Nowadays, welding is needed to connect parts made of different materials, such as metal. There are many varieties of this process because welding is used for many purposes: from household needs to the creation of more complex structures.

The technology itself is not very complicated, if you understand the theory well (types of welding, technologies, basic concepts), then all that remains is to practice creating seams so that they are of high quality, and therefore not only beautiful, but also durable.

So anyone can do this, the main thing is to devote time to self-education.

Electrode tilt

Welding seams are classified according to several criteria. The types and types of welding joints must be considered sequentially, delving into the intricacies of the process. The seam is affected by the location, direction and trajectory of the electrode.

After fixing the selected electrode in the clamp, setting the current, connecting the polarity, the welding process begins.

Each master has his own preferred angle of the electrode. Many consider the optimal value to be 70° from the horizontal surface.

An angle of 20° is formed from the vertical axis. Some work at a maximum angle of 60°. In general, most training guidelines include a range of 30° to 60° from the vertical axis.

In certain situations, when welding in hard-to-reach places, it is necessary to orient the electrode strictly perpendicular to the surface of the material being welded.

You can also move the electrode in different ways, in opposite directions: away from you or towards you.

If the material requires deep heating, then the electrode is directed towards itself. Following him in the direction of the welder is the working area. The resulting slag covers the fusion site.

If the work does not involve strong heating, then the electrode is moved away from you. The welding zone “crawls” behind it. The depth of heating with this type of weld is minimal. The direction is clear.

Types and methods of making welding seams

The ultimate goal of any welder is to obtain a high-quality weld. The strength and durability of the connection of parts depends on this. For successful operation, it is important to make the connection correctly; select the current strength, the angle of the electrode; have a good command of the seam technique. The result of proper work will be reliable welding of metal parts.

Electrode tilt

Welding seams are classified according to several criteria. The types and types of welding joints must be considered sequentially, delving into the intricacies of the process. The seam is affected by the location, direction and trajectory of the electrode.

After fixing the selected electrode in the clamp, setting the current, connecting the polarity, the welding process begins.

Each master has his own preferred angle of the electrode. Many consider the optimal value to be 70° from the horizontal surface. An angle of 20° is formed from the vertical axis. Some work at a maximum angle of 60°. In general, most training guidelines include a range of 30° to 60° from the vertical axis. In certain situations, when welding in hard-to-reach places, it is necessary to orient the electrode strictly perpendicular to the surface of the material being welded.

You can also move the electrode in different ways, in opposite directions: away from you or towards you.

If the material requires deep heating, then the electrode is directed towards itself. Following him in the direction of the welder is the working area. The resulting slag covers the fusion site.

If the work does not involve strong heating, then the electrode is moved away from you. The welding zone “crawls” behind it. The depth of heating with this type of weld is minimal. The direction is clear.

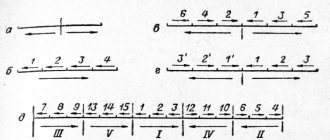

Trajectory of movement

The trajectory of the electrode has a particular influence on the seam. In any case, it has an oscillatory character. Otherwise, it will not be possible to sew the two surfaces together. Oscillations can be similar to zigzags with different steps between the sharp corners of the trajectory. They can be smooth, resembling movement in an offset figure eight. The path can be similar to a herringbone or a capital letter Z with monograms at the top and bottom.

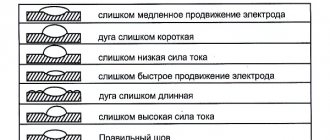

An ideal seam has a constant height, width, uniform appearance without defects in the form of craters, undercuts, pores, or lack of penetration. The name of the possible flaws speaks for itself. Having mastered your skills well, you can successfully apply any seam and weld a variety of metal parts.

Standards and the concept of leg

The weld begins to form in the working area when the metals are molten, and is finally formed after solidification. The existing classification groups seams according to various criteria: the type of connection of parts, the resulting shape of the seam, its length, the number of layers, orientation in space.

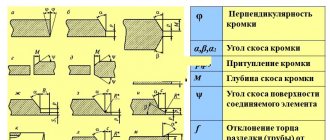

The types of possible welded joints are shown in the standard for manual and arc welding GOST 5264. Connections made by arc welding in a shielding gas atmosphere are standardized by the GOST 14771 document.

GOSTs have a designation for each welded joint, as well as a table containing the main characteristics, in particular the values of the leg of the weld.

It’s quite easy to understand what a leg is by looking at the drawing of the parts being connected. This is the side of a speculative isosceles triangle of maximum dimensions that will fit in the cross section of the seam. A correctly calculated leg value guarantees the strength of the connection.

For parts of uneven thickness, the cross-sectional area of the part in its thinnest part is taken as a basis. You should not try to unduly increase the leg. This can lead to deformation of the welded structure. In addition, the consumption of materials will increase. Checking leg dimensions is carried out using universal reference templates presented in specialized literature.

Types of connections

Depending on the relative position of the parts, welding joints occur:

- end-to-end;

- overlap;

- in an angular way;

- in a tee way.

When butt welding, the ends of two parts located in the same plane are welded. The joint can be made with a flange, without a bevel, or with a bevel. The shape of the bevel may resemble the letters X, K, V.

In some cases, welding is done with an overlap, then one part is partially mounted on another, located parallel. The combined part is an overlap. Welding is done without bevel on both sides.

Often there is a need to make a welded corner. This connection is referred to as the corner type. It is always done on both sides and may not have bevels or have a bevel on one edge.

If the welded parts result in the letter T, then a T-joint has been made. Sometimes parts welded with a T-seam form an acute angle. In any case, one part is welded to the side of the other. Welding is carried out on both sides without a bevel or with bevels on each side.

Shape and extent

The shape of the seam can be convex, even (flat). Sometimes it becomes necessary to make a concave shape. Convex joints are designed for increased load. The concave areas of the alloys withstand dynamic loads well. Flat seams, which are made most often, are characterized by versatility.

The length of the seams is continuous, without intervals between the fused joints. Sometimes interrupted stitches are sufficient.

An interesting industrial variation of the intermittent seam is the joint formed by resistance seam welding. It is done on special equipment equipped with rotating disk electrodes. They are often called rollers, and this type of welding is called roller welding. Continuous connections can also be made using such equipment. The resulting seam is very strong and absolutely airtight. The method is used on an industrial scale for the manufacture of pipes, containers, and sealed modules.

Layers and spatial arrangement

A metal seam can consist of a bead made in one pass. In this case it is called single-layer. If the parts being welded are thick, several passes are performed, as a result of which beads are sequentially formed one on top of the other. This welding joint is called multilayer.

Considering the variety of production situations in which welding occurs, it is clear that the seams are oriented differently in each specific case. There are lower, upper (ceiling) seams, vertical and horizontal.

Vertical seams are usually welded from bottom to top. The trajectory of moving the electrode along a crescent, herringbone or zigzag is used. It is more convenient for novice welders to move the crescent.

When welding horizontally, several passes are made from the lower edge of the parts being joined to the upper edge.

In the lower position, butt welding is carried out or by any angular method. A good result is obtained by welding at an angle of 45 °, “in a boat”, which can be symmetrical or asymmetrical. When welding in hard-to-reach places, it is better to use an asymmetrical “boat”.

The most difficult thing to do is weld in the ceiling position. This requires experience. The problem is that the melt tries to drain out of the work area. To prevent this from happening, welding is carried out with a short arc, the current strength is reduced by 15-20% compared to normal values. If the thickness of the metal at the welding site exceeds 8 mm, then several passes must be performed. The diameter of the first pass should be 4 mm, subsequent ones - 5 mm.

Depending on the orientation of the seam, the appropriate position of the electrode is selected. To make horizontal, vertical, ceiling connections, and weld non-rotating pipe joints, the electrode is directed at an angle forward. When welding corner and butt joints, the electrode is directed at an angle backwards. Hard-to-reach places are welded with an electrode at a right angle.

Weld joint processing

When welding, slag is formed. If slag inclusions get into the weld, its quality deteriorates. All slag deposits must be cleaned off.

If welding is performed in several passes, then the seams are cleaned after each welding stage. In this case, any methods are used. First, the welded parts are hammered and cleaned with a stiff brush. Then a rough cleaning is carried out. Small parts are cleaned with special knives or grinding wheels. Large blanks are cleaned on machines. At the final stage, the welded joint is polished. Often a fiber wheel of a grinding machine is used for this. There are other ways to polish welded joints.

Welding is constantly evolving. New materials are appearing and technology is improving. It is necessary to follow the news in welding to learn a lot of new and interesting things.

Similar articles

svaring.com

Trajectory of movement

The trajectory of the electrode has a particular influence on the seam. In any case, it has an oscillatory character. Otherwise, it will not be possible to sew the two surfaces together.

Oscillations can be similar to zigzags with different steps between the sharp corners of the trajectory. They can be smooth, resembling movement in an offset figure eight. The path can be similar to a herringbone or a capital letter Z with monograms at the top and bottom.

An ideal seam has a constant height, width, uniform appearance without defects in the form of craters, undercuts, pores, or lack of penetration. The name of the possible flaws speaks for itself. Having mastered your skills well, you can successfully apply any seam and weld a variety of metal parts.

Ignition of an arc with an electrode

In order to light an arc, you need to bring the electrode to the metal and lightly tap it on the surface, immediately moving it upward. There is no need to move the electrode too far, since the arc will certainly go out. It is enough to withdraw by 2-3 mm.

You can also light an electrode by striking its end against a metal surface. We just take it and, as it were, move the electrode with a short movement across the metal until the welding arc lights up.

Standards and the concept of leg

The weld begins to form in the working area when the metals are molten, and is finally formed after solidification.

The existing classification groups seams according to various criteria: the type of connection of parts, the resulting shape of the seam, its length, the number of layers, orientation in space.

The types of possible welded joints are shown in the standard for manual and arc welding GOST 5264. Connections made by arc welding in a shielding gas atmosphere are standardized by the GOST 14771 document.

GOSTs have a designation for each welded joint, as well as a table containing the main characteristics, in particular the values of the leg of the weld.

It’s quite easy to understand what a leg is by looking at the drawing of the parts being connected. This is the side of a speculative isosceles triangle of maximum dimensions that will fit in the cross section of the seam. A correctly calculated leg value guarantees the strength of the connection.

For parts of uneven thickness, the cross-sectional area of the part in its thinnest part is taken as a basis. You should not try to unduly increase the leg. This can lead to deformation of the welded structure. In addition, the consumption of materials will increase.

Checking leg dimensions is carried out using universal reference templates presented in specialized literature.

Features of welding technology

According to the generally accepted classification, there are two options for an ideal weld, in particular:

- Detachable view.

- One-piece look.

Detachable technology includes seams and connections that can be separated without damage without breaking the connecting elements. The simplest elements are a bolt and a nut. Permanent connection refers to high-strength structural solutions; the parts are in no case separated, and the uniqueness and integrity of the structure is not compromised. This option includes riveting and welding technologies. Experience shows that in order to achieve ideal quality, an excellent option would be the heat-affected zone of the weld, which ensures a high joint result.

Types of connections

Depending on the relative position of the parts, welding joints occur:

- end-to-end;

- overlap;

- in an angular way;

- in a tee way.

When butt welding, the ends of two parts located in the same plane are welded. The joint can be made with a flange, without a bevel, or with a bevel. The shape of the bevel may resemble the letters X, K, V.

In some cases, welding is done with an overlap, then one part is partially mounted on another, located parallel. The combined part is an overlap. Welding is done without bevel on both sides.

Often there is a need to make a welded corner. This connection is referred to as the corner type. It is always done on both sides and may not have bevels or have a bevel on one edge.

If the welded parts result in the letter T, then a T-joint has been made. Sometimes parts welded with a T-seam form an acute angle.

In any case, one part is welded to the side of the other. Welding is carried out on both sides without a bevel or with bevels on each side.

Shape and extent

The shape of the seam can be convex, even (flat). Sometimes it becomes necessary to make a concave shape. Convex joints are designed for increased load.

The concave areas of the alloys withstand dynamic loads well. Flat seams, which are made most often, are characterized by versatility.

The length of the seams is continuous, without intervals between the fused joints. Sometimes interrupted stitches are sufficient.

An interesting industrial variation of the intermittent seam is the joint formed by resistance seam welding. It is done on special equipment equipped with rotating disk electrodes.

They are often called rollers, and this type of welding is called roller welding. Continuous connections can also be made using such equipment. The resulting seam is very strong and absolutely airtight. The method is used on an industrial scale for the manufacture of pipes, containers, and sealed modules.

Layers and spatial arrangement

A metal seam can consist of a bead made in one pass. In this case it is called single-layer. If the parts being welded are thick, several passes are performed, as a result of which beads are sequentially formed one on top of the other. This welding joint is called multilayer.

Considering the variety of production situations in which welding occurs, it is clear that the seams are oriented differently in each specific case. There are lower, upper (ceiling) seams, vertical and horizontal.

Vertical seams are usually welded from bottom to top. The trajectory of moving the electrode along a crescent, herringbone or zigzag is used. It is more convenient for novice welders to move the crescent.

When welding horizontally, several passes are made from the lower edge of the parts being joined to the upper edge.

In the lower position, butt welding is carried out or by any angular method. A good result is obtained by welding at an angle of 45 °, “in a boat”, which can be symmetrical or asymmetrical. When welding in hard-to-reach places, it is better to use an asymmetrical “boat”.

The most difficult thing to do is weld in the ceiling position. This requires experience. The problem is that the melt tries to drain out of the work area. To prevent this from happening, welding is carried out with a short arc, the current strength is reduced by 15-20% compared to normal values.

If the thickness of the metal at the welding site exceeds 8 mm, then several passes must be performed. The diameter of the first pass should be 4 mm, subsequent ones - 5 mm.

Depending on the orientation of the seam, select the appropriate position of the electrode . To make horizontal, vertical, ceiling connections, and weld non-rotating pipe joints, the electrode is directed at an angle forward.

When welding corner and butt joints, the electrode is directed at an angle backwards. Hard-to-reach places are welded with an electrode at a right angle.

The ideal welding seam - what is it?

If you need to get a beautiful and high-quality seam, buy modern electrodes. Yes, yes, leave the “old-fashioned” wire, on which there is almost no coating left. Use new and dry electrodes according to the manufacturer's instructions. Find on the package with electrodes the current at which you need to cook, as well as the polarity, that is, + and - connections.

If reverse polarity is indicated on the electrodes, then connect the plus from the inverter to the electrode holder. If you need to weld with direct polarity, then the plus should go as a mass, that is, connect to the metal being welded.

So, we connect the cables to the inverter and insert the electrode into the electrode holder. We set the required welding current on the inverter and turn on the machine. The electrode must be held in the holder strictly at an angle of 90 degrees and nothing else.

Weld joint processing

When welding, slag is formed. If slag inclusions get into the weld, its quality deteriorates. All slag deposits must be cleaned off.

If welding is performed in several passes, then the seams are cleaned after each welding stage. In this case, any methods are used. First, the welded parts are hammered and cleaned with a stiff brush.

Then a rough cleaning is carried out. Small parts are cleaned with special knives or grinding wheels. Large blanks are cleaned on machines. At the final stage, the welded joint is polished.

Often a fiber wheel of a grinding machine is used for this. There are other ways to polish welded joints.

Welding is constantly evolving. New materials are appearing and technology is improving. It is necessary to follow the news in welding to learn a lot of new and interesting things.

Basic characteristics of the work process

Now you need to figure out how to properly weld the correct seam, which ensures the ideal plane of the parts being connected. As you know, welding itself is a unique technology; the parts being connected are joined together under the influence of melting, while ensuring a reliable connection. To understand how to make a weld correctly, it is necessary to study various factors of the welding process, among which are:

- The principle of design and operation of technological equipment.

- General degree of adjustment of the working device.

- Size range of electrode diameters.

- Classification, experience and skill of a master of technological devices and equipment.

The last factor is significant, and allows us to solve the difficult problem facing a specialist - how to correctly lay a welding seam using electric welding.

Welding a perfect weld

Equipment options for work technology

Innovative developments do not stand still, just like traditional methods; an ideal weld without stripping involves the use of one or another version of devices, where the priorities are:

- Contact technology.

- Gas compression.

- Roller group.

- Electroslag.

- Thermite method.

- Friction.