Each metal or alloy has unique properties, including its melting point. In this case, the object passes from one state to another, in a particular case, it becomes liquid from solid. To melt it, you need to apply heat to it and heat it until the desired temperature is reached. At the moment when the desired temperature point of a given alloy is reached, it may still remain in a solid state. As exposure continues, it begins to melt.

Mercury has the lowest melting point - it melts even at -39 °C, tungsten has the highest - 3422 °C. For alloys (steel and others) it is extremely difficult to determine the exact figure. It all depends on the ratio of the components in them. For alloys it is written as a numerical interval.

How the process works

Elements, whatever they are: gold, iron, cast iron, steel or any other, melt approximately the same. This occurs due to external or internal heating. External heating is carried out in a thermal furnace. For internal applications, resistive heating is used, passing an electric current or induction heating in a high-frequency electromagnetic field . The impact is approximately the same.

When heating occurs , the amplitude of thermal vibrations of molecules increases. Structural lattice defects appear , accompanied by the rupture of interatomic bonds. The period of lattice destruction and accumulation of defects is called melting.

Depending on the degree at which metals melt, they are divided into:

- low-melting - up to 600 °C: lead, zinc, tin;

- medium-melting - from 600 °C to 1600 °C: gold, copper, aluminum, cast iron, iron and most of all elements and compounds;

- refractory - from 1600 °C: chromium, tungsten, molybdenum, titanium.

Depending on what the maximum degree is, the melting apparatus is selected. It should be stronger the stronger the heating.

The second important value is the boiling degree. This is the parameter at which liquids begin to boil. As a rule, it is twice the melting point. These values are directly proportional to each other and are usually given at normal pressure.

If the pressure increases, the amount of melting also increases. If the pressure decreases, then it decreases.

Characteristics table

Metals and alloys are an indispensable basis for forging , foundry, jewelry and many other areas of production. Whatever the craftsman does ( gold jewelry , cast iron fences, steel knives or copper bracelets) , in order to work correctly, he needs to know the temperatures at which this or that element melts.

To find out this parameter, you need to refer to the table. In the table you can also find the boiling degree.

Among the most commonly used elements in everyday life, the melting point indicators are as follows:

- aluminum - 660 °C;

- copper melting point - 1083 °C;

- melting point of gold - 1063 °C;

- silver - 960 °C;

- tin - 232 °C. Tin is often used for soldering, since the temperature of a working soldering iron is exactly 250–400 degrees;

- lead - 327 °C;

- melting point of iron - 1539 °C;

- the melting point of steel (an alloy of iron and carbon) is from 1300 °C to 1500 °C. It varies depending on the saturation of the steel with components;

- melting point of cast iron (also an alloy of iron and carbon) - from 1100 °C to 1300 °C;

- mercury - -38.9 °C.

As is clear from this part of the table, the most fusible metal is mercury, which at positive temperatures is already in a liquid state.

The boiling point of all these elements is almost twice, and sometimes even higher than the melting point. For example, for gold it is 2660 °C, for aluminum - 2519 °C , for iron - 2900 °C, for copper - 2580 °C, for mercury - 356.73 °C.

For alloys such as steel, cast iron and other metals, the calculation is approximately the same and depends on the ratio of components in the alloy.

Read also: How to bend the end part of galvanized steel

The maximum boiling point of metals is rhenium - 5596 ° C. The highest boiling point is for the most refractory materials.

There are tables that also indicate the density of metals . The lightest metal is lithium, the heaviest is osmium. Osmium has a higher density than uranium and plutonium when viewed at room temperature. Light metals include: magnesium, aluminum, titanium. Heavy metals include most common metals: iron, copper, zinc, tin and many others. The last group is very heavy metals, these include: tungsten, gold, lead and others.

Another indicator found in the tables is the thermal conductivity of metals . Neptunium is the worst conductor of heat, and the best metal in terms of thermal conductivity is silver. Gold, steel, iron, cast iron and other elements are in the middle between these two extremes. Clear characteristics for each can be found in the required table.

Each metal or alloy has unique properties, including its melting point. In this case, the object passes from one state to another, in a particular case, it becomes liquid from solid. To melt it, you need to apply heat to it and heat it until the desired temperature is reached. At the moment when the desired temperature point of a given alloy is reached, it may still remain in a solid state. As exposure continues, it begins to melt.

Mercury has the lowest melting point - it melts even at -39 °C, tungsten has the highest - 3422 °C. For alloys (steel and others) it is extremely difficult to determine the exact figure. It all depends on the ratio of the components in them. For alloys it is written as a numerical interval.

How the process works

Elements, whatever they are: gold, iron, cast iron, steel or any other, melt approximately the same. This occurs due to external or internal heating. External heating is carried out in a thermal furnace. For internal purposes, resistive heating is used, passing electric current or induction heating in a high-frequency electromagnetic field

. The impact is approximately the same.

When does heating occur

, the amplitude of thermal vibrations of molecules increases.

Structural lattice defects

appear , accompanied by the rupture of interatomic bonds. The period of lattice destruction and accumulation of defects is called melting.

Depending on the degree at which metals melt, they are divided into:

- low-melting - up to 600 °C: lead, zinc, tin;

- medium-melting – from 600 °C to 1600 °C: gold, copper, aluminum, cast iron, iron and most of all elements and compounds;

- refractory – from 1600 °C: chromium, tungsten, molybdenum, titanium.

Depending on what the maximum degree is, the melting apparatus is selected. It should be stronger the stronger the heating.

The second important value is the boiling degree. This is the parameter at which liquids begin to boil. As a rule, it is twice the melting point. These values are directly proportional to each other and are usually given at normal pressure.

If the pressure increases, the amount of melting also increases. If the pressure decreases, then it decreases.

Characteristics table

Metals and alloys are an indispensable basis for forging

, foundry production, jewelry production and many other areas of production.

Whatever the craftsman does ( gold jewelry

, cast iron fences, steel knives or

copper bracelets)

, in order to work correctly, he needs to know the temperatures at which this or that element melts.

To find out this parameter, you need to refer to the table. In the table you can also find the boiling degree.

Among the most commonly used elements in everyday life, the melting point indicators are as follows:

- aluminum – 660 °C;

- copper melting point – 1083 °C;

- gold melting point – 1063 °C;

- silver – 960 °C;

- tin – 232 °C. Tin is often used for soldering, since the temperature of a working soldering iron is exactly 250–400 degrees;

- lead – 327 °C;

- melting point of iron – 1539 °C;

- the melting point of steel (an alloy of iron and carbon) is from 1300 °C to 1500 °C. It varies depending on the saturation of the steel with components;

- melting point of cast iron (also an alloy of iron and carbon) – from 1100 °C to 1300 °C;

- mercury – -38.9 °C.

As is clear from this part of the table, the most fusible metal is mercury, which at positive temperatures is already in a liquid state.

Read also: How to test a non-polar capacitor with a multimeter

The boiling point of all these elements is almost twice, and sometimes even higher than the melting point. For example, for gold it is 2660 °C, for aluminum

- 2519 °C

, for iron - 2900 °C, for copper - 2580 °C, for mercury - 356.73 °C.

For alloys such as steel, cast iron and other metals, the calculation is approximately the same and depends on the ratio of components in the alloy.

The maximum boiling point of metals is rhenium – 5596

°C

. The highest boiling point is for the most refractory materials.

There are tables that also indicate the density of metals

.

The lightest metal is lithium, the heaviest is osmium. Osmium has a higher density than uranium

and plutonium when viewed at room temperature. Light metals include: magnesium, aluminum, titanium. Heavy metals include most common metals: iron, copper, zinc, tin and many others. The last group is very heavy metals, these include: tungsten, gold, lead and others.

Another indicator found in the tables is the thermal conductivity of metals

. Neptunium is the worst conductor of heat, and the best metal in terms of thermal conductivity is silver. Gold, steel, iron, cast iron and other elements are in the middle between these two extremes. Clear characteristics for each can be found in the required table.

Melting point, along with density, refers to the physical characteristics of metals

.

The melting point of a metal

is the temperature at which a metal changes from its normal solid state (except mercury) to a liquid state when heated.

During melting, the volume of the metal practically does not change, so normal atmospheric pressure does not affect

.

The melting point of metals ranges from -39 degrees Celsius to +3410 degrees

. For most metals, the melting point is high, however, some metals can be melted at home by heating on a regular burner (tin, lead).

Classification of metals by melting point

- Low-melting metals

, the melting point of which ranges

up to 600

degrees Celsius, for example

zinc, tin, bismuth

. - Medium-melting metals

that melt at temperatures

from 600 to 1600

degrees Celsius: such as

aluminum, copper, tin, iron

. - Refractory metals

, the melting point of which reaches

more than 1600

degrees Celsius -

tungsten, titanium, chromium

, etc. - - the only metal that is in a liquid state under normal conditions (normal atmospheric pressure, average ambient temperature). The melting point of mercury is about -39 degrees

Celsius.

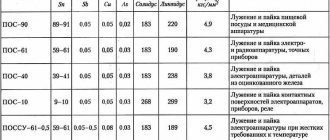

Table of melting temperatures of metals and alloys

650

1000

| Metal | |

| Aluminum | 660,4 |

| Tungsten | 3420 |

| Duralumin | |

| Iron | 1539 |

| Gold | 1063 |

| Iridium | 2447 |

| Potassium | 63,6 |

| Silicon | 1415 |

| Brass | |

| Low melting alloy | 60,5 |

| Magnesium | 650 |

| Copper | 1084,5 |

| Sodium | 97,8 |

| Nickel | 1455 |

| Tin | 231,9 |

| Platinum | 1769,3 |

| Mercury | –38,9 |

| Lead | 327,4 |

| Silver | 961,9 |

| Steel | 1300-1500 |

| Zinc | 419,5 |

| Cast iron | 1100-1300 |

When melting metal for the manufacture of metal castings, the choice of equipment, material for molding the metal, etc. depends on the melting temperature. It should also be remembered that when alloying the metal with other elements, the melting temperature most often decreases

.

Do not confuse the concepts of “metal melting point” and “metal boiling point” - for many metals these characteristics are significantly different: for example, silver melts at a temperature of 961 degrees Celsius, and boils only when the temperature reaches 2180 degrees.

The melting point of a metal is the minimum temperature at which it changes from solid to liquid. When melting, its volume practically does not change. Metals are classified by melting point depending on the degree of heating.

Melting point of steel

A table of melting temperature values for common grades of steel is presented. Steels for castings, structural, heat-resistant, carbon and other classes of steels are considered.

The melting point of steel ranges from 1350 to 1535°C.

The steels in the table are arranged in order of increasing melting point. Melting point of steel - table

| Steel | tmelt, °С | Steel | tmelt, °С |

| Steels for castings Х28Л and Х34Л | 1350 | Corrosion-resistant heat-resistant 12Х18Н9Т | 1425 |

| Structural steel 12Х18Н10Т | 1400 | Heat-resistant high-alloy 20Х23Н13 | 1440 |

| Heat-resistant high-alloy 20Х20Н14С2 | 1400 | Heat-resistant high-alloy 40Х10С2М | 1480 |

| Heat-resistant high-alloy 20Х25Н20С2 | 1400 | Corrosion-resistant steel X25S3N (EI261) | 1480 |

| Structural steel 12Х18Н10 | 1410 | Heat-resistant high-alloy 40Х9С2 (ESKH8) | 1480 |

| Corrosion-resistant heat-resistant 12Х18Н9 | 1410 | Corrosion-resistant ordinary 95Х18…15Х28 | 1500 |

| Heat-resistant steel Х20Н35 | 1410 | Corrosion-resistant heat-resistant 15Х25Т (EI439) | 1500 |

| Heat-resistant high-alloy 20Х23Н18 (ЭИ417) | 1415 | Carbon steels | 1535 |

Sources:

- Volkov A.I., Zharsky I.M. Large chemical reference book. - M: Soviet School, 2005. - 608 p.

- Kazantsev E.I. Industrial furnaces. Reference manual for calculations and design.

- Physical quantities. Directory. A. P. Babichev, N. A. Babushkina, A. M. Bratkovsky and others; Ed. I. S. Grigorieva, E. Z. Meilikhova. - M.: Energoatomizdat, 1991. - 1232 p.

Medium melting metals

Medium-melting metals begin to transform from solid to liquid at temperatures from 600°C to 1600°C. They are used to make slabs, reinforcements, blocks and other metal structures suitable for construction. This group of metals includes iron, copper, aluminum, and they are also part of many alloys. Copper is added to alloys of precious metals such as gold, silver, and platinum. 750 gold consists of 25% alloy metals, including copper, which gives it a reddish tint. The melting point of this material is 1084 °C. And aluminum begins to melt at a relatively low temperature of 660 degrees Celsius. This is a lightweight, ductile and inexpensive metal that does not oxidize or rust, therefore it is widely used in the manufacture of tableware. The melting point of iron is 1539 degrees. This is one of the most popular and affordable metals, its use is widespread in the construction and automotive industries. But due to the fact that iron is subject to corrosion, it must be additionally processed and covered with a protective layer of paint, drying oil, or prevent moisture from entering.

Read also: Designation of surface cleanliness class in drawings

Zirconium

It is one of the most expensive metals, so its use for technical purposes is difficult. However, its physical characteristics make it simply indispensable in many other industries.

Under normal conditions it is a beautiful silvery-white metal. It has a fairly high melting point - 1855 oC. It has good hardness and corrosion resistance, as it is not chemically active. It also has excellent biological compatibility with human skin and the entire body as a whole. This makes it a valuable metal for medical use (instruments, prosthetics, etc.).

The main areas of application of zirconium and its compounds, including alloys, are as follows:

- nuclear energy;

- pyrotechnics;

- metal alloying;

- medicine;

- production of bioware;

- construction material;

- like a superconductor.

Even jewelry that can influence the improvement of human health is made from zirconium and alloys based on it.

Refractory metals

The temperature of refractory metals is above 1600°C. These are tungsten, titanium, platinum, chromium and others. They are used as light sources, machine parts, lubricants, and in the nuclear industry. They are used to make wires, high-voltage wires, and are used to melt other metals with a lower melting point. Platinum begins to transition from solid to liquid at a temperature of 1769 degrees, and tungsten at a temperature of 3420°C.

Mercury is the only metal that is in a liquid state under normal conditions, namely, normal atmospheric pressure and average ambient temperature. The melting point of mercury is minus 39°C. This metal and its vapors are poisonous, so it is used only in closed containers or in laboratories. A common use of mercury is as a thermometer to measure body temperature.

Each metal and alloy has its own unique set of physical and chemical properties, not least of which is the melting point. The process itself means the transition of a body from one state of aggregation to another, in this case, from a solid crystalline state to a liquid one. To melt a metal, it is necessary to apply heat to it until the melting temperature is reached. With it, it can still remain in a solid state, but with further exposure and increased heat, the metal begins to melt. If the temperature is lowered, that is, some of the heat is removed, the element will harden.

The highest melting point among metals belongs to tungsten : it is 3422C o, the lowest is mercury: the element melts at -39C o. As a rule, it is not possible to determine the exact value for alloys: it can vary significantly depending on the percentage of components. They are usually written as a number interval.

Molybdenum

If you find out which metal is the most refractory, then, in addition to the indicated tungsten, you can also name molybdenum. Its melting point is 2623 °C. At the same time, it is quite hard, plastic and amenable to processing.

It is mainly used not in its pure form, but as an integral component of alloys. They, thanks to the presence of molybdenum, are significantly strengthened in wear resistance, heat resistance and anti-corrosion.

Some molybdenum compounds are used as technical lubricants. This metal is also an alloying material that simultaneously affects both strength and corrosion resistance, which is very rare.

How it happens

Melting of all metals occurs approximately the same way - using external or internal heating. The first is carried out in a thermal furnace; for the second, resistive heating is used by passing an electric current or induction heating in a high-frequency electromagnetic field. Both options affect the metal approximately equally.

As the temperature increases the amplitude of thermal vibrations of molecules , and structural defects in the lattice arise, expressed in the growth of dislocations, jumping of atoms and other disturbances. This is accompanied by the rupture of interatomic bonds and requires a certain amount of energy. At the same time, a quasi-liquid layer forms on the surface of the body. The period of lattice destruction and defect accumulation is called melting.

Metal separation

Depending on their melting point, metals are divided into:

- Low-melting: they need no more than 600C o. This is zinc, lead, hang, tin.

- Medium melting: melting point ranges from 600C to 1600C. These are gold, copper, aluminum, magnesium, iron, nickel and more than half of all elements.

- Refractory: temperatures above 1600C are required to make the metal liquid. These include chromium, tungsten, molybdenum, titanium.

Depending on the melting temperature, the melting apparatus is also selected . The higher the indicator, the stronger it should be. You can find out the temperature of the element you need from the table.

Another important quantity is the boiling point. This is the value at which the process of boiling liquids begins; it corresponds to the temperature of saturated steam that forms above the flat surface of the boiling liquid. It is usually almost twice the melting point.

Both values are usually given at normal pressure. directly proportional to each other .

Which metal doesn't heat up?

American physicists have discovered a metal that conducts electricity without heating up. We are talking about the metal vanadium dioxide (VO2). ... This material is known for its ability to transform from a dielectric to a conductive metal at a temperature of 67 degrees Celsius.

Interesting materials:

Where did they call 904 from? Why does 0 squared equal 1? Why don't British cats like to be held? Why does Excel remove leading zeros? Why do raspberries have no berries? Why is the oceanic crust thinner? Why are olives green? Why is the fur coat with the fur on the outside? Why does an owl's head turn? Why are there 20 cigarettes in a pack?