A vacuum cleaner is a necessary thing in every home. Many people think about the question of how to make a filter for a vacuum cleaner with their own hands. It is already difficult for any housewife to imagine cleaning without using this device. The machines do an excellent job of removing accumulated dirt, and some models also help with wet cleaning.

An important part of a vacuum cleaner is the filters, which are responsible for retaining and collecting debris and dust. Like any thing, they tend to wear out, so every owner of such a device can decide to make a filter with their own hands. Modern models use different types of them - from ordinary bags to specialized ones with additional functions.

Some you can try to make at home. This will cost less than buying a ready-made filter in a store, and will last much longer.

Types of filters

There are several types of such collections:

- Membrane. It is used very often in modern models. The cheapest way to eliminate dust. Membranes are a semi-permeable medium that allows water and oxygen to pass through, but can retain impurities on the surface.

- Water. Passes air and dirt through a container of water, leaving all harmful particles in the liquid, releasing uncontaminated air out.

- Cyclonic. It is a cheaper filter compared to water and membrane filters, but not inferior in quality. Passes air with dust through a cylindrical body.

Advantages and disadvantages

An undoubted advantage of homemade filters is the saving of time and money on replacing them. In some cases, the cost of installing such a filter will not be necessary at all - often all the necessary elements for its creation are present in the household.

Homemade filters significantly expand the functionality of vacuum cleaners, allow you to achieve better cleaning quality, and even complement dry cleaning with wet cleaning. At the same time, in terms of their operational parameters, “homemade” filters are in no way inferior to factory ones, and in some cases even surpass them.

However, keep in mind that homemade filters may not always be able to be installed. When the equipment is under warranty, you will be denied free service and repair if the device includes “foreign” parts. At the end of this period after the first filter change, try to make sure that the rework does not increase the load on the vacuum cleaner and energy consumption.

What does a cyclone filter mean in a vacuum cleaner?

To understand what it is - a cyclone filter as a type of dust collector, you do not need to have any special knowledge. Most models on the market are equipped with transparent tanks or containers for collecting debris and dust, which allows you to see how the entire cleaning process occurs.

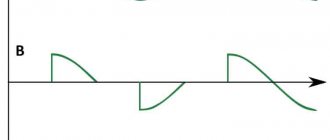

When air is sucked in with a certain force, an air flow is formed inside the cyclone, flowing with turbulence.

The principle of operation of a cyclone type filter is reminiscent of a tornado, only in a reduced size.

Inside the cyclone vacuum cleaner there is a special filter that has the shape of a cone.

The centrifugal force generated by the suction of the air flow causes all collected debris, dust and dirt to be “pressed” into the walls of the container and deposited on the filter pad.

Step by step, the work of a cyclone-type industrial vacuum cleaner or home models can be divided into a number of sequential operations:

- The user turns on the device, which results in a powerful air flow that sucks debris and dust into the vacuum cleaner.

- Before entering the cyclone filter tank, all dirt passes through the primary filter, which is a fine-mesh plastic mesh.

- Next, a second barrier stands in the way of dust, which is represented by a HEPA filter, which is a plate made of a material similar in structure to ordinary cotton wool.

- The next step is to get 90% of the garbage into the cyclone itself.

- This form is not chosen by chance, but is the result of engineering calculations. It is the truncated cone that ensures the creation of a vortex effect, leading to the fact that the remaining particles of debris settle on the bottom and walls of the container.

- As a result of work, the vacuum cleaner comes out of air purified of unnecessary impurities by 97%, which is a very good indicator of operating efficiency.

The most important thing in the operation of a cyclone is the creation of centrifugal force of the air flow, which ensures that particles settle on the walls of the tank

To obtain a more powerful centrifugal force, the container is shaped like a cut cone.

The invention of the cyclone dates back to the 80s of the 19th century. During the existence of the technology, various designs of cyclone filters have been developed, but the essence of the work of all remains the same.

Before entering the cyclone, dust passes through two filters: mechanical, in the form of a mesh, and HEPA, which has a porous structure

There is a rule that follows from the physical meaning of the cyclone: the degree of cleaning depends on the height and diameter of the device to create centrifugal force. At the same time, the greatest efficiency is demonstrated in the retention of particles of a large fraction.

Pros and cons of a cyclone

The main advantages of a cyclone filter:

- deep cleaning of the surface due to multi-level filtration;

- minimal dust emissions when air exits the vacuum cleaner;

- convenient cleaning of the filter and dust collector;

- compactness, since the filter usually has small dimensions (one of the reasons for its frequent use on vertical vacuum cleaners);

- the ability to wash all parts of the structure;

- The absence of dust bags saves money.

Also worth noting is the strength of the filter container, which, unlike cloth or paper bags, can hold back glass or nails. Typically, vacuum cleaners with cyclone filters have filling indicators, but if they are absent, clogging can be determined by a decrease in suction power.

With all its advantages, the cyclone filter also has a number of disadvantages:

- rapid reduction in power when clogged;

- increased noise level;

- increased cleaning time due to low power;

- passage of small dust particles.

Since in standard models of vacuum cleaners with cyclone filters, dust microparticles fly out with the exhaust air stream, it is recommended for allergy sufferers to purchase a model with an aquafilter and an increased level of filtration.

This type of vacuum cleaner has been popular for over thirty years. The body itself is lighter than that of vacuum cleaners with an aqua filter, since it is empty inside. The essence of such filtration is the effect of centrifugal force on the debris sucked inside. Due to the hurricane wind flow, large and small particles of pollution settle in different containers. After disconnecting the vacuum cleaner from the power supply, you just need to pull the container out of the body and clean it.For such a homemade filter we will need:

- Plastic container with a sealed lid.

- Two corrugated or plastic pipes two meters long.

- Cone (you can buy a regular car cone in the store).

Cut off the bottom of the cone and connect it to the pipe. To make a sealed hole, we close all holes and cracks with plywood. We connect the cut part of the cone to a pipe into which all the debris will fall. The end of this pipe should fit into a plastic container. We seal it with a piece of plywood. You need to connect it to the vacuum cleaner using an outlet pipe. We attach it to the inlet of the vacuum cleaner using a hose.

The design of cyclone filters makes them much more convenient and efficient than conventional garbage disposals. Due to their spaciousness and hygiene, such purification systems are becoming increasingly popular. However, not everyone can afford the high cost.

The principle of operation is as follows: the air flow passes through primary filters, which trap small dust particles. Next, the air enters the cyclone filter - a container in which, under the influence of the vortex effect, larger particles of debris swirl and settle to the bottom under their own weight. At the outlet, the air is 98% purified.

Materials for production

The simplest way to make a cyclone filter is to use a plastic bucket as the main element. The volume is calculated quite simply. For every 100 W of power, add 1 liter of capacity.

A mandatory requirement for the container is the presence of a hermetically sealed lid.

In order to design a cyclone system filter, you will need the following tools:

- stationery knife;

- glue gun;

- silicone;

- compass.

Materials you will need:

- container with a lid (you can use paint or building mixture buckets);

- 45° elbow - 2 pcs.;

- 90° elbow - 2 pcs.;

- O-rings;

- plastic pipe.

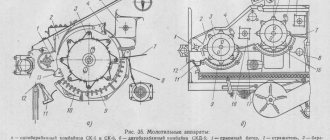

The manufacturing process is carried out as follows:

- Two holes are made along the edges of the lid, the diameter of which coincides with the diameter of the pipe. In this case, the holes should be 4 cm from the edges.

- Silicone is applied to the edges of the holes, after which a sealant is inserted into the inner part, and then the knee itself.

- The outer side of the elbow is located almost at the level of the lid. From the inside, the pipe is directed to the center of the container and is also equipped with a 45° rotation.

- The second elbow is also supplemented with a rotating part on the inside, but in such a way that it is directed towards the wall of the bucket.

- When connecting elbows, it is necessary to use rubber seals (rings).

- Next, the structure is attached to the vacuum cleaner. The pipe, which is located on the outside at the level of the lid, goes to the vacuum cleaner hose, the second one goes to the corrugated pipe, which will bring out a clean air flow.

How to make a cyclone from scrap materials

Leroy sells 48-liter polyethylene euro-barrels for 880 rubles; they are great for creating a cyclone.

If you have 2 primer buckets, you can make a body out of them. One bucket is cut off at the top and bottom and these cones are inserted into the second bucket to strengthen the walls.

For a bucket body, the lid is reinforced with plywood.

You will also need 2 sewer angles for 40. A hole is drilled in the center of the lid with a 38 mm crown. The second hole is drilled close to the edge. Sewer corners are inserted into the holes. They need to be securely fixed. To do this, you can heat them with a hair dryer or use sandpaper to enlarge the hole and place the corners on hot glue. The extreme corner must be secured especially well so that it does not rotate and directs the air flow in the desired direction for twisting.

The cyclone is connected to a construction vacuum cleaner. Paper bags are not suitable for construction waste vacuum cleaners, as they tear quickly. Use synthetic filters, they cost about 600 rubles per set. To save money, you can insert a synthetic bag inside instead of a filter for 20 rubles. With a bag, the garbage will not settle in the bag, but in the vacuum cleaner tank itself, and you can shake it out of there as if from a bucket.

It is also advisable to use a cartridge filter in a vacuum cleaner for construction dust.

History of invention

Until recently, all vacuum cleaners included a garbage bag. However, in the late 1970s, the British engineer D. Dyson offered the world a completely different design. An engineer is unhappy with the rate at which the vacuum cleaner's bags are becoming clogged and their suction power is decreasing. Not finding a suitable option among the purifiers that existed at that time, he developed his own copy of the technique.

It was a new type of vacuum cleaner: a cyclone. Dyson based his invention on the principle of air purifiers. In them, the flow inside rotates in a spiral, increasing the speed in the narrowing area of the settling tank. Over 15 years of work, the engineer created 5,127 prototypes of a modern vacuum cleaner. It was only in 1986 that the Japanese company Apex Inc took over the production of one of the Dyson models. He was given the name G-Force.

Dyson vacuum cleaner

In 1993, the engineer opened his own research center, where he continued to improve his technologies. Here he managed to create a device capable of collecting even fine dust. The Dyson vacuum cleaner, the price of which is still quite high, is one of the best options for such equipment.

Almost every modern company in this industry uses this technology. But each of them has its own unique engineering solutions and improvements.

Aqua filter for vacuum cleaner

Water filtration systems are perhaps the most popular among users. However, the price of vacuum cleaners equipped with this cleaning method is often too high. Therefore, there are many options for homemade aqua filters. Below is another example.

Materials for production

To construct a homemade aqua filter you will need:

- 10 liter PVC bucket with lid;

- plumbing adapters (3 pcs.);

- PVC panel;

- corrugated pipe for air flow outlet.

On one side of the bucket, two holes are cut out, the diameter of which is equal to the diameter of the pipes. The walls of the holes are lubricated with silicone. An elbow is inserted into one of them and another pipe attached to it so that its end is located right near the bottom of the container (a gap of no more than 2 cm) - this part will act as an inlet for air flow. An additional cover with a hole for the pipe and a slot for air outlet is pre-cut from PVC, after which it is installed in a bucket (with a slight slope).

Another pipe is installed in the second hole, located above the membrane, to which a hose for the vacuum cleaner will be connected in the future. Before work, about 2–2.5 liters of water are poured into the container.

How to make an aqua filter for a vacuum cleaner

Some modern vacuum cleaners are equipped with aqua filters. When polluted air passes through such a water filter, most dust, debris and small particles remain in the water. This increases the service life of filters and dust bags several times. This filter is very easy to make and can be made at home. Materials. — Plastic 10-liter bucket with a lid — Corners of plastic sewer pipes — Flexible corrugated pipe, PVC panel — Insulating tape, sandpaper, glue sticks. Tools used by the author. — Wireless glue gun — Marker, knife.

Manufacturing process. So, a 10-liter plastic bucket with a lid will serve as a housing for the filter. First of all, two holes with a diameter of 50 mm are cut in its upper part. The surfaces around the holes are treated with coarse sandpaper. A corner is inserted into the first hole, and a part of a 50 mm pipe is put on it. The length of the pipe should be such that there is a gap of 20-30 mm between its end and the bottom. Through this tube, contaminated air will enter the filter. Then the author cut out a partition from a PVC panel, in which he prepared a cutout for the tube. The inner surface of the body, which will be joined to the partition, also needs to be sanded. On the opposite side of the partition you need to cut off part of it, making a hole between the upper and lower chambers of the filter.

Another corner is inserted into the second hole; purified air will come out through it. Next, all pipe joints and partitions with the body are sealed using a glue gun. You can also use various liquid nail sealants.

The partition should be slightly tilted towards the opening between the chambers, then drops of water will flow into the lower compartment. The hose from the brush fit perfectly into the 50th corner. And the connection between the flexible corrugated hose and the filter had to be sealed by wrapping it with insulating tape. To check whether splashes of water were flying from the lower chamber to the upper one, the author connected the blower of the vacuum cleaner to the filter inlet. It is enough to pour 2.5 liters of water into the filter, it will be at a level of 50 mm from its bottom and will block the inlet pipe. During testing, it became clear that the cutout in the partition between the chambers needed to be increased. Now splashes of water do not enter the outlet along with the air flow.

At the same time, there was almost nothing in the dust collector of the vacuum cleaner, and no water got into it. Using a filter of this design, you can collect small amounts of spilled liquid by monitoring the level in the container. You can use a bucket or other larger container as a body. After using the filter, it is advisable to let the vacuum cleaner run idle for a couple of minutes to remove moisture from the filter elements. As expected, the author made several changes to the design over time. Namely, he had to reinforce the seams with liquid nails.

It was also necessary to install an additional petal on the inside of the outlet pipe, since drops of water sometimes got into it. The partition is made from scraps of a thick-walled plastic bottle from household chemicals. Of course, such a filter cannot fully replace an industrial vacuum cleaner for wet cleaning, but it will expand the functionality of an old Soviet or imported vacuum cleaner. I thank the author for the recommendations on making a simple aqua filter for a vacuum cleaner, which will be useful not only at home, but can also serve in the workshop.

How to make a water filter for a vacuum cleaner

More often it is called an aquafilter. Nowadays such models are popular in the household appliances market. Their secret is that they not only collect garbage, but also humidify the air without causing unpleasant odors. The only negative is the heavy weight of the vacuum cleaner due to the vessel with water inside, but it is compensated by the good quality of cleaning.

The principle of its operation is very simple. With the help of a motor, all debris ends up in a compartment with water, which then needs to be drained.

Diagram of operation of a vacuum cleaner with an aqua filter

How to make this type of filter? It’s quite simple if you have all the necessary parts and a work plan.

You will need a separator, water container, fan and pump. The smaller the fan you choose, the less noise it will make. When choosing a pump, keep in mind that the water level in the vessel will rise by almost a centimeter. Choose all fasteners with zinc coating. Don't forget about the built-in turbo brush, it will help thoroughly clean carpets. To get a good result, carry out the work in stages:

- Install the dust collector casing, storage tank and disintegrant.

- Attach the pump with a rubber ring. Watch the gaps between the housing parts.

- To make the vacuum cleaner as silent as possible, stick polyethylene on the bottom.

- Before use, pour water strictly according to the marks on the container.

There are other ways to create an aqua filter. Maximum effort and desire - and you will do high-quality work that will be useful for a long time.

Possible difficulties during manufacturing

When making filters, it is important to ensure the products have the required strength and pay special attention to the joints of the parts. The air creates a lot of pressure in the filter, so all fastenings must be as reliable as possible.

The seams on the dust bag should not come apart, otherwise dust will settle inside the vacuum cleaner and harm the motor. In a cyclone and aquafilter, the main danger is disconnected hoses and leakage.

It is not difficult to make filters for a vacuum cleaner, but for this the craftsman must have at least minimal skills and experience. Filter designs require accuracy and careful adjustment of all elements to each other.

Rate this post

How to care for the filter

Working with this device is intuitive. To do this, you need to remove the container and empty the garbage out of it. It is not necessary to wash the plastic after work. If the dust container is only slightly full, there is no need to empty it immediately. This can wait until next use.

Cyclone filters can be purchased separately

When the owner wants to wash the tank, it is enough to rinse it with water. There is no need to use additional detergents. For more thorough cleaning, it is enough to use, for example, laundry soap. After this, you need to rinse with clean water and wait until it dries completely.

If liquid gets inside during operation, it must be removed, then dry the filter. Only after this will it be possible to continue work.

When the filter is used for industrial purposes, it is important to ensure that the dust container is filled. Once enough debris has accumulated, it needs to be emptied. It is important to ensure the tightness of the cyclone filter connections. This will eliminate the possibility of debris re-entering the surrounding atmosphere.

Sources

- https://tehnika.expert/dlya-chistoty-i-poryadka/pylesos/filtr-dlya-pylesosa-svoimi-rukami.html

- https://promusor.info/machines/vacuum-filter-selfmade/

- https://its-city.ru/dlya-uborki/ciklon-svoimi-rukami-s-domashnim-pylesosom.html

- https://dustbag.ru/posts/filtry-meshki-shchetki/filtry/svoimi-rukami/

- https://PyleSOS.tech/filtry/kak-sdelat-filtr-dla-pylesosa-svoimi-rukami.html

- https://remboo.ru/instrumenty/samodelnyj-cziklon.html

- https://USamodelkina.ru/19271-kak-sdelat-akvafiltr-dlja-pylesosa.html

- https://m-strana.ru/articles/tsiklonnyy-filtr/

[collapse]