fixed on stops;

- the pipe is pressed with a template on the handle to the required angle.

A hand tool of this type for metal-plastic materials d 16-20 mm is inexpensive and weighs up to 2 kg.

Segmental

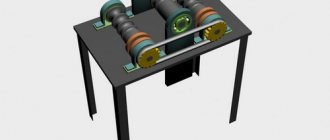

A segment (or rolling) pipe bender is a metal machine made of two rollers with pipe clamps. The tool allows you to change the guide axis by 180 degrees. Manufacturers offer electromechanical, hydraulic and manual devices.

A segment pipe bender often has a universal purpose; it is used not only for metal-plastic, but also for aluminum and copper materials. The principle of operation is simple - the pipe is fixed on a roller template and, by rolling a smaller roller, it is “wrapped” around the template. To install household communications with your own hands, it is unprofitable to purchase a segmental pipe bender. This is a professional tool.

Spring

A spring pipe bender is an elastic metal spring that is inserted inside a metal-plastic pipe or put on top. This is a hand-held, inexpensive tool that is convenient for working in hard-to-reach places, for example, when passing communications through an obstacle. The spring weighs from 200 to 600 g, depending on the size.

- the spring is inserted inside the pipe, having previously secured a wire at its end for extraction;

- the pipe is bent into the required configuration by hand;

- It is acceptable to use the knee as a middle lever.

The internal spring not only maintains the required bending radius, but also serves as a mandrel, preventing deformation of the internal lumen.

The nuances of working with a manual pipe bender

Let's look at the features of using this equipment using the example of its most popular types.

Crossbow pipe bender. For home craftsmen faced with the need to bend thin-walled pipe products made of brass, aluminum and copper, or thin metal-plastic pipes, such a tool is the best choice. It is excellent for working with pipes whose diameter varies in the millimeter range. At the same time, anyone with only basic technical skills can cope with the job.

The simplicity of the crossbow pipe bender design is realized by converting the force on the handle into the force of pressing the lever. Thus, the compressive force of the tool handle directly determines the bending angle of the final product. As practice shows, in order to form a smooth, deformation-free arc from a pipe with a bending angle of 90 degrees, the effort of one male hand is sufficient. But there is one requirement here: in order to avoid crumples or ruptures of the walls, it is necessary to select the correct punch. It must match the diameter of the workpiece being bent.

A simple crossbow pipe bender suitable for working with pipes up to 32 mm in diameter

Manual hydraulic pipe bender. Equipment of this type comes to the rescue when the capabilities of a crossbow pipe bender and hands alone are not enough. The device is ideal for metal pipes with a diameter of 12 ≤ D ≤ 100 millimeters. Before using a manual hydraulic pipe bender, make sure the cylinder rod is positioned correctly. In this case, it should be in a non-working position. That is, in order to prepare the unit for operation, the contractor will need to lift the bypass valve screw half a turn.

Note! Before work, it is necessary to place the hydraulic cylinder on a horizontal, flat surface and fix the lower crossbar.

To prepare a hydraulic manual pipe bending machine for work, take a bending shoe. Its marking must correspond to the diameter of the workpiece. Next, we attach this accessory to the hydraulic cylinder rod so that the punch takes a horizontal position on the pipe bender rod. Having installed the bending segment, insert the stops into the holes closest to the hydraulic cylinder. Now the manual pipe bender is completely ready for work.

How to prepare pipes

To get a high-quality result with a hydraulic pipe bender, you will need a little mathematics. It is necessary to take into account that such a fairly powerful device can damage pipes. This applies, first of all, to products characterized by the following ratio:

Sst/Din < 0.06,

where: Sst. – wall thickness; Din. - outer diameter.

For example, for a 20 mm pipe with a 2 mm thick wall, this figure is 0.1, which is quite acceptable. But a thin-walled (1 mm) pipe of the same diameter is not suitable for this condition, since the ratio is 0.05. If you use a manual hydraulic pipe bender, you will not be able to avoid fractures and jams in the walls of such a pipe product. You can avoid these troubles by filling it to the brim with dry and clean sand and sealing the pipe on both sides.

To prevent creases on a thin-walled pipe, it is filled with sand.

And one moment. Let’s say you don’t have a segment of the required size for the workpiece to be bent, but there are some for larger diameters. Installing an additional soft copper or aluminum insert between the segment and the pipe will help solve this problem. Its thickness is calculated using the following formula:

Svst = (Dpr.s. - Dt)/2,

where: Sst. – insert thickness; Dpr.s – diameter of the segment groove; Dt. - pipe diameter.

Consider the following example. There is a segment designed for pipes with a cross-section of 26 mm, and the workpiece installed in the manual pipe bending machine has a diameter of 18 mm. Substituting this data into the formula, we find that the thickness of the plate should be (26-18)/2 millimeters.

For manual hydraulic pipe benders, there are also restrictions on the minimum permissible bending radius - 4 pipe diameters. That is, a tubular product with a diameter of 20 millimeters can be bent to a minimum radius of 80 millimeters.

Hybrid.

Hybrid types of machines combine different types of drives. Typically electric and hydraulic are used. These machines have high processing speed of workpieces, as well as high bending force. They are usually quite massive, so you will need at least two people to carry even the smallest models. To operate such equipment, access to an electrical outlet is required, which distinguishes it from purely manual and hydraulic pipe benders.

Hybrid pipe bender

Making a pipe bender

It’s not difficult to create a simple pipe bending device with your own hands. The only thing you will need are plumbing skills and a certain tool:

- Bulgarian;

- welding machine;

- pencil and tape measure.

Assembling a primitive pipe bender is not difficult, the main thing is to buy or make templates of the required size

The materials you will need are several metal sheets with a thickness of 10 and 3 millimeters, and, in addition, a certain amount of steel rods.

Make a pipe bender in the following sequence:

- prepare the pulleys. To create a universal device, that is, suitable for working with pipes of different diameters, you should use 2 triple pulleys: a pair for three-quarter-inch pipes, a pair for half-inch pipes and a pair for inch pipes.

Advice! Order such pulleys from a workshop, since you will not find them on sale.

The wheel should have a recess on each side measuring half the diameter of the pipe. Since the bend is formed by a stationary roller, in order to minimize the radius of the arc, the diameter of this element should be as small as possible;

- Next, make a base, which is a plate, in the corners of which holes are drilled for fastening to the desktop. Use a metal sheet about 10 millimeters thick for this;

- then use welding to install a pin in the center of the plate. Its diameter should correspond to the internal cross-section of the small triple pulley;

- After manufacturing the frame, the rotating mechanism is performed. First of all, weld a U-shaped part from 2 metal plates. The height of its legs should correspond to the diameter of the large and small pulley. In this case, it is necessary to control the possibility of placing a large movable pulley and half of a stationary pulley at this distance ;

- weld a handle about 25 centimeters long to the top of the part. Subsequently, a pipe will be put on it, playing the role of a lever;

- Having done this, install a large pin on the edge of the part and secure it with cotter pins. The small pulley is mounted on the base pin simultaneously with the entire structure;

- do the emphasis. To do this, weld another pin, and then put a pulley on it.

You can also make a device for bending profile blanks with your own hands.

This completes the production of the tool. All that remains is to attach the manual pipe bender and start working on bending the pipes.

Electric profile benders

Manufacturers also equip equipment for bending corrugated pipes with an electric drive. This machine for a profile pipe is a professional device that allows you to bend the workpiece as accurately as possible in accordance with the given dimensions. Electric profile bending machines are used by specialized companies for the serial production of bent parts of metal structures. Its customizable rollers are designed for bending metal products, which can be made from various steel, copper, aluminum alloys and so on.

High-quality steel is used in the manufacture of electric pipe benders. Rolling rollers are made from it. They are highly wear resistant. Therefore, they do not have to be replaced frequently with new parts.

Electric pipe benders for corrugated pipes are not mobile devices. They are stationary equipment. For their operation, a constant connection to the electrical network is required. Such machines are installed in production shops and forging plants.

Features of bending with a homemade tool

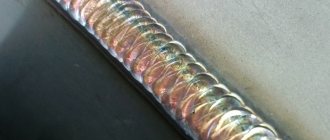

When bending pipes, you need to know the principles of the process and the diameter of the products. Then the correct deformation of the material without crumpling or tearing will be ensured. On machines that use hydraulics, bending with heating is possible. This allows you to bend pipes made of polymers, durable alloys, as well as products with a sufficiently large wall thickness. But in practice, at home, the “cold” method is more often used, aimed at working with pipe products made of plastic material - aluminum, copper, metal-plastic. However, it is possible to carry out bending from other metals with the exception of cast iron. In this case, in order to obtain a high-quality bend, before the deformation procedure, water (ice), oil, or salt or sand are poured into the pipe.

The minimum bending radii are indicated in the tables below: the first contains data for copper and brass pipes, and the second for steel.

Table 1

| Lmin | R | d | |

| 60 | 90 | 30 | |

| 55 | 72 | 24 | |

| 50 | 36 | 18 | |

| 45 | 30 | 15 | |

| 35 | 24 | 12 | |

| 30 | 20 | 10 | |

| 25 | 16 | 8 | |

| 18 | 12 | 6 | |

| 12 | 8 | 4 | |

| 10 | 6 | 3 | |

table 2

| D | R, if the wall thickness | |

| Exceeds 2 mm | Up to 2 mm | |

| 60-140 | 5d | — |

| 35-60 | 4d | — |

| 20-35 | 3d | 5d |

| 5-20 | 3d | 4d |

In the tables: L min - length (minimum) of the straight section; R – smallest bending radius; d is the diameter of the workpiece. The unit of measurement for all indicators is millimeters.

You can bend any pipes with a homemade pipe bender, but you need to take into account their diameter and the maximum possible bending radius

Where is metal-plastic used?

Due to the properties of its components, metal-plastic has become widespread:

- in the heating water supply system;

- for supplying drinking water;

- as a gas pipeline;

- for supplying substances used in agriculture;

- for compressed air supply;

- as a sheath for electrical cables.

But despite such a variety of areas of its use, metal-plastic also has limitations in use:

- cannot be used where there is a high fire hazard;

- cannot be used in systems with liquid pressure exceeding 10 atmospheres;

- Do not install near hot surfaces whose temperature exceeds 150 degrees.