- Peculiarities

- Areas of application

- What are they?

- Dimensions

- Installation

Adjusting anchors are indispensable elements of the stop that allow you to compensate for the shrinkage of timber and other lumber made from natural wood. Their types and sizes are quite varied, making it possible to determine a suitable option for the installation of structures for temporary and permanent purposes. The use of anchor bolts for timber for a height-adjustable floor can be a good solution if you need to shrink the material without risking the entire building.

Peculiarities

An adjustable anchor is a metal product that has a prefabricated structure. It contains a supporting and mating part, a threaded sleeve and fasteners screwed into it. To compensate for shrinkage, simply change the height adjustment anchor, increasing or decreasing it. The supporting parts of the plates have holes in their design, with the help of which they are attached to the surface of wooden structures. Sometimes the response platform contains guide tubular elements.

The basic rule for choosing an adjusting anchor is this: its supporting pads must be sized to match the cross-section of the log or beam that they are to hold. The operating principle of the shrinkage compensator is quite simple. It is installed strictly in those areas that were planned during the design, under a pillar or support beam, with the counter element being attached to the floor joists, roof structure, or other load-bearing element of the building or structure.

This type of hardware is manufactured from alloy or carbon steel. Hot zinc coating is used to protect against corrosion. The stud and nut have a standard design with a fairly wide thread pitch. When moving the locking element, it is possible to reduce the gap between the plates.

The connection is considered detachable - it can be removed from the structure upon completion of the shrinkage process.

This is interesting: How to choose the right drill for a dowel for fastening various objects

Height adjustment anchor: purpose and installation features

Adjusting anchors are indispensable elements of the stop that allow you to compensate for the shrinkage of timber and other lumber made from natural wood. Their types and sizes are quite varied, making it possible to determine a suitable option for the installation of structures for temporary and permanent purposes. The use of anchor bolts for timber for a height-adjustable floor can be a good solution if you need to shrink the material without risking the entire building.

What are adjustable anchors?

It is almost impossible to give a clear answer to the question of what is better than an anchor or a dowel. Since a lot really depends on this process, first of all, the type of fastener used, the material in which the fastener will be installed, and more.

You may have heard the term "dowel rod." A dowel is more or less a miniature version of a rod. The more common name for miniature “rods” is “pins,” and they are most often made of wood, plastic, or metal.

Small, durable, cylindrical...

Read more

Chemical anchor capsule with adhesive composition

Anchor is a chemical capsule containing an adhesive composition for attaching an anchor bolt to a base material such as masonry or concrete.

This capsule contains an outer container containing base materials consisting of liquid unsaturated resin and granular stone aggregates, and an inner container embedded in the base materials containing a hardener.

The chemical anchor has the following characteristics: It is a high-load adhesive system for attaching the substrate to the…

Read more

Which dowel is suitable for a chemical anchor?

Almost any dowel can be used for a chemical anchor. In this situation, much depends on the structure that you want to install using this burdock material.

Despite this, most people prefer to choose only dowels for chemical anchors that are suitable in terms of characteristics. After all, the further installation of various structures and elements depends on this.

What anchor is it for and what is it for? Anchors are rated by weight, so what you hang is...

Read more

Hex Anchor Bolt

The 316 stainless steel hex head anchor bolt is ideal for outdoor use. Galvanized steel anchor bolt is suitable for indoor use only.

Installation is quick and easy using a drill and wrench. Tip for Drilling and Installing a Hex Anchor Bolt The anchor bolt requires a 12mm diameter mounting hole.

This anchor bolt is an ideal choice for use with beskar…

Read more

Chemical anchor for aerated concrete

A special chemical anchor for aerated concrete is considered a fairly reliable and fairly durable method of fastening elements.

This fastening structure provides an excellent opportunity to attach completely heavy products to aerated concrete. The significantly increased cost of these fasteners is the main disadvantage.

But despite this, the fasteners are in demand and convenient to use. A chemical anchor can become almost indispensable for fastening various…

Read more

Reinforced wedge anchor with size table

Nowadays, such a fastening element as a reinforced wedge anchor is in great demand. Therefore, in our article we will tell you in detail about what it is and where a reinforced wedge anchor is used.

Anchor elements are used for various fields of activity. How to Install a Reinforced Wedge Anchor Connect the two pieces and drill a 1/8" alignment hole through both of them where the machine screw/bolt should be installed.

Separate the two parts and set the top part aside...

Read more

Threaded rod va

Today, the special va threaded rod from the leading MKT manufacturer is relevant among many people interested in improving their own activities.

Thanks to this, every interested person will find the most suitable option for improving various areas of activity. Threaded rod va There are two common ways to attach most bolts or pins.

For these shackles, the bolt or pin forms part of the loop itself. When they are open, the bolt or pin...

Read more

Wedge anchor

In our time, interest in products that are sold as reliable fasteners is extremely high among modern society.

The wedge anchor is sold for various fields of activity, and is an almost indispensable fastening element for most people. Wedge anchor 6 Today, such a fastening element as the wedge anchor 6 is in great demand.

This fastener is intended for various fields of activity. Therefore, it is an almost indispensable fastening element...

Read more

Reinforced wedge anchor

The reinforced wedge anchor sold in our catalog from the leading manufacturer MKT is relevant among many people operating in various fields of construction and repair.

It is actively used in concrete structures, brickwork and other areas of repair and construction. In our article we will consider in detail the answer to the question of what it is and where a reinforced wedge anchor is used.

Areas of application of the reinforced planned anchor This fastening anchor has a number of advantages…

Read more

Anchor stud

Today, many people are interested in the question of what a hairpin anchor is and where it is used. Therefore, we decided to consider in detail the information about this fastener, as well as installation and application.

All this is so that each buyer can get an answer to the question in the process of choosing fasteners for their own purposes. An anchor pin is a piece of metal secured by a bolt, pin, or spring that connects objects together.

A pin anchor is a special type of staple that is used for…

Read more

Where is the anchor used?

Today you can notice the active use of anchors in various fields. Since such a fastening element is multifunctional. Due to this, it can be used in various areas of repair, construction or just everyday life.

Wall anchors are like insurance policies. They ensure that the wall can support whatever is designed to be hung on it and other loads, no matter how heavy the hanger is or the material the accessory is made from.

..

Read more

Chemical vp capsule

Today, the vp chemical capsule is in great demand among most owners of large enterprises and individuals. In addition to the above, any interested person will be able to clarify the nuances of interest about the product.

And understand how the specialized chemical capsule vp 8 functions and more. Since a reliable and time-tested manufacturer of MKT sells reliable items with a guarantee of a long service life.

Therefore, after purchasing them, you can effectively improve your business in re...

Read more

04/25/19 Administrator

Height-adjustable anchor fasteners are used in structures that may be subject to shrinkage over time, so the second name for this fastener is shrinkage compensator. Thanks to the use of such anchors, negative consequences can be avoided and the structure preserved in its original appearance.

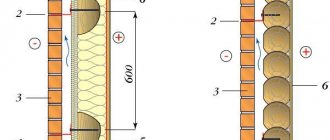

Adjustable MKT anchors consist of 2 plates : a support and a response, which have holes for fastening to structural parts. After securing it to the installation site, the threaded part is set to the maximum, and as the structure shrinks, it is lowered, thereby completely maintaining the correct geometric parameters.

Application area

Currently, adjustable anchors have become an indispensable assistant in the construction industry, because they allow you to compensate for the shrinkage process in frames, pillars, beams, floors, etc.

In addition, the height-adjustable anchor acts as a basic support for individual parts of the structure and allows you to set the correct position of the horizontal and vertical planes in the structure.

Typical sizes

Adjustable anchors MKT

, which can be purchased wholesale and retail on our website directly from the manufacturer, are presented in a wide variety of sizes to suit the requirements of your project. The most popular adjustable anchors are metal products with a height of 15 cm, and the diameter of the threaded part varies from 20 to 24 mm.

Material

Due to the fact that adjustable anchors are subject to high loads during use, MKT uses only high-quality steel compositions in production

.

To ensure a high level of protection of these anchors from the influence of negative external and internal factors of the working environment, the products are galvanized. The thickness of the zinc layer is usually more than 50 microns.

The threaded rod, which directly carries out height adjustment, is applied with a metric thread.

Thanks to the use of adjustable anchors in projects of any complexity, it is possible to long-term regulate the location of load-bearing elements and compensate for any differences in shrinkage. MKT products meet all the requirements of current standards and guarantee the highest quality results.

Tips for choosing

Legs serve as supports for furniture, so you need to choose them carefully. This fittings must withstand the weight of the product with additional load, be replaceable, and fit the dimensions of the structure. There are several criteria that need to be taken into account when choosing this fittings:

- The weight of the furniture - if it is large, it is better to abandon curved legs as less strong elements. Straight supports cope better with high loads.

- Design - in addition to aesthetic characteristics, it is important to find out in advance whether it will be easy to choose an alternative if the leg fails. The more interesting the design, the greater the risk that a similar furniture leg will not be found right away, so you will have to either change all the other elements or violate the integrity of the overall picture.

- Furniture dimensions - it is important to take into account both its parameters and your own preferences. For example, some users will find it convenient to place an adjustable coffee table lower, while others will want to raise it to its maximum height.

- Style - legs should not stand out from the overall interior design. On the contrary, with the right choice, they will become its harmonious component.

- Quality - supports need to be checked for defects (dents, chips, etc.). Their presence indicates insufficient durability of the product.

A high-quality furniture support should have anti-vandal properties or include pads made of soft materials to prevent damage to the floor covering.

If the furniture has significant weight, it is better to avoid curved legs.

The more interesting the design, the greater the risk that if it breaks, it will be extremely difficult to find a similar product.

It is important that the height of the furniture can be adjusted according to your own preferences

Legs must match the overall style of the interior

Defects on the legs may cause the product to become unstable.

How to choose the right shrinkage compensator?

When choosing control elevators, you must first take into account the massiveness of the structure. The range of manufactured elevators includes models designed for loads along the axis of the product from one to tens of tons. This value depends on the size of the anchor pin used, as well as the area and thickness of the support plates (ladders). Depending on the predicted load, the size of the jack anchor for the future structure is selected.

Geometric parameters of adjusting anchors:

- Size of platforms: 50x50, 100x100, 110x110, 120x120, 150x150, 250x250 mm.

- Pad thickness: 4 – 20 mm.

- Spire diameter: M20, M24, M30, M36, M48.

- Spire height: 150 – 400 mm.

The larger the area of the plates and the thicker the compensator pin, the higher its load characteristics. For example, the simplest model made of carbon steel with an M20 pin and 100x100 mm plates can support a weight of 1.6 tons. And the model with an M30 pin and 150x150 mm platforms can withstand a load of 3 tons.

Recommendations for choosing the size of the shrinkage compensator

- When choosing a screw support for a log house, you should take into account that the size of its platforms must correspond to the diameter of the vertical column and the width of the horizontal support beam.

- For one-story houses, bathhouses and outbuildings, shrinkage elevators with a platform side of 100-120 mm and a thickness of 4 mm are used. The diameter of the threaded rod for such models is usually 20 mm.

- For heavy structures made of large diameter logs, models with 150x150 mm ladders made of 6 or 10 mm thick steel with a 24-30 mm anchor rod are used.

- For increased loads, shrinkage compensators are usually manufactured to order. The thickness of their pads can reach up to 20 mm, and the diameter of the rod up to 36 mm and above.

- The length of the shrink jack pin is selected taking into account the size and type of wood, since different materials are characterized by different percentages of shrinkage. The largest shrinkage is observed in logs (30-60 mm/m), the lowest in laminated timber (10-30 mm/m). In practice, adjustable supports with pin lengths of 150 and 200 mm are most often used.

- When installing an elevator under a column on a concrete base, you should choose models with large holes in the supporting platform, which are designed for concrete anchors.

Dimensions

In addition to shape and material, the legs vary in size. This parameter is one of the most important, since the permissible load on the furniture depends on it. There are three main groups - low products, medium and high. The choice of the appropriate option will depend on the type of furniture:

- Low size group - used in cabinets, kitchen sets, coffee tables. The height of the legs is 50–60 mm.

- Medium - 65–90 mm, suitable for shelves and chests of drawers.

- High - 90–850 mm. Such supports are usually mounted on tables.

The degree of adjustment is determined by the size group. For example, legs with a height of 100 to 120 mm vary within 10 mm. From 150 to 180 - up to 20 mm. The maximum range - 30 mm - is typical for legs with a height of 200 mm.

In terms of changes in diameter, an adjustable furniture leg does not differ from standard supports. This parameter varies from 45 to 145 mm in increments of 5 (45, 50, 55 and so on). The widest products are used for large cabinets.

The standards also define the ratio of height and diameter. Typically, the lower the support, the smaller its diameter. However, the size chart is wider than the basic parameters, so almost any furniture store offers an impressive assortment of this fittings.

Types of accessories for upholstered furniture, functionality and characteristics

The degree of height adjustment of the legs is determined by the size group

Low

Average

High

How to close the adjusting mechanism?

If you leave this shrinkage device open, the appearance of the structure will suffer, and the illusion of its integrity and solidity will disappear.

To decorate the gap between the column and the horizontal element, casings are made to match the color of the wood, which are placed on the column. While adjusting the mechanism, they are moved back or removed depending on the design. Screw jacks are made from high-strength carbon or alloy steel. The devices are supplied assembled with reinforced washers and nuts of high strength class. Thick steel support and response platforms provide extraordinary rigidity and strength of the structure. All elements of this mechanism are galvanized. The thickness of the coating must be at least 50 microns, which guarantees long-term protection against corrosion.

Useful tips30.08.2019 16:37:23

Areas of application

The main purpose of using adjustable anchors is to maintain the specified geometric parameters of a wooden structure after it shrinks . Installing a spacer element makes it possible to eliminate distortions that occur when the humidity of logs and beams changes. The wood does not crack under pressure, there are no deformation changes that manifest themselves in warping of frames, doorways, or the formation of cracks and gaps. Average shrinkage can reach 50-150 mm, and sometimes reaches 300 mm, so the use of shrinkage compensators is almost mandatory when building houses and bathhouses from timber and logs.

Adjustment anchors are most in demand when assembling frames of buildings and structures, installing support pillars, columns, and rafter systems . For both timber and round logs, platforms with a square base are used. This measure is especially relevant during the first 3 years after the construction of the facility.

It is during this period that natural wood continues to lose the natural moisture accumulated over the years of its growth.

The most vulnerable to deformation loads are joints and stiffeners. This is important for the floor, for the roof joists, pillars and columns on which the walls of the building rest. In some cases, the use of a driven brass collet and steel stud is possible even without plates. For example, when installing adjustable floors over a concrete base, it is enough to simply place the collet in the monolith and the threaded element in the joist.

Adjustable floors and rafter systems are well suited for use in areas with seasonal use. Sheet materials are used as flooring on adjustable floors - most often thick plywood of at least 18 mm for single-layer installation and from 12 mm when using a double structure.

Of course, special anchors are more appropriate in such structures, but due to their high cost they are often replaced with adjustable analogues.

This is interesting: Pipe rolling

Design and installation

The height-adjustable anchor consists of two plates - a support and a response. They have holes for mounting on structural elements of a wooden structure. The response plates of some models of such products can be equipped with guide tubes used to securely fix the supporting post.

When choosing a height-adjustable anchor, it is necessary to take into account the fact that the size of its counter plate and the diameter of the log from which the supporting post is made must be the same. It should also be taken into account that the location in the building in which the height adjustment anchor will be installed is determined at the design stage.

Schemes for installation and operation of the adjusting anchor

The principle by which this type of anchor works is as follows.

- An anchor adjusting in height is installed under the support beam or pillar, and the support platform of such an element can be attached to the support post or log, roof elements or to the floor beam using screws. The rafter system of the building and its supporting porch can also serve as a place for installing a height-adjustable anchor.

- First, the threaded element of the anchor is set to its maximum height position.

- As the wooden building shrinks, the amount of which can be 7–9 cm per year, the height-adjusting anchor is lowered, which makes it possible to compensate for geometric changes in the building. Typically, this procedure is performed once every two months, which is quite enough to prevent critical changes in the structure of the building that arise due to shrinkage processes.

» data-lazy-type=»iframe» src=»data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7″>

If the height-adjustable anchor is installed correctly, then the building, after all shrinkage processes are completed, will retain all its original geometric proportions.

What is a height-adjustable anchor used for?

In wooden house construction, this fastener is necessary, since the tree continues to “breathe” and react to interaction with the external environment, the soil, during the first three years, and to some extent, throughout the entire period of its operation. Wood, log or timber, is a natural material, closely related to water, like all life on Earth. Before becoming a building material, for decades a whole system of capillaries operated in the tree trunk, with the help of which vital juices circulated. These same small channels are filled with moisture when a “dead” frame or timber is installed in a building. Natural material bursts with moisture and then the deviation in the house can reach up to 4-5 cm.

The walls themselves do not require height adjustment - all elements will lower approximately equally. But the joints and hard parts will each live their own lives. In addition to interaction with the external environment, the shrinkage of the house will also be affected by the premises erected on top. It is quite natural that the partitions will be located according to the architect’s idea, which means the load on different nodes will be different: for example, in the southern half of the house there is a large warm terrace where it is pleasant to relax, and in the northern half there are rooms where the main activities and most things take place .

Height-adjustable anchors come in handy if you need to build on a foundation that, for various reasons, has already settled and this has happened unevenly. Using anchors, you can adjust the level for the subsequent construction of superstructures.

Finally, vertical columns and pillars are often used as an architectural solution, serving as support inside the building. These elements will either not have shrinkage, or this value will be significantly less relative to the attached structure. For all this, an adjustable anchor, also known as a construction jack, is an excellent solution.

Installation

The installation procedure for adjusting anchors is quite simple. The product is selected according to the size of the base, its supporting platform and counter element are equipped with suitable fasteners. Let's consider the further procedure.

- Trimming timber/logs with a feather drill . It is performed taking into account the length of the screw. After this, you can install the plate.

- The mating part is attached to the base of the building, most often to a concrete foundation, using an anchor . Drilling is also done in advance.

- The elevator stud with nut is installed. To begin with, it is turned out to its full length. Then they are installed on the end or horizontal joist or foundation. It is worth considering that the location of the compensator does not matter much, but for the convenience of subsequent adjustment, installation is usually performed from below the support.

- Using a lifting mechanism, the vertical support is mounted on the regulator. It is optimal to secure the structure in the upper third of the stud, and then adjust the size of the gap using a nut. For periods when height changes are not required, it is recommended to use a decorative casing.

- Changing the lift height . During the period of active shrinkage of the building, it is required once every 3-6 months. The average time required to change the height of the support is no more than 15 minutes.

Installation of adjusting anchors is carried out exclusively in compliance with safety regulations. A prerequisite is the participation of at least 2 workers in this procedure. This eliminates accidental collapse of the structure and prevents injury. During the construction phase, installation must be carried out exclusively by a group of workers, with insurance for all elements.

You can learn how the adjusting anchor works from the video below.

Where is it used?

The main task of the anchor, which can be adjusted in height, is to compensate for the shrinkage of such elements of a wooden structure as its frame, pillars, connecting columns, etc.

Wooden house construction is the main area of use of adjustable anchors

Made of durable metal, the height-adjustable anchor simultaneously performs two functions in the building:

- serves as a supporting base for structural elements;

- allows you to adjust the correct position of horizontal surfaces in relation to vertical ones.

Various modifications of these anchors are used when installing adjustable floors

Adjustment-type anchors are installed in those places that are most susceptible to deformation during shrinkage. Such a place in a wooden structure, in particular, is a node that serves as the basis for the foundation structure. In modern construction, an adjustable floor anchor is often used. It allows you to maintain the horizontal position of the floor even if the entire structure has undergone significant shrinkage.

» data-lazy-type=»iframe» src=»data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7″>

Main Dimensions

Modern industry produces height-adjustable anchors of various sizes, and they should be selected depending on the purpose for which they are planned to be used. To compensate for the shrinkage processes to which wooden buildings are subjected, adjusting anchor products with a height of 15 cm are most often used. The most popular of these products are anchors with a threaded element diameter of 20 and 24 mm.

For installation in wooden structures made from large-diameter logs, adjusting anchor products with a height of more than 15 cm and a diameter of threaded elements of more than 30 mm are used. Such anchors, which experience significant loads during operation, also have more reinforced support plates with a thickness of up to 1 cm and an area of up to 15x15 cm.

Main parameters of adjustment anchors

Dimensions of height adjustment anchor

They produce several versions of anchors , their size depends on the purpose. The model with a height of 15 cm is used for installation in wooden houses and log buildings. In terms of screw diameter, the most popular models are 20 and 24 mm. They are designed to regulate the shrinkage process of wooden buildings.

And here is an article about installing anchor bolts.

This subsection https://ru-house.net/stroitelstvo/krysha/metall/ contains all the information about metal types of roofing.

Material of manufacture

Since height-adjustable anchors experience significant loads during their operation, only high-quality steel alloys are used for their manufacture. To protect the surface of such products from the effects of negative environmental factors, it is coated with a layer of zinc, the thickness of which is usually at least 50 microns. The pin, with the help of which the height of the anchor is adjusted, has a metric type thread.

In addition to a simple stud, adjustable anchor designs can use bushings or tall nuts

Using height-adjustable anchors, which are manufactured in accordance with all generally accepted requirements and standards, the owner of a wooden structure can change the position of its load-bearing structures over a long period of time, thereby compensating for shrinkage processes.

Made from high-quality material and coated with a protective compound, such anchors are able to withstand significant loads and not be destroyed by corrosion.

Installation and adjustment

When installing adjustable legs yourself, it is important to focus on the furniture parameters. First you need to measure its actual height, then decide how many centimeters you want to raise or lower it. If necessary, you can use the recommended standards:

- It is better to place the sink one meter from the floor - with this placement it is most comfortable for a person to use it.

- Work and other kitchen surfaces are raised to a height of 85 cm.

- Oversized wardrobes rise 190–210 cm above the floor surface.

Types of furniture fasteners, their characteristics and application features

The most difficult thing is to make the correct markings. A cross is formed at the corners; for this, a distance of 50 mm is taken from each side. Usually the leg has several holes for fastening - central and side. The first one needs to be aligned with the crosshairs, the center of the others should be marked with a pencil, then pricked with an awl. Now you can put the leg back on and secure it with self-tapping screws. Then the height is set - using a screwdriver, screw in the screw until the desired level is reached. There are configurations that are easy to set manually. It is more convenient to mount if you first unscrew the leg and then reassemble it. If you don’t want to waste time on this, you can use a magnetic holder that will help you handle the assembled support.

50 mm is the standard size, from which there may be deviations. In the kitchen, it is often determined by the location of household appliances - for example, a dishwasher under the countertop can limit the permissible depth of the supports.

In addition to proper installation, it is necessary to monitor the supports during use. It is important to observe the maximum permissible load and avoid moving loaded furniture. Wooden legs require special care, and metal elements can easily damage the flooring if handled carelessly.

In addition to materials and shapes, it is important to choose the right size. The legs must be suitable for the height of the furniture, its weight and the planned load. When choosing, you also need to pay attention to the quality of the fittings and the possibility of replacing them. In order for the product to last a long time and ensure ease of use of the furniture, it is necessary to provide for all these points.

It is better to place a cabinet with a sink at a height of one meter from the floor

The kitchen set is usually raised to a height of 85 cm

The optimal height for sliding wardrobes is 190–210 cm from the floor

In order for the product to last a long time, it is important not to exceed the permissible load and avoid moving loaded furniture

The legs must be suitable for the furniture in terms of height, weight and planned load.