Countersink

What is the difference between countersinking and countersinking? Although they sound similar, they are different operations. Each has its own purpose and a specific tool for execution.

What is countersinking? It involves cutting off a larger layer of material in order to create a conical or cylindrical recess in the upper part of the hole, intended for hidden installation of fasteners. Countersinking is also used to select chamfers. A special device for performing this operation is called a countersink. The following types are distinguished:

- cylindrical, used to make cylindrical recesses at the top of the hole to hide the heads of screws or nuts;

- conical, with their help they cut out a cone-shaped recess in the lower part of the hole, chamfer and form recesses for fasteners.

- end, also called counterbore, such a tool is needed for cleaning out recesses before installing fasteners.

Structurally, the countersink consists of two parts: the working head and the shank. A guide pin is provided on the shank, ensuring alignment of the selected recesses.

A drilling machine is usually used as equipment along with countersinks. Less commonly, they are clamped into the chuck of a multi-axis machining center or a simple lathe. Drills and other hand-held drilling tools are not recommended for use as they cannot provide proper alignment and accuracy.

Countersinking is the processing of the inner surface of a hole to improve its quality.

- accuracy;

- roughness;

- forms.

Countersinking is used to process holes made by drilling, stamping or casting. A countersink is used to perform the operation. It resembles a drill, but differs from it in the following ways:

- a large number of cutting edges;

- thickened bridge between edges;

- beveled corner.

These design features determine the stability of the position of the countersink relative to the hole and their coaxiality. The countersink does not deepen the hole, but only improves the smoothness and shape of the surface, removing a very thin layer of material.

Countersinks have from six to eight cutting edges; small diameter tools (up to 20 mm) are made in one piece, while larger ones have inserted blades.

Applications and types of countersinks

A countersink is a multi-bladed, multi-toothed cutting tool used for finishing pre-made round holes in parts and workpieces made of different materials (pictured). Processing by this method is used to increase the diameter and obtain a better surface of the hole by cutting.

This process is called countersinking. The cutting method is similar to the drilling procedure: the same rotation of the countersinking equipment around its axis and simultaneous translational movement of the tool along the axis are observed.

Countersink with carbide inserts

We developed a countersink for the metalworking industry to process drilled, slotted or stamped holes. A countersink for metal, the requirements for the characteristics of which are regulated by GOST 12489-71, is used when performing intermediate or final processing. In this regard, there are two types of tools:

- for subsequent deployment with allowance;

- to obtain a high-precision hole - with quality H11 (tolerance 4–5 accuracy classes).

You can familiarize yourself with the GOST requirements for countersinks by downloading the document in pdf format from the link below.

GOST 12489-71 Solid countersinks. Design and dimensions

When using a boring tool, the diameter increases, surface accuracy and hole cleanliness improve. Countersinking is intended mainly for:

- achieving a smoother, cleaner hole surface before reaming or tapping;

- calibrating the hole for a bolt, stud or any other fastener.

Countersinks are used, the requirements for which are determined by GOST 12489-71, also when processing end surfaces and when performing certain operations that give the hole the desired profile (for example, expanding the recess in the upper part of the hole intended for bolt heads).

Countersinks are divided into several types according to the method of their fastening into the machine:

- mounted;

- shank (with a metric taper or with a Morse taper - types of shank for mounting in a machine).

Diamond countersink

By design, countersinks are of the following types:

- prefabricated;

- solid;

- welded;

- with carbide plates.

A solid countersink is similar to a drill, so its second name is a countersink drill. It has more spiral flutes and cutting edges (3 to 6 teeth) than a simple drill. The cutting part of the tool, as stipulated by GOST 12489-71, is made of high-speed steel P18, P9 or made with carbide inserts (BK4, BK6, BK8 for processing cast iron, T15K6 for processing steel). Tools equipped with carbide inserts have greater productivity (higher cutting speed) than those made of high-speed steel.

There are also conical countersinks (for processing surfaces of a conical configuration) and the so-called reverse type of countersinks.

Spiral tail countersinks

Types and application of countersinks

Depending on the purpose, countersinks are divided into the following types:

- for making conical or cylindrical recesses inside holes;

- to create reference planes rippled with a hole;

- for chamfering;

- to prepare holes for installation of fasteners.

Based on the shape of the working surface there are:

- cylindrical;

- conical;

- end or straight.

Depending on the diameter, countersinks are divided into:

- regular (0.5 ÷ 1.5 mm);

- with limiter cone (0.5 ÷6 mm);

- with a cone-shaped shank (8÷12 mm).

For the reaming operation, a combined device is used, which includes a drill, a reamer, a countersink and a countersink. They are mounted on a common shank, and the working surfaces are spaced apart in height and come into contact with the metal in turn, as the tool is immersed in the material. The use of such a combined tool allows you to drill a hole, make chamfers, and improve the quality of the surface in one technological pass. This saves a lot of time on changing tools and ensures the accuracy of the dimensions of each structural element. Such a device is expensive and is assembled anew for each hole size, so its use is economically justified only for mass production or for a product with a large number of identical holes of a complex configuration.

countersinks

Countersinks (Fig. 3.34, a) are designed for processing holes in workpieces obtained by casting, stamping or pre-drilling.

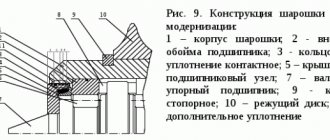

Unlike a drill, a countersink has a larger number of cutting edges (three or four), which ensures surfaces with higher accuracy and roughness. By design, countersinks are mounted and solid and can have a different direction of the spiral angle (right, left, straight). Countersinks are made of high-speed steel or equipped with plates made of hard alloy grades VK6, VK8, BKbM, VK8V, T5K10, T15K6. Carbide plates are fixed in the countersink using soldering or wedge fastening, which allows the countersink body to be reused. The working part of countersinks made of high-speed steel has a reverse taper (towards the shank) of the order of 0.05... 0.1 per 100 mm of the length of the working part and is connected to the shank in the same way as with drills, by a neck. Solid countersinks are fixed directly in the conical hole of the machine spindle, and attachment ones are installed on a special mandrel, which also has a conical shank for installation in the machine spindle.

Multifaceted carbide plates are used as the cutting part of mounted countersinks The fastening of such plates in the body of the mounted countersink is carried out mechanically (Fig. 3.35). The cutting plates 1 are fixed in the housing 2 using a rod 3, which makes it possible to replace the plates directly on the machine. To do this, it is enough to move the rod 3, rotate the plate with the next edge or replace it with a new one, fasten the rod again and continue working. The ability to equip such countersinks with plates made of various tool materials can significantly expand the technological capabilities and productivity during countersinking.

The geometric parameters of the cutting part of the countersinks (see Fig. 3.34, b) are selected depending on the processing conditions: leading angle f = 30... 60 rake angle y = 3... 30 ° for countersinks made of high-speed steel, for countersinks equipped with hard plates alloy, this angle ranges from 5 to -5°; clearance angle a on the main cutting edges is 8... 15 The choice of countersink design and material of the working part largely depends on the material being processed and the parameters of the hole being machined:

• countersinks made of high-speed steel, having three to four teeth and a diameter of 10 to 40 mm, are used for machining holes in workpieces made of structural steel;

• countersinks equipped with hard alloy plates, having three to four teeth and a nominal diameter of 14 to 50 mm, are used when machining holes in workpieces made of difficult-to-cut and hardened steels;

• countersinks with mounted heads made of high-speed steel with a nominal diameter from 32 to 80 mm are designed for processing holes in workpieces made of structural steel;

• countersinks are used for processing blind holes in workpieces made of cast iron and non-ferrous metals;

• for processing blind holes with a diameter of 15 to 25 mm, a special countersink is used, in which a special hole is made in the body for supplying coolant to the cutting zone (Fig. 3.36).

Wear of countersinks (Fig. 3.37) occurs along the rear surfaces, where areas with a rear angle equal to zero and width h3 are formed; along the front surfaces with the formation of a hole; along the ribbon with the formation of transverse grooves along the length Ll; along the corners to form conical or cylindrical sections hy. As a criterion for wear of countersinks when processing steel workpieces, the wear of the countersink at the corners is equal to 1.2 ... 1.5 mm, and when processing workpieces made of cast iron - 0.8 ... 1.5 mm. Sharpening and regrinding of worn-out countersinks is carried out, as a rule, on special equipment in sharpening shops.

Design

The conical countersink has two main structural parts:

- a shank designed for attaching a countersink to the chuck of a drilling or lathe;

- a working body for countersinking holes, consisting of 6 ÷ 12 cutting edges of increased thickness (compared to a drill.

The cone sweep angle is from 60 to 120°. The number of edges depends on the diameter of the tool; the larger it is, the more edges there are.

A cylindrical countersink is structurally similar to a drill, but has a larger number of cutting edges. Their length, unlike a drill, is limited by the diameter of the cylinder, since the countersink makes only small recesses in depth.

At the end there is a guide pin that ensures fastening in the chuck. A removable belt can be installed behind the ends of the cutting edges, limiting the depth of immersion into the workpiece. The limiter can be designed as a non-removable part of the countersink. If necessary, a cutting attachment is mounted on the countersink. When depicting a hole in a drawing, the type and size of the countersink is indicated next to it or in an explanatory note in the margin.

For the manufacture of countersinks, high-quality steels are used: tool, high-speed, carbon. The tool is subjected to multi-stage heat treatment, which improves its strength properties.

Countersinking and related operations

Countersinking is similar to the drilling operation: both processes are carried out with a finished hole. The difference is that the countersinking result is more accurate. During the operation, imperfections that arise after stamping, casting or drilling are eliminated. Indicators such as surface cleanliness and accuracy are improved, and a high degree of alignment is achieved.

Often, when forming holes with a drill (especially deep ones), there is a deviation from the center due to the low rigidity of the tool. A countersink differs from a drill in that it has higher rigidity due to the increased number of cutting teeth. It is important that this difference provides a more accurate direction of tool movement, and with a smaller cutting depth, high cleanliness is observed. When drilling holes, you can obtain grades of 11–12, the surface roughness of the hole is Rz 20 micrometers. During the countersinking operation we obtain grades 9–11, roughness 2.5 micrometers.

Morse taper reamers

An even more precise operation is the deployment process (6th–9th grades, Ra 1.25–0.25 micrometers). This is already finishing cutting. Countersinking holes is a semi-finishing operation. Countersinking and reaming of holes, if both of these operations are provided for by the technological process, are performed during one installation of the part on the machine.

Countersinking and countersinking of holes are often confused and another tool, a countersink, is incorrectly called a countersink (see photo below). Countersinks, unlike countersinks, have a different design and are used to solve other technological problems.

Conical countersinks

Countersinking is used in the process of chamfering the top of holes, as well as to produce conical-shaped recesses. There is also a cylindrical countersink, but it is more correct to call such a tool a counterbore. With the help of such a tool, recesses of the appropriate shape are obtained in the parts. To perform such a countersinking operation, a universal tool can also be used - a drill, specially combined with a countersink.

After watching this video, you can easily understand the principle of operation and purpose of a countersink, as well as its difference from a countersink and other related tools for making holes.

In order not to get confused in similar operations, it is enough to consider and remember this diagram, which clearly explains the design differences and the purpose of tools for processing holes

Features of countersinking holes

Countersinking holes is a high-precision operation that requires high-quality tools and proper drilling equipment. Countersinks must undergo periodic inspection to ensure compliance with the standard for diameter and taper angle. The test results are recorded in the instrumental section log.

Metalworking specialists have formulated the following recommendations for performing the operation:

- when working with hard steel or cast iron alloys, special emulsions, for example, coolant liquid, should be used to cool the material and tool;

- when selecting a tool, you need to take into account the material of the part, its strength and hardness;

- Before starting work, you should check the reliability and accuracy of fixation of the tool in the chuck and the absence of any special spindle runout;

- to countersink an internal chamfer, you should use a special mandrel that centers the tool;

The countersunk hole should be checked for compliance with the dimensions of the drawing only with a verified measuring tool.

Design features

If we look at the countersink, we can highlight some of its parts

- Cutting part. This is the main part that performs the countersinking process. Consists of several cutting edges located at an angle from the center to the sides.

- Shank. Using a shank, the countersink is secured in the tool or machine in which the work will be performed. The shank can be tapered or cylindrical.

- The part between the shank and the cutting part has a particularly thin shape in one place. This part acts as a fuse. If the countersink gets stuck, in order to avoid serious consequences, it is in this part of the countersink that it breaks.

The structure of a countersink

One of the varieties of a countersink has welded blades on the working part, which makes it possible to process hard metal alloys.

Rules for working with a countersink

When performing work on a lathe or drilling machine with a countersink, you need to remember and follow a number of simple rules. Before starting work, check the condition of the chuck on the machine. After all, if the cartridge is in a faulty condition, it will not be possible to secure the countersink well, and thus you will not be able to get a high-quality machined hole. Countersinking of holes is carried out in accordance with the following rules:

- To perform the work, the countersink must be strictly in the center of the hole being machined.

- When processing hard metals such as cast iron, you need to take breaks from work and use special solutions to remove heat. In everyday life, technical oil is used for such purposes.

- When operating, do not exceed the speed specified by the manufacturer. Failure to comply with this rule will result in rapid wear of the cutting edges due to heating.

- Select the correct countersink diameter for the hole being machined. If you choose the wrong size, the processing will not be of high quality, namely incorrect centering, uneven edges.

Current GOST

Currently, state standard 14953-80 continues to apply. It regulates the technical conditions for countersinking, standard dimensions of the tool, and the material for its manufacture. The standard also describes the operating modes of the equipment depending on the mechanical characteristics of the material being processed.

Download GOST 14953-80

Tables for selecting standard countersinks serve as an aid for designers and technologists in determining design parameters and developing technical processes.