A metal such as aluminum is very common in the world. A considerable amount of it is contained in the human body, and there is even more of it in the surrounding world. Among the materials from which houses are built, as well as in the design of any car, there is a certain amount of aluminum.

Furniture parts are often made from this substance. And if suddenly one of these breaks, then you can either purchase a new product in the appropriate store, or repair the product yourself. In the latter case, you will have to melt the metal at home, and for this you already need to know about some of the properties of this metal.

To manufacture any aluminum structure, it is not at all necessary to study in detail all the characteristics of the substance, but you should pay attention to the main points, including knowing at what temperature aluminum melts.

Composition and structure of aluminum

Aluminum is the most common metal in the earth's crust.

It is classified as a light metal. It has low density and mass. In addition, it has a fairly low melting point. At the same time, it has high ductility and shows good thermal and electrical conductivity characteristics. Aluminum crystal lattice

Aluminum structure

The tensile strength of pure aluminum is only 90 MPa. But, if you add some substances to the melt, for example, copper and a number of others, then the tensile strength increases sharply to 700 MPa. The same result can be achieved using heat treatment.

Aluminum, which has extremely high purity - 99.99%, is produced for use in laboratory purposes. For industrial applications, commercially pure aluminum is used. When producing aluminum alloys, additives such as iron and silicon are used. They do not dissolve in the aluminum melt, and the additive reduces the ductility of the base material, but at the same time increases its strength.

Appearance of a simple substance

The structure of this metal consists of simple cells consisting of four atoms. This structure is called face-centric.

Calculations show that the density of pure metal is 2.7 kg per cubic meter.

How to make a casting mold

Creating a simple solder material does not require making a special mold. You can pour metal onto a steel sheet.

The following materials are used to create the form:

- Gypsum.

- Sand.

- Clay.

- Coal ash.

- Liquid glass.

The alloy is poured into the mold in different ways:

- Open.

- Closed.

The open method is simple. The molten metal is poured into a regular container, tin can, cup, etc. When the substance solidifies, the blank is removed from the container. If the shape of the metal object is not important, you can leave the aluminum on a durable surface.

Complex casting requires the product to comply with the specified parameters; for this, molding elements are used. Silica is a common substance that is often used in open pour applications. The product consists of two containers into which earth is poured and compacted. The silica elements are compressed and a casting pattern is placed between them. This way you can get an accurate print of the required part. The model is removed and hot aluminum is placed into the mold. For the closed casting method, river sand mixed with liquid glass is used.

Plaster can be used for one-time casting. Models are made from paraffin or foam plastic. The use of such materials requires working in an open space with good air access. The foam is not removed from solid plaster, it is filled with hot aluminum. The combustion products of this substance are harmful to health.

Melting aluminum

Influence of alloying elements and impurities

Adding other elements to aluminum, including alloying ones, reduces its melting point, or more precisely, the beginning of its melting. Thus, for some cast aluminum alloys with a high content of silicon and magnesium, the melting point decreases to almost 500 °C. In general, the concept of “melting point” applies only to pure metals and other crystalline substances. Alloys do not have a specific melting point: the process of their melting (and solidification) occurs in a certain temperature range.

Figure 4 - Change in the specific volume of pure metal (aluminum) and the alloy of this metal (aluminum alloy) [4]

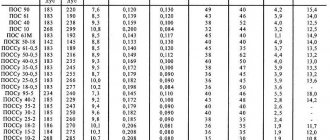

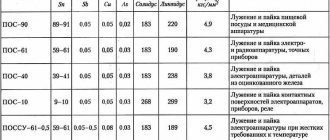

Melting temperature ranges

The table below presents the liquidus and solidus temperatures of some commercial wrought alloys. It must be borne in mind that the concepts of solidus and liquidus temperatures are defined for equilibrium transformations of the liquid phase into the solid phase and vice versa, that is, for infinite duration of the processes. In practice, corrections must be made taking into account the rate of heating or cooling.

Melting silumin

Not all alloys have a range between solidus and liquidus temperatures. Such alloys are called eutectic. For example, in an aluminum alloy containing 12.5% silicon, the liquidus and solidus points are reduced to a point: this alloy, like pure metals, has not an interval, but a melting point. This point and temperature is called eutectic. This alloy belongs to the famous cast aluminum-silicon alloys - silumins with a narrow solidus-liquidus interval, which gives them the best casting properties.

In the Al-Si binary alloy, the solidus temperature is constant and amounts to 577 °C. As the silicon content increases, the liquidus temperature decreases from a maximum value for pure aluminum of 660 °C to coincide with the solidus temperature of 577 °C at a silicon content of 12.6%.

Among other alloying elements of aluminum, magnesium lowers the melting point the most: the eutectic temperature of 450 ° C is achieved with a magnesium content of 18.9%. Copper gives a eutectic temperature of 548 °C, and manganese - only 658 °C! Most alloys are not double, but triple and even quadruple. Therefore, with the combined influence of several alloying elements, the solidus temperature—the beginning of melting or the end of solidification—can be even lower.

Application of metal in industrial production

Under natural conditions, aluminum tends to form a thin oxide film, which prevents reactions with water and nitric acid (without heating). When the film is destroyed as a result of contact with alkalis, the chemical element acts as a reducing agent.

Keeping in mind that most binary systems of aluminum and magnesium are very well established, transferring a multicomponent system into a known "quasi-binary" system has great industrial and research potential. This type of system could be used to calculate several parameters of the thermophysical process and the solidification process of multicomponent aluminum alloys under casting or melt conditions. To calculate various thermophysical and metallurgical parameters of solidifying aluminum-cast alloys, the characteristic solidification temperatures of the alloys must be known with the highest possible degree of accuracy.

In order to prevent the formation of an oxide film, other metals (gallium, tin, indium) are added to the alloy. The metal is practically not subject to corrosion processes. It is a popular material in various industries.

Properties and characteristics

Aluminum is a metal with a silvery-white surface. As already noted, its density is 2.7 kg/m3. The temperature is 660°C.

Its electrical conductivity is equal to 65% of copper and its alloys. Aluminum and most of its alloys are resistant to corrosion. This is due to the fact that an oxide film forms on its surface, which protects the base material from exposure to atmospheric air.

In the untreated state, its strength is 60 MPa, but after adding certain additives it increases to 700 MPa. The hardness in this state reaches 250 HB.

Aluminum can be easily processed under pressure. To remove work hardening and restore ductility after processing, aluminum parts are annealed, and the temperature should be within 350°C.

Toxicity

It has a slight toxic effect, but many water-soluble inorganic aluminum compounds remain in a dissolved state for a long time and can have a harmful effect on humans and warm-blooded animals through drinking water. The most toxic are chlorides, nitrates, acetates, sulfates, etc. For humans, the following doses of aluminum compounds (mg/kg body weight) have a toxic effect when ingested: aluminum acetate - 0.2-0.4; aluminum hydroxide - 3.7-7.3; aluminum alum - 2.9. Primarily affects the nervous system (accumulates in nervous tissue, leading to severe disorders of the central nervous system). However, the neurotoxicity of aluminum has been studied since the mid-1960s, since the accumulation of the metal in the human body is prevented by its elimination mechanism. Under normal conditions, up to 15 mg of the element per day can be excreted in the urine. Accordingly, the greatest negative effect is observed in people with impaired renal excretory function.

The standard for aluminum content in drinking water is 0.2 mg/l. In this case, this MPC can be increased to 0.5 mg/l by the chief state sanitary doctor for the relevant territory for a specific water supply system.

Melting point of aluminum

The production of aluminum melt, like many other materials, occurs after thermal energy has been supplied to the original metal. It can be supplied either directly into it or from outside.

The melting point of aluminum directly depends on the level of its purity:

- Ultra-pure aluminum melts at a temperature of 660.3°C.

- With an aluminum content of 99.5%, the melting point is 657°C.

- With a content of this metal of 99%, the melt can be obtained at 643°C.

Aluminum melt

Aluminum production process

An aluminum alloy can contain various substances, including alloying ones. Their presence leads to a decrease in the melting point. For example, if there is a large amount of silicon, the temperature can drop to 500°C. In fact, the concept of melting point applies to pure metals. Alloys do not have any constant melting point. This process occurs within a certain heating range.

In materials science there is a concept - solidus and liquidus temperatures.

The first temperature indicates the point at which the melting of aluminum begins, and the second shows at what temperature the alloy will finally melt. In the interval between them, the alloy will be in a mushy state.

§ 56. PRODUCTION OF CASTINGS FROM ALUMINUM ALLOYS by chill casting.

The bulk of castings from aluminum alloys are produced by casting in chill molds and under pressure.

Many small and large-sized castings with walls with a thickness of 2 or more millimeters and a weight of up to 300 kg or more are made in chill molds. The widespread use of aluminum alloys for chill casting is explained by their good casting properties, which make it possible to confidently produce large-sized castings without defects.

Metal rods and liners are widely used to design various internal cavities and through holes when casting aluminum alloys in a mold.

For the manufacture of castings from aluminum alloys, molds with different parting planes and designs of gating systems are used.

The melt supply from above is used when casting AL2, AL4 alloys. The advantage of such a gating system is that the riser simultaneously serves as a thrust and a profit, feeding massive sections of the casting from above, and directed crystallization of the melt from bottom to top is ensured. This pouring method is used to produce simple castings with a height of no more than 150 mm with smooth transitions between walls of different thicknesses. Filling from above also gives a good result with a variable angle of inclination of the chill mold, i.e. when the melt is poured into an inclined chill mold, and at the end of pouring it is returned to a vertical position.

The melt supply from below is used when casting large and complex castings (engine cylinder blocks, crankcases, etc.). If the height of the cast part is more than 200 mm, a riser with various bends is used, which reduce the flow rate of the melt.

To supply the melt to the molds intended for the production of castings such as pistons, pipes, housings and other parts, a vertical slot gating system is used. The slot feeder ensures smooth filling of the die cavity with the melt, reduces the likelihood of aluminum oxide films getting into the casting body and creates its directed solidification.

Aluminum alloys are poured into the mold at the temperature given in table. 13.

13. Temperatures for pouring aluminum alloys

| Alloy | Temperature, °C | |

| overheating | fills | |

| AL2 | 80—160 | 720—800 |

| AL7, AL12 | 60—110 | 700—750 |

| AL8 | 100—150 | 700—750 |

| AL9 | 100—150 | 700—800 |

| AL3 | 100—250 | 700—850 |

| AL4 | 100—220 | 700—820 |

| AL5 | 100—200 | 700—750 |

Before pouring, the chill molds are heated to a temperature of 150-250°C. When producing thin-walled castings, the heating temperature can reach 300-350°C, in some cases 500°C.

To ensure that the working surfaces of the chill mold do not cool down below the required temperature during cyclic pouring, electric heaters are used; the wall of the chill mold is made of two layers with a gap filled with asbestos or other heat-insulating material. In some cases, the thickness of the working wall in chill molds is reduced, which ensures significantly better heating from the poured melt.

The time from the end of pouring to knocking out of the casting mold is taken from 6 to 10 s when casting small thin-walled castings, for compact thick-walled castings weighing from 3 to 8 kg, respectively, from 1 to 3 minutes.

Castings of aluminum alloys obtained in a chill mold are subjected to standard heat treatment. Annealing (T2 mode) is used to relieve internal stresses and reduce gas content; hardening followed by short-term (incomplete) artificial aging (T5 mode)—to obtain high tensile strength and maintain increased ductility; complete artificial aging (T6 mode) - to achieve maximum tensile strength with a slight decrease in ductility.

The choice of one or another type of heat treatment is determined by the composition of the aluminum alloy and the purpose of the cast part.

Source

Melting point of pure aluminum

Melting of aluminum , like other substances, occurs when thermal energy is supplied to it, from the outside or directly into its volume, as happens, for example, with induction heating.

The melting point of aluminum depends on its purity:

- Melting point of ultra-pure aluminum 99.996%: 660.37 °C.

- With an aluminum content of 99.5%, melting begins at 657 °C.

- With an aluminum content of 99.0%, melting begins at 643 °C.

General information about the process

In the solid state, the crystal lattice of a metal consists of grains that are spatially oriented in an arbitrary manner (such structures are called polycrystalline).

During the melting process, the volume of the metal increases. In chemically pure ones, it occurs quickly and at certain temperatures. Example. Actual Al melting temperature (t):

- ultrapure, with a percentage of Al 99.996%, equals 660.37 ° C;

- when the proportion of pure metal decreases to 99.5, t=657°C;

- at 99.0%, t=643°C.

A sharp increase in volume occurs under the influence of a certain heat, which initiates melting. This quantity is called latent heat.

The latter contributes to the fact that the original crystalline structure of the material loses order and density. The process is reversible (cooling/heating).

Decrease temperature

Before you start melting metal, you can perform certain operations that will reduce the melting temperature. For example, sometimes aluminum powder is melted. In a powdered state, the metal begins to melt somewhat faster. But with such processing, there is a real danger that when interacting with oxygen contained in the atmosphere, aluminum powder will begin to oxidize with a large release of heat and the formation of metal oxides; this process occurs at a temperature of 2300 degrees. The main thing is to prevent contact between the melt and water at this moment of melting. This will cause an explosion.

Melting point of metals

Metals and non-metals

Any piece of metal, such as aluminum, contains millions of individual crystals called grains. Each grain has its own unique orientation of the atomic lattice, but collectively the grains are oriented randomly within that piece. This structure is called polycrystalline.

Amorphous materials such as glass differ from crystalline materials such as aluminum in two important ways that are related to each other:

- lack of long-range order in molecular structure

- differences in the nature of melting and thermal expansion.

The difference in molecular structure can be seen in Figure 1. The close-packed and ordered crystal structure is shown on the left. An amorphous material is shown on the right: a less dense structure with a random arrangement of atoms.

Figure 1 – Structure of crystalline (a) and amorphous (b) materials. Crystalline structure: ordered, repeating and dense, amorphous structure - more loosely packed with a random arrangement of atoms.

Melting metals

This difference in structure manifests itself during the melting of metals, including the melting of aluminum of various purities and its alloys. Less densely packed atoms produce an increase in volume (decrease in density) compared to the same metal in a solid crystalline state.

Melting process at home

The relatively low melting point of aluminum allows this operation to be carried out at home. It should be noted right away that using a powdered mixture as a raw material in a home workshop is too dangerous. Therefore, either ingots or cut wire are used as raw materials. If there are no special quality requirements for the future product, then anything made from this metal can be used for melting.

Melting aluminum in a homemade forge

In this case, it is not particularly important whether the raw materials are coated with paint or not. When aluminum melts, all foreign substances will simply burn out and be removed along with the slag.

To obtain a high-quality melting result, it is necessary to use materials called fluxes. They are designed to solve the problem of binding and removing foreign impurities and contaminants from the melt.

Means of protection

A home craftsman who decides to melt aluminum at home should be aware that this is a rather dangerous process. And therefore it is impossible to do without the use of protective equipment. In particular, gloves, an apron, and goggles should be used. The fact is that the melt temperature is within 600 degrees. Therefore, it makes sense to use the protective equipment that welders use.

Using protective equipment when melting aluminum

By the way, when melting aluminum and using cleaning chemicals, it is necessary to protect the respiratory system from combustion products.

Defects in castings made of non-ferrous alloys and methods for their prevention

Common characteristic defects of castings during chill casting are:

- underfilling and non-filling at low temperature of the melt and chill mold before pouring, insufficient pouring speed, high gas content of rods and paints, poor ventilation of the chill mold;

- shrinkage defects (sinks, sink marks, porosity, cracks) due to insufficient power supply to massive casting units, excessively high temperature of the melt and die, local overheating of the die, irrational design of the gating system;

- cracks due to untimely detonation of a metal rod or insert, high pouring temperature, low-tech casting design;

- slag inclusions when using contaminated charge materials, insufficient refining of the alloy before pouring, improper operation of the gating system;

- gas porosity due to disruption of the smelting process (use of mixtures contaminated with moisture and oil, excessively high overheating, insufficient refining or deoxidation of the alloy).

Specific defects in castings made of magnesium alloys are defects of shrinkage origin (porosity, cracks, looseness), caused by a wide temperature range of their solidification. To eliminate these defects, it is necessary to fine-tune and strictly adhere to technological conditions - melt and chill temperature, use of paint, etc. Often, castings made of magnesium alloys, due to poor performance of the gating system, are affected by slag inclusions, which leads to corrosion of the casting during its operation and storage. Such defects are eliminated by careful fine-tuning of the gating system.

Specific defects in castings from copper alloys are: gas porosity due to poor refining and cleaning of the alloy from slag particles, secondary oxide films when casting aluminum bronzes due to the division of the melt flow into jets and its oxidation in the mold, cracks due to poor deoxidation of the alloys during melting.

Source