Any repair, especially a major one, or construction work involves working with wood and processing it, which requires not only high-quality, but also correctly selected tools. One of the simplest processes in working with wood is drilling.

Wood drill bits

What to look for when choosing

Before purchasing a part, you need to familiarize yourself with its characteristics, make sure that there are no defects: chips, dents, nicks, scratches and others. Any of these shortcomings negatively affects the quality of work performed. A defective tool will not last long.

The assembly technology is determined by the color of the product:

- Black. The steam treatment method was used, it increases strength.

- Yellow-gold. The technology was aimed at relieving metallic stress.

- Bright gold. Titanium nitride is used to extend service life.

- Steel gray. Finishing was not carried out, the tool was not reinforced with additional spraying.

This is interesting: DIY inverter welding machine repair

Types of tools

Any modern electric drill includes a standard set of drills, which differ in size and length. But sometimes for some types of work this kit is not enough, so certain types of products have to be purchased additionally.

Screw products

diameter screw drills for wood are suitable for drilling holes of large diameter and depth This product is easy to use and is often used by workers who build log houses. The products are made in two types: with a conical tip and with a scoring tip. They are identical in performance. You can start working immediately after connecting the unit to the power tool. Screw models are produced in lengths of 220, 450 and 600 mm. Tool Features:

- The most common option is the 600 mm long model. It is suitable for drilling holes in thick products.

- The screw model is used if it is necessary to drill holes in log houses through 3 logs.

- The assembly in the drill chuck is securely secured using a hex shank.

- To get the job done more efficiently, you need to use a drill with a rotation speed of 800 rpm.

- The edges of the holes are smooth, and the inner walls are smooth.

Forstner drill

The Forstner drill has many positive advantages. That is why it is often used in furniture production. These are reliable massive units ranging from 10 to 60 mm. The drilling depth is about 10 cm. If you need to drill a deeper hole, you can purchase an additional 300 mm extension. Advantages of the tool:

- Unlike other models, this drill creates a perfectly even edge and a smooth inner surface of the hole made.

- Has a long service life.

- Suitable for creating blind recesses for locks and cup hinges.

- Thanks to the massive design, the tool does not overheat.

The centering spike of the drill protrudes a few centimeters, and this allows you to drill blind holes. Other tools do not have this function.

Feather models

Feather models are the most popular because they are simple and easy to use. Even a person without experience can master working with this tool. The drilling diameter ranges from 10 to 60 mm with a maximum drilling depth of about 150 mm. Advantages of the tool:

- You can purchase drills individually or as a set. The set includes products of 5-6 pieces, which are small in size. Large wood drill bits are sold individually.

- Due to the lack of chip removal, creating a deep hole becomes problematic. But you can avoid this by using an extension cord. An additional extension will help securely fix the drill and increase its length by 300 mm.

- There is now a new model of pen drills called the adjustable pen. The tool allows you to create holes with a diameter from 22 to 76 mm at low speeds. But at the same time, the power tool must have sufficient power.

The disadvantage of feather products is the holes are of poor quality. If you work fast enough, the result will not be perfect. Having a fragile structure, you cannot put strong pressure on the tool while drilling holes.

Ballerina on wood

The design of the device is similar to a compass. The drill is installed in the middle. And the cutting parts are attached on both sides, move along the crossbar and are fixed in different positions. Many people know this device under a different name. People call it a wood ballerina. Unlike other models, this device has the most diverse range of all kinds of hole drilling. The diameter can vary from 30 to 140 mm. You need to buy this model carefully, as there are many fakes on sale. Advantages of the tool:

- The ballerina perfectly processes wooden products with a thickness of no more than 20 mm, as well as sheet blanks.

- Copes well with a variety of materials: plywood, fiberboard and chipboard, etc.

- The kit includes a center punch, which is used to make marks on the surface of the product. The hex key helps set the cutting units in the desired position.

Cutting units are subject to heavy loads during operation. To prevent them from breaking, the drilling process should take place at low speeds.

Ring models

Ring models have many advantages , which is why they are very popular among craftsmen. This device is designed to create large diameter holes. Ring products received a second name - tree crowns. Outwardly, they look like a ring, the edges of which are equipped with sharp teeth.

- This tool allows you to drill a large hole quickly and easily. The drilling range varies from 19 to 127 mm.

- Drills are sold in sets of 6 to 12 pieces, so the cost of the set is quite high.

Cheap ring sets are disposable because they are of very low quality.

Milling cutter

If it is necessary to perform complex processing of elements made of wood or thin metal, milling models are used . With their help you can make grooves of various parameters. First, a round hole is drilled, and then it is bored to a certain shape. The tail part of the tool has a cylindrical shape, it can also be conical, triangular, tetrahedral and hexagonal:

Tapered shank is used in production equipment.- The triangular shank is installed only in a three-jaw chuck. Large loads will not be able to rotate it in the chuck, since it is very well secured.

- Square instruments are used in rare cases.

- The hex drill fits standard and three-jaw chucks. Under heavy loads it can turn in the chuck.

Flexible drill

There is no such tool as a flexible drill. This name is given to flexible shafts . They operate on a drive principle. One end of the flexible shaft is installed in the chuck of a power tool, and a milling cutter or drilling element is put on the other. Rotation is transmitted from the chuck to the drill. This tool is convenient because it can be used to reach hard-to-reach places. Large drills are not suitable for the tool; only small and medium diameters are suitable.

Long wood drills

The length of the drill depends on its diameter. A product that is too thin may break, so models that are too thin and long are not produced. A drill whose length is 45 cm has a diameter of 10 mm. And a product 60 cm long is 12 mm. If you do not drill a hole in thick beams, there is no point in buying such a product. When buying any drill, you should follow the proportions. For example, a simple household drill will not be able to turn a tool whose length is 45 cm and diameter is 52 mm.

Feather (feather) drill for wood: types and features of operation

To drill holes in products made of wood, you can use tools of various types, differing in design, material of manufacture and geometric parameters. One of these tools is a feather drill for wood, the design features and technical characteristics of which are worth dwelling on in more detail.

Feather drills differ in the shape of the cutting part and the sharpening of the blades

When do you need a special tool for drilling wood?

The question of how and what is the best way to drill a hole in a product made of chipboard, MDF, plywood or solid natural wood is relevant not only for carpentry specialists and those who professionally make furniture, but also for home craftsmen who prefer many jobs around the house do it yourself. The choice of drills for wood in such cases is made depending on what type of holes need to be drilled:

- blind, without an exit from the opposite side of the product (intended for mounting hinges on interior doors or on doors that are equipped with furniture structures);

- through (threaded connection elements (bolts and studs) are placed in them; without such holes it is impossible to install door handles and locks).

The main purpose of feather drills is to quickly make through holes of small depth. When drilling blind holes, be aware of the protruding tip of the drill bit.

For woodworking, you can purchase an expensive tool (such as a disk cutter). However, its use is not justified in all cases. For most situations where wood needs to be drilled, a tool that is easier to use and significantly less expensive will do the job. These are, for example, feather drills, which, despite their affordable cost, are highly efficient in use. A wood drill bit can be used in combination with either an electric drill or a regular screwdriver.

Main characteristics

When using pen drills for wood, it is advisable to know how they differ from other types of cutting tools and what advantages they have.

Comparison with other types of instruments

Like metal drills, tools designed for woodworking are available in various designs and, accordingly, differ from each other in characteristics and functionality. When choosing such tools, you should have an idea of the advantages and disadvantages they have.

Table 1. Comparison of different types of wood drills

Feather drills, as can be seen from the table presented, have a number of advantages when compared with other types of tools. Meanwhile, a pen-type tool is not recommended for making large-diameter holes (more than 60 mm), since their edges may turn out torn. For such purposes, it is better to use core drills, which are made in the shape of a metal cup with cutting teeth located on its end part.

A pen with a threaded tip is more suitable for working on a machine: it drills faster, but the hole may end up oval-shaped if the part is not secured with clamps

Due to the low cost of feather drills for wood, any home craftsman can purchase a set of them. Having such a set in your home workshop makes it easy and quick to select a tool for drilling holes of different diameters.

Design Features

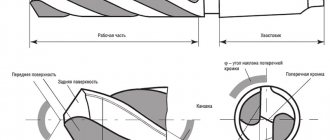

The tip drill has a very simple design, the elements of which are the working and tail parts.

Feather drill design

The working part is a flat blade, in the center of which there is a sharp protrusion used to center the hole being made. On the working part of the pen drills there are two cutting blades located on either side of the central protrusion. Each of these blades starts from the tip of the central protrusion and reaches one of the edges of the working part. The tilt of sharpening the blades of feather drills for wood, if you look at their working part in cross section, is done to the right. When making drills of this type, manufacturers adhere to certain ratios between the thickness and width of the cutting part.

Table 2. The ratio of the thickness and width of the cutting element of the drill

The tail part is made in the shape of a hexagon. This cross-sectional shape allows not only to securely fix the tool in the chucks of drills and screwdrivers, but also to use magnetic adapters and extensions for these purposes.

The simplicity of the design, which distinguishes drills related to pen drills, the absence of spiral grooves, ribbons and other complex elements, are not indicators of the low efficiency of this tool.

Twin-scoring point drills penetrate wood more smoothly and leave fewer burrs along the edges of the holes.

Recommendations for selection

When choosing a pen drill intended for woodworking, you should pay attention to several parameters:

- correctness of shape (wood drill feathers located on the right and left sides of the central protrusion must be symmetrical and identical in their linear dimensions);

- degree of sharpness of the cutting part (sharpening of new pen drills must be carried out in the factory and meet standard requirements);

- absence of visible defects (if the surface of a new drill contains visible defects of various types, this is a clear indicator of the low quality of such a product, most likely produced in artisanal conditions);

- color (by the color of the metal you can determine the types of additional processing to which the finished product has been subjected).

Table 3. Influence of manufacturing technology on the color of the drill bit

Operating rules

To increase the efficiency of using pen drills for wood and extend their service life, when performing processing, you must adhere to the following recommendations.

- Markings must be applied to those areas of the product where future holes will be located.

- For equipment that will be used in conjunction with a pen drill, it is better to choose a drill with a power regulator.

- Drilling wood using feather drills is performed at a low rotation speed (200–500 rpm). The specific value of the drill rotation speed depends on the diameter of the hole being made: the larger it is, the slower the tool should rotate.

- When the length of the pen drill is not enough to make a deep hole, special adapters are needed that are installed in the chuck of the equipment used. Otherwise, such an adapter is not required.

- Before starting drilling, the tool is brought to the surface to be processed strictly at an angle of 90°, while its sharp protrusion should be located exactly in the center of the future hole.

- Drilling should begin at low speeds, and as the drill deepens into the wood, the rotation speed can be increased.

- Chips that accumulate in the hole being created must be periodically removed from it. As soon as you notice that too many chips have accumulated, you need to stop drilling, remove the drill from the hole and remove the processing waste.

- As soon as the tool is immersed in the hole being created to the required depth, the drilling process can be stopped.

How to sharpen feather drills

Unlike other types of drilling tools, pen drills designed for woodworking are quite easy to sharpen. To perform this procedure, you can use a sharpening machine equipped with a diamond wheel. If such equipment is not at your disposal, a quality rule will do. The sharpening procedure itself is as follows.

- If the craftsman has a set of feather drills, a new, unused tool is taken from it, which will act as a sample.

- Focusing on the geometric parameters of the sample, sharpen the cutting part of the dull drill.

- When sharpening a pen drill for woodworking, you should be very careful not to accidentally damage its central protrusion.

It makes no sense to sharpen feather drills in cases where their cutting part is sharpened too much. Given their low cost, it is easier to replace heavily worn-out products with new ones than to try to return them to working condition.

As a conclusion

Despite the simplicity of their design, drills classified as feather drills allow you to create holes of various depths and diameters in wood. Spade drills are also successfully used for metal work. Naturally, to effectively process products made from different materials, it is necessary to select the right tool.

The advantages of using drills of this type also lie in the fact that even a person who is not highly qualified can sharpen and restore their cutting part efficiently, which cannot be said about drills of any other category.

If it is no longer possible to restore the functionality of the tool, it can be easily replaced with a new one. The low cost of feather-type wood drills allows you to always have a set of them on hand and easily select them to match the parameters of the hole you need to make.

met-all.org

Tips for choosing

An instrument of any form has its own criteria and must meet them. You can determine the quality of the instrument you are purchasing by its appearance, color, and also by the material from which it is made.

- Material . It is impossible to visually determine the quality of the material. Therefore, before purchasing, you need to make sure that the product has a quality certificate. Chinese counterfeits are often sold without documents.

- Appearance . A high-quality product has a flat, smooth surface. Various cracks, scratches and damage are defective. The cutting area must be carefully sharpened. Long drills must be straight. It is very easy to check their quality; just roll them on a flat surface. All irregularities will be immediately visible.

Color . To ensure that the tool has additional strength, it is manufactured using a special technology. You can find out which processing method was used by the color of the product. The steel color indicates that no additional processing was carried out. The yellow-gold spraying relieves metallic stress. A product treated with titanium nitride (a tool with a bright gold color) will have a long service life. The black drill has increased strength. Steam was used to process it.- Package . Products from well-known manufacturers have good, high-quality packaging. All fakes are poorly packaged, and the text is sometimes written with errors.

- Price . The higher the price, the better the quality of the product. All budget tools have a short service life.

Caring about their reputation, well-known stores will not sell counterfeits. And no matter what kind of tool you buy, in order for it to be of high quality and last a long time, you should contact reliable and trusted suppliers.

A set of wood drills – what should it contain?

Modern drills are often sold with a set of different drills, however, basically, they are always the same type of product, just of different lengths and diameters. So you have to independently select the types of wood drills that suit all your tasks. Of course, such a set should include a twist drill for wood; products are presented in a wide range - from 3 to 52 mm in diameter! A good tool of this kind should have an edge that will prevent it from slipping off the surface.

Products with a diameter of 10 mm or more must have a hexagonal shank so as not to rotate during operation. It is also important to know what number of revolutions during drilling should correspond to a particular tool diameter. For example, if you are dealing with small products up to 14 mm, you should set no more than 1700-1800 rpm for soft wood and half as much when drilling hard wood. When working with tools with a diameter of 16 to 25 mm, on hard rocks you should stick to 500 revolutions; the speed can be increased three times when drilling soft rocks.

The larger the diameter, the lower the speed - by observing this ratio, you will extend the service life of the product for a long time! When choosing tools, pay attention to the color of the metal - if it is a regular gray color, then such a product has not been subjected to any additional processing, and accordingly it will not last long . The black color indicates treatment with very hot steam, and the yellow color is inherent in products that are treated with titanium nitride, which increases the service life significantly.

How to choose?

Craftsmen who work with wood often wonder how to choose the best drill bits for drills and screwdrivers. When deciding on a nozzle for forming holes in plywood or chipboard, it is worth considering important points.

- Drill material The best parts are those made from a metal alloy. Such products are characterized by high levels of wear resistance and strength.

- Presence of marriage. The consumer must carefully inspect the drill for the presence of cracks and deformations. Defects on the nozzle can cause poor performance results.

- Color . Yellow drill models are considered the highest quality. Black tips have proven themselves to be quite good, while gray tips are considered the most short-lived.

- Package . A high-quality product intended for woodworking should be packaged in a durable box.

- Price . As practice has shown, the cost of a set of drills has a direct impact on the quality of the product. Budget-type models are characterized by a short period of use.

Nowadays on the market there are sets with drills for working with wood , which contain models with different lengths and diameters. In this case, the craftsman should ensure that each product has a well-pointed tip. A drill that has a diameter of more than 10 mm must have a 6-sided shank.

Tool structure

The feather drill has a simple design. The tool consists of two parts:

- Working. It is a flat blade equipped with a special rigid protrusion in the center. During the drilling process, it performs alignment. The working part is also equipped with two cutting blades, which are located on both sides of the protrusion. The sharpened cutting edge extends from the tip of the protrusion to the edge of the working part of the drill. The tool has a right- or left-hand sharpening inclination. These attachments perform drilling in one direction. For such a cutter, a sharpening angle of 75-90 degrees is provided. There are also double-sided nozzles, the cutting angle of which is 120-135 degrees.

- Tail. The cross section has a hexagonal shape, thanks to which the drill is securely fixed in the chucks of a drill and screwdriver. In addition, the attachment can be installed in magnetic adapters and extensions.

Getting a Big Hole

Home craftsmen are often interested in how to make a hole in a tree of large diameter. There are several ways you can do this:

- A circle of the required diameter is drawn. A small drill is used to drill inside the circle of holes. Then, using a chisel, the jumpers are cut out.

- Take a water pipe. One side is sharpened for teeth in the direction of the cut. In the second, a hole is made for the knob. The pipe is placed against the surface and slow rotation begins.

- At the first stage, a through hole of smaller diameter is drilled. At the second stage, a crown is taken and inserted to the maximum depth. At the final stage, the under-drilled wood is knocked out with a chisel. Chips will not occur because the crown has already set the direction.

Wood drills have a broad classification. This is an important item at home. However, each type of work requires the use of a specific tool. With the help of one, holes are made, the other - countersinks, the third - grooves. Knowing all these subtleties, it is necessary to have sets of such drills that will never lie around the household.

This is interesting: Homemade sandblasting gun: device, instructions, video

Acquaintance

A pin drill is a special cutting tool designed for drilling various holes in wood. They can work with both natural wood and chipboards and MDF products.

The master can also use such an expensive tool as a disk cutter. However, judging by consumer reviews, such use cannot be considered sufficiently justified. It is more advisable to purchase a feather drill for wood. Compared to a disk cutter, this tool is much cheaper, and moreover, it is no less effective. You can work with it using either an electric drill or a regular screwdriver.

Features and areas of use

A wood drill is easy to find in a specialty store or on the construction market. It is used to make holes in wood materials. Typically, the functionality of the drill is limited, so if it is overloaded, it may break. Experts recommend using it in accordance with the technical parameters and capabilities.

The set of drills contains various models that can work with wooden surfaces of different thicknesses and specific types of wood. For example, a 20 mm product can cope with oak, alder and cedar. Often the drill has a hexagonal base with a volume of 5 to 50 mm.

High-quality products are always well sharpened, so they are tightly fixed to the surface. A large base has a low drilling speed. Interaction is based on the frictional force between elements. A set of high quality fixtures is usually yellow in color , this shade indicates the presence of titanium dioxide in the alloy. Yellow drills have a long service life, unlike gray drills, which are disposable.

The strong and wear-resistant drill is black in color, as it is produced by hardening the metal. Since modern interiors contain a large number of wooden elements, in order to fix them, it is necessary to use special drills that accurately and correctly make the necessary holes.

A wood drill bit can be used to create two types of holes.

- Deaf . In this case, there is no exit from the reverse side of the material. Using these holes you can mount hinges for installing an interior door or furniture door.

- Through . This type of hole is necessary for installing a door handle or lock.

The advantages of attachments that are used for drilling wood are a wide range of models, the ability to extend and sharpen if necessary, as well as ease of operation.

Flaws:

- limited diameter;

- possibility of forming rough holes;

- tendency to periodic dulling.

Sharpening rules

Despite the fact that wood drills can be used for many years, in some cases the product needs to be sharpened. If the attachment begins to creak in the first minutes of operation, it means that it is time to sharpen it. The procedure can be carried out on a machine or using special devices. Craftsmen who are provided with special equipment will have no problems restoring the functionality of a metal product.

At home, a craftsman can use an electric machine with a sharpening stone. The type of sharpening is influenced by the shape of the product. Usually the procedure is carried out on the rear edges; in this case, the feathers should be processed evenly. To sharpen a drill, it is pressed against the end of a grinding stone and rocked by hand to create a conical surface.

During sharpening, the product must not be removed from the stone . The nature of the movements should be slow and smooth. For the procedure to be successful, the original shape of the product should be maintained as much as possible. In production, after the tool has been sharpened, it is recommended to fine-tune it. This procedure can smooth the surface and eliminate nicks.

After finishing work, the drills do not wear out so quickly. To carry out this procedure, use a round carbide grinding stone. If the cutting part of the drill is too sharp, then it is not worth sharpening it. Due to the fact that such a product is inexpensive, it would be advisable to replace it with a new one.

A drill for wood material is characterized by a simple design , but it is simply irreplaceable when it is necessary to create a hole in a soft or hard material. Usually, a high-quality drill has a high cost; if the product is cheap, then you should refuse to purchase it, since such a product will not last long. There is nothing complicated in using a drill, so even a novice master can drill through wood.

Experts advise adhering to basic safety rules when working with drills, as well as other cutting tools.

You can learn how to sharpen a metal drill into a wood drill from the video below.

Overview of species

Wood drills come in different sizes, diameters and purposes, but they look similar. On sale you can find many varieties of this device. To perform a specific task, a craftsman can purchase a large adjustable, beam, cup, circle, hand, slotting, extension, formwork, through, centering or sliding drill.

Screw

For spiral-type drills, the working part is presented in the form of a screw . Craftsmen use this attachment when preparing holes with small diameters. A feature of the screw design is that, in addition to its main purpose, it effectively removes chips. Thanks to the use of twist drills, drilling occurs accurately and accurately.

This category of devices includes an auger type of Lewis drill , which has an improved working part.

Such a tool is considered relevant for forming a deep hole, which also has a large diameter.

Feather

This type of drill for working with wood surfaces is used if you want to create a hole with a diameter of less than 25 mm . It is used when there are no strict requirements for compliance with parameters.

These metal products are characterized by low price and ease of maintenance.

Forstner

Unusual Forstner tips are used by craftsmen to create a blind hole rather than a through one. If this type of product is used in conjunction with additional accessories, it is even possible to make a square hole.

Circular

They are also called ballerinas . Thanks to them, craftsmen create large holes in plywood, chipboard, and wood.

This drill bit can also be used for drilling tiles.

Ring

Crowns are needed to produce large-diameter holes, namely from 1.9 to 12.7 cm in boards, plywood or lining. Using a ring drill, craftsmen produce round blanks and wide holes, which are later indispensable when installing spotlights.

Crowns can have different diameters and a removable base.

Milling cutters

The milling attachment not only drills wood, but also makes grooves in it with different configurations. The use of devices of this type is considered most relevant when complex processing of wooden surfaces is necessary.

The main difference between a cutter and another wood drill is the presence of a cutting edge along the entire device.

Flexible

Flexible drills are shafts with a drive mechanism that transmit torque from the chuck to the tool. This device must be used in conjunction with an electric drill, screwdriver or drill.

With the help of a flexible shaft, it became possible to make holes even in hard-to-reach places.

Long

The long nozzle for forming holes in a wood surface depends on the diameter . Consumers will not be able to find thin and long drills on sale; often the opposite is true: short products have the smallest thickness.

The use of long-length drills is especially important when it is necessary to drill through a thick wooden block.

Advantages of a feather drill

There are a very large number of different types of drilling machines and devices for processing various materials. But for wood, a feather drill is better suited than others. Experts say the most important advantage is the cost of the drill, since it is one of the cheapest types.

In terms of cost and efficiency, a feather drill for wood is compared with a device that bears the name of Fostner. Sometimes these two types are confused by calling one and the other cork. The latest drills have become widespread in the manufacture of furniture, since it is really better than other types for creating blind holes.

Fostner drill.

Because the former cannot be used in this capacity due to the tip. In addition, it is worth considering that the working diameter of the drill and other devices are different. There is an advantage on the side of the first unit, which has a wider range of working diameters.

It is important to remember that with the help of the first devices, mostly rough work is performed.

Since its accuracy suffers, which is undoubtedly the main drawback, a hole with a diameter of 40 and 60 millimeters after drilling sometimes has to be processed and additionally sanded, since the cutters passing through the walls of the hole leave fluffy wood residues on them. This affects the quality of the holes and their appearance, so when using a pen it is better to always have sandpaper on hand.

One important advantage is the ability to sharpen the nib yourself, although it is noteworthy that the point loses its sharpness too quickly. In addition, a quality woodworking pen can be used not only for drilling wood, but also for drilling thin sheets of metal. The maximum diameter is from 40 to 60 millimeters.

Classification by size

To choose the best drill and not overpay, it is enough to know what length sizes these products are usually divided into. If drilling metal does not require making deep holes, then purchasing models that are too long will lead to cost overruns.

It is customary to classify drills by length as follows:

- Short, 20-131 mm long. Tool diameters are in the range of 0.3-20 mm.

- Elongated, length is 19-205 mm, and diameter is 0.3-20 mm.

- Long series with a diameter of 1-20 mm and a length of 56-254 mm.

When performing drilling work of various depths, you should select the tool that is most suitable for the specific task.

Simplicity of the device and wide possibilities: ballerina on wood

If it is necessary to make a large-diameter hole in the material, a drill can be used, which in everyday life has received a very euphonious name - ballerina (due to the external similarity of the separated cutting elements of the device with the image of a dancer). Such a device consists of a centering drill and cutters, which move apart along the guide in different directions at the same distance, thereby outlining the dimensions of the diameter of the future hole. Most ballerinas have two incisors, but there are also models with three.

The operating principle of this type of drill bit:

- the central drill makes a hole in the material;

- the incisors mark a circle line, which determines the size of the future recess;

- The device is set in motion manually (using a rotary tool) or using a rotary power tool.

With a ballerina, you can make holes in wood, wood materials, drywall, ceramic tiles, and plastic. This attachment is inexpensive and quite suitable for non-professionals.

Helpful advice! When using a ballerina as an attachment for a manual mechanism, efforts should be made when carrying out the centering and first rotational movements of the incisors, outlining the contour of the future recess. Uncertain movements can cause chips on the top edge of the material.