Greetings to dear readers! In this material I tried to collect all the data about PIC solder. This Tin-Lead Solder is the most popular solder for mounting radio components and is used more often than others in radio engineering. I will try to explain why this is so and tell you about the types and technical characteristics of POS series solders. I’ll also tell you a terrible secret about POS-60 and POS-62 solders. Go!

Types of POS solders

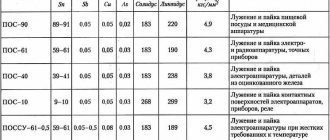

First, let's remember what types of solders are made from alloys of the tin-lead group. The most popular are antimony-free solders POS-10, POS-40, POS-61 and POS-90. POS solder containing antimony is called POSSU. Antimony in the solder adds several percent to its strength.

When we talk about melting a mixture of tin and lead, we need to remember the definitions of solidus and liquidus . When any mixture of two or more metals is heated, the melting (transformation from solid to liquid phase) of the lightest particles occurs first. This temperature mark is called the solidus of the alloy.

With a further increase in temperature, more refractory components begin to melt. As soon as they melt, the liquidus . The PIC solder is now completely melted. This process is explained in more detail by a picture taken from a presentation on the topic of alloys.

Between these two points is a state of increased ductility of the solder . In this state, the solder can be pulled and deformed without losing integrity.

There are eutectic alloys - solders, in which the solidus and liquidus points coincide. This is very convenient when soldering and indicates the high quality of the solder.

Description [edit | edit code ]

Solders are produced in the form of granules, rods, wire, powder, foil, pastes and embedded parts.

Soldering is carried out either to create a mechanically strong (sometimes hermetically sealed) seam, or to obtain electrical contact with low contact resistance. When soldering joints, the solder is heated above its melting point. Since solder has a melting point lower than the melting point of the metal (or metals) being joined, from which the parts being joined are made, it melts, while the metal of the parts remains solid. At the interface between molten solder and solid metal, various physical and chemical processes occur. Solder wets the metal, spreads over it and fills the gaps between the parts being connected. In this case, the components of the solder diffuse into the base metal, the base metal dissolves in the solder, resulting in the formation of an intermediate layer, which, after solidification, connects the parts into one whole.

Solder is selected taking into account the physical and chemical properties of the metals being joined (for example, melting point), the required mechanical strength of the solder, its corrosion resistance and cost. When soldering live parts, it is necessary to take into account the specific conductivity of the solder.

The fluidity of low-temperature solders makes it possible to solder products of complex shapes.

About the composition of solder

The name of the solder of the tin-lead group indicates the tin content in it. For example, POS-40 contains 40% tin, and POS-61 contains almost 61% tin. The rest consists of lead and additional impurities. By appearance, you can estimate the composition . If the PIC solder is more matte and dark, then it contains more lead. If it is lighter and shiny, then there is more tin. This is best understood by comparison. Look at the photo to see what a sheet of tin and a sheet of lead look like.

The strength of solder depends not only on the alloy alloy, but also on the metal being soldered. For example, to solder copper or zinc, several percent of copper or zinc are added to the POS solder, respectively. This reduces chemical erosion of the metal and increases the surface strength of the joint.

Solder alloying

To improve performance characteristics, alloying of solder with the following substances is used:

- adhesion is improved by the addition of copper, cadmium, antimony, aluminum, silver and zinc;

- ductility and resistance to thermal cycling are improved by the addition of indium, silver, manganese, bismuth, and lithium;

- Nickel, cobalt, zinc, silicon, boron, iron add strength

- The corrosion resistance of solder is increased by nickel and copper;

- Heat resistance is increased by silicon, zirconium, tungsten, vanadium, cobalt, niobium, hafnium.

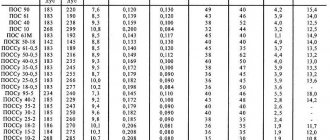

Technical characteristics of POS and POSSu solders

In order not to describe all the technical characteristics of solders of the tin-lead group, I will simply provide a table of parameters. It can be used to determine the melting point, density, electrical resistivity, thermal conductivity, tensile strength, elongation, impact strength and Brinell hardness of solders.

An analysis of the table shows that the most fusible among the list is cadmium with a melting point characteristic of 145 degrees Celsius. The strongest solder is POSSu 4-6 solder with a tensile strength of 6.5 kgf/sq.m. mm.

Technical characteristics of POS-10 solder

POS 10 solder has a distinctive chemical composition. It contains 9-10% tin, about 89% lead, 0.2% bismuth, 0.1% antimony and other impurities in small quantities. POS-10 solder is used for soldering and tinning contact surfaces of electronics. For example, they solder relays and fill control plugs in radio electronics housings.

The POS-10 soldering temperature is 299 degrees Celsius. The solidus point is 268 degrees.

Advantages of POS-10 solder:

- high melting point is useful when soldering equipment cases.

Disadvantages of POS-10 solder:

- low strength and tensile strength of about 3.2 kgf/sq.mm.;

- high resistivity - 0.2 Ohm x sq.mm./m;

- high content of lead, which is hazardous to health.

Technical characteristics of POS-30 solder

Solder for soldering of the POS 30 brand is an intermediate link between POS 10 and POS 40. The composition of POS 30 solder is as follows: 30% tin and 69.5% lead. The rest is impurities and doping. Solder POS 30 can be easily replaced with POS 40, which is described below. The melting point (liquidus) is 238 degrees, and the plasticity temperature (solidus) is 183 degrees Celsius. According to the technical characteristics, POS 30 solder is most often used for soldering and tinning of zinc sheets and radiators.

Advantages of POS-30 solder:

- good adhesion;

- high strength.

Disadvantages of POS 30 brand solder:

- high lead content;

- often produced in rods.

Density of solders and babbits, their thermal conductivity and thermal conductivity

The tables give the thermophysical properties of some solders and babbitts (anti-friction bearing materials) at room temperature. Properties such as density, coefficient of thermal expansion and thermal conductivity are presented.

The properties of the following solders and babbitts are indicated: POS-30, POS-18, PSr45, POTs70, POTs60, 34A, eutectic silumin; babbits, B83, B16, BKA, B88, B89, B6.

It should be noted that the density of solders, coefficient of thermal expansion (CTEL) and thermal conductivity of solders and babbitts have similar values, with the exception of solder 34A and eutectic silumin, which are 2-4 times lighter.

Technical characteristics of POS-40 solder

The chemical composition consists of 39-41% tin, 59% lead. The remaining impurities are in the same ratio as in POS-10. Soldering solder POS-40 is often used for soldering and tinning radio equipment casings made of galvanized iron with galvanized seams.

The soldering temperature of the solder is 238 degrees Celsius, and the solidus is 183 degrees.

Advantages of POS-40 solder:

- good ratio of ductility and melting point;

- because of this, it tolerates thermal cycling better than POS-61.

Disadvantages of POS-40 solder:

- high lead content, which is harmful to health;

- elevated liquidus temperature.

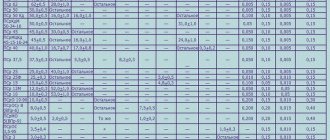

The terrible secret of POS-60 solder

Now the time has come for the terrible secret of POS 60 solder . According to GOST 21930-76 entitled “Tin-lead solders in ingots. Technical specifications" and GOST 21930-76 "Tin-lead solders in products. Technical specifications", solder such as POS-60 simply does not exist. GOST 21930-76 itself can. Here is the complete table from this GOST.

So “ POS-60 ” is jargon or a popular designation for “the solder that everyone solders with.” It seems to me that this is due to confusion in the designation of POS-61. Because when the tin content in the solder according to GOST is from 59 to 61%, it is more logical to call it POS-60 rather than POS-61.

Among the solders produced according to international standards there is Sn60Pb40 solder . This is a solder solder containing 60% tin and 40% lead. It could be called POS-60, if at least specifications for it were developed. According to international data describing the characteristics, the melting point of 60/40 solder is 191 degrees Celsius.

The same story with POS-62 type solder . Such lead solder according to GOST has not yet been invented. So, if they ask me “what is the melting temperature of POS-62 solder,” I know that the answer with the figure 184 degrees Celsius must be looked for in the imported solder catalog. For example, you can use the Kester solder catalog.

Melting point of tin for soldering microcircuits

Working with microcircuits is very delicate, as they are complex devices with many contacts. All of them are made in fairly small sizes, so if you need to solder something, then you need to select the appropriate equipment and consumables, not to mention experience working with such things.

Naturally, to facilitate the work, it is necessary that the temperature of the solder be relatively low, so that the temperature does not damage other parts located nearby. When choosing which solder to use for soldering microcircuits, you need to pay attention to its quality.

Even at a high cost, it will be quite justified, since during soldering of this kind a relatively small amount of material is used.

Using solder when soldering a microcircuit

Solder is used both in the private sphere, among many radio amateurs, and in factory production and repair shops. Unlike other varieties, when choosing which solder to solder microcircuits with, you need to pay attention not to strength, temperature resistance and other mechanical parameters. Electrical conductivity, soldering properties and melting point are more important here.

Suitable brands

There are different types of solders for soldering, but it is worth highlighting the most suitable for working with microcircuits that can be found on the modern market. One of the most common options is POS 61. It has the following chemical composition:

| Chemical element | Composition ratio, % |

| Tin | 61 |

| Lead | 38,5 |

| Iron | 0,02 |

| Bismuth | 0,01 |

| Antimony | 0,05 |

| Nickel | 0,02 |

| Sulfur | 0,02 |

The technical characteristics of the material are as follows:

| Melting temperature, degrees Celsius | Density of deposited material, g/cm squared | Thermal conductivity | Tear resistance | Elongation, % | Impact toughness, kgf/cm squared |

| 189 | 8,5 | 0,12 | 4,3 | 46 | 3,9 |

An analogue from the same POS 30 series can also be used. It is inferior in quality, but has a sufficiently low melting point to provide comfortable working conditions. Its composition has virtually no impurities:

The technical characteristics of this brand are as follows:

| Parameter | Units | Meaning |

| Melting temperature | degrees Celsius | 183 |

| Weld material density | kg/cubic meter | 10,1 |

| Relative elongation | % | 58 |

| Mechanical tensile strength | MPa | 32 |

| Crystallization interval | degrees | 73 |

Criterias of choice

In addition to this, there are other brands, so people often have a question about which solder to choose for microcircuits, based on the parameters. First of all, you need to pay attention to the conductivity of the composition.

If it has high resistance, then it may not be suitable for complex circuits.

For ordinary home soldering, the criteria are not so significant, but if there is serious work to be done, then it is better to pay attention to silver solders rather than tin-lead solders, although they are cheaper.

Silver solders

One of the important parameters is the swimming temperature. There is no need for high strength and the temperature itself in the diagram will not rise above a hundred degrees. At a low melting point, solder melts better and adheres to the surface. It is also easier to remove residues that may stick if not handled carefully.

It is better if the material is made in the form of a rod or wire, as this is more convenient in practical use. After all, you need to measure out relatively small portions, therefore, you need to be able to take a minimum amount of material with a soldering iron.

"Important!

You should always have a supply of flux for the solder that will be used.”

Soldering Features

When choosing which solder is best for SMD soldering, it is worth considering that the soldering process itself has some differences. Firstly, for the job you need to choose a thin soldering iron that has a sharp flat tip. Its power should not exceed the melting point of the consumable material too much. Flux should be used liberally to improve the speed and reliability of the connection.

Technical characteristics of POS-61 solder

The designation of solder, as we found out, is quite controversial, but you can’t argue against GOST. POS-61 is used for soldering and tinning of electronic components and printed circuit boards of precision instruments with highly hermetic seams, for which overheating is not allowed.

Composition of POS-61 solder

The chemical composition of POS-61 solder is as follows:

- Tin 59 - 61%;

- Antimony - no more than 0.1%;

- Copper - no more than 0.05%;

- Bismuth - no more than 0.02%;

- Arsenic - no more than 0.02%;

- Iron - no more than 0.02%;

- Nickel - no more than 0.02%;

- Sulfur - no more than 0.02%;

- Zinc - no more than 0.002%;

- Aluminum - no more than 0.002%;

- Lead - everything else - about 38.7 - 40.7%.

The soldering temperature of POS-61 solder is 220 degrees Celsius. Solidus is 183 degrees. I even shot a slow motion video of this solder melting on my Olympus Tough TG-860 at 240fps.

Solder POS 61 GOST 21931-76 has the following technical characteristics:

- Density determines weight and is equal to 8.5 g/cu. cm.;

- The electrical resistivity is 0.139 Ohm x mm2/m;

- Thermal conductivity is 0.12 kcal/cm x s x deg;

- Temporary tensile strength is 4.3 kgf/sq.mm.;

- The relative elongation is 46%.

Advantages of POS-61 brand solder:

- the best ratio of melting temperature and strength;

- good adhesion to metal surfaces;

- universal solder for soldering and most radio installation work;

- accessibility and prevalence;

- low cost;

- often produced in the form of wire, for example POS 61 T2A solder.

Disadvantages of POS-61 type solder:

- versatility reduces performance in special cases, for example when soldering zinc;

- melting temperature is not suitable for all devices;

- solder fumes (lead in it) are harmful to health.

Flux for soldering with a soldering iron

An auxiliary substance that promotes the spreading of soldering materials over the surface of the parts being soldered is flux. High-quality connections are created by solders and fluxes ; without one of the components, soldering is impossible. A common type of flux is rosin, made from hard coniferous trees. Softening occurs at 50 °C, and when the temperature reaches 250 °C, the process begins to boil the composition.

Flux for soldering aluminum

Due to the hydrolysis provided for in the manufacture of rosin, the material is not resistant to atmospheric influences. After soldering, it is necessary to remove flux residues, because... the compound may undergo an oxidation process. By absorbing moisture from the atmosphere, rosin can disrupt the operation of radio components.

Popular fluxes for soldering with an electric soldering iron

Soldering of metal joints occurs using various substances. Fluxes are divided into three main categories, differing in their area of application and method of preparation. The process of preparing elements for work may vary; after soldering, it is necessary to remove residues in the manner described in the instructions.

- Inactive rosin fluxes are used for soldering copper and other types of soft metals. There is a light rosin that is ready for use and does not include additional substances. Alcohol-rosin solution is made from components with a concentration of 1 to 5. It is used for soldering in hard-to-reach places, it is produced in powder form, and must be mixed with alcohol before use. Glycerin - rosin materials are used when a hermetic connection is necessary.

- Active fluxes suitable for soldering precious and non-ferrous metals include zinc chloride, alcohol or petroleum jelly. The last parameter differs in its composition, when used in a liquid or paste state. It is more convenient to work with flux as a paste; it is possible to apply it directly to the product in the required amount.

- Acid-active flux is divided into zinc chloride and phosphoric acid. It is performed in the form of liquid solutions or paste, using rosin, zinc chloride, alcohol or petroleum jelly.

Orthophosphoric acid consists of water, ethyl alcohol and the acid itself with a density of 1.7. It is used for soldering stainless materials, copper, and silver. Alcohol-based fluxes must be stored in airtight containers. A convenient container for storage is a nail polish jar, the brush does not react to the active medium, and the lid allows you to tightly close the container, avoiding evaporation of the components.

Tinol soldering pastes for soldering

Among the substances offered, there are solder pastes that are produced with a mixed type of flux. It is used when installing open-frame elements in hard-to-reach places. Application occurs with a special spatula, then heating with an electric tool. The result is a reliable, high-quality connection, which is actively used by novice craftsmen in the absence of appropriate experience.

It is possible to prepare an alloy for soldering with your own hands; for this you will need the solder required by the element. Using a medium-grain file, tin for soldering in the form of wire is crushed to the state of metal chips. A flux selected from the above in a liquid state is added to the composition, after which the elements are mixed. The composition must be prepared in a small container, the shelf life is limited to 6 months, after which the metal oxidizes in an acidic environment.

Technical characteristics of POS-63 solder

Solder POS 63 is described in GOST and in the industry standard OCT 4G 0.033.200. POS-63 solder is understood as an alloy that consists of 63% tin and 37% lead. This is a kind of modernization of POS-61 solder, adjusted to the international standard J-STD 006B. Most are also labeled Sn63Pb37 . These are eutectic alloys with a melting point of 183 degrees Celsius.

POS-63 is used for soldering and tinning the leads of microcircuits and packaged radio components, printed circuit boards, wires and cables. In general, of modern solders, this is the most common. The technical characteristics of POS 63 solder are approximately the same as those of POS-61. But I haven’t found the exact values yet.

Advantages of POS-63 solder:

- the most common POS series solder;

- relatively low melting point;

- coincidence of solidus and liquidus points;

- low cost;

- supplied in the form of wire filled with flux.

Disadvantages of POS-63 solder:

- often counterfeited, especially by the Chinese;

- contains lead, which increases the cost of recycling electronic equipment in accordance with modern safety standards.

Other [edit | edit code]

Special types of metal alloys not related to solders themselves are used in electric vacuum technology for electrical leads that are fused into glass and operate at relatively low temperatures, when the use of refractory but relatively expensive metals (tungsten, molybdenum, platinum) is not required. For these materials, the temperature coefficient of linear expansion ( α l > ) is of particular importance, which, in order to obtain a vacuum-tight input, must be matched as accurately as possible with α l > glass. For example, kovar (alloy grade 29NK), used for the manufacture of electrical leads through glass flasks for various gas-filled and electric vacuum electronic devices and lighting lamps, has an approximate composition: Ni - 29%, Co - 18%, Fe - the rest; its resistivity is about 0.49 μOhm m, and α l > about 4...5·10 −6 K −1.

The process of repairing electronics and performing work in radio engineering occurs with the help of a soldering iron. High-quality work serves as the basis for durable connection of parts. The work is done with a soldering iron; reliable connections are made not only with a high-quality tool, but also with flux and solder. The main solder is an alloy of light-alloy metals, which melts when a certain temperature is reached. Tin in its pure form is considered the most suitable option, but the material is very expensive.

Technical characteristics of solder POSSu-61-0.5

Solder marking POSSu-61-0.5 indicates a type of antimony solder containing 61% tin, up to 0.5% antimony and about 38% lead. This solder is used for soldering and tinning of printed circuit boards and galvanized radio components under increased operating temperature requirements. But its melting point is 189 degrees.

Advantages of POSSu-61-0.5 solder:

- increased adhesion to the metal surface due to the antimony content;

- technical characteristics are almost the same as POS-61.

Disadvantages of POSSu-61-0.5 solder:

- difficult to find on sale;

- increased cost.

Use of tin-lead group alloys

The soldering process is the joining of several metallized parts together. In this case, the exposure temperature does not exceed the critical threshold at which destruction of parts or circuit boards occurs. The main objectives of using soldering products are to ensure the most even temperature viscosity, at which uniform spreading occurs over the surface.

Tin is used for soldering quite often; the material serves as a component of the largest number of solders. In its pure form, the metal is very expensive and is used for soldering important products and elements. Divided into categories with and without lead.

Lead solders

Various soldering materials are used using lead. The material is fusible, soft and easy to process. Easily dissolves in an alkaline environment and acidic impurities.

Products labeled PIC are considered the most popular in use. The percentage of elements allows you to work with different environments and materials. They differ in temperature and other parameters that are important for a reliable connection. Zinc, bismuth or antimony are added to lead compounds to provide protection against oxidation and other destructive factors.

Technical characteristics of POS-90 solder

POS-90 brand solder consists of 90% tin and 10% lead. It also contains about 0.1% antimony and 0.05% copper. It is mainly used for soldering and tinning internal seams of food utensils and medical equipment. Yes, 10% lead can already be put into food products - surprisingly, everything is in accordance with GOST 1976. According to the technical characteristics, the melting temperature of solder type POS 90 is 220 degrees.

Advantages of POS-90 solder:

- low lead content;

- rarely counterfeited;

- low resistance;

- high strength.

Disadvantages of POS-90 brand solder:

- high cost (higher than pos-61);

- low plasticity.

How to choose solder

The main task for the master is to create a high-quality, reliable fastening that will last for a long time. Solder selection is based on the following parameters:

- Materials that are processed. It is necessary to accurately familiarize yourself with the characteristics of the materials being soldered. There is a temperature threshold for melting fragile elements, transistors, capacitors, etc. Radio amateurs use fusible substances.

- The composition of the solder is selected according to the parameters of thickness and purpose of the product. When soldering wires and other large elements, it is possible to use refractory elements.

- Some cases require choosing the optimal conductivity. The resistance of tin is lower than that of lead; more expensive brands of solder are used on high-frequency boards.

In any situation, it is necessary to be scrupulous about the compliance of soldering parameters and the product. High-quality products are used for soldering, the price is not high, and the choice on the market is huge.

If you find an error, please select a piece of text and press Ctrl+Enter.