Why use thread lockers?

Thread adhesive is able to complete polymerization when there is no access to air, resulting in an ideal connection of pipe parts, for example, in a water supply system. This avoids water leakage, gas escaping, etc. It also prevents parts from unscrewing under the influence of vibration and mechanical influences.

Using thread adhesive is simple, and there are different forms of similar compounds available. This allows every master to find a convenient option for his work.

Thread adhesive is able to complete polymerization when there is no access to air, resulting in an ideal connection of pipe parts, for example, in a water supply system.

Types of Durostone® fastening joints

EPR S5/EPR S7. Chemical and marine applications; Particularly resistant to aggressive environments - heat resistance up to 180 ° C.

EPR S6

Durostone® EPR S6 is a high-pressure epoxy laminate with superior properties designed specifically for threaded rod applications.

UPR S19

Durostone® UPR S19 is a Sheet-Moulding-Compound (SMC) threaded rod made from unsaturated polyester resin and fiberglass.

- A special type of polyester meets the highest dielectric constant requirements.

- At the same time, it does not produce an internal discharge even at high electric field strengths and is highly resistant to stray currents CTI 600.

VEG-Z/VEM

Used in chemical fields with low mechanical requirements.

EPR S1/EPM 203

Standard quality for use in electrical, marine and mechanical applications; heat resistance up to 180°C.

Basic properties:

- Electrical properties. All Durostone® fasteners are electrically insulating and anti-magnetic. In addition, some models are particularly resistant to parasitic currents and operate without internal discharge up to high electric field voltages. Thus, they are excellent for use in transformers, electrical machine manufacturing, high-frequency and switching devices, and electrostatic grinding devices.

- Chemical properties. Durostone® fasteners are particularly resistant to aggressive environmental conditions. Transformer, ultraviolet radiation and atmospheric influences will not be able to cause any significant harm to it. Applications include, for example, the production of chemical equipment, cable routes, flue gas desulphurization, seawater desalination, and wastewater treatment.

- Thermal properties. Compared to steel (15–58 W/mK), all Durostone® material types have a very low thermal conductivity of 0.3 W/mK and are thus on the level of mineral wool, which is used in construction as an insulating material. They are therefore excellent for use in refrigeration and air conditioning systems and in areas where thermal bridges must be avoided.

- Lightweight design. Durostone® fasteners have a density of 1.9 to 2 g/cm³, which is approximately the density of steel. It is very well suited for applications where weight reduction is an important factor, such as in the production of automobiles or gondola cars for wind turbines.

- High strength. Compared to threaded rods made from thermoplastics such as polyamide, Durostone® threaded rods have six times the tensile strength.

Advantages and disadvantages

Thread sealant for bolts stands out for its ease of use, which is why they are often chosen. The popularity of the products is also due to the positive properties described below:

- After applying the product and drying, they do not move or shrink;

- Additional protection of the metal from rusty formations is created;

- The presence of different types of compositions facilitates their use for parts of different sizes;

- Adhesives for bolted joints prevent loss of fixation force, withstand vibration loads, as well as impact;

- Their consistency allows the composition to penetrate into the smallest crevices, providing an airtight seal.

Stop thread sealant also has disadvantages:

- Reinforced types of means do not make it possible to easily unscrew the threaded rods if necessary, then they resort to high-temperature exposure or special tools;

- When choosing, take into account the specifics of the material so that the composition does not damage its integrity;

- Adhesives dry quickly, so it is necessary to accurately apply the layer; it will be impossible to change the position of the bolts, and it is impossible to return the composition to a liquid state;

- You should not use adhesives at low temperatures, this affects how long the layer will take to dry, the period will become longer.

Thread sealant for bolts stands out for its ease of use, which is why they are often chosen.

Who recorded who?

Well what can I say? The overall impression is quite pathetic. Of the twenty-one drugs tested, only six were able to withstand a modest initial torque of 5 Nm, and only two of the remaining ones advanced beyond 10 Nm.

However, the Teflon nut and lock washer also failed at the first stage. And nail polish turned out to be unsuitable for serious matters. The extra-grade glue left over from previous examinations lasted a little longer - it gave in under a load of 10 Nm. And the most curious thing is that at a torque of 30 Nm... the cotter pin was cut off! It would seem that the metal part would last longer, but it only repeated the results of the best drug we tested.

The winner was the American drug IMG MG‑414 High Strength

.

By the way, it is far from the most expensive. The second result is also from the “American” - this is Permatex 24026

. There is no point in awarding third place with such test results.

The results obtained relate to a specific sample of thread lockers and cannot serve as a characteristic of the company’s products as a whole.

And further. Remember: the larger the area of the treated surface, the stronger the clamp will “grab” into it.

But don’t be afraid to use clamps: our experiment showed that, if necessary, you are guaranteed to unscrew any connection processed by them in the car.

Grover.

This is a spring split washer used as a locking element. Grovers cannot be used on deformable materials such as aluminum and its alloys, as well as copper or bronze.

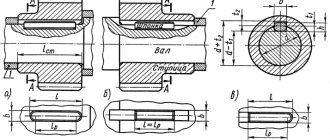

Polymer insert.

A bushing is inserted into a special groove, which is deformed when the nut is screwed onto the thread. Once tightened, the polymer insert increases friction, preventing the connection from loosening due to shaking. The disadvantage of such fasteners is the limited number of assembly/disassembly operations.

Fold washer.

Such washers are usually made of mild steel and equipped with claws. One of the legs is bent to the edge of the nut, which must be secured against unscrewing, and the other is fixed, if possible, on the part being tightened. It is clear that such parts are disposable.

Glue or cosmetic varnish.

Nail polish or glue are often used for locking threads. The main advantage of such techniques is simplicity and confidence that things won’t get worse. But these drugs do not work as intended, so you should not expect serious protection from them.

Cotter pin.

A metal rod is inserted into the through hole and its ends are bent. As long as the cotter pin is in place, the nut will not come off. It is clear that cotter pins can only be used with special nuts and bolts that have a hole. In addition, they will not help fix the bolt or stud in the body of the part.

Nut with safety collar.

Those who dealt with the front hubs of Zhiguli cars probably remember a large nut, the thin collar of which had to be bent into the grooves of the axle in two places. The disadvantage of this solution is the need for a special part such as a bolt and a rather rare nut.

Lock-nut.

The most primitive solution in the fight against self-loosening is locknuts. The additional nut is pressed against the main one and locks it. This solution cannot be used everywhere - sufficient space is required on the threaded part of the stud or bolt.

Composition of thread locker

The instructions for each product specify the components used in production. Each type will include different components, so you should carefully study the composition before purchasing. The level of connection depends on the composition, and determines the resulting properties.

The level of connection depends on the composition, and determines the resulting properties.

How to Choose the Best Thread Locker

To get a high-quality result, you need to choose the right composition for the task. In this case, the criteria that influence the result are determined. Experts advise paying attention to: fixed moment of resistance, state of aggregation, resistance to process fluids, polymerization time.

To get a high-quality result, you need to choose the right composition for the task.

Fixed moment of resistance

This parameter helps you understand what size bolt the product will be suitable for. If the composition is intended for small bolts, then it will not be possible to obtain reliable fixation of large ones. Conversely, when small bolts are attached to reinforced clamps, then unscrewing them may become impossible. But manufacturers do not always specify this parameter.

This parameter helps you understand what size bolt the product will be suitable for.

State of aggregation

There are paste and liquid thread lockers. The first option is not so convenient to use, but they will not spread to unnecessary areas. Liquid types are standard for hard-to-reach bolts, but may bleed.

When choosing, take into account the size of the thread; the larger it is, the harder the option should be chosen for gluing.

When choosing, take into account the size of the thread; the larger it is, the harder the option should be chosen for gluing.

Resistant to process fluids

When operation involves exposure to different liquids, then when choosing a composition, you need to pay attention to indicating whether the layer can withstand this influence. If there are no such requirements, then you can choose any composition.

When operation involves exposure to different liquids, then when choosing a composition, you need to pay attention to indicating whether the layer can withstand this influence.

Polymerization time

The drying time for adhesives varies; they begin to perform their function only after the drying stage is completed. Manufacturers write how long it takes for complete polymerization. For urgent repairs, this parameter will be important.

The drying time for adhesives varies; they begin to perform their function only after the drying stage is completed.

Value for money

One of the most important parameters is obtaining good quality at an affordable price. Here it is better to focus on popular brands that have proven themselves as high-quality adhesives. They will be discussed in detail below.

One of the most important parameters is obtaining good quality at an affordable price.

Areas of application

Anaerobic sealant is used in metal gaps when installing fittings or when gluing flat parts for the purpose of:

- preventing spontaneous loosening of threaded connections - increases resistance to vibration and shock loads;

- sealing defects in welding seams or castings, as it completely fills the space;

- sealing and fixing flange and cylindrical connections - increases the shear and deformation strength of products without creating metal stress.

To seal plastic joints, a type of anaerobic substance with a high concentration of special activators is used - isopropyl alcohol, copper salts or fluoroplastic.

How to work with thread glue

When using a retainer, it is distributed over the area where the nut should be, a thin layer is made, optimally up to 5 millimeters thick. When the parts begin to tighten, the glue will spread over the entire surface, ensuring reliable fixation.

When working with blind cracks, the product is applied to the bottom and not to the threaded area. It is recommended to clean and dry the part in advance. Also, better adhesion is achieved by treating the metal surface with a special brush.

When using a retainer, it is distributed over the area where the nut should be, a thin layer is made, optimally up to 5 millimeters thick.

ANTIBACTERIAL TREATMENT OF AIR CONDITIONERS

Every year, people have a greater impact on the environment, and nature takes revenge for this. Recently, people were faced with a new pulmonary disease, and this led to another review of safety measures, including in transport. The ubiquity of air conditioning has increased comfort, but has led to the emergence of new additional risks, namely the risk of lung infections. The evaporator of an air conditioner, whether it is a home split system, a central air conditioning system or a simple car air conditioner, has a constant temperature and high humidity. Any doctor will confirm that this is a favorite breeding ground for a variety of bacteria. For the first time, humanity encountered pulmonary infections caused by bacteria from air conditioning systems in the 60s of the last century. Several dozen people became victims, and there were even deaths. The pathogen was found and named Legionella. Central air conditioning systems have begun to be disinfected, but isolated cases of the disease still occur.

What should the owner of a modern car with air conditioning do? What if the air conditioner is in an apartment or country house? Is it really possible to run to the sanitary and epidemiological station and pester the doctors with requests that are unclear to them? A solution to this issue has been found.

Liqui Moly presents a range of products for antibacterial cleaning and disinfection of automobile air conditioners: both for individual use and for service operations.

How to Unscrew a Thread Locker

An option for unscrewing bolts that were locked using clamps is temperature exposure. For different fixation levels you will need different temperatures: for red – 200-250 degrees; for blue – 100 degrees; the green type can unscrew at lower temperatures. The heating tool is a soldering iron or a hair dryer.

An option for unscrewing bolts that were locked using clamps is temperature exposure.

Thread adhesives provide a high level of thread bonding and can withstand varying degrees of stress. When choosing, take into account the operating conditions in order to use a type of product that is sufficient in terms of adhesion force.

What is it for?

Such thread lockers are essentially one-component sealants of various chemical compositions. What unites them is their operating principle. Under the influence of oxygen, a reaction starts in them, this oxygen is displaced, and then the reaction continues in its absence. This principle is borrowed from anaerobic microbes and is important so that polymerization can occur in spaces where oxygen access is limited - for example, in the gaps of threaded connections. Such compositions should not be used as conventional sealant or glue. With open access to oxygen, their polymerization may be incomplete.