Welding is considered a dangerous and harmful type of work. At production sites, traumatic situations arise constantly.

The organization of the welding process refers to a whole range of procedures.

This is due to the presence of flammable substances and heated objects. Therefore, when carrying out welding work, it is necessary to observe safety precautions.

The need to follow the rules

Regardless of the type of equipment used, the welder and other people present at the work site are affected by negative factors.

The need to comply with the rules is explained by the possibility of the following traumatic situations:

- sparks getting on the welder’s clothes;

- burning shoes made of fusible materials;

- injury to the skin of the face and organs of vision by hot metal vapors;

- ignition of materials located on the site due to the spread of sparks;

- burns from particles falling on the skin;

- high-intensity electric shock;

- falling of poorly fixed parts of metal structures.

What errors might there be?

Incorrectly selected current - if its value is low, the arc will constantly go out and the seam will be interrupted. A high current value leads to penetration, burning through the body of welded metal structures.

The slag output is controlled by the angle of inclination of the electrode and depends on its type. If the bath moves quickly, slag inclusions remain in the seam.

High-alloy steels must be heated before processing, otherwise the edge material will not have time to melt or a transition zone will form.

Welding of non-ferrous metals must be carried out with special electrodes in a shielding gas environment. The polarity of the current must be straight in order for the metal coated with oxides to melt.

What is the danger?

The physical and chemical hazards of welding include:

- high noise level emitted by welding machines;

- intense infrared and ultraviolet radiation;

- blinding visible light;

- content of heavy metals in melt vapor;

- presence of hot particles above the weld pool;

- thermal energy generated during burner operation.

When carrying out welding work, a person is exposed to ultraviolet radiation.

Hazards of indoor welding work

Any welding operation involves the use of high temperature. The electrode, which electric welding cannot do without, and the torch for gas welding during operation have a temperature measured in thousands of degrees Celsius. The metal structures being processed are heated to almost the same degree, regardless of whether we are talking about cutting or welding elements.

VT-metall offers services:

All this leads to the fact that accidental contact of welding with flammable objects easily turns into the cause of a fire. You also need to understand that hot metal can spread, drip, and splash around. This means that during welding work in the room, finishing materials often burn through, and furniture can be burned through.

The most serious danger is posed by gas welding cylinders - if storage standards are not followed, they can lead to an explosion.

If you are welding indoors, be mindful of your neighbors as hot metal particles may fly beyond your square footage. Let’s say that welding on the balcony, replacing risers and other operations performed in the bathroom can lead to such unpleasant consequences.

When welding in any room, it is important not to forget about the existing risk of fire. It is recommended to notify other residents in advance about the planned actions, and after welding, monitor the situation in the area of completed work for several hours to avoid a smoldering fire.

General provisions when carrying out welding work

When connecting elements of metal structures in any way, observe the following rules:

- The equipment is installed in specialized workplaces equipped with protective screens. The height of the screen must be at least 180 cm.

- In a closed room, welding begins after starting the supply hood.

- In workshops with high humidity they work in a rubber protective suit. When the welder takes a sitting or lying position, felt pads are used.

- Before starting welding, check the integrity of the power and grounding cables.

- When repairing a car, the battery mass is first disconnected. The fuel tank is dismantled.

- The unit can only be moved when disconnected from the network. The holder is installed on a dielectric substrate.

Requirements for an employee to be allowed to work

A person starting welding must:

- Have the qualifications required by law.

- Provide evidence of completion of a brief training on TB.

- Have skills in working with welding units. The devices are used strictly for their intended purpose, with the permission of the master.

- Use personal protective equipment and maintain work clothes in proper condition.

- Be familiar with the procedure for providing first aid to people injured during production.

- Be able to use fire protection systems in emergency situations. It is necessary to familiarize yourself with the principle of operation of alarm sensors, the location of emergency exits, and the evacuation plan.

We recommend reading: How to repair a gas tank using welding

The employee must have professional skills and knowledge.

Necessary skin and eye protection

When starting work, the welder must use the following accessories to prevent injury:

- Work suit. Special clothing is issued by the enterprise. It is sewn from fire-resistant fabrics - tarpaulin, suede, split leather. Suits made of synthetic fabrics are prohibited. In winter, they wear cloth clothes.

- Mittens or gloves. Suede products are of the highest quality. The tarpaulin burns quickly, so you will have to change the mittens often.

- Shoes made from different materials. Most often, enterprises provide employees with tarpaulin boots or boots with rubberized soles. Shoes should not have nails that increase the risk of electric shock.

- Welding mask. It is not advisable to use self-made shields. Even a small gap in the mask can cause damage to the organs of vision.

Increased demands are placed on industrial safety equipment for welding.

Requirements for employees and managers

Before starting work, you must entrust it to competent employees and their managers. In general, according to the FNP standards, in any welding production there should not be a shortage of personnel performing high-quality work.

If any workers are appointed, then they are obliged to follow the welding technology and not deviate from the technological map. Managers are required to establish the authority of employees and check the quality of their work. All production employees must observe safety precautions, comply with labor protection and environmental protection rules. These are general provisions.

Now let's talk more about the leaders. Managers are required to fully train personnel to perform diverse tasks and certify their employees. Training and certification are carried out based on the welder’s job responsibilities, skills and category. Managers and welders can be people who have undergone appropriate training and have an education document. The work assigned to welders must correspond to their qualifications.

Managers themselves must have all the necessary knowledge and skills to delegate work and monitor the process. Specialists must be able to competently draw up technical documentation, control the quality of welding work and monitor the progress of welders’ duties.

As for welders, qualifications are assigned to them based on the resolution of the Ministry of Labor. All masters must have a certificate indicating their rank. To verify the authenticity, the ID must have a personal QR code and a number by which the document can be found in the unified register.

Only those who comply with the rules stated above are allowed to manage and perform welding work in hazardous production. Next, we will talk in more detail about the requirements for the welding work itself, and find out what the craftsmen should be provided with at their workplaces.

Occupational Safety and Health Regulations

By properly starting and maintaining the welding process, most problems can be avoided.

Preparation for work

The work shift begins with an assessment of the condition of the equipment, during which the following actions are performed:

- check the main units of the device, consumables and accessories;

- when working at height, securely secure scaffolding and other structures;

- the unit is grounded, which eliminates the possibility of electrical injuries;

- dry the power cables if there are drops of moisture on them (water contributes to the destruction of the insulation);

- measure the length of the wire (you cannot use products longer than 10 m).

Before work, check the main units of the device and consumables.

At the end of the process

When completing welding, you must also comply with labor safety requirements.

Workers perform the following actions:

- Disconnect the unit from the electrical network.

- Before checking the quality of the welded joint, wait until the parts cool down. It is prohibited to touch hot metal.

- Clean the equipment from contaminants and check the integrity of the main units. Place auxiliary tools in specially designated containers.

During emergencies

In such cases, special requirements for labor protection are imposed.

We recommend reading Features of flux-cored wire welding

These include the following rules:

- when the pipeline is under pressure, welding work is stopped;

- welding is prohibited in the presence of explosive vapors in the room;

- it is necessary to think over an action plan to help prevent injury to employees in accidents.

Planning and compliance

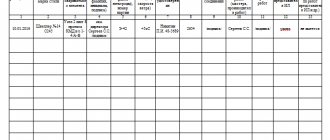

The design work plan (PWP) is drawn up taking into account pre-approved standards, according to which the so-called “technological maps” are prepared.

Accurate implementation of the instructions contained in them allows you to competently organize the welding process and ensure the solution of the following important tasks:

- technological calculation of the volume of proposed work (preparation of statements of labor and material costs);

- drawing up a general power supply diagram for the enterprise;

- taking into account comments on the technological features of the welding process and its quality control;

- compliance with basic safety requirements (TB) and labor protection standards.

General and technical supervision of welding work is carried out by the chief welder (for large volumes of products or a staff of more than 200 operators).

In other cases, either the leading engineer or the foreman (master) of the welding section is appointed as the responsible person for this part of the production process.

According to the requirements of state standards, this class of installation operations is subject to mandatory regulation, which allows for competent organization of the work process.

Current welding standards (subject to strict adherence to the instructions of the relevant documents) make it possible to increase the current output and quality of the finished product.

The main indicator of standardization is the time spent on manufacturing a structure of a given complexity, which consists of many components.

Based on this time, enterprises establish a production rate per performer, which is an indicator of the average productivity of welding work.

According to the provisions of SNiP concerning the organization of welding operations, this parameter takes into account a number of factors, including the rate of energy consumption, as well as the costs of auxiliary materials and auxiliary tools. In addition, based on the production rate, other calculated indicators of a specific welding operation are determined.

What should the room where the work is performed look like?

Welding is carried out in a specially equipped workshop with good ventilation. When working in closed containers, additional means of protection against harmful vapors are used. The room must have a compartment for storing gas cylinders.

Each workplace is fenced off with a screen.

The welding room must have good ventilation.

Special requirements are placed on the level of illumination and the absence of explosive materials in the welding zone.

Safety requirements for premises, materials and equipment

Normally, welding should be carried out in places designated for this purpose with special equipment and ventilation. When such work has to be carried out in closed containers or rooms, it is important for the specialist to protect the respiratory system with the help of additional means. Safety precautions when welding using gas equipment indoors require that the cylinders be kept separately, and each workplace be isolated with screens.

Recommended reading

- Cutting copper with a laser: advantages and disadvantages of technology

- Types of metal cutting: industrial applications

- Metalworking according to drawings: convenient and profitable

Another important parameter is illumination, so it is necessary to ensure sufficient access to light.

Don’t forget to carry out equipment maintenance on time; the preventive maintenance schedule included in the instructions will help you with this.

All safety standards can only be observed in specialized workshops, where welding is recommended. To do this, the elements of the structure to be welded are laid on flat, clean surfaces that are not capable of conducting current, or they are connected to each other using clamps or magnetic squares. Remember that it is important to first clean any equipment used during the work process from dirt and adhering particles. In addition, only tools made of materials that are not subject to ignition are suitable for welding.

Standards for storing tools and operating equipment

When storing and using technical equipment, observe the following safety rules:

- The equipment is stored in a dry, heated room, free from insects and rodents. Damp hoses and cables cause accidents.

- Electrodes are stored in a cool, dry place. When storing in conditions of high humidity, the rods cannot be used to initiate an electric arc.

- Generators are placed so that they do not fall or be subject to shock. Devices without a water seal cannot be used for welding. It is not recommended to use generators at temperatures below zero.

- It is forbidden to install hoses longer than 20 m. When working at heights, the length of the elements can be increased to 40 m. It is forbidden to swap oxygen and acetylene supply hoses. After completing the work, they are folded into rings, without bending or squeezing.

- Before removing the cap from the cylinder, check the integrity of the fitting and valve. Do not knock out the part with a hammer or direct the flow of gas towards yourself or other people. The cylinder is placed on a flat stand in a vertical position. Do not place it near heat sources.

What is electric welding?

Electric is one of the welding methods when an electric arc is used to heat and subsequently melt metals. The temperature of the latter reaches 7000°C, which is much higher than the melting point of most metals.

The electric welding process proceeds as follows. To form and maintain an electric arc, current is supplied from the welding device to the electrode.

During the welding process, the base metal and the metal core of the electrode are melted and mixed, forming a strong and unbreakable weld (+)

When the electrode rod touches the surface to be welded, welding current flows. Under its influence and the influence of the electric arc, the electrode and the metal edges of the elements being welded begin to melt. From the melt, as welders say, a weld pool is formed, in which the molten electrode is mixed with the base metal.

Molten slag floats to the surface of the bath, which forms a protective film. After the arc is turned off, the metal gradually cools, forming a seam covered with scale. After the material has completely cooled, it is cleaned off.

Non-consumable and consumable electrodes can be used for welding. In the first case, filler wire is introduced into the melt to form a welding seam, in the second this is not required. To form and subsequently maintain an electric arc, special equipment is used.

Skills in the field of welding in domestic conditions are required to perform a wide range of jobs:

Image gallery

Photo from

Construction of a metal greenhouse frame

Assembling reinforcement mesh for the foundation

Manufacturing of large and small fences

Construction of stairs and entrance groups

Prohibited actions

According to safety regulations, when performing welding work you must not:

- Continue the process if the welding helmet is damaged.

- Work with a faulty or disconnected ventilation system. You cannot continue welding outside after it starts to rain or snow. This increases the risk of electrical injury.

- Connect loose metal workpieces using electric welding. Do not hold parts with your hands.

- Cook in areas with flammable materials or gases.

- Connect new elements to pipelines under pressure.

- Use thick metal sheets or profiles as grounding.

- Keep the holder or electrode closed for a long time. This contributes to the failure of welding equipment.

We recommend reading What is GOST 16037-80

Safety precautions - rules for safe welding work.

Types of Welding Machines

Based on productivity and power, welding machines can be divided into two types: household and industrial. Parts up to 5–6 mm thick can be welded first. Industrial equipment can operate for a long time without stopping.

Welding of metals occurs due to heating to high temperatures. Melting is achieved in various ways. Each of them has its own equipment. It is divided into groups according to the principle of operation:

- transformers;

- inverters;

- rectifiers;

- TIG devices;

- semi-automatic;

- spotters.

In addition, devices are used for gas processing of metal workpieces, cold welding, which creates high pressure, and other types of joining parts.

Welders

Transformer

Classic welding machines were the first to be invented. They simply lowered the voltage, leaving it variable. The power transformer reduces the network voltage to no-load values - 50–60V. By setting operating parameters, the following types of equipment are distinguished:

- thyristor - phase adjustment;

- with magnetic dispersion;

- with standard dispersion.

The disadvantage of the device is the unstable arc due to alternating current. Transformers are large in size and have high energy consumption.

Inverters

Inverters create optimal conditions for metal welding. They equalize alternating current and make it high-power, regulated with great precision. Inverters operate from a consumer network of 220V with a frequency of 50 Hz, industrial at 380 V. During the conversion process, the current passes:

- network rectifier;

- a frequency converter;

- high frequency transformer;

- power rectifier.

Inverters are configured to work with forward and reverse current. They work with electrodes of any type, welding high-alloy ferrous and non-ferrous metals. They have protection against power surges. Suitable for training beginners because they have a stable arc.

To work with direct current, rectifiers are also used, which consist of diodes and semiconductors. They convert alternating current into direct current and allow you to regulate its value. They do not have fine tuning.

All other types of welding equipment are various versions of the transformer and inverter.

Separate safety precautions for specific types of welding

Some categories of work are subject to additional labor protection requirements.

Gas cutting and welding

When performing such welding work, the requirements will be more extensive.

The electric welder must comply with the following rules:

- Cylinders with acetylene or oxygen are stored and transported only in a vertical position. Used containers are stored separately from full ones.

- First of all, stop the supply of acetylene. This eliminates the possibility of a kickback.

- Gas generators should not be installed near oxygen cylinders or stairs.

- It is prohibited to connect several burners to one container. Do not turn off automatic systems without permission or work in clothes contaminated with oil.

- When working with a generator, you need to monitor the liquid level in the seal.

- There should be no open flame sources near the cylinders. Smoking is allowed at a distance of at least 20 m from the welding site.

- Frozen equipment cannot be heated with an open flame. For these purposes, boiling water is used.

- Gas reducers with broken pressure gauges are excluded from the production process.

Use of electrical equipment

Compliance with the following rules helps prevent injury during manual arc welding:

- All electrical devices are carefully zeroed and grounded. For this, copper cables of sufficient cross-section are used.

- Welding equipment is connected through a separate circuit breaker and RCD.

- If it is necessary to repair the wire, the break is repaired using a coupling. Cables are suspended at a height of more than 2 m. They should be lowered to the units through a grounded steel hose. The places where the wires are laid are equipped with rubber holders.

- When working in open areas, a canopy is built over the equipment. If there is precipitation, welding is postponed.

- Defective cables are replaced before starting work.

Plasma welding and cutting

When performing such types of work, the following rules are observed:

- During welding, both hands are protected with gloves. Mittens should not be damaged or dirty.

- To protect the respiratory system, wear a respirator. In addition, they use means to prevent hearing damage due to high noise levels.

- Pollution generated during welding is removed from the air using exhaust systems. Installations can be stationary or portable.

- To protect the skin from melt particles, wear special shoes, a leather apron, and mittens.

- The flash generated during electric welding is disposed of in accordance with waste management rules in a closed cycle of materials use.

Compliance with labor safety requirements during welding helps make the production process safer.

Gas welding and cutting

When working with gas welding equipment, the Safety Rules provide for:

- Be careful when transporting cylinders. They should only be in a vertical position. The valves must be closed with protective caps.

- In cases where the backfire pops are heard during operation, you need to quickly turn off the gas supply. First of all, acetylene closes and only then oxygen. For safety reasons, gas lines should be turned off strictly according to the instructions. Gas tanks must be located at least five meters from the work area. It is advisable to hang the hoses.

- Before starting work, you should carefully check the burner. The presence of oil is especially dangerous - it can lead to detonation of the combustible mixture.

- During operation, it is important to maintain an optimal gap between the workpiece and the nozzle. The gas pressure must be constant.