To harden a spring means to subject it to heat treatment in order to increase the strength, elasticity, hardness and ductility of the product, which will ultimately affect the physical and chemical properties and service life. The essence of the process is heating to a temperature at which the metal structure transforms into a special state, and high-speed cooling in various environments, including cooling in air. The choice of hardening technology depends on the grade of steel from which the spring is made and the diameter of the wire. This operation is performed in industrial and home conditions.

A homemade spring is not recommended for use in devices operating under increased loads.

Do-it-yourself spring manufacturing and hardening technology

Almost every home craftsman knows that it is possible to make a spring from almost any wire and successfully use it in everyday life. Basically, there are no problems with making the part yourself. However, sometimes situations arise in which it is necessary to either make a spring of non-standard dimensions, or give it increased strength and elasticity.

To do this, you should resort to heat treatment operations. It is quite possible to harden a spring at home. It goes without saying that a homemade part should not be used in particularly critical devices operating under increased load. For such purposes, it is recommended to use factory-made springs.

But for home use in a device operating in a lightweight mode, the technology in question is quite suitable.

Required tools and materials

In order to make and harden a wire spring with your own hands, you need:

- Steel wire. The diameter is selected based on the necessary characteristics of the future product.

- Ordinary gas burner.

- Metalworking tools: pliers, hammer, etc.

- Vise.

- Stove. This may be, if available, a special one or an ordinary household one.

Additional devices that are selected individually in accordance with the size and stiffness of the spring can facilitate the process of winding the spiral.

If the use and hardening is intended to be made from wire with a diameter of less than 2 millimeters, then it may not be preheated. It will bend without any problems without this operation. However, before starting winding, it is recommended to straighten it along its entire length and completely level it.

When using wire with a diameter of more than 2 millimeters, it should be burned before starting work. Without this operation, aligning and winding it will be problematic.

Features of the operation

- The right foundation is the key to success. In factory conditions, an alloy of non-ferrous metals (65G, 60HFA, 60S2A, 70SZA, Br. B2), alloy or carbon steel is used for production. During home production, the optimal base will be an old spring of the required diameter.

- A special furnace is best suited for annealing. If this is not available, brick or metal will do.

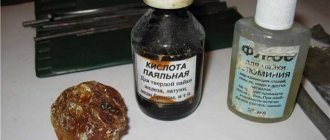

- For cooling after heating, it is recommended to use transformer oil. If it is not available, a spindle will do.

Sequencing

1. Before tempering the spring wire, you should check the base material and make sure that the wire used is carbon steel.

2. The annealing procedure, as mentioned earlier, can add plasticity. This will make the process of alignment and winding onto the mandrel easier. You can use a special oven or any suitable oven for this. In everyday life, it is possible to harden in the most suitable structure (metal or brick). To do this, a regular fire is lit and then the future spring is placed in the coal. After heating the workpiece red-hot, the wire must be removed and allowed to cool naturally. The cooled wire will be much softer and you can work with it comfortably.

3. The softened wire should be completely aligned and begin winding onto a mandrel of a suitable diameter. During the procedure, you need to control the tight arrangement of the turns to each other. To make it easier, you can use a screwdriver.

4. To impart the required elasticity, hardening will be required. Thanks to this heat treatment, the part is harder and more durable. Hardening springs involves heating them to a temperature of 830 to 870 degrees. To do this, you can use a gas burner. Earlier we talked about hardening metal at home.

It is unlikely that you will find a suitable thermometer at home that can accurately determine the temperature of a part. Therefore, you can navigate by the color of the metal. When the required temperature is reached, the workpiece will turn light red. We recommend watching a video with a detailed description of the heating temperature. After this, the spring is placed in a cooling medium (oil).

5. Afterwards, the hardened spring must be kept in a compressed state. This requires from 20 to 40 hours.

6. Finally, process and adjust to the required dimensions.

Correct implementation of such hardening will allow you to successfully use the spring in home mechanisms.

Do-it-yourself spring manufacturing and hardening technology Link to main publication

Source: https://oxmetall.ru/termo/tehnologiya-izgotovleniya-i-zakalki-pruzhiny-svoimi-rukami

Hardening steel over an open fire

Shock absorber support

It is possible to harden metal at home. For an easy and useful hardening process, you need to light a fire and prepare two large containers. There should be a lot of hot coals in the fire.

Diesel or motor oil is poured into one container, clean water, preferably from a well, is poured into the other. You should first prepare a tool with which you will need to hold the hot product.

It is advisable to find blacksmith pliers, but if they are not among the tools, you can arm yourself with something else similar to pliers.

When the preliminary work is done, metal drills or other objects are placed in the very center of the flame, that is, on hot coals.

Rich white coals are hotter than others

It is important to watch the hardening process - the flame should be crimson, not white. If the fire is painted in the last color, then there is a threat of overheating and even burning of the metal

It is necessary that the color is distributed evenly across the entire area of the fire. Black spots should not appear on the edge of the product that is being hardened.

And if the metal turns blue in places, this indicates that the material has softened too much and become too plastic. This should not be allowed under any circumstances.

Therefore, the process requires increased care, because you can overdo it and heat the ax blade white-hot.

When the metal equipment is heated in the fire, it is time to remove it from the high heat.

A hot object must be lowered into a container of oil many times with a frequency of 3 seconds, gradually increasing this period of time.

You cannot hesitate with these actions; you need to carry out operations to harden the metal edge quickly and sharply.

Next, the object is immersed in a bucket filled with water, which will have to be shaken a little.

At this stage, do not forget to be careful, as oil droplets on a knife or ax may burst into flames if they end up in water. The table shows how to correctly and incorrectly immerse various parts, including drills and disc cutters, in water:

The table shows how to correctly and incorrectly immerse various parts, including drills and disc cutters, in water:

Very often there is a need to harden drills. It is not recommended to immerse thin long elements flat into water, otherwise the lower layer of metal, cooled first, will shrink.

Video:

Drills should be lowered into the liquid with the thicker end.

If you follow all the rules and precautions, then hardening yourself will not seem like a complicated and dangerous procedure. It will bring the desired guaranteed effect

But sometimes at home you have to harden steel equipment or melt non-ferrous metal. Such operations require extremely high temperatures, 700-900 degrees.

And only a muffle furnace or an electric furnace can heat metal objects to this level. You can make a muffle furnace yourself. It is unlikely that you can make an electric oven at home.

How to make a spring at home with your own hands

Most often, the question of how to make a spring yourself, using improvised means, does not arise. However, there are situations when a spring of the required diameter is not at hand. It is in such cases that the need arises to make this element with your own hands.

Making a small spring is quite possible

Of course, springs for critical mechanisms operating under intensive conditions are best manufactured in production conditions, where it is possible not only to select correctly, but also to comply with all the parameters of the technological process. If you need a non-standard spring for use in a mechanism that will be operated in a gentle mode, then you can make it at home.

What you need

To make your own spring, prepare the following supplies and equipment:

- steel wire, the diameter of which should correspond to the cross-sectional size of the turns of your future spring product;

- a regular gas burner;

- a tool that every locksmith workshop must have;

- bench vice;

- a stove, which can also be used as a heating device for household purposes.

It is easier to wind a spiral using devices, the design of which depends on the size and stiffness of the spring

The wire, if its diameter does not exceed 2 mm, does not need to be subjected to preliminary heat treatment, since it is easy to bend without it. Before winding such wire onto a mandrel of the required diameter, it must be unbent and carefully aligned along the entire length of the winding.

When choosing the diameter of the mandrel, you should take into account the size of the spring that you are going to make at home. To compensate for the elastic deformation of the wire, the diameter of the mandrel is chosen slightly smaller than the required size of the internal cross-section of the future product.

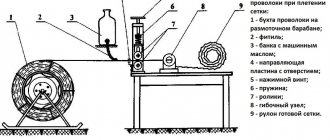

Coil spring winding device

If the diameter of the wire from which you are going to make a spring with your own hands is more than 2 mm, it must first be annealed, since without such a procedure it will be difficult to align it and wind it onto the mandrel.

Step-by-step instruction

Step 1

The first thing you need to do if you are going to make a spring with your own hands is to select the material for such a product. The optimal material in this case is another spring (the main thing is that the diameter of the wire from which it is made matches the cross-section of the coils of the spring that you need to make).

By selecting material from an old spring, you will be sure that the wire is made of hardened high carbon steel

Hardening technique

Simply put, hardening technology consists of two actions - heating the sample to a high temperature and cooling it.

Just don’t assume that everything is elementary, because groups of metals differ in their unique structure and characteristics.

Do-it-yourself heat treatment of metal is justified if:

The price of professional hardening of 1 kg is 100-200 rubles. Hardening small parts will cost less. The price for this service ranges from 6 to 20 rubles.

If you harden equipment at home, it is important to know some of the subtleties of this process. Heating requires uniformity, it must occur without the appearance of black or blue spots on the object

Under no circumstances should the sample be heated to extreme levels.

Heating requires uniformity; it must occur without the appearance of black or blue spots on the object. Under no circumstances should the sample be heated to extreme levels.

The fact that the product is heating up correctly will be indicated by its coloring in a bright red color.

Video:

For hardening a metal object such as a drill, equipment such as an electric furnace or thermal oven, as well as a blowtorch and a large fire are suitable.

What is more suitable - a furnace, an electric furnace or an open fire depends on the temperature required by the type of metal being processed.

When it is necessary to harden not the entire surface of a metal object, but only a certain place, jet hardening is used. It assumes that a stream of cold water is directed at the object pointwise.

The cooling method for a drill, screwdriver, chisel or crimp may vary. It can be carried out in several stages, one-time and abruptly, or gradually. It all depends on the type of metal.

If you plan to carry out an operation with one cooler, then special equipment, such as a bucket or barrel, is prepared. Even a bath is suitable for this.

When a two-stage cooling scheme is needed to lower the temperature of a metal object, two different media are used. This procedure also ensures the tempering of the metal.

So, first, drills or disk parts are cooled with water, then with oil, which can be machine or mineral.

Cooling with oil is carried out secondarily, since there is a risk of ignition due to high temperature.

Temperature conditions and other hardening indicators are reflected in the table below.

How to make a spring with your own hands from wire and in production: we describe it in detail

Steel springs can be of different configurations and it is not always possible to purchase the desired type - the product is quite rare on the market. For this reason, I make them myself for my needs.

Requirements for wire and its diameter

Steel wire for the manufacture of a spring, which will subsequently be hardened, must meet the requirements specified in GOST 14963-78. According to the document, it is classified according to the following criteria:

- winding method (cold and hot);

- method of surface finishing (without finishing and with finishing);

- manufacturing accuracy (normal and increased);

- class of mechanical properties (general and critical use);

- diameter (from 0.5 to 14 mm);

- type of delivery (in rods or coils).

At industrial enterprises, springs are made from wire with a diameter of no more than 16 mm using the cold winding method, and up to 80 mm using the hot method. In production, they are wound using a rotating mandrel, feed rollers and one or two stop pins.

Products are made from wire grades 51ХВА, 70С3А, 65С2ВА, 60С2А, 65Г, 60ХВА with a ground, polished surface or without grinding and polishing. Based on this characteristic and the manufacturing method, the wire is produced in rods or coils of the following groups:

- A, B, C, D, E – with special finishing;

- N - without finishing.

The wire symbol in the technical documentation and on accompanying tags consists of numbers and letters:

ХХХХХ (1) – Х (2) – Х (3) – Х (4) – ХХ (5) – ХХ (6) GOST 14963-78 (7)

Where:

- 1 – steel grade;

- 2 – surface finishing method;

- 3 – manufacturing accuracy;

- 4 — class of mechanical accuracy;

- 5 - winding method;

- 6 - diameter in mm;

- 7 - designation of the standard.

For example, a wire with a polished surface made of high-precision class I steel 60C2A for hot coil springs with a diameter of 2.0 mm will have the following designation:

60S2A – A – P – I – GN – 2.0 GOST 14963-78

The state standard specifies permissible maximum deviations, out-of-roundness and the inadmissibility of certain types of defects, as well as methods of packaging and transportation.

Spring calculation

To do this, you need to use the table in the spring section to correctly select the diameter of the steel wire, the number of turns and pitch. In this case, how the new spring should work - compression or tension - plays a huge role. The last type of springs can have a rather complex design, but you can also make it yourself. Having performed preliminary calculations and found out the thickness of the wire for a steel spring, the pitch and number of turns, as well as having determined the design features and created a drawing of the future spring, you can proceed to practical actions.

There is also special software for calculating all parameters:

Making a spring

We have a drawing, a steel string of the required thickness and a suitable diameter steel tube for winding the spring.

Common mistakes

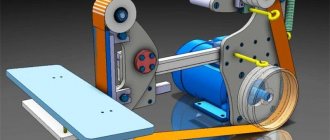

We clamp the mandrel in the chuck of the lathe. We insert the end of the steel wire into the hole in the mandrel, start the rotation and wind the steel string tightly.

After checking the thickness of the spring with a caliper, we cut the wire with wire cutters and watch how our spring increases in diameter.

In addition, removing it from the mandrel will be quite problematic - to do this you will have to cut the string at the very beginning of the turn.

Doing it right

We clamp the wire on the mandrel using a screw.

Now we need to create tension on the steel string before winding.

Using a regular piece of thick plastic to clamp the wire into the cutter holder will not be enough. We will need a special device with a guide, in which the tension of the wire can be adjusted by a pressure plate made of soft metal (copper or bronze).

It is also necessary to adjust the rotation speed of the lathe chuck and the movement of the work platform to obtain the desired spring pitch.

Source: https://intehstroy-spb.ru/tehnologii/kak-sdelat-pruzhinu-v-domashnih-usloviyah-svoimi-rukami.html

How to properly harden a spring? — Metals, equipment, instructions

Most often, the question of how to make a spring yourself, using improvised means, does not arise. However, there are situations when a spring of the required diameter is not at hand. It is in such cases that the need arises to make this element with your own hands.

Making a small spring is quite possible

Of course, springs for critical mechanisms operating under intensive conditions are best manufactured in production conditions, where it is possible not only to select correctly, but also to comply with all the parameters of the technological process. If you need a non-standard spring for use in a mechanism that will be operated in a gentle mode, then you can make it at home.

Heat treatment of springs. Articles of the company "OOO"

Springs and springs experience repeated alternating loads in operation and, after removing the load, must completely restore their original dimensions.

In connection with such operating conditions, the metal used for the manufacture of springs and springs must have, in addition to the necessary strength under conditions of static, dynamic or cyclic loading, sufficiently good ductility, high limits of elasticity and endurance and high relaxation resistance, and when working in aggressive environments (steam atmosphere, sea water, etc.) must also be corrosion-resistant.

Technological properties are also equally important for the metal of springs and springs - low tendency to grain growth and decarburization during heat treatment, deep hardenability, low critical hardening rate, low sensitivity to temper brittleness.

The quality of springs and springs is influenced by the condition of the surface of rods, wires and strips. The presence of external defects (cracks, sunsets, caps, hairs, shells, burrs, depressed scale, etc.

Material requirements

The strength parameters and fault tolerance of a product are largely determined by the material from which it was decided to be made. Metallurgists distinguish special spring steels in the classification of steels. They have a specific crystal structure, determined both by the chemical composition and the heat treatment of the products. Highly alloyed alloys of increased purity and high metallurgical quality provide high elasticity and ductility, and are able to retain their physical and mechanical properties after repeated deformations.

Spring alloys 60S2A, 50HFA and stainless steel 12Х18Н10Т have gained popularity among mechanism designers.

How to make a spring from wire

Springs are elastic structural elements that serve to accumulate or dissipate mechanical energy. They surround us on all sides - under the keys of the computer keyboard, in the car suspension and in the lifting mechanism of the sofa. The most common are coil compression springs. There are several ways to make them.

How to make a spring

Coil compression springs

Elastic elements can have different spatial forms. Historically, the first springs mastered by man were leaf springs. You can still see them today - these are springs on heavy-duty trucks. With the development of technology, people have learned to make more compact coil springs that work in compression. In addition to them, spatial elastic elements are also used.

Coil springs

Design Features

During operation, such springs take a load along their axis. In the initial position, there are gaps between their turns. The applied external force deforms the spring, its length decreases until the coils touch. From this moment on, the spring is an absolutely rigid body. As the external force decreases, the shape of the product begins to return to its original shape until it is completely restored when the load disappears.

The main characteristics describing the geometry of the part are:

- The diameter of the rod from which the spring is wound.

- Number of turns.

- Winding step.

- External diameter of the part.

The external shape may differ from cylindrical and represent one of the figures of rotation: cone, barrel (ellipsoid) and others

The winding pitch can be constant or variable. The winding direction is clockwise and counterclockwise.

Spring device

The cross-section of the turns can be round, flat, square, etc.

The ends of the turns are ground down to a flat shape.

Operating area

Cylindrical coil springs of constant outer diameter and constant pitch are used more widely than others. They are used in areas such as

- Mechanical engineering.

- Instrumentation.

- Vehicles.

- Mining industry.

- Appliances .

and in other industries.

Use of springs in everyday life

The following properties are required for the work to function effectively:

- high strength;

- plastic;

- elasticity;

- wear resistance.

To ensure the design values of these parameters, it is necessary to correctly select the material, accurately calculate the dimensions, develop and follow the manufacturing technology.

State standards determine the requirements for the manufacture of springs. According to permissible deviations, they belong to one of the accuracy groups:

- less than 5%;

- less than 10%;

- less than 20%.

Schematic representation of a spring

Strict requirements are imposed on the accuracy of geometry and surface cleanliness.

Products with scratches and other external defects that reduce the resource of the product and its service life do not meet the standard

Material requirements

The strength parameters and fault tolerance of a product are largely determined by the material from which it was decided to be made. Metallurgists distinguish special spring steels in the classification of steels. They have a specific crystal structure, determined both by the chemical composition and the heat treatment of the products. Highly alloyed alloys of increased purity and high metallurgical quality provide high elasticity and ductility, and are able to retain their physical and mechanical properties after repeated deformations.

Steel 60S2A

Spring alloys 60S2A, 50HFA and stainless steel 12Х18Н10Т have gained popularity among mechanism designers.

Features of the technology

The technological process for manufacturing elastic elements depends on the technical requirements for the design. Making a spring is not as easy as an ordinary part, which should not have special elastic properties. This requires special equipment and equipment.

Winding of springs with a round coil section is carried out using the following methods:

- Cold. Suitable for small and medium sizes (wire diameter up to 8 mm).

- Hot. For large diameters.

Spring coiling technology

After winding, the elastic elements are subjected to various types of heat treatment. During this process, the product acquires the specified properties.

Cold coiling technology without hardening

First you need to do preparatory operations. Before a workpiece is wound from wire, it is subjected to a patenting procedure. It consists in heating the material to the plasticity temperature. This operation prepares the wire for the upcoming change in shape.

During the winding operation the following parameters must be maintained:

- External diameter of the product (for some parts the internal diameter is standardized).

- Number of turns.

- Winding pitch.

- The total length of the part, taking into account subsequent operations.

- Compliance with the geometry of the end turns.

Cold coiling without tempering

Next, the end turns are ground down to a flat state. This must be done to ensure high-quality support for other structural parts, to prevent their destruction and the spring from slipping out.

The next stage of the technological process is heat treatment. Cold coiling of springs involves only tempering at low temperatures. It allows you to increase elasticity and relieve mechanical stresses that arise during winding.

It is extremely important to strictly adhere to the design heat treatment schedule, carefully controlling temperature and holding time.

After heat treatment, it is necessary to carry out test and control operations.

Further, if necessary, protective coatings can be applied to prevent corrosion. If they were applied by galvanic method, the products are reheated to reduce the hydrogen content in the surface layer.

The first stages of the technology coincide with the previous process. Changes begin at the heat treatment stage. It is carried out in several stages:

- Hardening. The workpiece is heated to a given temperature and held for 2 to 3 hours. Next, it is subjected to rapid cooling by immersing it in a container with mineral oil or saline solution. During the hardening stage, the workpieces must be in a horizontal position. This will avoid deformation

- Vacation. The workpiece is heated to 200-300° and kept for several hours to relieve internal stresses and improve elastic properties.

Further measuring and control operations are also carried out. The workpieces that have passed the inspection are sent for sandblasting to remove scale. If necessary, shot blasting should also be done to increase the strength of the surface layer of the metal.

The process is completed by applying a protective coating.

Hot coiling technology with quenching and tempering

Before winding, the workpiece is heated to plasticity temperature using one of the following methods

- muffle furnace;

- gas-burner;

- high frequency heating.

Next, the workpiece is supplied to the coiling equipment. The geometry is adjusted and flat ends are formed.

Heat treatment includes hardening and low-temperature tempering.

Heat treatment schedules are constructed based on the properties of the material and the dimensions of the workpiece.

Operating mode of the quenching and tempering furnace line

Next comes the control and measuring stage. Manufacturing is completed by applying anti-corrosion protection.

Equipment and fixtures used

To make an elastic element, specialized equipment is required. These are winding machines. You can make a part on a regular lathe, but it will require additional equipment with special equipment. Medium and large series are produced on semi-automatic machines that operate with minimal operator intervention. You can also make a spring from wire by hand. This will also require special equipment.

Coil compression springs

Elastic elements can have different spatial forms. Historically, the first springs mastered by man were leaf springs. You can still see them today - these are springs on heavy-duty trucks. With the development of technology, people have learned to make more compact coil springs that work in compression. In addition to them, spatial elastic elements are also used.

Design Features

During operation, such springs take a load along their axis. In the initial position, there are gaps between their turns. The applied external force deforms the spring, its length decreases until the coils touch. From this moment on, the spring is an absolutely rigid body. As the external force decreases, the shape of the product begins to return to its original shape until it is completely restored when the load disappears.

The main characteristics describing the geometry of the part are:

- The diameter of the rod from which the spring is wound.

- Number of turns.

- Winding step.

- External diameter of the part.

The external shape may differ from cylindrical and represent one of the figures of rotation: cone, barrel (ellipsoid) and others

How to harden a spring at home

› Other

Articles Loading...

To harden a spring means to subject it to heat treatment in order to increase the strength, elasticity, hardness and ductility of the product, which will ultimately affect the physical and chemical properties and service life. The essence of the process is heating to a temperature at which the metal structure transforms into a special state, and high-speed cooling in various environments, including cooling in air. The choice of hardening technology depends on the grade of steel from which the spring is made and the diameter of the wire. This operation is performed in industrial and home conditions.

A homemade spring is not recommended for use in devices operating under increased loads.

Making a spring with your own hands

To make a spring at home, you need to decide on the following characteristics:

- the grade of steel from which the product will be made;

- wire diameter;

- number of wound turns;

- turn step.

A homemade product can be made on a mandrel and using a screwdriver. You will also need nippers, a hammer, a vice, a heating source (stove, gas burner, fire), a cooling medium and additional accessories.

The simplest manufacturing method is to wind the wire onto a rod of suitable diameter by hand. In this case, it is necessary to ensure that the turns fit tightly to each other.

The process of making a spring using a screwdriver can be seen in the video:

When making a product with your own hands, you must adhere to the following simple rules:

- The wire must be absolutely straight. If the product is made from an uneven or old spring, it must be aligned.

- The wire must be free of rust, oils and other contaminants. To do this, use a soda solution or chemicals to dissolve oils and remove rust. It is recommended to wipe the wire with sawdust.

- Before coiling, wire with a diameter of more than 2 mm must be subjected to an annealing procedure by heating red-hot (temperature within 400 °C) and cooling in air.

- When winding, it is necessary to control the position of the turns relative to each other. They should fit snugly one to one.

Hardening of springs at home can be done in several ways: using a gas burner, heating in a stove made of brick or stone, or simply in a fire. Heating should be carried out to a temperature of approximately 870 °C. This is determined by eye by the color of the wire: during the heating process it becomes almost white. Then it must be placed in oil (transformer, spindle or other liquid medium), which will provide slow cooling. Let us remind you that rapid cooling can cause cracks that will negatively affect the quality of the spring.

In production conditions, springs are placed in a mesh basket, sometimes preheated (depending on the grade of steel). This basket is placed in a hardening furnace, which is heated to the required temperature and kept for a certain time in order to heat the material over the entire cross section. For the same purpose, the springs are fastened with wire or placed in a special cage.

The holding time for each steel grade is calculated and selected taking into account the spring material and its diameter. In production, special diagrams are usually used. The quenching medium is also selected depending on these parameters. This can be oil, liquid quenching medium, air, etc. The liquid medium is water to which chalk, lime or soap have been added in certain quantities.

The presence of these elements in the aquatic environment makes it possible to reduce the cooling rate and avoid the occurrence of cracks in the metal of the spring.

At home, a soap solution or transformer oil is usually used as a liquid medium, which is poured in sufficient quantities into a container. The springs should be completely immersed in it and cool there to room temperature.

It is recommended to keep a spring made by hand in a compressed state for some time. Typically, the holding time ranges from 20 to 40 hours.

The quality of workmanship and reliability of a home-made spring depends on its manufacturing technology. Properly performed heat treatment will reduce residual deformations and increase elasticity and viscosity. Hardening means obtaining high quality indicators that will allow the spring to be used in products for critical purposes.

Heat treatment of the spring using available means is shown in the video:

Source: https://gazsnabstroy.ru/prochee/kak-zakalit-pruzhinu-v-domashnih-usloviyah

Heat treated springs for corrosion protection

Heat treatment of springs is a generalized name for operations such as heating, holding and cooling of these products.

The main goal of such processing is to obtain the specified parameters and properties of elastic products, which is achieved by changing the internal structural structure of the metal alloys used in each specific case. To achieve this goal, steels/alloys are heated to a certain temperature, maintained under such conditions for a precisely specified time and cooled, depending on the technology, in a fast or slow way.

Such processing may be an intermediate operation in the technological process of manufacturing elastic parts, in which case it serves to improve the results of subsequent operations (pressure processing, cutting, etc.). If such processing is the final stage of the technological process, then it is carried out to ensure the specified properties of each product.

How to properly harden a spring?

Almost every home craftsman knows that it is possible to make a spring from almost any wire and successfully use it in everyday life. Basically, there are no problems with making the part yourself. However, sometimes situations arise in which it is necessary to either make a spring of non-standard dimensions, or give it increased strength and elasticity.

To do this, you should resort to heat treatment operations. It is quite possible to harden a spring at home. It goes without saying that a homemade part should not be used in particularly critical devices operating under increased load. For such purposes, it is recommended to use factory-made springs.

But for home use in a device operating in a lightweight mode, the technology in question is quite suitable.

Self-manufacturing and hardening of springs

Spring hardening as a type of heat treatment. Requirements for the material for the manufacture of the product, GOST. Symbol of wire for springs. Nuances of the manufacturing process and methods of hardening at home.

To harden a spring means to subject it to heat treatment in order to increase the strength, elasticity, hardness and ductility of the product, which will ultimately affect the physical and chemical properties and service life. The essence of the process is heating to a temperature at which the metal structure transforms into a special state, and high-speed cooling in various environments, including cooling in air. The choice of hardening technology depends on the grade of steel from which the spring is made and the diameter of the wire. This operation is performed in industrial and home conditions.

A homemade spring is not recommended for use in devices operating under increased loads.

Spring requirements

The following properties are required for the work to function effectively:

- high strength;

- plastic;

- elasticity;

- wear resistance.

To ensure the design values of these parameters, it is necessary to correctly select the material, accurately calculate the dimensions, develop and follow the manufacturing technology.

State standards determine the requirements for the manufacture of springs. According to permissible deviations, they belong to one of the accuracy groups:

Schematic representation of a spring

Strict requirements are imposed on the accuracy of geometry and surface cleanliness.

Products with scratches and other external defects that reduce the resource of the product and its service life do not meet the standard

How to harden a spring with your own hands?

Springs are elastic structural elements that serve to accumulate or dissipate mechanical energy. They surround us on all sides - under the keys of the computer keyboard, in the car suspension and in the lifting mechanism of the sofa. The most common are coil compression springs. There are several ways to make them.

How to make a spring

Cold coiling technology with quenching and tempering

The first stages of the technology coincide with the previous process. Changes begin at the heat treatment stage. It is carried out in several stages:

- Hardening. The workpiece is heated to a given temperature and held for 2 to 3 hours. Next, it is subjected to rapid cooling by immersing it in a container with mineral oil or saline solution. During the hardening stage, the workpieces must be in a horizontal position. This will avoid deformation

- Vacation. The workpiece is heated to 200-300° and kept for several hours to relieve internal stresses and improve elastic properties.

Further measuring and control operations are also carried out. The workpieces that have passed the inspection are sent for sandblasting to remove scale. If necessary, shot blasting should also be done to increase the strength of the surface layer of the metal.

The process is completed by applying a protective coating.