Today it is difficult to name a construction industry in which a variety of perforated fasteners would not be used. Taking this fact into account, we can even say that perforated fasteners will not lose their relevance in the future. This is due, first of all, to the stringent requirements that apply to modern construction - reduction of labor and time costs, low weight of building structures while maintaining the highest degree of their strength and reliability. And it is perforated fasteners that are able to satisfy all these requirements in the best possible way, significantly ahead of all other elements for fastening.

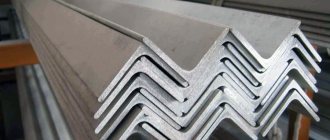

Perforated corner

Fastening certain elements using a perforated corner is one of the easiest ways to ensure reliable and durable fastening of wooden, plastic, metal and other elements. Moreover, all work with this type of fastener is carried out without specialized equipment, but only with the use of ordinary screws and nails, which makes the work extremely simple and fast. Today, perforated mounting brackets are also available in a wide range of different products and can be intended for a wide variety of installation and construction work. For example, a narrow-profile perforated corner is suitable for assembling furniture and a number of finishing or decorative elements. A wide angle is used in the installation of larger products, because it is able to support heavy wooden beams and other structures. For the installation of load-bearing elements, a beam corner is used, which is capable of withstanding the most severe mechanical loads. If we are talking about fastening elements with the highest degree of load, then a reinforced corner made of galvanized steel of durable grades will help to cope with this task. Finally, an anchor fastening angle is the best option for securing the same wooden, beam and other structures in a solid base - concrete walls, brickwork, natural stone, and so on.

Criteria for selecting quality products

Whatever product option you require, it is important to check its compliance with several criteria in order to be guaranteed to receive high-quality products:

| Strength | High-quality options are made of steel with a thickness of 2 mm or more. The weight of the elements should be impressive, and they should not bend simply with your hands. If the product is not very reliable and bends easily, then its use will be of little use, so low price should in no case be the determining factor when purchasing |

| Reliable coverage | In order for the units to withstand adverse influences well, they are coated with a layer of zinc, which serves as protection against moisture and temperature changes. Determining the quality of galvanizing is simple: the surface must be uniform without any streaks or stains; any flaws indicate that the technology has been violated or the products have been stored in a damp place for a long period of time |

| Optimal parameters | Needless to say, large corners are not suitable for small structures and vice versa - massive elements will not be supported by small fasteners. It is worth choosing the best option for each situation to ensure reliability and not spend extra money |

Important! Some developers make corners themselves; this is not the best option, since the strength of home-made units is several times lower than those made in a factory.

To illustrate the use of this or that element, many sellers assemble a small structure, everything in it can be seen very clearly

Perforated plate

A perforated plate is the most versatile type of fastener. The plates are used for direct connection of parts of building structures made of wood. In the same way, like the corner, mounting plates can be used in all construction areas without exception if there is a need to secure two or more elements in the same plane. Perforated plates can be straight, sliding, angular, L-shaped, T-shaped, beveled. Such fasteners are also excellent for connecting elements subject to increased loads, including in roofing work.

Types of fasteners

Any store offers a wide range of products, but you need to choose those options that are suitable specifically for the work that you perform.

Plates

This type of product, which allows you to connect elements located in the same plane, the main options are the following:

- Connecting plates are products of different widths and lengths, along the entire surface of which there are symmetrically located holes with a diameter of 5 mm. With their help, you can splice various elements - lengthen them, build them up, etc. The work is simple: position the product so that it is located in the middle of the mounting location and secure it with self-tapping screws;

There are a lot of sizes - choose the one that fits best

Important! One option is a plate rolled into a roll, the length of which can be from 5 to 10 meters. The main convenience is that you can cut yourself pieces of the desired length.

- The fastening plates have holes of different diameters, which allows them to be fixed with a variety of types of fasteners - from self-tapping screws to screws and threaded rods, and this is very convenient in places with high loads;

This option is designed for high loads

- Nail plates do not require the use of self-tapping screws, since their design is such that on one side the surface consists of many nails. It is enough to simply hammer it into the surface to fix the elements.

An interesting option suitable for quickly completing work

Corners

Fastening metal corners are the largest product group; it contains elements of various sizes, which are designed to fasten elements located at an angle to each other.

The main options are as follows:

- Equilateral perforated corners can be of various sizes, which simplifies the choice; for example, 20x20 is suitable for furniture, and 100x100 or even more for massive elements. The holes on the surface are the same size and located symmetrically;

The fastening angle for 50x50 timber is indispensable when assembling battens and frames for partitions

- Fastening metal corners for timber with a stiffener can withstand even significant loads; they are available in several versions, the smallest is 50x65, the largest is 130x100. It is advisable to use them where greater reliability and resistance to deformation is needed; for particularly critical areas, elements with double reinforcement are used;

Stiffening rib provides additional deformation stability

- Other configurations are also used - mounting angles for timber at an angle of 135 degrees, asymmetrical elements, Z-shaped options, they are needed for certain jobs.

Supports and holders

Very useful elements when performing some work:

- The open beam support is designed for fastening elements to the wall without cutting a groove; this not only simplifies the work, but also significantly speeds it up. There is another option - closed supports, they differ in that the attachment point is not visible in them - the element is bent inward and hidden behind the beam;

The photo clearly shows the difference between open and closed supports

- The metal beam holder allows you to fasten the beams together, even if the elements are located at an angle to each other, this makes this option popular and useful in the construction of rafter systems.

Holders allow you to assemble a rafter system very quickly

Special options

Here we will talk about two types of products that can be very useful in some situations:

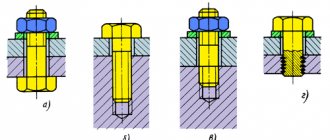

- The supports are designed for installing wooden elements on surfaces made of any materials; with their help, you can very quickly build a canopy or place a reinforcing beam on a concrete floor;

This is how easy it is to install wooden supports

- Shrinkage compensators are used where it is necessary to compensate for the displacement of elements due to changes in humidity; with their help, you can always maintain the ideal geometry of the structure.

Using the threaded part you can easily set the desired position

Perforated tape

Perforated tape is mainly intended for fixing minor auxiliary structural elements in construction. Moreover, with the help of mounting tape, it is possible to ensure the connection of elements that are not subject to heavy loads during operation, while the scope of its application still remains as wide as possible. This includes installation of various types of equipment, installation of various plumbing equipment, strengthening of units with an average degree of physical stress, fastening and installation of ventilation systems and other work.

Conclusion

The choice of fastenings for the construction of a wooden house depends on many factors: the type of work, the degree of load on the structure, the shape and cross-sectional size of the beams. For installation of the ceiling and facade of the building, the best option would be anchors designed for heavy loads. To compensate for shrinkage, staples or couplings with a washer are suitable; corners are suitable for fastening timber, assembling floors or wooden canopies.

All products have high strength, durability and reliability. However, it is recommended to buy them from trusted manufacturers.

Other perforated fasteners

It is worth noting that when performing any construction work you have to use a much larger variety of fasteners, it is simply impossible to talk in detail about each of them. These include beam holders, closed and open beam supports, double and reinforced supports, brackets and much more. All this will certainly be needed when building a gazebo, canopy, barn, house, garage, as well as when installing equipment and decorative hanging elements.

The online store of building materials and power tools offers its customers to buy various types of perforated fasteners from the best manufacturers presenting their products on the market of Moscow and Russia at the best prices in the country.

Types and features of metal products

Rectangular metal fasteners are necessary to create a strong butt joint between parts with proportional load distribution at the joint. When two planes are fused, deformation is eliminated. Plates with variable hole sizes are universal; they can be used with any hardware.

To maintain the exact geometry of the joints and quickly assemble the units, angular or L-shaped perforated fasteners are used. To install the workpieces perpendicularly, no special tools or equipment are required. For rafters, fastening elements are produced with a bend of 135 degrees, providing the necessary slope of the roof slope. There are options with an additional stiffener for loaded joints, equilateral, asymmetrical, narrow and wide.

For internal, external and separate connections of beams, Z-shaped fasteners, modifications of complex configurations and U-shaped metal fasteners of different sizes are required. The holders are adapted to the standard of lumber, different methods of installing wooden blocks to the base. They are used in frame housing construction, civil and industrial construction.

Perforated mounting tape is indispensable when laying air ducts, installing ventilation ducts, fastening other utilities inside and outside buildings, and pipelines for various purposes. The electrical installation tape is equipped with special brackets for fixing the cable. It is used when installing heated electric floors.