- June 5, 2020

- Tools and equipment

- Igor Nezhvinsky

The quality of the tool always plays an important role, and especially when working with wood. Wood is a soft and warm material, responsive to handwork. The market offers a wide range of machines for precise and high-quality wood processing, but to this day only the hand of a master can create a masterpiece.

The art of wood carving has a long history that has given the world unique works of art. Working with wood and creating beautiful things is easy. All you need is patience, perseverance and a good tool. Experience and knowledge will come with time.

The beginning of time

The woodworking master begins with a wooden block, which for an unexpected and incomprehensible reason attracted his attention, and a sharp kitchen knife. The situations can be very different:

- needed a spice rack in the kitchen;

- the door fell off the closet in the bedroom;

- you need to make a rack for children's toys;

- decorate a jewelry box with an ornament;

- you need to put a lock on the front door, etc.

Such tasks are not wood carving, but you will have to cut, drill, saw, sand, etc. If the result is in demand and it has captured the attention of the beginner, then a new star lights up in the sky, and the young master begins his journey of transforming wood into unique and practical products.

Main tool

A kitchen knife can easily cut out a whistle, a simple toy or a spoon. Many people start with a pocket knife for the purpose of carving a spoon. This is not woodworking or creativity - this is a memorable beginning. Tools for wood carving need special and, most importantly, sharp ones.

A beginner can start his practice only with this instrument. This is a blunt knife. If you want to cut out simple designs or give the desired shape to a wooden surface, this knife will help you do it perfectly. You don't need to specially learn to work with it. Once in your hand, this knife “will show you” how and what to do. There are only two conditions for the first tool:

- very sharp made of high quality steel;

- fits very comfortably in the hand.

There is no need to think about what tools are needed for wood carving and spend money on beautiful sets at the very beginning of practice - they will all be waiting in the wings. One sharp corner knife with a straight blade is enough.

Wood carving for beginners: Chisel

A chisel is a hand tool designed for working on wood, as well as other materials (leather, metal, etc.). Used by woodcarvers and carpenters to perform wood carvings, create recesses, notches, and grooves. Consists of a handle, usually wooden, and a metal part. Thus, a chisel, a cranberry, a spoon cutter are all chisels.

Classification

Chisels can be classified according to the method of advancement, handle shape, size and other parameters. The main classification of chisels is based on their shape, longitudinal or transverse. Moreover, a chisel is often determined by these two parameters at once.

Transverse shape:

Depending on the shape of the transverse, that is, end, profile of the chisel blade, the following types of chisels are distinguished.

Radial

- this is 95% of all incisors, which appear in various publications under the names: semicircular, sloping, semi-flat. In the classification proposed by Shamil Sasykov, a radius chisel is a chisel with a profile that has part of a circle in cross section. For example, for a chisel numbered 20/2-1, the width of the blade is half a circle with a diameter of 20 mm (designation 20/2), and the last number - 1 - is a characteristic of the thickness of the cutter of 1 mm. Another example: a chisel numbered 20/5-0.5 is a chisel with a blade width of 1/5 of a circle with a diameter of 20 mm and a cutter thickness of 0.5 mm.

Flat

- chisels having a straight, flat transverse profile. Cutters vary in the width and thickness of the blade and the shape of the cutting edge of the blade, which can be oblique or straight.

Box or bracket

- flat straight chisels with sides of different heights.

Corner

- with a profile in the form of an angle, the Latin letter V. The size of such cutters is determined by the height of the side of the corner of the tool, as well as the size of the angle in degrees between the sides. In most cases this is an angle of 60-90 degrees.

Longitudinal shape:

Depending on the shape of the longitudinal, that is, lateral, profile of the blade, the following types of chisels can be distinguished.

Direct

- chisels with a straight blade, like a ruler, without any bends.

Klukarzy

- chisels that have a fairly steep longitudinal bend of the blade, which begins closer to the end of the blade.

Curved

- chisels with a longitudinal bend in the blade. But, unlike cranberries, most of the canvas bends.

The proposed classification allows us to identify the main types of chisels based on simple and understandable parameters, which is important for a novice carver. But it is worth remembering that there are other types of chisels, distinguished by other characteristics. We will talk about them as needed. For example, this list can be expanded dramatically by highlighting chisels sharpened on the reverse side, which are usually called reverse chisels or reverse chisels.

Another important criterion for classifying chisels is

principle of operation

Type 1

Chisels are advanced by striking the handle with a hammer, mallet, mallet or electric tool (electric chisel), as a result of which the wood is cut. Such chisels are usually used when carving hard rocks, when a lot of force is required, or soft ones, when you need to cut a lot of material at once.

These chisels look large, long, and sometimes simply huge. They are held with one hand and hit the handle with a hammer with the other. The handle of such chisels is usually looped so that it does not fall apart. But sooner or later they still fall apart, and therefore it is preferable to use a rubber or polyurethane hammer to make the tool last longer.

Type 2

There are chisels, sometimes as long as in type 1, but their cutting part is somewhat narrower. They work with both hands, pressing and pushing using the efforts of the hands. It is clear that this is possible mainly on soft wood. The head of the pen is round, smooth, and comfortable to fit in the hand. You can use a mallet to a limited extent, or better yet, a rubber mallet: a handle, even a birch one, can withstand many years.

Type 3

And finally, chisels, which are used to cut, moving them only with your hands. They are, of course, much smaller in size than those described above, even the metal part is thinner and sometimes harder. They can be used on any wood, it all depends on the sharpening angle of the blade and the size of the object. They are convenient for cutting out small things like netsuke: from juniper, cypress, apple tree, cherry.

From the history of terminology

The word "chisel" is borrowed from the German - Stemmeisen.

The German word Stemmen translates to “chiseling, chiseling, gouging.” This term in German is used to refer specifically to a chisel, but a thin one, pushed forward by hand without using a mallet. To designate this particular type of cutters, it was borrowed by Russian craftsmen. This term most likely came into use by craftsmen during the era of the reforms of Peter I. Interestingly, a chisel most often meant a flat hand tool, which today is called a chisel. Here is a fragment from A. A. Pchelnikov’s book “Conversations with Children” (1858): “With this flat one, which is called a chisel, sawn spikes or hollowed out holes, etc. are cut out and cleaned. With a semicircular chisel, semicircular recesses are removed and cleaned. Using slotting tetrahedral chisels, wide and narrow, they gouge out holes, take out grooves for inserting thin planks into frames, etc.” And in the Dictionary of Church Slavonic and Russian Languages (volume 4, 1847) a chisel is defined as “... a kind of chisel. Carpentry chisel, flat and tenon.” A more detailed definition is given by the authors of the Desktop Dictionary for reference in all branches of knowledge (volume 3, 1864): “A chisel, a carpentry tool, is used for gouging out holes and replacing a chisel. It is made of steel, 4 inches long, up to one inch wide” (1 inch = 4.45 cm).

It is not known exactly when the term “chisel” began to be used to refer to semicircular incisors. But in the publications we found before the end of the 19th century, this term is used specifically to designate a chisel, while the word “chisel” refers to cutters of various shapes, including semicircular ones. In the 30s of the XX century. Several editions have been published in which the chisel comes in different shapes, including a semicircular one. In the current linguistic tradition, including in the professional vocabulary of woodworking masters, a chisel is a common name for cutters of a similar design (most often semicircular), and a chisel is a straight cutter with a profile in the form of a hexagon or trapezoid, intended for creating grooves and splitting material and other operations.

Read about the types of chisel handles, recommendations for choosing chisels and other features of working with this type of hand tool in other specialized articles on our website.

Chisels and mallet

A set of chisels and a good mallet increase the capabilities of a novice craftsman. When choosing a set, you need to pay attention to the material of the blade and the quality of the handle. These are essential wood carving tools for beginners and professionals.

Having chisels of different shapes is an opportunity to make ornaments, cut grooves, make straight lines, and select recesses of the desired shape.

A mallet is a special hammer. It can be rubber or wood. It is recommended to have both options in your arsenal. A metal hammer will quickly destroy chisels.

The handle of a chisel does not necessarily have to fit well in your hand. But when working with a chisel, the hand must be protected, and it would not be superfluous for a beginner to have a robe made of durable fabric that protects the body from a sharp object. For example, a leather apron or a regular robe inlaid with leather, plastic or other inserts.

When working with wood, movements are often directed towards oneself or the auxiliary hand. To avoid scratches and puncture wounds, it is advisable to protect yourself.

Jigsaw

Suitable for cutting materials of small thickness, but the main functionality of an electric jigsaw is figure cutting. The thin and narrow blade gives flexibility and maneuverability to this hand-held electric tool, allowing you to set the desired direction of the cutting line.

When choosing a jigsaw, pay attention to the presence of a pendulum stroke - this increases its efficiency and increases the speed of work. But this mode should only be used when sawing “straight”, otherwise the risk of damage to the surface being processed increases.

As consumables, jigsaws come with all kinds of saw blades, thanks to which you can choose the optimal accuracy and cleanliness of the cut, as well as achieve maximum operating speed.

The jigsaw is slightly inferior to the manual version - in the manual version, the minimum bending radius of the cut line is smaller, which allows you to perform more precise work.

In general, working with a jigsaw is an activity for the patient and requires a lot of endurance, accuracy and painstakingness.

What you need to know when choosing

- The harder the material, the lower the speed;

- To accelerate, use the pendulum stroke (for soft materials);

- For “shaped cutting” and clean cutting of hard materials, a pendulum stroke is not needed;

- The higher the speed, the more often it is necessary to take breaks to “rest” the tool.

Lessons from a recognized master

Meeting an experienced carver is a rare success. Just one visit to a professional carver’s workshop leaves a lasting impression on a beginner. The workshop has everything: from the smell of wood to a clear understanding of what tools are needed for wood carving. The first impression falls on the subconscious, and the beginning carver “already knows” what and when he should purchase or make.

A professional does not use standard sets of tools. He prefers to make his own instruments. This point is important to keep in mind. No manufacturer will make what you need. Any tool on the market is a tribute to established traditions, the shape of blades, handles, and accessories.

If you have a chance to become an apprentice to an experienced carver, this is a rare success. You can learn not only the technique of wood carving, but also the logic of making a tool, and master important rules for sharpening and using it.

Fraser

As the name suggests, it is needed for milling, namely chamfering, cutting quarters and cutting grooves and splines.

What to pay attention to

All the tools collected here are most often suitable not only for woodworking operations, but also for working with other materials: plastic, metal, plywood. You just need to choose the right consumable.

Wood surface and sanding

Depending on the item being manufactured, one or another surface treatment is required. A shelf or rack for the kitchen, a table or bedside table for the bedroom requires a perfectly flat and smooth surface. A toy figurine, panel or box does not need sanding, but a drawing made with a chisel cannot be sanded at all.

Cutting wood with a knife and shaping the surface with a chisel does not require preliminary sanding, and once the work is completed, the surface simply cannot be sanded.

In the creative process of wood cutting, the idea often arises: not to cut out what you want, but to refine a natural solution. When a fancy piece of wood (a branch, a stump, a trunk) falls into the hands of a craftsman, the idea arises of adding to it rather than cutting it out.

Work surface and vice

Wood carving tools should be within easy reach. The desktop must have a perfectly flat, horizontally leveled surface. At least one vise must be firmly fixed to the workbench.

A metal corner, a level, clamps, and wood glue must be purchased immediately, and they should always be at hand.

Auxiliary equipment is a sharpening machine, a hand-held circular saw with the possibility of stationary installation, a grinding machine, and an electric jigsaw. A hand jigsaw, a set of needle files and files will come in handy.

Additional equipment and tools are not associated with wood cutting, but without this you will have to spend time doing auxiliary work elsewhere.

A good master should have everything at hand.

Types of knife blades

A classic jamb knife can have blades of different widths, blade angles and a conveniently shaped handle for a specific type of work. The blade of the knife can be made in the form of a triangle (the flag knife is very popular) or have another shape.

The knife can have different sharpening options, smooth or sharp cutting edge shapes. Understanding which blade is needed depends on the specific type of work, the design being performed and the experience of the craftsman.

As in the case of a blunt knife, the prerequisites for the quality of a knife with any blade shape are the sharpness of the blade and the comfort of the handle. The attachment of the knife blade to the handle must be perfect and reliable.

Description of turning tools

The wood cutter is made of high strength steel.

Although wood is a soft material, the cutting part is subjected to significant loads, and even heats up from constant friction. Therefore, factory cutters are made from alloy and carbon steels, which hold an edge for a long time and at the same time are not too fragile, that is, they do not crumble as a result of a sharp increase in load (for example, when they hit an internal knot in hard wood).

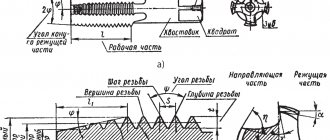

Each cutter consists of the following parts:

- blade – comes into contact with the workpiece and, due to its sharpness, removes a layer of wood;

- working part (body) - one end of it is sharpened to a blade, and the other ends with a shank, the turner holds it with his hand;

- shank - the narrowed end of the working part, onto which a wooden handle is mounted.

The handle is usually made of wood and consists, in turn, of a thick cylindrical base and a narrow neck, on which a metal ring is usually put on, which protects it from cracking when placed on the shank.

Varieties

All devices used for the manufacture, finishing and decoration of turning workpieces can be divided into several general types:

. The shape resembles a knife, but unlike a regular knife, a turning knife uses only the tip. Parting tools are worked by turning their plane vertically, unlike chisels, which are held horizontally. Using a turning knife, a part of the workpiece is cut off and deep grooves are made.

Cut-off- Chisels . Flat or semicircular objects with a sharpened blade. They select a part of the material, pressing it against the workpiece parallel to the floor or at a slight angle. Thanks to chisels, a beam or log, sandwiched between the headstocks, takes the shape of a curly bed leg or an evenly tapering baseball bat.

- Scrapers . They are used after the product has been given a rough shape. Unlike a chisel, a scraper does not have a sharpened blade - the cut is made using the hard edge of the end. Thanks to scrapers, both decorative and functional complex ring cuts can be made in wood. The most common scrapers are shaped like the letter R.

Various options and their purpose

The variety of cutting tools for wood when rotating on a lathe is very large. Experienced craftsmen create cutters of the shape they consider convenient for the implementation of individual tasks. Therefore, one personal cutter is not similar to another. However, there are standards for factory tools, some of which are basic, others highly specialized.

Reyer

This is one of the basic incisors. It can be recognized by its characteristic shape - the working part of the rail is not flat, but curved, forming a groove. Sharpening is done from the inside of the curve. They work with a rake, bringing it to the workpiece with the groove up.

Thanks to the shape of the blade, this cutter selects wood in a semicircle. Its longitudinally curved shape makes it very durable, making it well suited for rough turning of workpieces. With the help of a reyer you can also make smooth transitions and grooves with a semicircular profile.

The width of the rib ranges from 4 to 30 mm, and the sharpening angle is about 30 degrees.

Meysel

If a reyer is a relatively simple tool, which is intended primarily for rough, rough work, then a meisel is already much more difficult to use.

It is unlikely that you will be able to master it in a couple of days of practice. This cutter is used already when the outlines of the wooden product are formed.

However, for an experienced turner, the use of a meisel gives an even, smooth surface of wood of a given geometry.

The Meisel is a bit like a regular flat hammer chisel, but its blade is angled. Accordingly, the master must have at his disposal at least two meisels - left- and right-handed - in order to process mirrored areas.

Sharpening the meisel can be done either by beveling one side until it comes out flat, or by equally removing the metal layer from both sides. In this case, the width of the blade can reach up to 40 mm, and the bevel angle ranges from 60 to 75 degrees. When sharpening a cutting edge on both sides, the angle should be 20 – 25° on each side.

Shaped

After the main processing of the part in the headstocks has been completed, it is the turn of the figured cut. For this purpose, shaped cutters are used. They can have different shapes for turning grooves, grooves, and select grooves of complex shapes.

Klukarza.

The most common “styles” are:

- Klukarza . The shape of the cutter is similar to the reyer, but has a bend in the working part near the blade. Thanks to this shape, the cranberry can be used for small and complex work; it can reach places where tools with a straight working part cannot reach.

- Comb . It makes parallel grooves and grooves. With the proper level of skill, a thread is cut using a comb.

- Hook . Allows you to make an internal recess with a protruding edge, as well as various curved grooves.

- Crescent or dovetail . Used for turning round and faceted beads.

The process of turning a workpiece on a lathe significantly depends on the sharpening angle of the tool. Small angles (20 – 30°) are intended for fine work.

They remove wood well, but if moved carelessly they can damage the workpiece or break themselves. Large angles (60 – 75°) are intended for rough work with hard rocks.

They can remove less in one pass, but they are not afraid of knots and pressure created by the turner.

About creating with your own hands

Experienced turners make their own cutters for work, not being satisfied with the assortment that is on sale. Plus, it's significantly cheaper. The material used is old tools that have served their purpose: files, needle files, rasps and other flat objects with sufficient hardness.

In order to make a cutting edge, sharpening machines with diamond wheels are used. The easiest way is to make a straight blade - to do this, just sharpen the end of the tool.

When removing metal on a wheel at high speed, you must avoid overheating the steel. Otherwise, the metal will be tempered, and the future cutter will quickly lose its sharpness. Supplying water to the wheel while sharpening is one of the best cooling options. However, if you overheat the cutter during the process, it doesn’t matter. It can be hardened again by heating it red-hot with a propane torch and then running in water or oil.

What wood lathe cutters do you use?

Blades with complex configurations will have to be adjusted manually using thin files and diamond needle files. If the farm has an engraver, it can also be used with conical, cylindrical and spherical burrs (cutters). This way you can get a cutter of any configuration.

After the body is ready, they begin to handle the handle. On turning tools, the shank is increased to accommodate a longer handle for convenience. It is advisable to burn the drilled hole in the handle by heating the shank and inserting it “hot” so that the wood will crack less.

Best sets

DEXX 1834-H11_z01

- type : chisel;

- profile : flat, oblique, curved;

- handle material : wood;

- blade material : alloy steel.

One of the most affordable sets. There are 11 chisel-type cutters, there are both semicircular and oblique blades. Suitable for most small carpentry work.

Factory sharpening is only indicated, so upon purchase you will need to bring the tool into working condition.

STAYER 1831-H33

- type : cutter;

- profile : V-shaped, semicircular, flat, oblique, curved, square;

- reinforced handle;

- handle material : rubber, plastic;

- blade material : hardened steel.

Set with an impressive set of cutters. Some of them almost duplicate each other, so in case of breakdown there will be no problems. The cutters are put on the handle. There are two types: for rough shaping of the workpiece and for fine work.

Bogorodsk knife “Tatyanka”

The name “Tatyanka” and the Bogorodsk knife were formed historically. They are associated with carving with only one cutter by hand. This knife works on soft wood for cutting small sculptures and figure cutting.

Bogorodskaya carving came out of peasant craft. Her most recognizable scene is "man and bear", and her carving technique is often called power. One knife, one workpiece. A carver of this style is a unique master. He doesn't wonder what tools are needed for wood carving. He just takes his knife and makes unique things with it.

There are many options for making a Bogorodsk knife. There are many options on the market, even a folding product. The best will always be your own.

Power carving with one knife is creativity, and creativity never fits into the framework of a standard manufacturer. When a beginner decides to devote himself to Bogorodsk carving, he will not have a question about what tools are needed for wood carving, he will not have a desire to purchase them, but he will have a clear understanding of how to make his own version of a knife.

Household ornament and “kitchen” cutting

The kitchen is the most popular place in the house. The whole family often gathers here, friends come here, and the interior of the kitchen should always be at its best. A kitchen tool is important for a good housewife, and its quality should be better than others.

To decorate a shelf, rack or cutting board, there is no need to perform figured cutting. Household ornaments should be beautiful, simple and easy to clean quickly. Here it is necessary and sufficient to have a simple set of wood carving tools.

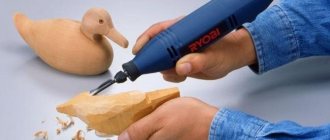

As a rule, a set of chisels will be enough to give a unique look to any wooden item for use in the kitchen. Any surface in the kitchen must be clean. From this point of view, it is more convenient to use an electric tool for wood carving - this will allow you to get straight and smooth lines, an easily cleaned ornament and avoid grooves and recesses in which dirt can accumulate.

The choice between manual work and the use of a machine is up to the master, but the cleanliness and “cleanability” of the product should be in the foreground.

What chisels are needed when working?

Of course, the main handmade tools are wood carving chisels. The most common types of chisels include the following tool:

- Straight type: used as an auxiliary tool.

- Semicircular type: the main type of chisel, which is necessary for any type of work. There are flat, medium and round options.

- Klukarzy. They have a curved working part; there are flat, angular and semicircular varieties.

The process of carving with a crab cutter - Cerasics. They look similar to the semicircular type, but are designed for cutting thin grooves - for this purpose the blade width is 2-3 mm.

- Thicknessers or corner chisels. Used for cutting V-shaped grooves and contour cutting. Such wood carving cutters have an angle between the working cutting knives of 55-75º.

- The graver has a mushroom-shaped handle, and the bend angle is 15º. The tool is designed for making various grooves.

This is what wood carving pens of various sizes look like - Rivets: sharpening of the working edge is made in the form of a sword or leaf, and is used to process the main background in areas where other chisels do not pass.

- Nail is a type of chisel-rivet with sharpening in the form of a nail, used for processing in hard-to-reach places, as well as when making staple carvings.

Children's room and bedroom

The surfaces of shelves, cabinets, tables, chairs are smooth and even. This does not apply to legs, arms or ornaments. As a rule, artistic cutting can be applied along the edge of the surface of a table or bedside table, but most often it consists of making additional elements.

A carved handle for a cabinet door, a carved leg for a table or a horse chair for a child will require a simple tool. For example, a set of chisels of various shapes can be used to mark a horse’s mane or make a tail.

Types of tools and wood carving for household use is a technique of personal creativity. A person does not set himself the goal of creating a masterpiece. In his opinion, a masterpiece will be a children's room in which his child will feel comfortable; a set of simple wooden toys that will develop motor skills and imagination. The bedroom will be decorated with a unique lamp made from a tree stump modified with a Bogorodsk knife or a book shelf with a light ornament.

Wood cutting for the interior of a living space is significantly different from cutting figurines, sculptures or artistic paintings. Everything here is simple and easy to use: the most affordable materials and tools. Wood carving in everyday life is the art of designating, clarifying, and decorating.

For a beginner, “household cutting” is an excellent school of skill.