When welding, the parts are exposed to high temperatures, so it is very important to attach importance to the melting temperature of metals, taking it into account during the work process, since these indicators play an important role in the current parameters. In the burner, when gas is burned during the action of an electric arc, thermal power is created in order to destroy the crystal lattice of the metal. The melting characteristics of metals are given attention when selecting materials for the construction of units subject to frictional forces or metal structures that are exposed to temperatures.

What is melting point?

To find out at what temperature the metal melts, in laboratory conditions, the starting point at the beginning of the melting process is calculated to the hundredth of a degree. Moreover, this indicator does not depend on the force applied to the part.

When a certain pressure is created under vacuum conditions, metal blanks have the same melting point. This phenomenon can be explained by the accumulation of energy inside the substance, during which the bonds between molecules are destroyed.

Physiological action

Nickel and its compounds are toxic and carcinogenic.

Nickel is the main cause of allergies (contact dermatitis) to metals that come into contact with the skin (jewelry, watches, denim studs). In 2008, nickel was named Allergen of the Year by the Contact Dermatitis Society of America. The European Union limits the nickel content in products that come into contact with human skin.

In the 20th century, it was found that the pancreas is very rich in nickel. When nickel is administered after insulin, the action of insulin is prolonged and thus hypoglycemic activity increases. Nickel affects enzymatic processes, the oxidation of ascorbic acid, and accelerates the transition of sulfhydryl groups to disulfide groups. Nickel can inhibit the action of adrenaline and lower blood pressure. Excessive intake of nickel into the body causes vitiligo. Nickel is deposited in the pancreas and parathyroid glands.

Difference between melting and boiling points

The melting point of metals is the point at which a solid crystalline substance transitions into a liquid state. In the composition of the melt, the molecules do not have their own location; they are held due to the force of attraction, therefore, in a liquefied state, the volume is retained, but the shape is lost.

During the boiling process, a loss of molecular volume occurs, and the molecules interact sluggishly with each other, moving chaotically in different directions, lagging behind the surface. Boiling point is the process by which the pressure level of metal vapor is balanced with the pressure of the external environment.

At what temperature does it melt?

Metal elements, whatever they are, melt almost one to one. This process occurs when heated. It can be both external and internal. The first takes place in a furnace, and for the second, resistive heating is used, passing electricity or induction heating. The impact is almost the same. When heated, the amplitude of molecular vibrations increases. Structural lattice defects are formed, which are accompanied by the breaking of interatomic bonds. The process of lattice destruction and the accumulation of such defects means melting.

Melting point of various metals

According to knowledge from the section of physics, the process of transforming a solid into a liquid occurs only in bodies with a crystal lattice. The melting point of metals and alloys occurs in a different range of values. But it is very problematic to accurately calculate the boundary temperature of phase states in alloys. For pure elements, every degree is significant if these are compounds with slight fusibility.

Iron

The melting point of iron compounds must be high. If the element is technically pure, it melts at a temperature of 1,539 °C. Its substance contains sulfur inclusions, so its extraction requires a liquid state. Purified iron is also obtained through the electrolysis of metal salts.

Cast iron

Cast iron is considered the best material for melting. It has good fluid flow and shrinkage properties, so it can be used effectively in the casting process. Below are the boiling temperature indicators for cast iron:

A gray type of cast iron whose temperature reaches 1,260 °C. And when poured into molds, it increases to 1,400 °C.

A white variety of cast iron whose temperature rises to 1,350 °C.

One of the important points is that the temperature of cast iron is 400 units less than the same steel. Therefore, the processing of this material is less energy intensive.

Steel, melting point

The average melting point of steel is 1400 °C.

Steel is an iron-containing alloy containing carbon. Its main characteristic is strength. This is achieved due to the fact that it retains the parameters of volume and shape for a long time. In this case, the arrangement of molecules in the substance is in a balanced state. That is why a balance is achieved between the force of attraction and the force of repulsion.

The melting range of steel is higher than that of cast iron, so it is more energy-consuming.

Stainless steel

The melting point of stainless steel falls in the middle range between cast iron and steel. Stainless steel is a substance made of alloy steel that has anti-corrosion properties due to the chromium content of 11% or more in its composition.

The melting point of stainless steel ranges from 1,300 to 15,000 °C.

Aluminum and copper

The melting point of aluminum is 6,600 °C, so it has established itself as one of the medium-melting metals. Melting of pure copper compounds occurs at a temperature of 10,830 °C, and of alloys - 930 - 11,400 °C.

Silver and gold

Silver in its pure form melts at a temperature of 9,620 °C. Moreover, at the melting point of silver, it can be compared with the melting point in degrees of copper alloys.

Gold melts at a temperature of 10,640 °C.

Mercury

Mercury has the lowest melting point with a negative value. It is - 38.80 °C.

Characteristics and properties of metal

Gold is a medium-melting metal: those that melt (transition from solid to liquid) at temperatures from 600 °C to 1600 °C are considered to be such. Many metals (nickel, iron, cobalt, silver) and alloys (steel, brass, cast iron) fit the definition of medium-melting metals. Gold can be smelted using tools suitable for most metals. The boiling point of gold is 2700 °C. In addition, it has:

- high ductility and malleability;

- very high density;

- low hardness.

A bar of pure gold can be forged into thin wire without the use of high-tech equipment. With simple tools and skills, this is theoretically possible even at home, because gold is very malleable and easy to process.

Melting point table

| Low-melting metals | |

| Lithium | + 180 °C |

| Potassium | + 63.60 °C |

| Indium | + 156.60 °C |

| Tin | + 2 320 °C |

| Thallium | + 3,040 °C |

| Cadmium | + 3 210 °C |

| Lead | + 3 270 °C |

| Zinc | + 4 200 °C |

| Medium melting metals | |

| Magnesium | + 6 500 °C |

| Aluminum | + 6 600 °C |

| Barium | + 7 270 °C |

| Silver | + 9 600 °C |

| Gold | +10 630 °C |

| Manganese | + 12 460 °C |

| Copper | + 10 830 °C |

| Nickel | + 14 550 °C |

| Cobalt | + 14 950 °C |

| Iron | + 15 390 °C |

| Duralei | + 6 500 °C |

| Brass | + 950 – 10 500 °C |

| Cast iron | + 1,100 – 13,000 °C |

| Refractory metals | |

| Titanium | + 16 800 °C |

| Platinum | + 17 690 °C |

| Chromium | + 19 070 °C |

| Zirconium | + 18 550 °C |

| Vanadium | + 19 100 °C |

| Iridium | + 24 470 °C |

| Molybdenum | + 26 230 °C |

| Tantalum | + 30 170 °C |

| Tungsten | + 34 200 °C |

What does the melting temperature depend on?

Different materials also have different melting points, at which a radical restructuring of the lattice occurs to the state of liquid. Metal products and alloy products have the following features:

- Different materials also have different melting points, at which a radical restructuring of the lattice occurs to the state of liquid. Metal products and alloy products have the following features:

- They are rarely found in their natural form, i.e. without impurities. It is the composition that determines what the melting temperature should be. An example is tin, to which silver inclusions are added. Thanks to impurities, the material begins to become resistant to temperature.

- There are alloys that, due to their chemical composition, transform into a liquid state when the thermometer rises just above + 1,500 °C. There are also alloys that “stick” if they are heated to 30,000 °C.

- It is worth considering the fact that one of the most important properties of substances is their melting point. An example is aviation technology.

Types of metal alloys

The types of metal alloys vary based on their melting point, so the alloy variants are as follows:

- Low-melting (tin, zinc, lead, bismuth) with a melting point of no more than 600 °C.

- Medium melting (aluminum, magnesium, nickel, iron) with a temperature of 600 - 1,600 °C.

- Refractory (molybdenum, tungsten, titanium) with a temperature of more than 1,600 °C.

Next, we’ll tell you a little about the types of steels, wood alloy and solders.

Features of Carbon Steel

This material contains an admixture of carbon, approximately 2.13%. Moreover, it is devoid of alloying additives, but contains impurities of silicon, manganese and magnesium.

Features of Alloy Steel

In addition to the carbon and iron content, additional elements are added to it to improve its properties.

Features of stainless steel

Stainless steel differs from carbon steel due to the content of the element chromium in its composition, due to the properties of which it is not susceptible to oxidation, and, therefore, to rust.

Features of tool steel

It also has a carbon composition (0.8 - 0.9%). Demonstrates hardness, strength, and is easy to process. Used in the manufacture of instruments, such as medical ones.

Wood's alloy

It is a material used in soldering parts for radio receivers, as well as in electroplating, when working in laboratory conditions with pesticides.

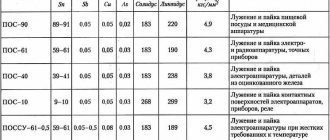

Soldering alloys

Another name for them is solders. Materials for solders are different. It all depends on what is included in the materials that need to be combined. For example, aluminum requires one alloy of solder, but copper is completely different.

Application

In 2015, 67% of nickel consumption came from stainless steel production, 17% from non-iron alloys, 7% from nickel plating and 9% from other applications such as batteries, powder metallurgy and chemical reagents.

Alloys

Nickel is the basis of most superalloys - heat-resistant materials used in the aerospace industry for power plant parts.

- Monel metal (65-67% Ni + 30-32% Cu + 1% Mn), heat-resistant up to 500 °C, very corrosion-resistant;

- white gold (for example, 585 standard contains 58.5% gold and an alloy (ligature) of silver and nickel (or palladium));

- nichrome, an alloy of nickel and chromium (60% Ni + 40% Cr);

- permalloy (76% Ni + 17% Fe + 5% Cu + 2% Cr), has high magnetic susceptibility with very low hysteresis losses;

- invar (65% Fe + 35% Ni), almost does not expand when heated;

- In addition, nickel alloys include nickel and chromium-nickel steels, nickel silver and various resistance alloys such as constantan, nickel and manganin.

- Nickel is present as a component of a number of stainless steels.

Nickel plating

Nickel plating is the creation of a nickel coating on the surface of another metal to protect it from corrosion. It is carried out by electroplating using electrolytes containing nickel(II) sulfate, sodium chloride, boron hydroxide, surfactants and gloss agents, and soluble nickel anodes. The thickness of the resulting nickel layer is 12–36 microns. The stability of the surface gloss can be ensured by subsequent chrome plating (chrome layer thickness - 0.3 microns).

Currentless nickel plating is carried out in a solution of a mixture of nickel(II) chloride and sodium hypophosphite in the presence of sodium citrate:

NiCl2 + NaH2PO2 + H2O → Ni + NaH2PO3 + 2HCl

The process is carried out at pH 4-6 and 95 °C.

Battery production

Production of iron-nickel, nickel-cadmium, nickel-zinc, nickel-hydrogen batteries.

Chemical Technology

In many chemical technological processes, Raney nickel is used as a catalyst.

Radiation technologies

The nuclide 63Ni, which emits β particles, has a half-life of 100.1 years and is used in krytrons, as well as electron capture detectors (ECDs) in gas chromatography.

Medicine

- Used in the manufacture of bracket systems (titanium nickelide).

- Prosthetics.

Coinage

Nickel is widely used in the production of coins in many countries. In the United States, the 5-cent coin is colloquially known as the nickel.

Music industry

Nickel is also used for winding strings of musical instruments.

Nickel prices

During 2012, nickel prices fluctuated between $15,500 and $17,600 per ton.