Articles

All photos from the article

A hacksaw is one of the most common woodworking tools that almost every man has in his home. However, like any other cutting tool, it must be sharp, otherwise its effectiveness will be significantly reduced. Below we will look in detail at how and how to properly sharpen a hacksaw on wood yourself if it has become dull.

Sharpening a wood saw with a file

How to determine when it's time to sharpen a hacksaw

An experienced carpenter can determine when it’s time to sharpen the saw by the following signs:

- the sound of cutting wood changes;

- the teeth change shade.

A number of signs are also available to less experienced people:

- increased material resistance;

- it is difficult to maintain the perpendicularity of the cut;

- the blade does not adhere well to the cutting line, the line deviates or bends;

- the blade becomes wedged in the wood.

Before sharpening the saw, it is necessary to spread the teeth, that is, to ensure that they are deviated from the plane of the blade at a certain angle. Properly spaced teeth ensure that the cut is wide enough to prevent the blade from getting stuck in the material. If the teeth are too far apart, the cutting width will be too large, which will increase material loss, broaching force, and also reduce accuracy. If you sharpen a wood saw correctly, it will restore its working qualities.

Hacksaw device

During sharpening, the following geometric characteristics of the teeth are restored:

- step;

- height;

- profile angle;

- bevel angle of cutting edges.

Important: Blades with hardened teeth cannot be sharpened. They are easy to distinguish - they are black with a blue tint. Regular blades can (and should) be sharpened in a timely manner.

Requirements for hacksaw wiring

The width of the tooth tips corresponds to the width of the cut. It was experimentally established that the best width of the layout exceeds the thickness of the blade by one and a half to two times for hard types of wood and two to three times for softer ones. Considering the most popular saw thickness for wood is one millimeter, we get a spread of up to half a millimeter for hard varieties and up to a millimeter for soft ones.

Saw teeth of various shapes

When setting, it is also very important that all teeth bend at equal angles. Teeth that are set wider than others will increase drawing resistance and wear out quickly. Teeth that are set apart further than the rest will not participate in the sawing process, and their tips will slow down the broaching and reduce its uniformity, making work difficult.

Attention: the teeth are bent starting from the middle part. An attempt to bend the tooth at the base leads to a decrease in the strength of the blade and to its destruction.

Teeth setting

The teeth deviate from the plane of the blade in a checkerboard pattern, for example, all even ones to the left, all odd ones to the right. Only very experienced carpenters are able to set saws on wood “by eye”. This skill comes after several hundred diluted saws. Less experienced craftsmen are better off using a special tool - wiring. The simplest version of the tool is a flat plate of durable metal with a slot into which the blade fits tightly, with minimal clearance. The saw blade should be clamped in a bench vice. The teeth should protrude slightly from the jaws. The teeth, one after another, are clamped into the groove of the plate tool and bent in the middle part. The wiring angle must be constantly monitored. First, bend all the even-numbered teeth in one direction, then all the odd-numbered teeth in the other. Once the wiring is complete, you can spread the jaws to the width of the wiring and stretch the fabric between them. If any of the teeth are bent more than necessary, they will hit the vice. They need to be fixed.

Teeth setting

Canvases with hardened teeth are not subject to routing.

Consumables

In electric sharpeners, special wheels are used to sharpen chains, which are gradually ground down.

Instructions for replacing the wheel are in the user manual, but we’ll talk about the characteristics that need to be taken into account when buying a new one.

The characteristics of the grinding wheel are as follows:

- grain size (the number of grains per square centimeter, the fewer grains, the smoother the sharpening);

- outside diameter;

- bore diameter;

- thickness.

Important: when purchasing a new wheel for a sharpening machine, you must make sure that the diameter of the mounting hole and the maximum diameter of the wheel correspond to the same parameters of the machine, otherwise the wheel will not fit.

The diameter of the mounting hole of the circle must exactly match the mounting sleeve of the machine; the outer diameter can be chosen a little smaller, this is not critical.

The choice of grinding wheel thickness depends on the size of the chain that you plan to sharpen. Circles with a thickness of 3.2 and 4.5 mm are mainly used.

A consumable material for manual machines is a file.

On our website you can find an article that describes in detail how to choose a file for sharpening a chain; you need to select a file for a manual machine in the same way.

Height alignment

With different heights of cutting teeth, the efficiency of woodworking is greatly reduced. The higher ones take on a greater load and are subject to accelerated wear, while the lower ones do not participate in cutting. The drawing becomes uneven and jerky. Both the accuracy of the cut and the quality of the cut surface are reduced. Alignment of the height of the teeth should be carried out before sharpening the blade. The height is checked as follows: the canvas is pressed against a sheet of paper lying on the table. The profile is imprinted on a sheet, and from the imprint you can determine the height of a particular tooth. To align teeth with different heights, the blade must be clamped in a bench vice. Teeth protruding above others must be ground down with a file.

Device for leveling tooth heights

Universal sharpening machine

Such a model, as is not difficult to understand from the name, will allow you to perform all the operations described in the previous paragraph. At first glance, such a solution seems ideal. But the following factor introduces a fair fly in the ointment: an electric tool will be more susceptible to various breakdowns and failures. This is due to multitasking - other electrical and electronic devices suffer from similar problems. But you can simultaneously perform both rough and fine surface treatment. With the help of such a “beast” you can sharpen objects of both flat and three-dimensional shapes

General requirements for sharpening

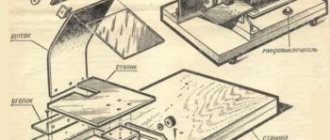

You can sharpen a hacksaw on wood in a regular vice, but this is inconvenient and time-consuming. It is better to use the so-called multi-axis vice, the frame of which is rotated and fixed at a certain angle so that the working stroke of the file is horizontal. There is also a specialized device that clamps the blade at angles of 90° and 45° to the plane of the work table. It is attached to the workbench with a clamp. The work area must be well illuminated with a gooseneck lamp. Such equipment for sharpening a hacksaw on wood can be purchased at a tool store, or you can make it yourself.

On a base of wood measuring 2x5 cm, two right-angled isosceles triangles and a steel plate of 20x3 mm are attached from a block with a thickness of 2 cm. A support plate made of plywood or OSB with a thickness of one and a half centimeters with dimensions of 15x40 cm is attached to the triangles, and the same plate-clamp is attached to it from below on hinges. The plates are tightened with screws or studs with wing nuts. If installation at an angle of 45° is required, the plates are fixed to the hypotenuses of the support triangles, and if 90°, then to the legs.

Rules for sharpening a hacksaw

To sharpen a saw, you will also need several files, differing in cross-section and notch pitch. All of them must be in good working order, with no cut lines knocked down or clogged with dust. To sharpen a saw on wood, the file must be moved smoothly, with constant pressure and at a constant angle. The working movement of the file is carried out “from itself”. It should easily pull towards itself, practically without touching the surface of the metal.

Review of popular sharpeners

There are a large number of chain sharpening machines on sale, which, in fact, differ only in name and manufacturer. From a technical point of view, most of the machines that can be found on sale are practically no different. This applies only to household models, in the price category up to 4000-5000 rubles.

Kraton CSS-180

Main characteristics of the machine:

- power 180 watts;

- rotation angle of the chain guide, 35 degrees to the left and right;

- operating voltage 220 volts;

- disc mounting hole diameter 10 mm;

- maximum circle diameter 100 mm;

- rotation speed 3000 rpm.

The machine is equipped with a transparent plastic protection. The base is stable, cast from aluminum alloy.

It is characterized by small dimensions and weight. Assembled in Russia, but parts are supplied from China. This model is classified as a household model, which means it is not intended to perform large volumes of work. The cost is within 3000 rubles. Similar machines can be found under the brands Caliber, Vikhr, Rezer, Oregon.

ANAB X1

The professional automatic device ANAB X1 has the following characteristics:

- sharpening motor power 0.3 kW;

- pneumatic 6 bar;

- power supply 220 volts;

- sharpening angle 35 degrees;

- rotation angle 28 degrees;

- pitch of sharpened chains 1/4″, 325″, 3/8″, 404″.

Below you can watch a video of how the ANAB X1 machine works.

How to sharpen a wood hacksaw with a file

To sharpen, the blade of a hand saw must be clamped between the plates of the equipment so that the teeth rise above them by one and a half to two centimeters. For different types of blades, sharpening a hacksaw for wood is carried out in its own way.

Fixing the file for sharpening the saw

To properly sharpen a cross-section hacksaw, the blade should be set at 45°. The file should be selected with a triangular cross-section profile. To ensure proper sharpening quality, the following sequence of actions must be followed:

- sharpen the left edges of the even (farthest from the master) teeth;

- turn the canvas over;

- sharpen the left edges of the even teeth;

- form sharp cutting edges and pointed tooth tips

Proper sharpening of a hacksaw

To sharpen a longitudinal or universal hacksaw, it should be secured at an angle of 90°. Here you will need a file with a diamond-shaped cross-section. The file moves in the plane of the work table. The sequence of sharpening the teeth is the same as for cross saws. During work, burrs usually appear on unsharpened edges, larger or smaller depending on the thickness of the hacksaw blade. They should be smoothed with a “velvet” file or an abrasive stone of minimal grit. The quality of sharpening can be checked in two ways:

- To the touch. The sharpness should be felt, but no burrs should be felt.

- By color. On properly sharpened edges, no glare appears when illuminated.

The quality is also checked by trial cutting. The hacksaw should not be pulled to the side; the cutting surface should be smooth, without loose wood fibers.

Electric semi-automatic

Electrically driven sharpeners are popular due to their high productivity and sharpening quality.

As a rule, such devices are used by specialized service centers that provide paid services for editing and sharpening. With the advent of household models of sharpeners, which are distinguished by reasonable prices, they have become popular among saw owners.

Advantages of an electric sharpener:

- High sharpening speed.

- Possibility of aligning the working tooth (when sharpening by hand, the teeth of the chain are not ground down evenly).

- Ideal sharpening angle and the ability to adjust it.

- Full or partial automation of the process.

- The ability to connect from both a 220 and 12 volt network, thanks to which you can use a car battery as a power source, which is quite convenient.

The disadvantages of an electric machine for sharpening chains include the need to connect to a power source, which is not always possible if it is necessary to sharpen the headset in a plot or during logging.

Using an electric sharpener requires certain skills from the operator. For example, an incorrectly set grinding depth can lead to the working teeth overheating during the sharpening process and then losing their properties. The metal becomes soft, does not hold an edge, and the teeth become dull easily during operation.

Another downside is that during operation, the grinding wheels gradually wear out and need to be replaced, which increases the cost of owning the unit.

To avoid grinding off the wheels, you can use special diamond grinding discs of a suitable size. The service life of such discs is several times greater than the service life of a conventional grinding wheel.

Design and principle of operation

A saw chain sharpening machine consists of several elements. The base is a frame that is used to mount the motor and a vice with guide rails for the chain. The motor is usually asynchronous with high speed and direct transmission. A sharpening disc is installed on the motor shaft and secured with a guide washer and nut.

The place where the engine is attached to the frame is movable, thanks to this scheme it is possible to adjust the position of the engine in space, which is necessary to set the correct sharpening angle.

A vise with a slide is designed to install the chain and hold it. A limit plate with the ability to adjust the depth of cut is attached to the vice. By turning the adjusting screw clockwise, the plate extends and the sharpening depth increases.

The operating principle of the sharpening machine is extremely simple:

- The chain is installed in the guide slide, the stop is lowered and rests against the back of the tooth being sharpened, preventing it from moving.

- After this, the engine with the disk installed on it is lowered. The disc touches the tooth and grinds down its edge.

- Next, the operator moves the chain to the next tooth and installs the stop bar, after which the process is repeated.

In practice, the principle of operation is a little more complicated, because before you start sharpening, you need to set up the machine. Setting instructions can be found in the documents for the sharpening device.

You can learn more about the operating principle of a semi-automatic chain sharpening machine by watching a video demonstrating operation of the VIHR SZTs-200 machine.

Necessary tool

To quickly and efficiently sharpen a hacksaw for wood, you should prepare a set of equipment for setting the teeth and sharpening. Required:

- Workbench;

- bench vice;

- pliers;

- whetstone;

- sandpaper;

- measuring tool: protractor and caliper;

- plumber's hammer;

- equipment that allows you to secure the blade at angles of 90° and 45°.

You will also need files:

- cross-section in the form of a triangle;

- cross-section in the form of a rhombus;

- flat ;

- files.

Sharpening tool

Sharpening a hacksaw with a file

The notch must be intact and not clogged with metal dust. If you sharpen a hacksaw on time and correctly, working with it will be easy and convenient. Such a tool will last much longer, delighting its owner with an even and precise cut and high quality surface of the wood cut.