Dowel

– an auxiliary element for fasteners that ensures reliable adhesion of screws or self-tapping screws to the load-bearing base.

Dowels are made of plastic (polypropylene, polyethylene, nylon) and metal (iron, stainless steel, brass). The dowel can be roughly divided into two parts. Expansion (in the photo below is the left part of the dowel), it is responsible for the force of holding the screw in the material, and non-expansion (in the photo below is the right part of the dowel). The non-spacer part of the dowel is needed in order not to destroy the soft layer of materials. For example, you are installing a dowel into a plastered brick wall, if there is no non-expanding part, then when you tighten the screw around the dowel, the plaster will collapse. You hang a wall cabinet by the base through the chipboard, then the length of the spacer should be equal to the thickness of the chipboard plus the size of the plaster layer, it turns out to be about 30 mm.

The non-spacer part of the dowel can have a countersunk, cylindrical or round flange. The flange prevents the dowel from sinking into the hole of the material being fixed or into the wall. The use of dowels with a flange is convenient if the flange will not interfere.

When screwing the self-tapping screw, the spacer part of the dowel, which has an internal diameter much smaller than the diameter of the dowel, tries to move apart, but the wall material interferes and the plastic of the dowel is compacted under great pressure, connecting the self-tapping screw to the wall into one whole.

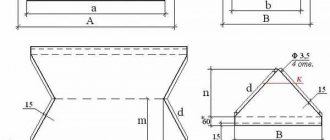

Appearance of the expansion dowel

The dowel consists of non-expandable and spacer parts. It is the non-expandable part that prevents damage to the plaster coating and destruction of the surface itself inside the hole (for example, a wall when fastening to a wall). Thanks to this part, the screw or nail itself easily fits into the hole and securely fixes the mount.

The dowel has a relief shape with two tendrils and one cut or four along the entire length. This shape and design, on the one hand, does not allow the bolt to rotate inside the concrete, and the antennae allow it to additionally catch inside the hole. This ensures better fixation of the product.

As a rule, its length is 25-100mm with a diameter of 5-14mm. Able to withstand long-term loads of up to 200kg.

The use of such a dowel is supported by the fact that environmental materials are used in its production. And the property of resistance to acid and alkali increases the service life and expands the scope of application.

- Rigidity and hardness, as well as resistance to high temperatures, make the dowel a unique and beneficial means of fastening (up to 80 degrees).

- And a separate advantage is worth noting the resistance of spacer dowels to corrosion, which makes it practically durable in use and reduces the cost, and therefore the selling price of the finished product.

- The only serious disadvantage is low resistance to frost and some fragility. Manufacturers recommend using this type of fastener indoors to preserve their service life.

Since in Russia GOST for the production of plastic cylinders for screws was canceled and a new one was not developed, manufacturers still rely on European standards.

Type and purpose of tools

In order for a drill to be as efficient as possible, you need to select it correctly, taking into account the properties of the material being processed, the requirements for hole sizes and the characteristics of the equipment. Manufacturers produce drills of many types, but they are all divided according to their scope of application into three main types:

- Machine tools (machine);

- Locksmiths;

- Construction.

Drills also differ in design. It is customary to distinguish between conical drills and twist drills. The last type of tool is the most common - twist drills are most in demand for use with drilling machines and hand-held power tools. In construction, the most popular are drills with special tipped hard alloys, which allow working with stone, brick and concrete. We'll talk about them today.

Types of expansion dowels

- Polypropylene. Suitable for interior decoration. The big plus is the low price. Simply put, it's plastic with spikes.

- Nylon. Can be used for external work and at a cost significantly higher than polypropylene. In another way, it is also called nylon, it has antennae (spikes).

- Metal. Recommended for working with hollow materials such as foam or aerated concrete. Made from steel, iron or brass. Has a nut.

- They also produce dowels for: concrete or drywall.

- The product consists of a steel nail-bolt, and the dowel frame for it is made of polypropylene or nylon. They are perfect, for example, for window frames or baseboards. The fastening is also suitable for brick, concrete or stone.

- A dowel with a screw and a side for quick work for fastening any wooden part to concrete or brick (Four-spread or chapai).

- Dowel-nail and dowel-pin. Especially for attaching light weights (sticks, pictures).

- Brass ones are not for great depths.

- The dowel clamp allows you to work with cables and wiring.

In general, there are a large number of manufacturers and types of dowels on the market, which sometimes have an unusual name, but in fact they are the same elements.

They are sold individually and have a low cost. Some stores provide delivery within the city when ordering over a certain quantity (we remind you that dowels are sold not by weight, but individually. Sometimes in sets of several pieces).

Material for making fasteners

Materials for the manufacture of dowels for concrete can be: plastic; metal. According to the installation method, fasteners can be: driven in with a hammer; install using a construction gun.

Plastic dowel in concrete

The fastener contains a cylindrical rod that expands when a nail is driven into its cavity, which ensures a strong fastening.

- At the upper end there is a cuff that prevents the fasteners from sinking into the pre-drilled hole. The cuff can be cylindrical or hidden.

- There are products with “whisker” spacers to increase the strength of fixation of fasteners in concrete.

- The dowel-nail can have a thread on the surface and a slot on the head. Screwdrivers are used to install such an element. The most common materials used for manufacturing are polyamide, polypropylene or polyethylene. The nail itself uses galvanized steel alloy.

- Plastic fasteners - their price is lower and are used for mounting small items. For heavy structures, their metal analogues are used.

Metal dowel for concrete

This type of fastener has a metal rod with a smooth surface without threads. The part expands when a nail is driven into a hole in the wall.

Tip: It should be borne in mind that metal dowel-nails are quite difficult to dismantle, so they are installed for a long period of use.

Doweled nails are installed when installing suspended ceilings and various metal frames. The greatest strength of fastening can be achieved on solid and hard materials.

How to choose an expansion dowel

To make the right choice, it is important to know what loads the future structure is designed for. The length of the dowel should be equal to the depth of the hole.

Here are examples:

- A dowel for a depth of 8.5 cm is perfect for attaching something heavy to the wall.

- A dowel with a diameter of 7-11mm and a length of 3cm is suitable for attaching a cabinet or shelves.

- If you have to work with heavy chandeliers, the hole-to-dowel ratio is important.

- Porous materials force you to work with metal dowels.

- When working with thermal or waterproofing, it is better to choose a dowel-pin with a cap.

The most popular sizes: 6*30, 10*50, 6*37.

The weight of the dowels itself does not matter when choosing, since dowels are sold individually, and for fasteners this indicator does not matter, since it is negligible in comparison with the total weight of the entire attached product.

Polyethylene

It is characterized by high viscosity and strength with minimal dowel fragility. Due to low hygroscopicity, it is moisture resistant. This is an excellent shock absorber, so the dowel will withstand heavy mechanical loads.

It is a dielectric that withstands the action of acids, alcohols, alkalis, oils, and is also insensitive to temperature changes and their low values.

At the same time, the material can age and crack over time, and reacts poorly to interaction with aromatic hydrocarbons. The disadvantage is that it is flammable.

Installation of expansion dowel

When working with spacer dowels, the sequence is important:

- Mark the location with a pencil.

- Make a small hole.

- We check that the diameter of the dowel matches the length of the hole in the drill, and the length of the dowel should match the length of the nail or screw used.

- The length of the hole should be slightly larger than the dowel itself. A mark on the drill itself will help with this.

- The drill is placed perpendicular to the wall.

- The hole must be cleaned of dust and covers.

- Next, insert the dowel into the hole. You can drive it in with a hammer and then insert a bolt or screw.

- Ready!

The main thing to remember before starting work is that the number of dowels and screws themselves should be equal. The expansion dowel is an excellent means of fastening in construction, household use and installation and repair work. Especially when working with complex materials such as brick, drywall or cables.

As for the reviews for this type of fastener, they are more positive, they note the ease of use and effectiveness of such fastening.

Users confirm that it is important to choose the right size and follow all the rules in order to achieve your goal in work.

Features of the work

If we are talking about old houses, then you need to pay attention to the following points. We use nylon dowels with a diameter of 10–12 mm, length 60 mm. In this case, the diameter of the drill is 2 mm less than the diameter of the fastener used. This is due to the characteristics of the softer material in the walls and ceilings of older houses. The hole will be wider, so a wider fastener will work just fine. Please take into account this important feature of old base materials!

As for brick walls, as in any business, there are a lot of nuances that need to be taken into account before starting work. It must be remembered that brick is a material that crumbles during drilling. Therefore, the technique is as follows. First, a hole of smaller diameter is made (at least 2–5 mm, depending on the length). Then the drill is replaced with an element of larger diameter and, accordingly, the hole expands. Thus, stage-by-stage work will not allow the brickwork to crumble.

Photo of expansion dowels

Secrets of proper drilling

When installing a dowel into an old wall, you can often encounter such an unpleasant phenomenon as turning it. This is an alarming signal that indicates that the fastener is not ready to perform its functions 100%. In this case, the hole is carefully drilled out and a product of larger diameter is installed into it. To initially prevent this phenomenon, they begin to drill a hole using a tool with a diameter smaller than necessary. If you need to install using a 10 mm dowel, work begins with a 6 mm drill, and then continues with an 8 mm drill. It may seem strange that with this technology for preparing holes for dowels, a tool corresponding to the diameter of the fastener is not used at all. The last stage of work will be drilling, again with an 8 mm drill, but with a blow. This will create a hole into which a nylon dowel with a diameter of 10 mm will fit tightly.

Sometimes you can hear arguments that in order to install the dowel as securely as possible, you need to choose a drill of a smaller diameter. This common mistake results in the fastener not fitting into the wall and having to be hammered in using considerable force. The benefit of such fasteners is questionable and the reliability of a dowel damaged by impacts is usually low.

- How to choose a dowel

- How to screw in a self-tapping screw

- How to hammer a nail

- tape measure and caliper.

- Calipers

There are two main types of anchor bolts: in the first, the bolt nut is located on the outside of the wall and, after installation, is tightened with an open-end, socket or box wrench. Use such bolts if the fastening point is not visible or is then covered with some kind of decorative overlay. In the second type of anchor bolts, a self-locking nut is inserted into the wall. This bolt is tightened with a Phillips screwdriver with profile PH No. 2 or No. 3. Use this type of anchor bolt if the mounting location is visible. There are double-expansion anchor bolts; they “stick” to the wall much more strongly; if possible, install them.

In old houses there may be walls and partitions made of gypsum block. Good fastening to such a wall is problematic, since this material is fragile and easily crumbles. To create the fastening, use nylon dowels with a diameter of 10 or 12 mm. Drive the dowel into the wall to a depth of 60 mm. Drill a hole with a Pobedit drill, the diameter of which is 2 mm smaller than the diameter of the dowel used, since the drill strongly “breaks” the hole in this soft material.