When processing products from various materials, situations often arise when tools such as a large cutter, file or abrasive wheel are impossible or impractical to use. In such cases, a roller cutter is used, a tool also called a burr.

Sharpening a chisel with an abrasive burr

Installed in the chuck of a conventional electric drill or on a stationary machine, cutters effectively cope with such technological tasks as cleaning and grinding surfaces (including in hard-to-reach places), as well as crushing materials.

What is a cutter

A roller cutter for a metal drill (cone bit, burr) is a device that appeared quite a long time ago. It consists of two parts: a fixing tail and a working element. The cutter can rotate at speeds of up to 60,000 rpm during operation.

Manufacturers today offer devices made of different materials and with working elements of various shapes and dimensions. Such a wide selection makes it possible to select devices for many technological tasks. When choosing, as a rule, they are guided by the parameters of the material that was used to create the tool being processed, as well as geometric characteristics.

Burrs are used in many areas, which include construction, mining, mechanical engineering, jewelry, medicine, etc. Using this device, you can effectively and efficiently process products not only from metal alloys, but also from glass, stone, wood, etc. plastics.

Roller cutters are also used in the manufacture of PVC windows . At mining enterprises, devices for stone of increased diameter and a working element with teeth made of hard alloy are used. Jewelers use these products to produce decorative parts and apply patterns and inscriptions to products.

Dentistry is another area where cutters are often used. This device is the main component of the famous drill. At home, burrs are installed in ordinary electric drills. Using them, home craftsmen solve a large number of household problems.

Using burrs, you can make a neat and even hole in ceramics, glass, brick, stone and wood products, make a good cleanup of welding seams and process hard-to-reach areas.

Drill attachment design

For many years, craftsmen have been using such equipment when processing hard-to-reach places. This device consists of several parts:

- Shank.

- Working part.

Special attachments for metal drills are fixed in the chuck thanks to a long shank. Its working head does the main job - grinding the desired surface. During operation, the cutter rotates at a speed of 60,000 rpm.

Factories produce a special set of cutters for metal. It consists of a special tool, the working head of which is distinguished by its dimensions and varied shape. A large, varied range of cones helps you select the right equipment to perform a specific technological task. When choosing attachments for a metal engraver, take into account the characteristics of the material of the part, as well as its dimensions.

Roller cutters are often called burrs. The main part of such devices is the shank pin, which is attached to the drive of the electric machine. A metal burr for a drill operates at a very high speed - 50-60 thousand rpm. min.

The special head is made of a very hard alloy. Depending on the surface of the workpiece being processed, the shape of the burr head is selected. To make the work more efficient, we first study the capabilities of the part and its technological characteristics.

Quite often, metal cutters for drills are used for cleaning welding seams. The versatility of this tool has made it possible to use it in various industries:

- Jewelry making.

- Dentistry.

- Medicine.

For such work, special burs are used , belonging to the group of carbide parts. An important difference between a burr and other devices is the ability to process hard-to-reach places. The long shank of the cutter, fixed in the drill chuck, allows you to process the surface from any side, even the one that is very difficult to approach.

This feature makes it possible to perform the operation much faster, without much physical effort. Today, industry is engaged in the production of several types of cutters designed for processing metal surfaces. They differ only in the material of manufacture:

- Carbon steel.

- Diamond sputtering.

- Hard alloys.

This is interesting: Making pellets with your own hands at home - the production process and the necessary equipment

Types of burrs

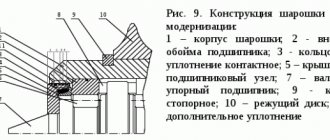

Burrs can have different designs and include various materials. The following structures of metal sharashkas are distinguished:

- single cone;

- double-cone;

- three-cone.

The shape of the working elements also differs. So, there are devices with an oval, spherical, cylindrical or conical head. The choice of a suitable cutter depends on the configuration of the workpiece and the tasks assigned to the tool.

Roller cutters also differ in the material used for their production. Here it is worth highlighting:

- carbon steel alloy fixtures;

- diamond-coated cutters;

- abrasive burrs;

- hard alloy cutters.

Carbon steel

The tool, made of carbon steel alloy, is used in combination with a screwdriver or electric drill. Its main advantage is its low cost.

Using this tool, you can create complex recesses, remove sharp edges from products, create neat and high-quality holes, and also expand the diameter of already created ones.

Diamond coated

These devices are professional. These cutters allow fine boring and grinding of drilled holes. This type of tool is effective when processing ceramics and glass , and when working with high-strength materials.

Engraving equipment is equipped with diamond-type cutters, which allows for the finest processing and application of inscriptions and patterns on various coatings.

Abrasive tool

Such devices are similar to diamond cutters. Due to the increased hardness of the working element, the abrasive burr is used for processing glass, ceramics, plastics, stone, metal, etc.

These cutters have an abrasive working element, which is made entirely of abrasive material or made by spraying. An abrasive roller bit is characterized by a low price, but is much less durable than a metal tool.

With carbide head

This tool is often used in production. Carbide-type cutters are used for processing high-hard materials such as cast iron, steel, titanium, etc.

This type of jig is also great for processing weld seams.

Material quality

According to their design, burrs are single-, double- and triple-cone. Metal cutters also differ in the type of material chosen for their production or further spraying.

Carbon steel tools are the most common. Most often they are equipped with a drill and are used for household needs:

- processing of sharp edges of parts;

- creating recesses on them;

- expanding the diameter or obtaining new holes.

These cutters can be used to work on wooden surfaces or metal. Their main advantage is their affordable cost.

The use of a burr depending on the type of cut

Diamond cutters can be equipped with both a hand drill and a machine. They are intended:

- for working with fragile materials – glass or ceramics;

- grinding products made of hard metals and alloys that are not amenable to metal burrs;

- for grinding and engraving decorative objects;

- boring small holes.

Diamond cutters provide jewelry precision and high quality.

Set of diamond cutters

Abrasive cones are made by spraying a high-strength powder, most often corundum, onto the head. Due to its high degree of hardness, corundum cutters are widely used in processing a variety of materials:

Corundum cutters

- metal and stone;

- ceramics and glass;

- concrete and brick walls.

Abrasive burrs are distinguished by low prices and fragility. Their service life is shorter than that of metal tools.

In industrial production conditions, when there is a need for stripping materials with high strength, cutters made of hard alloys are used.

They come in different configurations and are characterized by:

- resistance to heat;

- high level of durability;

- complete with high power tools.

Criterias of choice

In order to use cutters as effectively as possible, you need to consider several key points:

- the nature of the work to be done;

- properties of the material from which the workpiece is made;

- dimensions of the element to be processed.

It is also necessary to take into account the characteristics of the electric tool in which the burr will be placed. Here you should highlight power and speed.

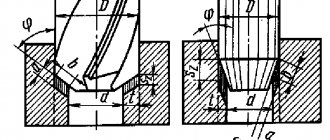

Another important parameter of a metal processing tool is the type of cutting and the configuration of the cutting teeth. Based on these characteristics, the following types of devices are distinguished:

- with the finest cuts;

- with universal cutting option;

- with ultra-thin cutting;

- for processing aluminum alloys.

The highest level of performance is demonstrated by a tool whose head is double sharpened. Experts advise immediately buying a set of metal cutters. Having such a set of devices at your disposal, you will cope with all the necessary tasks.

Design features

As mentioned above, almost every type of milling device has distinctive design features. This especially applies to end varieties. But at the same time, there are products with different tooth shapes.

An important element is the teeth.

the pointed teeth of the cutter have a serious drawback

The backed teeth behave completely differently. They are not afraid of frequent sharpening or intensive work with metal. Therefore, they are more reliable and durable. For drills, and for machines in general, this is an ideal option.

Is the milling cutter a single unit?

In addition to differences in shape, cutters are also divided into one-piece and prefabricated models. The first option is made from one piece. To avoid unnecessary waste of expensive material, many small cutters are made from one block. Therefore, this approach significantly reduces the cost of the product.

Prefabricated models are also available. As the name suggests, the cutter is manufactured individually and then all the components are connected to each other. Most often, the body is made of cheap types of steel, while the teeth are made of hard materials (most often alloys). Of course, the cost of the design increases, but thanks to this device, you can easily replace one component with another.

How to use it correctly?

Several decades ago, burrs were used to work in combination with hand-held tools. Subsequent technological development contributed to the fact that manufacturers of this type of product began to equip stationary equipment with cutters.

Despite the fact that work using burrs in hand-held electric tools is characterized by a high degree of efficiency, with such processing it is impossible to obtain perfectly smooth and high-quality surfaces. In addition, the use of such a chisel in conjunction with a hand tool has an adverse effect on the tool itself, whose cutting edges become dull.

Installing burrs on modern CNC machines allows you to increase the durability of the tool, the accuracy and quality of processing.

But, if you follow some rules for working with burrs in hand-held power tools, you can ensure that the tool will last a long time and effectively. So, you need to remember the following:

- The burr head must interact tightly with the plane being processed. You must also carefully ensure that the tail of the cutter does not touch the surface being processed, because this can deform the part.

- When working, you do not need to press hard on the device, otherwise it will negatively affect the quality of the processing or cause overheating of the tool.

- It is also important to choose the appropriate speed mode. This will give you the opportunity to save on electrical energy and extend the life of your drill.

- The head of the device is subject to intense abrasion and wear. There are several simple techniques that can reduce the level of wear on this part and increase the durability of the tool itself. For this purpose, you can use a special lubricant, which reduces the degree of load and allows the tool to slide better over the product.

- At the first signs of wear, it is advisable to change the tool immediately. Operating a significantly worn cutter can lead to tool failure.

Terms of use

Previously, attachments were used mainly for household needs in combination with a drill. However, when combined with hand tools, the cutters wear out faster and the quality of their cutting teeth deteriorates. With the development of technology, burrs began to be installed on numerically controlled machines, which makes it possible to clearly regulate the accuracy of the specified parameters during processing:

- chamfer height;

- nozzle inclination angle;

- depth of grooves on the metal;

- bore diameter.

Sharpening a chisel with an abrasive burr

Following a few simple rules will help increase the operating time of cutters when working with hand tools:

- the working head of the cutter must be in close contact with the surface of the part;

- the burr shank should not touch the product;

- strong pressure on the cutter during operation can cause it to overheat and break;

- correct calculation of processing speed will increase its efficiency;

- a special lubricant applied to the working head will reduce the degree of wear;

- Timely replacement of worn tools will protect the drill from damage.

Since the tool is not sharpened or refurbished, following proper use will extend its service life.

Video on the topic: Roller cutters, burrs for metal - review from a welder

Processing Tips

Using a burr on a screwdriver or electric drill, you can process a wide variety of materials. But here it is important to follow a number of rules.

When working with a tool on stone or porcelain stoneware, you need to constantly moisten the surface being processed with water. Liquid should not come into contact with the electric tool, otherwise it may break.

Using cutters you can process not only natural wood, but also MDF, plywood, chipboard and fiberboard. A characteristic feature of a wood burr is a fairly large notch on the working element. If during processing you begin to smell something burning, you should set the power tool to a lower speed.

When working with ceramic tiles or glass with a roller cutter, be extremely careful and attentive. When processing such workpieces, it is necessary to pre-draw the outline of the hole on their surface using a special cutter. Then the hole is punched with a burr with a spherical working element.

When using an electric tool with a cutter, you must not forget about precautions and safety measures. Protect your hands and eyes from particles by wearing gloves and goggles.

Areas of application

As a component for machine tools and hand-held power tools

A roller bit with a large diameter head is actively used when crushing stones with teeth made of hard alloy metal. A ball cutter for jewelry purposes is small in size and is used for processing small parts, applying inscriptions or patterns on jewelry, gift sets, and souvenirs.