When installing new interior doors, many are faced with the problem of drilling holes for door hardware. To simplify the task, templates are used for inserting hinges and locks. The use of such elements will greatly simplify the work and reduce the risk of damage to the door leaf.

Currently, a template for inserting loops (conductor) is sold in any hardware store or you can make it yourself. It must be remembered that it is not advisable to purchase a router for cutting in locks and hinges when you plan to install several panels.

Which router for installing doors

Milling cutter for cutting door locks and hinges: setup, templates and cutters, video

Such a hand-held electronic tool, like a milling cutter, can be successfully used to perform various types of processing of products made from wood. Using this equipment and a set of working attachments, you can not only decorate the surface of a wood product, but also perfectly prepare a furniture façade or door for installation by using a router for cutting in locks, door and furniture hinges. Naturally, you can perform the function of selecting grooves in a wooden product manually (using an ordinary chisel and hammer), but when using a router, the productivity of such an operation increases significantly, and the quality of the final result also increases significantly.

Selecting a recess for the lock using a router located on a special device

Briefly about the main thing

To cut a lock with a router or hang hinges on a door, you need to choose the right tool. It is best to use a simple submersible model, since the combined model is heavy. This will create certain inconveniences, especially if there is no experience in such wood processing.

Using a router to cut in fittings is easy. But the process is greatly simplified if there are special templates. Having placed the device in the desired place, all that remains is to set the required processing depth on the tool and install it on top.

When working, you need to carefully monitor the process in order to notice overload in time. It can occur if the wood structure is too hard. Then you just need to reduce the speed of the tool using a special switch on the body.

How to choose the right hand router

When choosing a router that you plan to use for inserting locks and hinges, or a device for any other purpose, you need to pay attention to the subsequent characteristics of such equipment.

To perform not very busy and not very complex work in a home workshop, low- and medium-power milling cutters are completely suitable, which can be used, among other things, for mortising door locks. More massive devices, which are used to a greater extent in the professional sphere, although they are capable of handling more complex tasks, cannot provide the highest rotation speed of the tool used. In addition, with an increase in power, the weight of similar power tools also increases significantly.

Ability to adjust tool rotation speed

The presence of such a function allows you to normally select modes for each of the technological operations performed by the milling cutter. Of the manual milling cutters that have this option, it is better to choose models whose speed switch is protected from external mechanical influences and contamination from wood dust and sawdust. In addition, it is better to give preference to models with switches that operate on a discrete principle.

The amount of overhang of the working part of the tool above the end of the chuck

It should be understood that the more important parameter is the actual overhang, and not the longest stroke length of the tool, which is indicated in the marking of each model.

The longer the cutter overhang, the less you will have to drill the groove to install the lock.

To assess this parameter, you should immediately take into account several features of the device, such as the weight of the router, its multifunctional capabilities, the convenience of the location of equipment controls, and the length of the electronic cord. Not only the comfort of the user, but also the quality of the processing performed depends on how comfortable it is to use a hand router.

How to choose a router for installing interior doors

Quality of view of the working area

This parameter is ensured not only by the design features of the router, but also by the presence of special lighting in its equipment.

Milling unit equipment

The functionality and ease of use of the equipment almost entirely depend on this property. That’s why, when purchasing any router (including for inserting hinges), opt for models equipped with different holders, additional attachments and other elements.

When choosing a router, you need not only to hold such a device in your hands, but also to turn it on. This way you can evaluate how freely and simply the working head of the equipment moves, test the moving elements of the milling cutter for free play and distortions, and find the level of noise emitted by the device during operation.

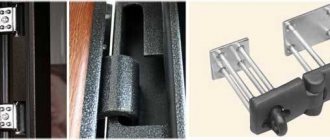

A useful addition to the router is a device for cutting hinges and door locks

By following these easy tips when choosing a hand router, you can purchase a device that will suit you both in terms of its technical features and ease of use.

Castle part

First of all, you need to select and prepare a feather drill. The diameter should be 2-4 mm larger than the thickness of the embedded part of the lock. It’s better to give a larger margin: it’s difficult to ideally hold the drill perpendicular to the end of the door; there will probably be a small error due to the fact that the drill may twitch slightly along different fibers . To ensure that the hole does not turn out to be too small, or, conversely, too deep, we wrap the perk with electrical tape at a level slightly larger than the dimensions of the recessed part. Markers and pencils are not very suitable for marking as they wear out quickly.

@youtube.com, channel DIY apartment renovation (Remontkv.pro)

After the nest is ready, we are not in a hurry to choose a recess for the cover. Firstly, we check whether the lock fits into the socket , and secondly, we set up the router on the block. And only then we select the recess.

The hole for the handle is drilled last. And then after we once again assessed the lock against the main frame and made sure that we had not made a mistake with the preliminary markings. Again, take a drill with a diameter of 12-16 millimeters - the handle will block the hole, and no one has canceled the error in measurements.

A common mistake is that the mating part of the lock on the frame is marked until the door is already installed and the mounting foam has dried. Don't do this! The answer will take its position only after installation, so do not try to calculate or guess it. There is no need to rush here, otherwise, most likely, you will have to interrupt it in place - for some reason the lock tongue will not fall into the slot intended for it.

Source

Preparing grooves for door hinges and locks

In order for the grooves created using a hand router for mounting door locks and hinges to be made very accurately and perfectly, it is recommended to use special templates for inserting hinges and locks. Purchasing a template for inserting locks and hinges of various designs and sizes on the modern market does not present any problems.

In order not to waste money on such a device for inserting, you can make it yourself. Without the help of others, you can make a very successful template for inserting hinges and locks from available materials - wooden boards and bars, slats, chipboard, threaded fasteners.

How to make a regular template

Getting a finished hole Installing a stubborn block Testing the template

The process of forming grooves using a hand router and the following installation of hinges for installing doors is carried out in the following sequence:

Preparing the site for installing the second half of the hinge, which is installed on the door frame, is carried out using a similar method. Exactly the same technology is used to prepare the groove into which the door lock will be installed.

If you have never used a manual router before when cutting in door locks and hinges, before starting work, study this function in detail by watching the corresponding video.

Source

Using a template

The procedure in question is also carried out with a special template. You can get it yourself as follows:

- First, the offset of the cutter is measured.

- You can determine the dimensions of the template for insertion using conventional measuring tools.

- 2-3 passes are performed.

- This step produces a finished hole.

After receiving the special element in question, you can embed the hinges using other various tools.

In conclusion, we note that the process of cutting hinges with a router is carried out to obtain a high-quality niche. The features of the tool can significantly speed up the process and reduce the likelihood of serious defects. By using special attachments, you can significantly expand the capabilities of the device.

The best inexpensive routers for home

Using the models presented in this section, furniture is repaired, original structures are assembled, and creative design projects are implemented. A good hand-held wood router performs its functions flawlessly. Such equipment is suitable for equipping a home workshop. It can be used to perform individual professional operations.

KRÜGER KR-1650

The Kruger KR-1650 manual electric router is used for processing edges, drilling holes, and cutting grooves. The tool has a fairly high power of 1650 W and a good speed of 160,000-30,000 rpm. A spindle lock is provided to simplify the replacement of equipment. There is a connection for connecting a vacuum cleaner, thanks to which you can keep your workplace clean. The Kruger router comes with 12 cutters, spare brushes for the motor and a ruler-copier for creating recesses of the same size. The manufacturer also has a model of the Kruger KR-2400 milling cutter with a power of 2400 W. It costs a little more, but has increased performance.

Advantages:

Kolner KER 1200V

With a maximum milling depth of 50 mm, the user can use the turret step-by-step mechanism to complete multiple passes correctly. To create identical recesses, a copy insert is useful. The spindle lock makes it easy to quickly replace the cutter. It is not difficult to take into account the characteristics of the material by adjusting the rotation speed in a wide range from 15,000 to 30,000 rpm. Timely removal of sawdust will ensure that the vacuum cleaner is connected through a special pipe.

Pros:

Minuses:

Hammer FRZ1200B

Attentiveness is a clear sign of good quality. Users note:

This inexpensive router is comparable in cost to the installation of one interior door. According to user reviews, similar actions can be performed independently, even without professional skills.

Pros:

Minuses:

Bort BOF-2100

The most powerful router in the review is suitable for professional use. This technique can be used to process materials that can be damaged by thermal deformation. The lower setting level (up to 8,000 rpm) eliminates overheating of the workpiece. The engine develops sufficient power with collets up to 12 mm. The soft start system prevents unnecessary loads and damage to workpieces, and extends the service life of the vertical router.

Pros:

Minuses:

Wert EVR 1450E

Rounding out the rating of budget devices is a multifunctional router that can fully replace cutters, jigsaws and drills. The Wert EVR 1450E model is lightweight (approximately 3 kg), which allows you to perform work without unnecessary stress. This technique is suitable for making furniture, processing construction parts, and creating decorative elements. The standard equipment includes spare brushes for the electric motor, two collets, a rip fence and a copy sleeve. This vertical router is prepared for immediate use without purchasing additional components and technological devices.

Pros:

Minuses:

Furniture hinge insertion

To select a large-diameter blind hole with a hand router, you need to make a template yourself. It has a stop bar, thanks to which the tool can be easily positioned on the furniture door. It is done very simply.

Milling for a furniture hinge Source amazon.com

A rectangle with sides 280×140 mm is cut out of plywood 4-5 mm thick. Divide the width in half and draw a line. We retreat 70 mm from the corners along one of the sides along the length and also connect these points with a line. At the intersection we drill a hole with a diameter of 51 mm.

We select a wooden plank for support. Its length is 140 mm, and its cross-section is 5×30 mm. We place the stop at the very edge of the hole, stepping back from the edge of the rectangle by 15 mm. We attach the plank with glue and small nails. The template is ready.

The depth is set on the router to 11.5 mm. The template is applied to the furniture board, and the strip rests against its end. And in several passes the groove is selected. In this way, a blind hole is made for a standard furniture hinge with a 35 mm cup.

The best professional routers

This category contains models designed for heavy loads. To extend the service life, this equipment is equipped with effective protective devices. A solid safety margin of individual components prevents damage. Manual milling machines in this category are highly powerful and suitable for processing metal and ceramic workpieces. Extended equipment helps you perform complex work tasks accurately and quickly.

Which router is better to choose? In any case, it is necessary to clarify the features of the operating mode. A particularly important parameter is reliability. For a correct assessment, it is recommended to check the configuration of the compared models, protective and auxiliary functions.

Makita RP1801F

Due to its sufficient energy potential, a professional milling cutter can be used to create recesses in solid workpieces. The powerful engine operates without overload, ensuring optimal thermal conditions are maintained. At relatively low speeds, large cutters can be used. This is useful for delicate processing of products with low heat resistance. Careful assembly ensures minimal play.

Pros:

Minuses:

BOSCH POF 1400 ACE

Using this router, it is equally convenient to create standard recesses for hinges and complex threads with a unique pattern. The proprietary Fine Depth Control adjustment system ensures processing accuracy with an error of no more than 0.1 mm. Engine speed is maintained automatically using an electronic control circuit. Stability is maintained even with significant voltage drops in the power supply network. A special fastening system allows you to securely fix and dismantle the copy sleeve without additional tools. To immediately lock the rotation, you can use a large button, which is located in a convenient place for the user on the right side of the case.

Pros:

Minuses:

DeWALT D 26204 K

A good router performs its functions without excessive noise, quickly and accurately. Uniform illumination of the work area simplifies the processing of workpieces. Speed adjustment allows you to select the optimal mode of rotation of the cutter. Correctly balancing the motor armature prevents excessive vibration. Smooth start-up extends the life of the router. With the light weight of the tool, it is not difficult to perform long and complex technological operations. The efficient sawdust removal system ensures a clean and comfortable environment.

Pros:

Minuses:

The essence of the technique

Instead of hollowing out a groove in the wood with a hammer and chisel after marking the loop, we resort to another method. Using a finger cutter , we will make these indentations much faster and more beautiful.

@youtube.com, channel Repairman School

Please note: it is better to make a socket for a mortise lock using a feather drill, without making a face or reconfiguring the router. Next I will describe this technique.

What types of milling cutters are there?

The most popular tool in this category is equipped with a device for vertical movement of the head. Precision movements are ensured by special rods. The router is used to create holes, grooves, and perform other standard operations. Taking into account the design features, such milling machines are called rod , vertical or submersible .

The following modification was created specifically for edging work. A milling cutter is used to carefully process the edges of parts. In addition to wood, you can use blanks made of polymer materials, laminate or plywood sheets.

For the correct formation of paired recesses, a lamella-type (filler) is used. This processing technology is used to create edging (dowel) connections. As a rule, such equipment is purchased to equip furniture production.

Which router is better to buy for your home?

If you plan to work on wood without excessive loads, it is quite enough to purchase an entry-level model. In addition to saving money, the relatively low weight is useful, which simplifies handling of the equipment. But you should correctly assess the significance of larger investments when purchasing professional-grade equipment. With this choice you can count on the following advantages:

The presented rating of the best routers for professional work and at home is recommended to be used taking into account the characteristics of future operation. The distribution of positions in the list is made on the basis of a comprehensive technical analysis after studying customer reviews and evaluation by professional experts.

Source

Instructions for installing hinges in interior doors with your own hands

Author of the article: Alexandra Ivanova March 18, 2021

Door hinges are an important element of an interior door, on which its functional purpose and correct opening/closing depend. The most popular are mortise hinges. By following the instructions and recommendations of experienced craftsmen, you can install them yourself.

The best edging routers

The edging or edging router is designed to:

It is possible to perform engraving operations. The accuracy of work and productivity are affected by tool power, frequency and speed control.

WORTEX MM 5013-1 E – inexpensive

The tool performs operations on the surface of wood, plywood, and laminated workpieces. The design allows for adjustment of the immersion depth, which ensures precision and accuracy of the processing process. The cleanliness of the work area is ensured by a connected vacuum cleaner.

INGCO PLM5002 – for private workshop

The universal small router processes edges and chamfers wood, plastic and composite materials. Milling is carried out on a vertical, horizontal, inclined or shaped surface. Long service life is ensured by the power of the electric motor. A milling depth limiter is provided. Equipped with a parallel stop.

HAMMER FRZ 710 – for small businesses

Quite lightweight, equipped with a powerful engine, the trimmer is used for precise work on milling grooves, grooves, and boring edges. Performs operations on profile and copy processing of wood and drywall. The design provides the “Soft Start” function, adjustment and maintenance of a constant speed when the load changes. It is possible to use collets of three sizes.

MAKITA 3709 – optimal for a private master

A compact, lightweight, vertical edging router is used for boring grooves of any configuration, making through and blind holes, and shaping edges and chamfers. Capable of working on wood, drywall, ceramic tiles and composite materials. This is facilitated by the high spindle speed and a fairly powerful engine. Convenient for installation work when installing interior doors.

Dewalt DWE 6005 – easy adjustment

Trimmer for engraving, copying, chamfering and edge shaping. The ergonomic design creates comfortable conditions for carrying out technological operations with wood, plastic, and composites. The design ensures smooth start-up, speed control, and maintenance of selected parameters during the processing of the workpiece. It is completed with a copier on bearings and a stop.

Bosch GKF 600 – long life

A small compact trimmer for milling work on wood, plywood, chipboard, MDF, plastic blanks and composite materials. Performs the entire list of technological operations, including engraving and decorative formation. It features a high-quality electric motor and an effective ventilation system, which contributes to long-term operation of the tool. Good additional equipment allows you to get started right away.

Design Features

Not the least role in the quality indicators of reliability is given to installation work; however, when creating a design, additional safety measures are used, which are achieved through the following indicators:

- The thickness of the steel sheets used to form the door leaf increases, reaching 3 mm.

For standard products, the thickness of the steel sheet relative to the requirements of GOST standards should even exceed 3 mm.

Internal doors are subject to more stringent, far from conditional requirements, which consist in the installation of additional reinforced stiffeners in the door leaf.

At the same time, standard entrance doors are equipped with only two or a maximum of three horizontally directed stiffeners, while internal doors are equipped with a combination of vertical and horizontal stiffeners. Thus, a unique, in visual perception, steel mesh made from a square section profile or from an angular profile makes it possible to eliminate deformations and mechanical damage to the door leaf.

The weak point of many internal opening doors is the vestibule; by the way, it is worth noting that interior units are on the same list. The design of the entrance type cannot afford such a disadvantage as a gap between the sash and the frame for many reasons.

If the interior blocks can be additionally and quite easily eliminated from the existing gap in the vestibule, then the entrance fabrications are quite difficult to reconstruct in this direction. At the same time, the existing gap in the vestibule opens up more opportunities for unauthorized entry into the building. They get rid of a typical problem during the manufacturing process of the structure in factory or factory conditions, by strengthening the site in the locking area. Thus, any type of impact, including a mechanical nature, is prevented in the bud.