To grill delicious shish kebab, you need a good grill

If the weather permits, we love to barbecue outdoors with friends. However, if the weather doesn’t allow it, we also… fry it. But in any weather, barbecue without a grill is not a serious matter. If you have a private house or cottage, you can make a permanent, solid installation that combines a barbecue grill and a barbecue grill. They are usually made partly from brick or natural stone, partly from metal. If you don’t want to build something serious, you can weld a metal brazier and place it nearby - in the backyard under a canopy, in the garage, in a storage room, etc. If you are a lover of outdoor recreation in any form, you cannot do without a portable barbecue. And one that will be convenient to carry/transport. This is how to make a barbecue out of metal with your own hands and will be discussed further.

We grill kebabs both when the weather permits and when it doesn’t... that’s why we need a grill at any time of the year

Yandex.RTB RA-1479455-2

What tools and materials will be needed

To make a collapsible grill yourself, you will need skills in working with metal.

Most often, stainless steel is used in the manufacture of transformers. The material is resistant to weathering and corrosion. Braziers are made of metal with a thickness of up to 3 mm and more than 3 mm. Thin-walled models are made to lighten the weight of the structure. The most common choices are stainless steel or aluminum. Such structures cannot withstand high temperatures, so coals are placed in them to fry meat. The service life of such products is up to three years.

Thick-walled barbecues withstand weathering, heat and corrosion. Made from metal 4-6 mm thick. Their main use is in the countryside. In winter, the grill is folded up and moved to the utility room for storage. Such products can be additionally equipped with:

- underframe;

- work surface;

- grate;

- adjustable blower;

- lid.

Having chosen the metal for the barbecue, prepare a set of tools and materials. To work you will need:

- welding machine;

- electrodes;

- Bulgarian;

- drill and metal drills;

- level;

- pencil;

- roulette;

- metal scissors;

- Metal sheet;

- metal profile 2*3 cm, corner or rod with a cross section of 1.2 cm for the legs.

Masonry mortar

Since bricks have different properties and are used for laying in certain parts of the barbecue, the solution for fastening them will also be different. This is due to its characteristics and ability to withstand a certain temperature.

Fireclay mortar

This mixture is one of the most convenient ways to hold bricks together. Fireclay mortar simplifies the work, since it only needs to be diluted with water in the required amount. It is necessary to read the instructions on the packaging to ensure correct proportions.

This type of mixture can withstand temperatures up to 1700°C, does not crack, and has high viscosity, so use will be as comfortable as possible.

Clay-sand mortar

For the firebox, smoke collector and barbecue, it is necessary to use a mixture that will retain its properties even at high temperatures. To create it, red clay and sifted sand are used (proportion 1:2).

Important: the clay must be pre-soaked for at least 3 days.

Cement mortar

The outer frame of the walls, part of the pipe and other parts of the barbecue, which are erected first, are held together with ordinary cement mortar. To do this, mix sand and cement in a ratio of 3:1.

Classification of barbecues with drawings and photos

Of all the parameters of metal braziers, only the height of the walls (side) remains more or less constant: it is usually in the range of 13-15 cm. If you make it smaller, closely spaced coals will burn the meat; if you raise it higher, you will need a lot of coals for normal roasting. And we don’t always have the opportunity or desire to wait until a sufficiently large number of them are prepared. So 13-15 cm is the most reasonable choice.

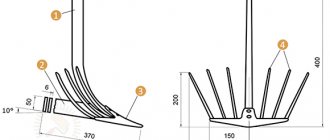

You choose all other sizes of metal barbecues based on your personal preferences or circumstances:

- The width depends on the size of the skewers used. It should be 8-10 cm smaller. If your skewers are 50 cm (excluding handles), then the width of the grill is 40-42 cm.

- The length of the grill depends on how many kebabs you plan to grill at the same time. The distance between them is about 8-10 cm. So do the math. If you need to lay 8 skewers at the same time, then you need 72-90 cm in length - depending on whether you will place them after 8 or 10 cm. In homemade barbecues, recesses are often made in the long walls for skewer. The notch can be triangular or rounded - depending on how you adapt. Everyone has their own ideas about which grill is the best, but there are certainly beautiful options

- The height of the legs is a purely individual matter. Some people don’t like to bend over and need a height of about 70-80 cm, while others can fry while squatting. High legs are often made for welded barbecues that stand near the house or in the country. For portable models, in order to save money, they are often small - about 20-30 cm.

- Metal thickness. And again, two approaches. If you are going to weld a grill and set it up, you can use thicker metal - 3 mm or more. If this is a prefabricated modification that is transported in the trunk or even carried in the hands, then it is better to use no more than 2 mm. If you think that this is too small, you can make the bottom from 3-piece, and the remaining walls from thinner metal.

Sometimes they also make a second plate at the bottom with longitudinal holes like grate bars. This is probably necessary so that the metal on the bottom does not burn out, but it is quite possible to do without this detail.

The designs of metal barbecues are not particularly diverse. This is a roasting pan with legs. The dimensions of the roasting pan and the height of the legs are all changes. There are, of course, real works of art, but there are simpler options for going out into nature.

Features of various configurations

Barbecue is a ritual. If it is not followed, it turns into ordinary fried meat.

The same is said about the right grill. Each housewife has her own pancake frying pan, and the owner has her own frying pan. It’s good that there are few types of it, unlike marinade. The following classification will help you determine your preference.

Firebox material

Before choosing a barbecue, you need to select the available blanks. They can be used as purchased sheet steel, as well as an old barrel or cylinder, or scrap metal in the backyard, which reduces costs to a minimum. The main thing is that it must be resistant to high temperatures. Depending on this, braziers are divided into the following :

- Cast iron - due to the complexity of processing, they are most often purchased in stores. They are the heaviest, but durable and do not require maintenance. In addition, they hold heat well. Due to their high cost, they are only partially used in the finished structure as grates and doors.

- Steel is the most popular option. Over the years, such material can completely burn out, rust, is difficult to clean and deforms when heated. However, if certain recommendations are followed, it will last at least 8 years without loss of functionality. The positive aspects are ease of accessibility, ease of processing and selection of thickness.

- Products made from thin-sheet rolled steel are an inexpensive traveling solution, the only but significant advantage of which is their weight and compactness, otherwise there is no point in using thin metal. Stainless steel fireboxes with a thickness of 1.5 mm will last longer.

Classification by weight

A sunny day or bad weather, a wind rose or a hike predetermine the future functionality of the firebox.

Based on their dimensions, there are three models: mobile, portable and stationary. The first ones are sold in the form of a designer set and weigh up to 6 kilograms together with skewers. Having a pattern, its folding parts can be easily cut out yourself. Their assembly is provided using bolted fasteners, using hinges or grooves. The fewer connections there are, the more durable it is. It is not recommended to light a fire inside such a box; using ready-made charcoal will extend the service life several times.

Well, what would a dacha be without a standard “aquarium on legs”? Portable braziers, consisting of four walls and a bottom, are its integral attribute. Conditional mobility is characterized by the presence of two porters or wheels. Their production without a welding machine and taking into account the fundamental subtleties is not crowned with success.

Stationary structures are already replacing a field kitchen with a home kitchen. Returning to the roots, people are increasingly giving preference to cooking with wood, from pizza to pilaf. Complex forged gazebos with a built-in barbecue, grill, stove and even a sink will decorate the most sophisticated landscape. The original will be a unit in the form of a whole locomotive or from the hood of a vintage car.

Authenticity or fashion - the choice is up to the owner

The choice of the design of the brazier based on functionality will also be important: barbecue or grill.

From a linguistic point of view, kebab is considered to come from Caucasian cuisine, and the derivative word from the Turkic “shish” is skewer. Thus, in the literal sense, it is a dish roasted on a spit. Among the largest native speakers (Azerbaijani people) kebab is called “kebab”, and in Turkey – “shish-kebab”.

Factors affecting the dimensions of the fryer

Since barbecue or any other food is prepared using specific technologies, the following factors are taken into account when calculating the optimal size of the barbecue:

- temperature regime - the number of coals, the distance from them to the meat;

- equipment for cooking - skewers or barbecue grill.

There are barbecue options with additional functions. For example, a brazier is equipped with a side compartment for unburnt coals with its own chimney. Or part of it is covered with a hob to simultaneously prepare a side dish and heat the kettle.

In this case, the main part of the grill should have the dimensions recommended in this manual. The remaining elements are attached in such a way that the process of preparing barbecue occurs without any interference.

Skewer design

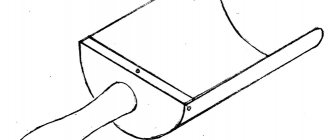

The only way to calculate the correct size of a roasting pan is to use skewers, a barbecue grill, or both of these tools of the same length. The standard skewer design is:

- length – total 45 – 50 cm, working 30 – 35 cm;

- curl - spiral, located near the handle, length 4 - 6 cm.

You can enlarge the drawing by clicking.

In camping (collapsible, folding) versions of the brazier, the size of the sword/skewer may be reduced.

If you lose/replace a working tool, adjust the length of the skewer in accordance with the fryer for which it is intended.

Similar requirements apply to barbecue ovens. The grate should be placed evenly above the coals at a height of 5–8 cm, since the meat is usually pressed by the grids on both sides and cooks faster. The industry most often produces mesh structures with dimensions of 18 x 28 cm, and a brick or steel box is adjusted to fit them into which the coals will be poured.

Temperature

Experts recommend frying meat on coals with your own hands, subject to the following conditions:

- coals - ready-made from a factory-packed bag or pre-burnt on a fire, and not inside a barbecue;

- filling the hearth with coals - a layer of 5 - 10 cm;

- the distance from the coals to the skewers is 5–10 cm, depending on the wood, the size of the firebrands and the shish kebab pieces.

Attention: There is still no consensus among experts on the issue of the need for holes in the side walls of the fryer. Some believe that they interfere with temperature control, and air should be supplied inside with a special fan. Others believe that fanning increases the likelihood of smoldering firebrands catching fire and prefer not to use a fan.

The main stages of making any barbecue and expert advice

We will need a tool:

- Welding machine;

- Bulgarian;

- Scriber;

- Wire bristle brush;

- Drill with drills ø 3-4 mm, and 12-15 mm;

- Metal ruler and square;

- Hammer.

The sequence is as follows:

- We weld the side walls. First, we grab at several points, aligning the corners with a square and a plane;

- We grab the bottom to the walls. Each wall at several points;

- We completely weld all seams;

- We weld the rectangular blanks to the ends of the corners - the future legs;

- We grab the corners of the legs to the body of the fryer. We make sure that the distance from the bottom of the roasting pan to the floor is the same;

- We weld the seams on the edges of the corners on both sides;

- We clean the seams from scale.

This completes the welding work.

Let's move on to metalwork:

- We mark the places for drilling holes on the walls of the fryer using a metal ruler, a square and a scriber;

- We drill holes. First, a thin hole – ø 3-4 mm. Next, drill out with a thick drill ø 12-15 mm.

- Knowing how to make slits on the grill for skewers, we apply markings on the edges of the side walls;

- We make cuts using a grinder according to the markings.

- Clean the holes and edges of the sidewalls from burrs.

At this point you can consider the work done. You can paint the outside of the grill with special heat-resistant paint. All work, including procurement, is completed in a few hours.

What do the barbecue parameters depend on?

The parameters of a barbecue can be considered its length, width, depth and height. These values depend on several factors.

- When choosing a barbecue, you must first decide how the meat will be fried on it: on skewers or on a barbecue grill. Skewers are mostly standard sizes, so the width of the frying pan must match them. You can choose any length. With barbecue grills everything is simpler. They often have different sizes, so it will be easier to choose a grate according to the size of the grill. Although a lattice with dimensions of 18x28 cm is considered standard.

- The second important criterion is the choice of the place where the meat will be most often cooked. If this is a private house or cottage, then a stationary barbecue is best suited here, which will have a permanent location and be cleaned only for the winter. It is better to make it from thick metal or cast iron for many years of use. If it is assumed that the hearth will need to be transported frequently, then it is better to make it light, foldable and compact.

- The depth of the grill directly depends on the material on which the meat will be cooked. When it comes to coals, a shallow one is ideal. If firewood is used for cooking, then it is better to choose a deep grill, since you will have to lay a large amount of wood to obtain the required volume of coals for frying.

How many people - so many opinions, desires and needs. Therefore, there are two main types of devices for frying meat - mobile and stationary.

Many of those who do not live in the private sector and do not have a suburban area prefer to go out for barbecues in nature. They do not need a massive grill, which includes additional elements. Compact structures made of thin material are ideal for them. They are lighter, have thin walls, low folding legs and a minimum of decorative elements. They can easily fit into any car and will not take up much space when stored in an apartment.

For those who want to set up a real barbecue corner on their site, large stationary metal barbecues or even stone hearths are suitable.

They are large in size, made of thick metal, and are often equipped with additional surfaces and places to store accessories. Therefore, cooking meat becomes not only enjoyable, but also a very comfortable experience.

Standard sizes of barbecue grill

Depending on the manufacturer, the dimensions of the barbecue grill can vary widely. However, most often their width is 0.3–0.4 m if you plan to use skewers for 8–9 pieces of meat. The depth can vary from 15 to 18 cm with a wall thickness of 4–8 mm.

Standard products are usually rectangular in shape

When working on the drawings of standard barbecues, manufacturers strive to choose sizes that will ensure good roasting of meat and prevent it from burning. Operating conditions are also taken into account. The length of stationary models can reach 1 m, and for portable products the correct dimensions are 0.6–0.7 m.

Portable models are made small for easy transportation

What should be the height and length of the barbecue: recommended values

It’s worth thinking about what the height of the barbecue should be in advance. This parameter is selected individually. It should not be low or high, so as not to experience discomfort during the process of preparing kebabs. That is why this parameter is selected taking into account the height of the person who will use it most often. On average, the height of a barbecue grill should be 75–125 cm.

Height depends on a number of parameters

The length is chosen taking into account the number of kebabs being prepared simultaneously. If 6 skewers are used at the same time, 60 cm is enough. If 10 kebabs are cooked at the same time, then the length is increased to 1 m.

The length is chosen taking into account the number of kebabs being prepared

Width and depth

The width is chosen taking into account the length of the skewers that they plan to use. Typically, their length is 45–50 cm with a working length of 30–35 cm. Taking this into account, the depth of the barbecue grill should be a maximum of 40 cm. An increase in the transverse dimensions will lead to incorrect consumption of the generated heat.

The depth is usually about 15–20 cm. When designing a barbecue grill for iron shish kebab, the dimensions are chosen taking into account that it is possible to form a layer of coals 5–10 cm thick. At the same time, there should be about 8 cm between the meat and the layer of coal.

If you plan to use firewood, the depth is made a little larger. In this case, to ensure optimal thermal impact, the thickness of the formed coal layer must be much greater.

Depth no more than 20 cm

Wall thickness

This is a fairly important parameter that affects the durability of the manufactured structure. It is worth considering the mobility of the frying device. For a stationary model, you should choose sheets up to 8 mm thick.

If the structure is planned to be periodically moved from one place to another, the correct size of the barbecue will be a thickness of up to 4 mm, since such a product will weigh much less.

Attention! The thicker the sheet steel, the longer the structure will last.

The thicker the metal, the better

How to make legs for a barbecue

The first step is to select dimensions, standard drawings and diagrams for the grill. The easiest way to make legs with your own hands: take the bent corners of metal and cut them, measuring 1 meter for each individual element. It is recommended to choose the metal carefully; it must be durable.

To make the stand stable, you need to weld even metal plates to the base

The optimal dimensions of a metal barbecue grill should be determined taking into account the length of the legs. If you choose a length greater than 1 meter, it will be inconvenient to cook, so the best dimensions of an iron barbecue grill are 60 cm long, 30 cm wide.

Stages of work when creating a forged barbecue

When you have decided which grill to make, you can start practicing. If you are a beginner, choose simple configurations.

1) Find a diagram or sketch on the Internet , in other open sources, or think about it yourself. All actions always begin with an image of the future product, the design and dimensions of which are indicated in the drawing.

2) Buy material, better with a reserve . To understand how many meters will be needed for forged elements, draw them with chalk on the working surface, according to the patterns in the sketch, in full size. According to the picture, measure the length with a regular rope.

3) Prepare tools . A sample list is:

- Bulgarian;

- Jigsaw;

- Welding machine;

- Profile bender;

- Cold forging machines;

- Drill;

- Roulette;

- Level;

- Metal brush.

Other consumables:

- Degreaser;

- Paint in a can, with fire-resistant, anti-corrosion properties;

- Or aerosol paint;

- Brush or roller for applying paintwork.

4) Be patient and use a bunch of swear words. No matter how paradoxical it may sound, in order to create beauty, sometimes you cannot do without them.

The best distance between skewers on the grill for preparing delicious dishes

Meat is cooked well only if the structure is assembled correctly. To find out how to properly weld a grill, dimensions and drawings, you need to go through all the stages of self-production:

- a sketch is drawn on paper. The parts are cut out and used as a layout;

- Dot markings are applied to the steel sheets according to the layouts. First you need to cut out the bottom and sides - two square, two rectangular;

- all parts are fastened using welding equipment;

- Legs of the same size are cut out of bent metal and welded to the main workpiece;

- the structure is assembled and tested for strength.

You should print the layouts in full size - this will prevent mistakes when cutting out metal

After assembling the structure, corners for laying skewers are cut out

To make it convenient to use the grill, it should be placed on a board or other flat surface.

Brick selection

To lay the barbecue you will have to use several different types of bricks. The fact is that each type of this building material has different characteristics. For this reason, different types of bricks will be used for different parts of the structure.

It is recommended to use the following types of bricks for the construction of a barbecue: fireclay fireproof, solid ordinary, red stove.

The table shows the scope and properties of each type:

| Brick type | Application | Properties |

| Chamotte | The lower part of the chimney, firebox. | The most durable brick, resistant to temperatures up to +1800°C. It has a low ability to conduct heat, so it does not heat up. |

| Stove red | Lower levels of the structure, chimney, walls. | Withstands temperatures up to +1200°C. |

| Red private full-bodied | Chimney pipe, overlap between the firebox and the place for igniting wood. | It has a long service life and can withstand temperatures up to +1200°C. |

| Facing | External masonry. | Ordinary brick. The advantage is the variety of shapes, sizes and colors of this type of building material. |

Important: the use of silicate, hollow and quartz bricks for the construction of a barbecue is not allowed. Under the influence of high temperature they will collapse very quickly.

Adviсe

In addition to the usual calculations for making a barbecue, you can use the additional tips given below to design a real recreation area in your country house or home area.

- If the length of the barbecue is planned to be more than 100 cm, then in this case it is recommended to equip the structure with additional legs. This will give greater stability.

- The metal grill can also be equipped with wheels. This will allow you to easily change its location on the site if necessary.

- A canopy can be constructed over barbecues and fireplaces. In this case, you can cook barbecue even in bad weather. If you also equip benches, plant flowers and shrubs, then this place will become the real heart of the garden plot, where in the evenings you can just sit by the fire, listen to the birds singing, and look at the starry sky.

- The design of a conventional metal barbecue can be additionally equipped with places for storing firewood, skewers, water and pokers. This will add additional charm and some charm.

- Cast iron is considered the best material for making a barbecue. It is very strong, durable and holds heat well. This will save on coal. In addition, it can be additionally decorated with forged elements.

- When choosing the location of a barbecue or hearth, you must be guided primarily by safety rules and not place the structure near buildings (the distance should be more than three meters), next to flammable objects, under trees, near fences, fences, gazebos.

- A stone hearth is best made from natural elements. But in order to build it in compliance with all building codes, rules, standards and technologies, it is better to resort to the help of qualified mason builders.

- It is better to cover a metal barbecue made by yourself with fire-resistant paint. This will make its appearance more aesthetic and significantly extend its service life.

- It is better to make slits for skewers on a roasting pan at a distance of 5 to 8 cm. This distance will allow you to easily turn each of them over without touching the neighboring ones.

- Before using the barbecue for the first time, it must be calcined, that is, light a fire in it, in order to get rid of all the harmful substances accumulated during construction.

- Near the hearth you can equip a small reservoir, pond or alpine slide. This will allow you to create a complete ensemble of a suburban recreation area.

It should be noted that the correct grill should always be made according to generally accepted standards, which must be slightly adjusted to individual requirements.

In this case, the meat will be cooked immediately in sufficient quantity, will not burn or dry out regardless of the cooking tool, the fuel material will be used efficiently and economically, and the heat will not escape into the air.

In addition, there is currently a wide selection of building materials that will be suitable for its manufacture, be it metal, steel, cast iron, heat-resistant brick or natural stone.

When decorating a barbecue, you can implement any ideas and projects, be it a small mobile fireplace, a stationary brazier or even a brick oven in your garden. Subject to compliance with building standards and fire safety, the result will only please the eye.

A real corner for cooking and relaxing with family and friends will become a favorite place to eat and spend time, relax and recharge with positive energy.

Use and care

After assembly, the grill should not be used yet, especially in situations where the metal used was not new.

First of all, it is immediately cleaned of dirt and rust that has formed on the material during operation or storage. A grinding machine or an ordinary drill with a specialized attachment is perfect for this.

If you decide to paint the grill, it is best to use heat-resistant acrylic paint.

If you don’t want to do this, but want the grill to shine, it needs to be blued. And first of all, to do this, degrease the surface by wiping it thoroughly with an alcohol solution.

Next, all the parts of the grill are placed in a solution of caustic soda and kept in it for about an hour and a half. This way you will not only make the grill beautiful, but also protect it with heat-resistant film, and also protect it from rust in the future.

DIY brick grill

Everyone knows that brick retains heat for a long time, and therefore on such a grill it is wonderful to cook barbecue, meat on the grill, as well as pilaf and fish soup. The choice of dishes is limited only by your chef's imagination.

If there is enough free space on the site, it is advisable to combine a brick grill with a gazebo or space for a dining area. The building occupies a decent area, has a foundation and cannot be removed or moved, so choose the location carefully.

The foundation is poured with a strip, going half a meter into the ground. The ideal material is natural stone and stove brick. Laying a fireplace requires knowledge and skills, so entrust this process to a specialist if you are not confident in your abilities.

When you decide to build it yourself, consult a specialist, do everything carefully and slowly.

Bring your ideas to life with confidence. We have on sale all the materials needed to make a barbecue - steel, cast iron, brick and stone. By following building codes and choosing a location in compliance with fire safety regulations, you will organize an oasis on your site, where you can fully relax, recharge your batteries, and be with friends and family. Good luck to you!

Stationary grill

It can be presented as a traditional model or combined options:

- Do-it-yourself grill-stove.

- Barbecue grill.

- Brazier with grill installation.

To build such furnaces, you will need certain construction skills, experience and a high-quality drawing. Every detail is important in the arrangement: from the chimney to the built-in grilles.

Choosing a place for a barbecue

To build a barbecue, you need to choose the right place. First of all, it is worth remembering that the barbecue cannot be located indoors, so it is placed in an open area.

It is advisable that the building be located away from the neighboring property. You can also position the grill taking into account the direction of the wind (so that it does not bring smoke and a burning smell to the neighbors’ property).

There should be no trees, flammable materials or other buildings near the barbecue (at least 1 m away). The ground next to the building is poured with concrete and paths are made.

As a rule, a gazebo and a relaxation area are placed near the barbecue. The wind should also not bring to them the smell of burning and smoke from the barbecue, which must be taken into account when choosing a place.

Important: there should not be constant dampness near the barbecue in the form of, for example, a wetland. In this case, the building will quickly collapse or the masonry will be damaged.

Portable structures

Most often, such barbecues are made of sheet iron or represented by forged products. They have standard sizes and side connectors for attaching skewers during cooking.

When working independently, special attention is paid to supports, which must ensure the strength and balance of the entire structure.

Appearance of the grill

The topic of appearance should be thought through and studied in advance, choosing the material consciously, taking into account quality and availability. You can leave the budget option, using inexpensive Vitebsk stove bricks and refractory ones according to the specification. Or you can use the oven face and change the color, round the corners with radius elements. Sometimes, having conceived a cladding made of natural or artificial stone, during the construction process one comes to the understanding that people have overestimated their material capabilities. Then in the first year the masonry is done with straight stove bricks, and the next year they are lined with the selected material. They also come with cladding with heat-resistant tiles or imitation tiles.

This version of an open barbecue grill has advantages due to the absence of high temperatures on the surface: it allows you to work with natural stone such as flagstone or round timber, it is glued to tile adhesive with a cement base. Complex barbecue complexes, which include closed ovens - such as a smokehouse, a cauldron stove, a bread maker - and having high surface temperatures, are more demanding on facing materials and they are discussed at the project development stage.

Let's return to our construction site. Now that we have read the masonry instructions, we can begin working on the ground. The question arises about the foundation.

Barbecue from a gas cylinder

Before making a grill from a gas cylinder, it must be completely emptied. Then the tap is unscrewed, after which the container is washed with water with the addition of chlorine or detergent to remove any remaining odor of the odorant.

Then markings for cutting are applied to the cylinder in the form of two longitudinal lines that divide the cylinder in half.

Cutting is carried out using an angle grinder; it is also recommended to fill the container with water so that it is more stable and the grinder disk does not heat up.

After this, a lid is made, the legs are welded and holes are made to supply air to the coal combustion zone.

Drawing of the arrangement of a corner barbecue

To build a corner barbecue, you must go through all the steps outlined above. First of all, markings are made, then the foundation is created.

It is also necessary to make a bottom under the structure, since its important parts will be located in the corner. To do this, dig a recess, like under a foundation, but of a different shape, also focusing on pegs with twine stretched over them. Fill with the same solution in stages.

After this, you can begin building the walls according to the drawing.

Metal barbecues with a canopy: drawings

To cook kebabs in bad weather, you can use a special grill design. This allows you to hide the heat and meat from precipitation, but this design itself is not simple. There are two options available here:

- installing a canopy directly on the grill;

- installation of an additional canopy that does not belong to the barbecue.

The latter option will be more rational, since it allows you to hide not only the kebabs, but also the person who monitors their preparation. The first option requires additional costs, since the base must withstand the load from the canopy.

In this case, we recommend attaching the structure to metal corners. This is the best option as it makes it easier to assemble. The canvas for the canopy is most often corrugated sheeting. It is fireproof, does not react in any way to temperature changes and is lightweight, which is important for a lightweight design.

Assembling a canopy is not much different from the usual one, and all that is required is fire protection and proper placement of the base. This way, you can safely prepare food without worrying about getting caught on the fittings.

It is worth noting that a metal grill with a canopy is a complex option that can be done by experienced welders. Here it is important to create a reliable structure, the weight of which will be evenly distributed on the base. For stationary barbecues it is much easier to make such a canopy, since a load-bearing foundation can be installed for them.

A structure with a canopy can be decorated with metal elements, as you can see in the photo. This will not only improve the appearance, but also make the canopy more stable and reliable.

Attention! If the roof is installed low, equip it with a special air duct.

Manufacturing technology of a collapsible fryer

First of all, a drawing of the barbecue is sketched out on paper with the dimensions indicated on it. In purely constructive terms, this device is a parallelepiped. That is, all its opposite paired walls are equal to each other. The only plane that is present in a single form in the roaster is the bottom.

The development of drawings for barbecues must be approached thoroughly. Because this is the basis of the future design. This is where the proportions of the frying pan are displayed. And although this is of little importance for a portable, collapsible version, a certain aesthetic side must still be present in the design.

See the drawing below, which shows the full details of the structure. This is exactly how the masters sketch it out on paper. The main task is to show the dimensions of each part, because they are each manufactured separately. And precise dimensions will help you arrange the parts into a single whole without adjustments.

Drawing of the barbecue and its parts Source remontik.org

If the drawing of a metal grill with dimensions is ready, the master proceeds directly to making the brazier.

See also: Catalog of companies that specialize in the installation of fireplaces and stoves.

Materials

As mentioned above, the material you will need is a steel sheet with a thickness of 2 and 3 mm. Reinforcement with a diameter of 10 mm can be used as legs. To connect the parts of the fryer you will need eight M6 or 8 bolts.

Marking

According to the drawing, all dimensions of the grill parts are transferred to a sheet of iron. As already mentioned, there will be two side walls, end walls too, and one part of the bottom. The paired walls are identical.

You cannot scatter markings all over the sheet. Many of the dimensions of the parts are the same, so the edges of the two parts will be indicated by a single line. This way you can save money by reducing waste.

You can find cut sheets of metal on the market. If you correctly arrange (make a competent diagram of the arrangement of parts) the markings, then you can purchase not a whole sheet, but a cut one. It costs several times less.

Metal marking Source setfsb.ru

Now the important point. The parts of the barbecue are connected using bolts (as one of the options), so sides are made under the joining points, which are bent inward from the main plane of the walls by 90°. In this case, on the side walls, the bend is made at three ends with fastening to the end walls and the bottom, on the end walls only on that side - to the bottom. Bend width:

- if an M6 bolt is used for connection - 10 mm;

- if the M8 bolt is 12 mm.

This parameter must be added to the dimensions of the parts. For example, if the length of the barbecue is 50 cm, then the length of the side walls is 52 cm, because a fold of 1 cm is added to it on both sides.

Cutting, bending, drilling

The next stage is cutting out all parts of the grill exactly along the marking lines. This is usually done with a grinder with a cutting diamond blade. You can also use other tools: a plasma cutter, a jigsaw with a metal blade. Cutting must be carried out exactly according to the applied markings. Everything must be done carefully.

Cutting with a grinder Source chrome-effect.ru

In the end, you should get five parts: side walls - 2 pieces, end walls - 2, bottom - one.

The next operation is bending the connecting areas of the grill parts. On the cut out parts of the roaster, indentations for bends are applied. Again, a ruler and marker are used. There will be three lines on the side walls: two parallel (to connect to the end walls), one perpendicular to them (to connect to the bottom). There is one line on the end walls. It should coincide in location with the line for the bottom.

A shallow cut is made along the drawn lines; it is not through, but with a small indentation of up to 0.5 mm. This is done in order to bend the bends easier and more evenly. Notice on the side walls where the cuts of perpendicular lines will create squares in two corners. They are cut off completely.

Now bends are made using a hammer. The workpiece is placed on the edge of the table, it is better if it is trimmed with a steel corner, and with light blows the edge of the bend is bent along the cutting line. The bending angle is 90°.

Drilling holes Source grandado.com

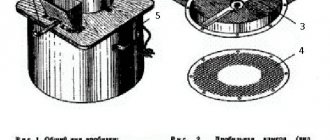

Models with barbecue grates

When considering the parameters of the barbecue, you should first of all take into account the size of the barbecue grate. They are 18x28 cm. The grate should be located at a distance of 5–8 cm from the surface of the coals.

In this case, it will be possible to ensure uniform roasting of the meat. Most often, the dimensions of an iron barbecue grill are 18x30 cm. This is enough to accommodate one grate.

Grate dimensions - the main parameter

Finished product painting

An important issue in making a barbecue is painting. You cannot do without it, since the metal used in the structure is subject to rust, and ash and soot do not improve its appearance.

For painting, special compounds are used, which meet the following requirements:

- heat resistance;

- resistance to temperature changes;

- no harmful fumes.

The following coatings meet these requirements:

- silicon-organic enamels;

- heat-resistant paints for various purposes.

It should be noted that painting a barbecue with your own hands is a rather complex and responsible process. They need special firing, after which they receive their properties. Another option is proposed - oxidation. It is quite expensive to implement, but it is possible to do it yourself.

It is better to choose black color for paint. Since there will be a lot of ash and soot nearby, the remaining coatings will quickly become dirty. With this color the plaque will be completely invisible.

Attention! Painting should only be done on the outside. Inside, the coating peels off quite quickly as a result of the high heat, and there is no point in this.

Additional functionality

Canopy

Protects in any weather. From the hot sun, precipitation, during cooking. It won’t protect you from heavy rain, but in light rain you won’t have to give up barbecue.

Brazier with lid

The presence of a lid reduces frying time, protects food from insects, drying out, and accidental combustion of coals. With it, the meat is saturated with the aroma of smoke and acquires a slightly smoked taste.

Double bottom

It is characterized by an air gap, with which the process of heating the coals is uniform.

Pens

Simple collapsible barbecues can be equipped with handles to make it convenient to lift. They are either welded or fastened with bolted connections. They can be made in the form of forged curls. And then the design will become not only functional, but also beautiful.

Scoop and poker

Can be made from the same square with a diameter of 10 mm. For greater decorativeness, the handles are twisted into a spiral on a torsion bar.

Brazier with cauldron

The grill can easily be supplemented with a place for a cauldron. A ring is welded to the side or rear wall into which a rod with a holder can be inserted. There is no excess metal consumption. There is a more complicated option: the design provides for an increase in length, the stove is welded to the side. With such a model, there will be pilaf, stew, and roast on the table.

Shelf

The shelf below performs not only a decorative function, but also an applied one. Firstly, it increases the rigidity of the frame. Secondly, you can stack the firewood, and if it is damp, it will dry out quickly from the heat of the fire.

Wheels

You can use wheels from an old car, or take furniture casters. Or make it yourself from rings of different diameters, adding iron knitting needles for connection. To attach them, an axle is welded to the legs, on which the wheels are already placed.

In addition to the above, the grill can be modified with many useful things. For example, an ash box, special shelves, a pipe, handles, hooks, tongs, etc.