Purpose of devices

The main purpose of a perforated corner is to create an elastic and rigid base and give ideal shapes to corners and various junctions. Less commonly, it is used as a beacon for applying plaster. Depending on the specific task, a straight perforated corner can be used or a special one for arches, flexible, and made of plastic to form the necessary bend of the opening.

This is the most common type of material. Can be internal or external. The perforated corner is made from a variety of materials (plastic, galvanized) and differs in the width of the margins.

Plastic perforated devices can be easily cut with a regular stationery knife. For galvanized steel, it is better to use metal shears.

You can use perforated corner in the following finishing areas:

- slopes;

- arches;

- corners of drywall structures;

- alignment of walls.

The old fashioned way

A kitchen corner made of wood looks chic in any setting, whether it is made from solid wood or boards from unusable construction pallets - pallets, see fig. And making a wooden kitchen corner with your own hands may not be more difficult or more expensive than the one described above.

Kitchen corners made of wood

To start carpentry on wood, and not on viscous and fragile chipboard, it is not necessary to immediately buy an expensive triad of a jointing machine - a manual milling machine - a sander. You can get by with traditional hand (and non-volatile!) hand tools. Processing small parts in piece production with it often turns out to be easier and faster than readjusting the machine for the next operation.

To begin with, in addition to a jigsaw (we are not pedants, this tool is not very expensive, is often needed and is better than a bow saw in all respects), you will need a regular carpenter's plane, a hand jointer and a set of wood rasps. At first, one so-called will be enough. cabinet rasp, flat-convex with a tapered end, on the right in the figure:

Woodworking tools

You will also need selected (emphasis on the “s”) straight and beveled chisel planes (on the left in the figure). Using a straight chisel, remove the folds and select grooves along the fibers, and with an oblique blade across and plan the ends.

For primary processing of knotty wood, you need a sherhebel plane in the center. The sherhebel is used with a slight sliding to the side, as if cutting off and trimming knots. You can turn an ordinary plane into a sherhebel by placing a “piece of iron” knife with a rounded blade in it.

Having gained a little skill, it will be possible to replenish the tool park with another 3-4 types of selected planes with replaceable pieces of iron for them, see next. rice. Take a closer look at antique furniture: it was made with just such a tool, and not with modern machines with shaped cutters.

Selected planers for figure planing

The last point is the assembly (pulling together) of furniture panels from boards, they are also an array of furniture. In theory, this requires special devices - clamps - 3 per tabletop, 4 per cabinet sides and 2 per smaller panels. Here, firstly, one clamp can be replaced with a pair of jaws with clips for mounting on a rod, and a piece of timber of suitable thickness for the clips will go onto the rod, see figure; usually 60 mm. Sets of jaws for clamps and long clamps are sold separately.

Tension clamp made from a pair of jaws with clips and a piece of timber

Finally, wide panels are not needed for the kitchen corner; Most often, a shield for 3-4 boards is required. In this case, a shield from boards can be assembled without any special equipment at all, see video:

Rules for installing the outer corner

The process of mounting a perforated corner is not as complicated as it might seem at first glance. First you need to collect a small set of tools and materials:

- 2 spatulas approximately 50 and 150 mm;

- drill with attachment (mixer);

- brush;

- level;

- primer;

- gypsum putty.

To prepare the solution, the required amount of water is collected in a container, the dry mixture is poured into it and the whole thing is stirred with a mixer until a homogeneous creamy mass.

After the mixture is ready, you can, armed with spatulas, begin to apply it to the corner. Use small strokes to cover one side of the corner along its entire length. Next, take a corner of the required length and simply press it into the solution. To begin with, it is better to align it more or less evenly by eye, and then, after removing the solution squeezed out through the holes with a spatula, use a level. Having measured all areas one by one and achieved the required level, you can consolidate the result by applying the solution on both sides of the corner.

You can wait a little and let the existing mixture dry, which will avoid displacement when puttying. It is worth noting that sometimes, due to the nature of the base, it is not possible to position and plaster the perforated corner. It slips and shifts. Ordinary self-tapping screws screwed into the holes will help solve this problem. After drying, they can be removed, and the nests formed after them can be carefully filled with putty.

Get to work!

Which corner of your kitchen is best suited is up to you. And here we will see what difficulties you will encounter when making it at home without experience, and how to cope with them. The analysis will be based on the example of a design known in RuNet, the drawings of which are given below; The main materials are laminated and simple sanded chipboard with a thickness of 16 mm.

Drawings of a kitchen corner made of laminated chipboard

Specification for kitchen corner drawings

On the one hand, this corner requires minimal materials and labor and can be made much more convenient, see below. On the other hand, the prototype is oriented towards industrial technology, its design is rational and well-developed, but we need to get a product no worse than that, assembling it at home on the knee and in weight. This particular sample was also chosen because it is capable of acquiring all the best qualities of a corner with a beveled corner, plus the ability to serve as a sleeping place, but technologically it is not much more complicated than a right corner. In addition, there is a generally correct specification for it with statements of material and fittings, see fig. on right.

Note: if you check/refer to other sources with descriptions of this sample, keep in mind that in some of them, and quite a few, in the drawings of the parts the dimensions are given mixed for sofas with a length of 100 and 60 cm. Assemble the blanks cut out from them into the product, of course, impossible.

For example, in the top row of Fig. Assembly diagrams are provided with the drawings, clear as day to a factory technologist. But what to do with them if you don’t have production equipment? The sample under consideration is a panel box-shaped structure, similar to the power circuit with load-bearing skin in the aircraft industry. Box-panel structures save material and labor as much as possible, resulting in very durable products, but their manufacturing technology is subject to a number of specific requirements. There are a lot of invisible tricks here, but we can deal with them, and we will do it. First for the sofas, in this order:

- Selection of fasteners;

- Adjusting dimensions for a specific room;

- Cutting laminated chipboard and chipboard into blanks, marking and drilling holes;

- Trimming the edges of beveled parts and edging;

- Covering the parts for which it is required with soft covering;

- Assembly.

Next, let's see how we can simplify the manufacture of a corner section (corner) and make it more convenient. The original design is modular, but in our apartment the corners of the walls do not change places by themselves. Knowing exactly where the corner will go, whether it will be right or left, the corner can be made hanging (see below), and this will make the work much easier and cheaper.

Fasteners

The main fastening elements of this kitchen corner that absorb operational loads are confirmed furniture screws and steel corner connectors; dowels play a supporting role, keeping the parts from moving. The specification above contains a list of accessories for assembly in an industrial environment, but for home use, some things will have to be changed in it.

Note: in products made from laminated chipboard and chipboard, it is possible to replace confirmats with wood screws to connect parts through the face into the edge occasionally. In this product - under no circumstances is it possible, because... the boards are very thin, 16 mm. The connecting corners are attached to the parts using wood screws, see below.

Confirmations

The standard size of confirmats 7x50 specified in the specification is the maximum permissible for a given chipboard/laminated chipboard thickness. This makes it possible to transport the corner modules in assembled form and reduce its cost somewhat, because there is no need for on-site assembly, and any of the modules is carried into the apartment by hand by a person with the physical development of an office type. But marking and drilling for the thickest possible fasteners also requires production precision (see below), which cannot be achieved by working at home with your hands. For example, can you, when working with a hand-held electric drill, feed the drill perpendicularly or parallel to the face of the board with a deviation to the side of no more than 0.1 mm? The question is rhetorical. Therefore, for manual work, provided that the product will not be transported over long distances with shaking and jolts, the size of the confirmats should be reduced to 6x50 or even 5x60. Otherwise, i.e. If you take fasteners according to industrial specifications, some of the parts may delaminate during drilling or assembly. If the chipboard/chipboard is taken from eco-friendly brands E0 or E1, then it will definitely delaminate, so the chipboard/chipboard should be taken from the household brand E2, and if you want E0/E1, then the thickness of the boards needs to be increased to 24/20 mm, adjusting accordingly. dimensions, see below.

Fasteners and connecting elements for the kitchen corner

The height of the screw neck H is important for the strength of the confirmed connection, see pos. 1 in Fig. H must be exactly equal to the thickness of the overlay board, on the right in pos. 1. Sometimes H is indicated by the 3rd digit in the name of the screw size, i.e. you will need confirmations 6x50x16 or 5x60x16 for the original structure or 6x50x24/6x50x20 or 5x60x24/5x60x20 in the case of using boards of greater thickness.

The confirmation drill must be taken exactly for the given screw size. The height of its skirt should be equal to H (in the center in position 1), the diameter should be equal to the diameter of the screw body without thread, and the length of the spiral part of the drill L (without cutting tip) should be equal to the full length of the threaded part of the screw. If the heel of the screw rests on the residual conical hole in the hole, then hidden delamination in thin boards is guaranteed, and it is only a matter of time before it spreads outward. Small.

Dowels

In all sources on the topic of the kitchen corner in question, photos of wooden dowels are given as illustrations with enviable consistency, but without proper understanding. This is a gross mistake in this case. Wooden dowels are designed for connecting wooden parts: they dry out along with the base material, and the connection remains strong for many years. Or centuries, if the furniture was made by an outstanding master.

Chipboard/chipboard do not dry out and are therefore connected with plastic dowels. If you take slightly more expensive propylene ones, then there is no need for rather labor-intensive and careful gluing of joints. For the reasons stated above, the diameter of dowels for manual production must be reduced to 6 mm, leaving their length the same. In the edges of the boards, holes for dowels are drilled only along the jig (item 4 in the figure); diameter - 5.3 mm, drilling depth 22 mm in the edges and 12 mm in the faces.

The seats (see below) can be made not folding, but removable, by placing them on dowels with round heads for detachable connections (above, position 2). This will allow you to avoid the rather complex installation of piano hinges, the costs of them and fasteners for them. And if they decide to rearrange the corner in a hurry, then the likelihood of damage to it is reduced: they grabbed the seat without thinking, it remained in their hands, and the sofa did not jump or hit anything. Getting something out of the chest under the seat on piano hinges is no more convenient, because... The seat cover reclines less than 90 degrees. It’s easier to remove it and lean it against the back than to rummage through the chest while holding the lid with your hand. But in the design under consideration this, unfortunately, is impossible, see below.

It is better to take other dowels for our kitchen corner with faceplates, at the bottom at pos. 2. Washer thickness 0.5-0.7 mm; At first such gaps will not be visible. After some time, the washers will be pressed into the chipboard (the parts are tightly tightened with confirmats), the gaps will converge, and the entire product will acquire additional strength. Another advantage of dowels of this type is different corrugations on the long and short parts, which provides even higher strength of the connection without the danger of delamination of the boards. You just need to select dowels of the required size: with a 20 mm long part and a 10 mm short part (for 16 mm boards). For boards 20/24 mm, the long part needs 30 mm, and the short part 12/16 mm.

Corners

For the design in question, you will need steel isosceles corner connectors 30x20x2 (for fastening obliquely) or 30x15x2 for fastening in a row. The first number indicates the length of the corner shelves, the second their width, the third – the thickness of the material. During assembly, the corners will have to be partially bent to install inclined parts, so you need to take them white or gray from viscous “raw” or moderately annealed steel. The presence of stiffness stamping on the bend for bent corners is unacceptable, pos. 4 in Fig. The internal and external folds of the corners should be smooth, without tears or wrinkles. The corners of burnt steel, yellowish with spots of tarnish, even if they bend, will then crack. Black phosphated corners from the so-called. Overdried steel is very strong, but when bent, it breaks immediately.

Note: just so you know, plastic furniture corners can be bent by thoroughly heating them with a household hairdryer at full power. But plastic corners last no more than 3-5 years, and then they dry out and crack.

Dimensions

Let's look again at Fig. with drawings (duplicated on the right). The dimensions have been corrected: the length of a sofa 1 m long is shown in black; red and blue next to the “black” ones for a small sofa 60 cm long. The green marks will come in handy later when we get to the corner seat.

The “red” dimensions are basic: you need to add to them the missing amount of 600 mm for longer sofas. For example, for a sofa 1.3 m long, you need to add 700 mm to the “red” dimensions. The longest possible length of a sofa of this design is 1.5 m. “Blue” dimensions are relevant for sofas up to 750 mm long. If the sofa is longer, you need to take “black” sizes instead of “blue” ones.

6th position

There is no 6th part in the drawings. This is a seat blank, a simple board without any holes. Its length is equal to the length of the lengths of the sofa (968/568 mm in the drawings) minus the double thickness of the upholstery fabric, it is kept within 1-3 mm. The thickness of the optimal flock and microfiber in the kitchen is approx. 1.5 mm taking into account folds, so in this version the seat length will be 965 mm for a large sofa and 565 mm for a small one. Minimum seat width 297 mm, including fabric upholstery and installation on piano hinges, see below. If the dimensions of the kitchen allow, the width of the seat can be increased, then an overhang will form in front. With the corner seat option discussed below, the maximum width of the sofa seats is 444 mm; then the seat bevel of the corner section is reduced. In this case, the width of the bed can be up to 900 mm.

Cutting and Sawing

Sawing chipboard/laminated chipboard sheets into parts is done using a jigsaw along the contour. The contour is drawn according to the template, so the jigsaw file must be guided along the inner edge of its line. The upper and lower edges of parts 2 (chest front) and 8 (back base) in Fig. with the drawings you need to cut it obliquely, for which you need a jigsaw with a tilting shoe or you will need to buy a shoe for the existing one. The angle of inclination of the front of the chest is 10 degrees, and the back is 5 degrees. Some shoe scales are graduated in units of relative inclination; for an angle of 5 degrees it is 0.085, and for 10 degrees it is 0.177. Not 0.175, as it might seem, since the relative slope is nothing more than the tangent resp. corner.

The jigsaw file for trimming is beveled inward from the edge to be trimmed. For children 2 (facade), the upper edge is cut from the face so that the upper outer corner remains intact, and the lower edge, on the contrary, from the underside (wrong side), so as not to cut off the inner lower corner. The edges of the backrest, because it is tilted back to the facade, cut in the reverse order: the top one from the back, and the bottom one from the front.

Edging

The free edges of the kitchen corner parts need to be covered with something that matches the overall tone. Edging PVC kitchen furniture with a T-shaped edge is undesirable, not because the groove for the edge needs to be selected with a milling machine, but because dirt will accumulate in the gaps of the edge. By the way, for the same reason, it is advisable to make a kitchen table under a ready-made postforming tabletop: it does not require edging at all and is equipped with a drip tray.

The visible and touchable edges of kitchen furniture are covered with a tape made of complex ABS plastic (ABS, acrylonitrite butadiene styrene) up to 2 mm thick, and the back ones and those above the floor are covered with crepe paper tape. ABS is absolutely safe, hygienic and environmentally friendly; medical equipment is also made from it. ABS and paper edges are produced dry and self-adhesive. The first ones are intended for industrial use with a separate supply of glue, so you need to get self-adhesive ones. Edging a kitchen corner with self-adhesive edges is done as follows:

- The edge strip is cut from the roll to the required length plus 2-3 cm. It is convenient to measure the lengths of curved edges with a tailor's meter.

- Peel off 2-4 cm of protective film from the end of the segment without touching the adhesive layer with your fingers.

- Place the end of the tape on the edge exactly lengthwise and press.

- Holding the tape with your hand, with the other hand you pull out the protective film from under it by the original “tail”. The tape should lie on the edge itself.

- When the tape is all on the edge, it is rolled with a rubber roller.

In general, the procedure is the same as for high-quality self-adhesive gluing. By the way, this is a good finishing option if you decide to make the entire kitchen corner from inexpensive sanded chipboard: there are few visible parts in it, and the textured self-adhesive under acrylic varnish from natural wood will not be immediately distinguishable even by an experienced carpenter. Self-adhesive gluing is done after sawing and trimming the edges before edging. In this case, the inside of the chest can simply be varnished.

Marking and drilling

The accuracy of marking parts of box-panel structures made of chipboard/laminated chipboard is required to be no worse than +/-0.5 mm, but how can it be maintained on edges and sanded chipboard if the size of the material fibers is of the same order? There are no problems with this at the factory; there are no markings as such - they cut and drill using automatic machines. In handicraft production, they use templates, but in order to check each one, you have to ruin up to 2-3 blanks. For piece production at home, this is unacceptable, if only because you need a lot of templates and so much time is required to make them that it is easier to buy a ready-made corner. Moreover, the quality of the product made from parts marked according to templates turns out to be 3+ at best.

Marking calipers

Firstly, the marking of holes on the parts of the kitchen corner made of chipboard/laminated chipboard should be done so-called. a marking caliper with sharp jaws for measuring external dimensions and a vernier for precise installation of the carriage (on the left in the figure). Experienced mechanics sometimes make a marking caliper from a regular one, sharply and very carefully sharpening the tightly knit outer jaws on fine sandpaper, but manually align the tool carriage exactly according to Vernier is difficult.

Note: electronic booms, incl. The marking ones (on the right in the figure) are actually not so convenient to use, and the marking accuracy is worse. Here electronics have not yet caught up with good old mechanics.

Next, marking the holes on all parts is done from the bottom. When marking asymmetrical sidewalls, keep this in mind so that it does not turn out to be a mirror image. The right and left sidewalls are, of course, mirror marked.

Then, between the centers of the outer holes for fastening the mating part, axial lines are drawn into the edge with confirmations and beaten from them to the sides along half the width of the attached board. The extension of the attached part is marked along the center line and is also marked to form the contour of its edge. On the bottom of each board, you need to mark the contours of all attached edges in this way, this is necessary for accurate assembly. The accuracy of beating edges is required +/-0.5 mm, which in this case is ensured by a fitter's angle with millimeter divisions and a steel fitter's ruler.

Sverlovka

Drilling of blind holes for dowels is carried out immediately along the required diameter to the required depth, as described above. But for now we drill holes for confirmations only through the faces of the boards and only with the spiral part of the drill, i.e. not to full diameter. We will drill it completely later, in the order of assembly, so the entire kitchen corner will turn out without distortions and cracks.

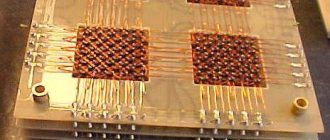

Modifications - corner with mesh

The construction industry does not stand still and continues to produce new materials and devices in order to make the work of finishers easier. The latest innovation can be considered a perforated corner with a mesh. It is a very ordinary corner with holes to which a mesh is attached. In some cases, special glue may be applied to the adjacent parts for more convenient installation.

This type of corner with a mesh is used for plastering walls with a large layer of mortar, although it can be successfully used in any other areas of finishing: drywall, arches or leveling slopes. The mesh in the design gives additional reinforcement and strength to the entire treated area.

Corner

The corner module of the original design is quite complicated (item 1 in the figure), not entirely convenient and not very hygienic: along the gap between the back and the seat, dust and crumbs will fall just where it is difficult to remove them. Since in our case the entire corner is made at the place of constant use, it would be more expedient to build a hanging corner for it, tightly fastened to the sofas. Drawings of its 5 parts - seat, support bar and 3 back segments - are given in Fig. The bevel of the corner seat with sofa seats 400 mm wide is 210 mm, and this is considered a half-window window that fits in a small-sized kitchen. The bevel can be straight, convex or concave. The most convenient thing is a slightly convex bevel, but then it will not be possible to attach a bench to arrange a sleeping place. The backrest has an upward camber, which further improves ergonomics.

Drawings of details of the corner section of the kitchen corner

The dimensions of the back segments must be verified according to the location. reasons. First, small parts are greatly affected by the thickness of the skin. Since the sofas were covered earlier, this value will be known by the time the corner section is manufactured. Secondly, all the dimensional errors accumulated in the sofas will converge into one in the corner.

And yet, the seat and backrest segments need to be trimmed freely, without tension, so that the backrest does not overtighten the fabric when assembling. The lower edges of the segments need to be beveled inward by 2 mm (at an angle of 10 degrees, this is with a margin). The tops of the segments can be figured (options in positions 4 and 5 in Fig.), as long as the contours converge at the connecting points.

Note: rear support posts do not need to be installed if there are no suitable scraps and the rider weighs less than 100 kg. If they are installed, then they are attached in pairs of confirmations through the face into the edge. The heel of the lower support is sealed with a piece of ABS and just stands on the floor.

Corners in a corner

This corner also has 2 secrets. The first is a nook under the seat. From the point of view of a domestic animal, this is a reliable reserve den at a safe distance from the main house. And from the point of view of the owners, it does not cause them unnecessary trouble.

Second. The middle segment of the backrest does not bear operational loads. If you place it on friction pins instead of self-tapping screws, a hiding place will form in the cavity behind it. You will just need to sew an outward-facing tongue-strap made of durable fabric to the upholstery of the lower edge, and sew up the corner section from the rear with fiberboard. When closing the cache, the tongue is tucked inward so that it is not visible. To open the cache, the tongue needs to be pryed and pulled out with a fork or something like that. Remove the segment by pulling the tongue and the top of the back. This cache is unlikely to hide anything from an experienced burglar or a professional search, but it is quite reliable from an amateur thief or overly curious household members.

Plastering slopes.

Slopes on windows, doors and other openings are especially important places, since a person looking there automatically compares them with a window or door. That is, with straight lines. This means that no deviations are allowed - deviations from the lines of the window or door. As for matching the level, the windows can easily be slightly blocked.

Therefore, slopes are plastered mainly according to level. It is recommended to use a corner for plastering slopes. And, again, as a plaster beacon. If the slopes were mounted from gypsum fiber board or gypsum board, and not of very high quality, then a perforated corner will help eliminate all the shortcomings.

By the way, before installing gypsum plasterboard or sandwich panels on slopes, the basic brick slope, according to technology, must be covered with plaster. The perforated corner installed at the same time will help to correctly align the sheet of drywall.

Dimensions

The dimensions of the fittings depend on its purpose. The material from which the corner is made and the recommended load also play an important role. The largest parts are considered to be reshaped parts, equipped with an additional hole for a hex bolt.

| Mounting type | Dimensions |

| For light connections (furniture corner for fastening shelves) | 40 × 40 × 20 |

| Angular | 40 × 40 × 60 |

| Reinforced | 60 × 60 × 80 |

| With locknut | 100 × 100 × 100 |

Amateur craftsmen rarely use reinforced corners; this type of fittings is usually needed by construction professionals. If the structure has a specific shape and design, such fasteners are made to order. Sometimes inexperienced craftsmen make the mistake of using reinforced corners to attach standard bookshelves. This will not affect the life of the furniture in any way, but such elements will cost much more, so there is no point in overpaying.

The most common and inexpensive type of fittings is for light connections. Such corners 2 mm thick will be quite enough to fix the shelf if there are no heavy objects on it. This variety is often used when installing open shelving in a living room or nursery.

For light connections

Angular

Reinforced

With locknut

Selection of materials

Restoration of kitchen corners requires a careful approach to the choice of material, taking into account operating conditions. Coloring, unusual texture, original design of the canvas are less important than wear resistance and quality. The material is chosen so that you don’t have to reupholster it every year, and the appearance is preserved as long as possible.

| Type of material | Description | pros | Minuses |

| Leather | It is better not to choose genuine leather for self-repair. There is a risk of spoiling the material. It is worth giving preference to artificial. | Durability, spectacular appearance. Wide range of colors, shades, ease of care. | Even artificial leather can be faked, and such material has a much shorter service life. |

| Tapestry | Ideal for frequent use. | Relatively inexpensive material, long service life. Easy to care for using soap solutions. | It becomes unusable after greasy stains appear. Fades with prolonged exposure to direct sunlight. |

| Chenille | Popular material for restoration. | Democratic price. Pleasant to the touch surface. This upholstery is tear-resistant, does not fade, and does not absorb odors. | A wide range is presented only in large cities. In small ones the choice is limited. |

| Flock | Non-absorbent fabric. Suitable for those who decided to upholster furniture themselves for the first time. | The material is resistant to fading and stains. | Short service life: the textured pattern quickly peels off from the surface. |

When choosing material for upholstery, preference should be given to non-marking colors. High-quality fabric is easy to clean; a budget option is more difficult to get rid of stains. It is better to take measurements based on the dimensions of the removed upholstery. If the kitchen is made in the same style, then the material must match in color and texture. The use of contrasting shades for backs and seats is popular. In this case, the corner will become a fashionable accent in the kitchen.

The upholstery of kitchen corners suffers from frequent use, and the fillings lose their elasticity. Sheets of foam rubber are placed inside. In order not to make a mistake with the size, add a centimeter to the measurements on each side.

Leather

Tapestry

Chenille

Flock

Foam rubber

Decor features

The beauty of garden benches is that they do not need special decor at all. Well-treated wood, varnished, will organically fit into the natural landscape. But you don’t have to make do with an ordinary bench if you have the skill and the opportunity to decorate it with decorative elements.

A successful design will make a comfortable attribute for relaxation a real decoration of the garden, which will stylishly fit into the landscape and significantly transform it.

It could be:

- wood carving - patterns or openwork elements;

- painting with acrylic paints;

- decoupage

You can combine several finishing options, for example, apply decoupage designs and add a carved back. A simple and interesting solution would be to use several bars to create a backrest. The design will be laconic but stylish. In the same way, you can assemble a seat using several narrow boards, fastened with ties or nailed end to end. The alternation of light and dark wood will look interesting.

Benches with openwork carved inserts and overlay ornaments will elegantly complement the design of the garden courtyard and family recreation area in a natural landscape style.

Assembly steps

Let's look at how to assemble a kitchen table with chrome legs. This option is simple and can be applied to any countertop. First, let's put marks for the subsequent screwing of the legs. Let's lean the mount against the tabletop and mark the points for the screws with a pencil. After this you need to screw the mount. To do this you will need a screwdriver or screwdriver. Then you need to install the leg into the mounting location. It easily screws into a special hole in the center. Similar actions need to be done with the remaining supports.

A more difficult question is how to screw the legs to a wooden kitchen table. Such a design is much more difficult to assemble, since you need to think about the types of connections.

Source

DIY corner sofa for the kitchen

The standard set of furniture for arranging a dining area includes a table, a corner sofa and stools.

According to the step-by-step instructions, to make a corner sofa for the kitchen, you will need:

- Board made of birch, beech or pine 2 by 4 cm - 100 cm.

- Beam with a section of 4 by 4 cm, about 135 cm.

- The beam is 2.5 by 2.4 cm, about 365 cm.

- Beam 1.5 by 1.5 cm thick - 300 cm. For covering the back wall, a sheet of fiberboard.

- Plywood 0.8 - 1 cm thick for the bottom and sides.

- You also need 5 cm thick foam rubber or padding polyester.

- Upholstery fabric (microfiber, tapestry, leather, nubuck and others).

To make a corner sofa for the kitchen with your own hands, prepare:

- jigsaw

- carpenter's corner

- plane

- furniture stapler

- screwdriver

- Sander

- drill

- bit

- hacksaw

- pliers

- roulette

- hammer

You will also need: confirmations, screws 0.4 by 2 cm, 0.4 by 6 cm and 0.4 by 8 cm, bolts and 0.8 cm washers, dowels, legs, hinges. If you plan to make a folding sofa with your own hands, then according to the instructions, you need a special mechanism. The drawing of the sofa for the kitchen should indicate the calculated dimensions and dimensions. In this case, your kitchen corner will fit perfectly into the dimensions of the room.

The workpieces are sanded and leveled, and only then can they be marked and sawed. The average length of a corner sofa is 120 by 90 cm, the corner insert is 45 by 45 cm, and the back height is 85.5 cm.

First, according to the drawings, the main parts of the sofa from the kitchen corner are made - these are the sides. They are made from a thick sheet of plywood. The markings are made with a pencil, and then the part of the kitchen corner sofa is cut out along the lines with a jigsaw.

The next step is to make two frames from 4 by 4 centimeter beams for both sides of the sofa. Both frames should be in the form of parallelepipeds, which are then fixed to the sidewalls. The connections at the corners should look like a mustache and a spike, which are subsequently glued. The T and L shape connections should be at a 90 degree angle.

At the corners, the connections can be with through holes or hidden, go into half of the beam, and also have one, two, or three tenons. They are secured with dowels or corners with self-tapping screws.

The frame of the corner sofa for the kitchen is connected to the back and secured on the sides. When the base is ready, you can assemble the hinged seat covers. Seats can be solid or sectional.

How to make a wooden shelf with your own hands read more

Rectangular frames for seats are made from a block 2.5 by 2.5 centimeters thick. Then they are sewn up with centimeter plywood. The seats are cleaned and covered with a layer of stain and varnish. Then foam rubber is glued and the fabric is stuffed.

A piano loop is attached to the long part of the corner sofa seats. Fastening the hinged covers is done at the end of the work. The corner module is assembled in the same way. A frame is made from a 4 by 4 centimeter block. The profile should be triangular in shape and have sides at angles of 45 and 90 degrees. The module is covered with plywood.

The assembled two parts of the sofas and the corner module are sanded. Exposed wooden elements are covered with stain and, accordingly, three layers of varnish on top. All parts are placed on the sofa legs and fastened together. The connection takes place using screws to the frame support. There must be at least 8 legs.

Structural details are adjusted when adjusting the height of the legs. Marks are made in the places of future fastening. Holes for bolts with a diameter of 0.8 centimeters are drilled. Bolts and washers for them should have wide margins. There should be twice as many washers as there are bolts, so that one goes under the bolt and the other goes under the nut.

The upholstery fabric depends on the proximity of the sofa to the stove and sink. The surface should be easy to clean and not exposed to chemicals.

For a small-sized sofa, 5 cm foam rubber is suitable. For a semi-soft corner of a larger size, padding is taken from padding polyester. Foam rubber or padding polyester is glued to the back with glue. The fabric is cut out according to patterns and stapled to the back of the back, as well as at the junction of the back with the seat. The material is stretched and securely fastened at the corners. Then it is fixed around the entire perimeter.

Preparation for installing corners for putty for wall reinforcement

Before fixing the part to the wall, it is necessary to pre-treat the surface. To do this, you need to clean it from dust and dirt particles using a degreaser.

If you plan to reinforce an area where wallpaper is already covered, you should remove the strip of covering before installing the element. To do this, attach the structures tightly to the corner, mark the lines with a pencil, and then carefully make cuts with a stationery knife. After this, apply a primer and then secure the part completely.

Required Tools

So that during the assembly process you do not have to be distracted by searching for the right item or material, you need to take care in advance of what may be needed for manufacturing. The master will need:

- hammer;

- jigsaw;

- drill or screwdriver;

- roulette;

- accessories;

- stapler;

- glue;

- sewing machine;

- stationery knife;

- anti-stapler.

What furniture to choose for a small kitchen, secrets of saving space The last tool is optional. With its help, it will be easier to remove failed areas of the upholstery, if there are any, but you can also do without it, which cannot be said about everything else. When assembling a kitchen corner, this minimum of tools is required.

Selection of materials

Restoration of kitchen corners requires a careful approach to the choice of material, taking into account operating conditions. Coloring, unusual texture, original design of the canvas are less important than wear resistance and quality. The material is chosen so that you don’t have to reupholster it every year, and the appearance is preserved as long as possible.

| Type of material | Description | pros | Minuses |

| Leather | It is better not to choose genuine leather for self-repair. There is a risk of spoiling the material. It is worth giving preference to artificial. | Durability, spectacular appearance. Wide range of colors, shades, ease of care. | Even artificial leather can be faked, and such material has a much shorter service life. |

| Tapestry | Ideal for frequent use. | Relatively inexpensive material, long service life. Easy to care for using soap solutions. | It becomes unusable after greasy stains appear. Fades with prolonged exposure to direct sunlight. |

| Chenille | Popular material for restoration. | Democratic price. Pleasant to the touch surface. This upholstery is tear-resistant, does not fade, and does not absorb odors. | A wide range is presented only in large cities. In small ones the choice is limited. |

| Flock | Non-absorbent fabric. Suitable for those who decided to upholster furniture themselves for the first time. | The material is resistant to fading and stains. | Short service life: the textured pattern quickly peels off from the surface. |

When choosing material for upholstery, preference should be given to non-marking colors. High-quality fabric is easy to clean; a budget option is more difficult to get rid of stains. It is better to take measurements based on the dimensions of the removed upholstery. If the kitchen is made in the same style, then the material must match in color and texture. The use of contrasting shades for backs and seats is popular. In this case, the corner will become a fashionable accent in the kitchen.

The upholstery of kitchen corners suffers from frequent use, and the fillings lose their elasticity. Sheets of foam rubber are placed inside. In order not to make a mistake with the size, add a centimeter to the measurements on each side.

Leather Tapestry

Chenille Flock

Foam rubber