Home > Knives made from 9ХС: pros and cons, characteristics, reviews.

Steel grade 9xc has good wear resistance and also perfectly resists the loads placed on it. First of all, this grade of steel is used in industry, where all kinds of drills, markers and cutters are made from it. 9xc steel is used in the manufacture of knives due to its strength and reliability, as well as good elasticity, due to which blades made from this grade retain their quality for a long time.

Decoding the 9ХС steel grade is very simple: 9 indicates that the steel contains 0.9% carbon, and the letters X and C indicate that this grade contains up to 1.5% chromium and silicon, so it becomes clear that it is alloyed steel.

Chemical composition of steel 9xs

HVG steel is considered to be the closest to 9xs steel in terms of characteristics. It contains 0.9% carbon and up to 1.5% chromium content. As mentioned above, the main area of application of 9xc steel is industry, where metal-cutting products are made from it.

On the other hand, 9xc is considered a high-tech steel; therefore, during production, cracks do not form inside it, reducing the strength of the product. Due to the fact that this type of steel can be easily forged, reliable knives are often made from it, popular among hunters, tourists and fishermen.

What is the difference between forged steel 9ХС and U8?

Now I am on Lake Koshkino. Here comes the pussy. Come here, Tom. Tom is getting ready to become a mother. She follows us like a dog around the lake, she will soon have kittens from the Maine Coon Zhimik. Soon, in a week at most, we will have kittens.

I’m on Lake Koshkino; in a few days we’ll open fishing. Over the winter, as you can see, we put up bridges, we put them here quite small, spacious - two by two. If you look at it, there were one, two, three, four, five bridges. In general, there are 12 here, and there is such a pier for a fish tank, there will be more fish tank here. There's a thirteenth one. What else have we done? Solar panels were installed. But we’ll review this later and tell you how effective they are. In principle, we liked the idea of solar panels. We installed a video camera for online surveillance so that from home we could understand what was happening here.

I want to say that the lake overwintered brilliantly, despite the high concentration of fish. The fish here are about two tons. In general, all the sturgeon survived, not a single one died. Carp is literally a small amount, less than 4%. Trout - 8 pieces as of yesterday, this is also about 4%. True, it’s not clear from the trout’s point of view. The first year the lake winters, but it seems to be visible how it chases the fry, rushes after the fry, but so far we have not seen anything special. Yesterday we did some test fishing. Our employee caught an 8-kilogram sturgeon. The sturgeon began to peck. That is, at the beginning of May, even if the carp don’t bite, the sturgeon will. They poured out a test grain, the carp also began to eat. That is, the lake had a wonderful winter.

The specialty of this lake is fishing - this, of course, is fishing for sturgeon, Russian sturgeon, beluga, kaluga and Siberian sturgeon. I’ll say it again, Siberian sturgeon - up to 15 kg, beluga - up to more than 40 kilograms, and Russian sturgeon are also somewhere up to a point here.

Now I want to talk about knives. Lately there have been a lot of videos about our budget knives. We have now started making a lot of them. People like that we make budget-friendly things that are affordable. The price-quality ratio is good, to put it mildly. And today in the video I’ll probably talk about this. I very often said that in Russia it is customary to pass off one piece of hardware as another if it is similar. And the fact is that, to be honest, in any business, including knife business, there are a lot of newcomers who came, perhaps recently, they need to earn money, you can understand them. And that’s why, probably, all methods are good for them. I'm not saying that's all of them, but some. I talked about this. Those companies that have been around for a long time, those that have been more or less established, have earned money, probably, everything is somehow more or less transparent with them. For us, this is metal transparency, it is one hundred percent. Anyone who has known me for a long time understands that, on principle, I don’t like to joke in this regard.

Now I want to show knives from U8 and 9ХС. I’ll now show them close-up, and you can see for yourself that, in principle, they are no different, but they differ in price. Let's take a close-up. Look, an “Uzbek” knife, steel 9ХС, thickness about 2.4, lens, handle – elk horn. Look, it’s shiny now, so cool, but there are small cracks on it. Moreover, I will say that when they were collected, they were not there. They appear because horn is organic material. And at the same time, now I’ll tell you about the horn. Look, this blackness is the heterogeneity of the horn. As soon as you work with it a little, with this handle, this place will be rough. Let me clarify - not because we are doing something wrong, here is a knife with a handle made of horn “Uzbek” bolster brass. Basically, 9ХС steel. The price is on the website. Not cheap.

And let’s say we take “Mushroom picker”. This “Mushroom picker” from U8. Look, visually it is no different from 9ХС, but it is much easier to forge, although U8 and 9ХС, they are each good in their own way, but this is a matter of taste. 9XC will hold an edge longer, it is harder by definition. The U8 has a more pleasant soft cut. U8 is much easier to forge, and therefore its price is cheaper. As I already said, visually you cannot distinguish either by color, or shade, or processing, or anything. We do it for ourselves - we put our embossed stamp on the 9XC, and on the U8, so that we ourselves don’t just get confused in the warehouse, we put ready-made blades from cell to cell so as not to confuse them, because even though these steels are both quite worthy, but However, you still need to understand that you cannot pass one off as the other. This is, to put it mildly, a bummer. The situation is the same here. “Bychak” 9ХС with cream, “Lynx-2” U8. Everything is drawn out, everything is done. I say again, you can’t tell by color or anything. But here's another point. You must understand that if hand-forged you end up with U8 instead of 9XC, it will probably be dishonest, because it costs less, but whatever. It is much worse if the same thing is forged from something, but in appearance it will be the same. Especially, for example, if it is 65 g spring or U7 - these are spring steels, and they have nothing to do with forged iron.

I always say that when you buy something already in the region of dozens, it’s still probably right to buy from those companies that you trust. I will say right away that I have a very large number of regular clients, those who hire from us, naturally, friends of friends, like it. I say again, there were no complaints about the U8 at all, in general the forgeable ones from the U8 were made by hand. Apparently, people are absolutely satisfied with the ratio between price and this. I don’t know about 9 XC, over the last 15 years that we’ve been making it, there won’t be ten dubious reviews. Again, I repeat, it’s all one guy who says that I said that the 9XC is a “Mercedes”, but it turns out it’s not a “Mercedes”. This is the only one. Why do I call him? In reality there were still five people. All owners of 9XC knives are happy and the only thing they don’t like is the price. And butchers and hunters use our knives, and all this is very, let’s say, in demand.

I am asked a question: will steel blades, for example, forged blades be placed on a budget handle? We don't plan yet. I don't know, maybe we'll try. But it's not about the handle. A knife costs, for example, 12,000. with a rubber handle it will cost 10,000, let's say. Or a knife costs five, but with a rubber handle it will cost four. Cheaper, cheaper, no question, still cheaper. But that won't happen. Or I liked it, one guy writes: “Is it possible to bake a blade from the Finnish Hunting-1, for example, into a rubber handle? I don’t even know what to answer in such cases. Can. Such a blade will cost 12,000 and will have an excellent handmade blade and rubber handle. But it's not right. For what? Buy a Finnish car for two rubles. It cuts normally and is durable. We have plenty of these, there are even cheaper than 2,000 fincas. Meaning?

Next I want to say. You write your wishes, what you would like, a review of which knives. Comments, wishes, what kind of knives to produce, some ideas are also accepted, because I learn many things from you, I listen, I watch. For this, of course, YouTube and the VKontakte group are very convenient. I just go on VKontakte and see what they are talking about. There our employees communicate with the group members and answer. And on YouTube too. I have nothing more to add. I just want to say again that the knives are hand-forged 9ХС and У8... even on the bridge you can cut them. Do you see how the knife goes? These are knives that can be used to work, plan something, do something. Who really understands knives, who needs working tools, when a person needs a knife for work, and not to ruin felt, to destroy the work of the people who did it, but precisely for, I say again, this is meat, fish, wood, then Of course, 9XC and U8, they are simply beyond competition. I want to say again that I’m not too keen on powders yet. I'm not saying they are bad, no. This time, for example, at the “Blade” exhibition, I exhibited a vanadis blade on cutting knives. Vanadis 10, 64, even checked - 64. He was not included in the prize. In principle, this is not the first time the same famous Vanadis, no matter how much I try, it is not included in the top three. At the same time, for example, thermocycled D2 entered the top three without any problems, 9ХС entered the top three. Damascus even. Even a couple of times they took first places in Damascus - once at Klink, once in St. Petersburg at Klink. That's it. In general, what I’m talking about is that we have both expensive and cheap things, so come in and here you will choose exactly what you want, you won’t regret it. All the best, goodbye.

Characteristics of steel 9xs

The main advantage of 9xc steel is its high elasticity, which makes it possible to make almost any product from it. In addition, it is characterized by the highest strength and is unpretentious in maintenance, which makes knives made of 9xc steel indispensable in camping or hunting conditions.

Its wear resistance is also important. Products made from 9xc are practically not subject to corrosion, regardless of environmental conditions. Despite its elasticity, 9xc has more than decent Rockwell hardness values, HRC = 63; not every steel can boast of such figures.

Steel 9xs pros and cons:

Like any other steel, 9ХС has positive and negative sides, let’s consider them in more detail.

Pros:

- Anti-corrosion steel, lovers of long stays in the wild will not be able to help but appreciate such a simple but certainly useful quality.

- The hardness of 63 units speaks for itself; the knife can easily cope with any work in a camp and cutting wood and bone.

- Easy and well-controlled cutting on any material. Wear resistance, elasticity and bending resistance.

- 9ХС blades are made only by hand forging. So if you buy a knife made from this steel, you can be sure that it is FORGED.

Of course, we won’t ignore the disadvantages either; all steels have them.

Minuses:

- Peculiar appearance. The forging features of this steel make the appearance of the knife not the most “marketable”.

- Production features affect not only the appearance, but also the price. The steel is not premium, but it cannot be called cheap either.

- Steel is capricious in processing - it is not recommended to buy it from artisans; violations of the technological process are possible.

Results:

- A reliable and unpretentious tool that is not subject to corrosion and has a huge margin of safety.

- The cutting part of the knife is brought down to zero, and the closest analogy to such sharpening is a straight razor.

- All 9xc knives are made by hand.

What knives is it used for?

9ХС steel is widely used for the manufacture of knife blades. No special equipment is required to give the alloy the desired shape, which is why knife makers love this brand.

Knives made of 9ХС steel are most often purchased for tourism, hunting, and fishing. They cope remarkably well with the tasks that arise in traveling conditions. Thanks to the special 9XC alloy, the knives are highly durable. It is able to withstand significant loads: impacts, torsion, contact loading.

Knife Marten 24.5 cm - 8100 rub.

One of the most important characteristics for a tourist or hunting knife is good cutting properties. Blades made of 9ХС steel can easily cut hard objects, such as tree branches or animal bones, and are suitable for cutting carcasses. They tolerate aggressive environmental conditions well and are not afraid of water and high temperatures. Although, due to the insufficiently high percentage of chromium in the composition, they cannot be classified as stainless.

Reviews of knives from 9ХС

Vox populi vox Dei “the voice of the people is the voice of God.” Let's listen to the opinions of hunters and fishermen. Those who have chosen knives made from this steel.

Share link

In the creation of industrial tools, a specialized alloy alloy is used - steel marked 9ХС. In creating this mixture, additives are used that improve basic indicators. Alloying substances improve the technical and operational characteristics of products made from it.

The strips were 9ХС steel.

Content

Characteristics

9XC steel contains many alloying additives that provide the desired characteristics and properties. In addition to the main components, there are silicon, calcium, chromium, carbon, sulfur, in total 12 alloying and additional components. Thanks to this complex of substances, steel has the following main characteristics:

- density (r) – 7830 kg/m3;

- Rockwell hardness (HRC) depends on the tempering temperature - from 63-64 to 39-48 ∂;

- HB 10-1 = 241 MPa;

- forging temperature indicators: from 1180 to 800 degrees.

Due to its increased elasticity, pronounced strength, wear resistance and density, steel of this type is considered the best option for creating cutting tools and components of this type.

Explanation of markings

Each type of steel has its own marking, which encodes the characteristics of the composition. The marking of 9ХС steel has the following meaning:

- the number “9” shows that the alloy contains 0.9% carbon;

- the letter “x” indicates the presence of chromium in the steel;

- the letter “c” indicates that silicon has been added to the composition.

The presence of carbon provides increased viscosity of the substance. Chromium is a universal component; it increases the thermal impact capabilities of the alloy, makes it as durable as possible and eliminates the risk of corrosion.

pros

9ХС steel has advantages that set it apart from other alloys.

- It has unique technical characteristics that allow it to be used in the manufacture of strong, elastic, wear-resistant parts with a high bending resistance coefficient.

- In alloy 9ХС, carbides are always evenly and correctly distributed over the cross-section, which improves the performance qualities of the finished product, in particular, threaded elements created from it.

- It has a high degree of resistance to mechanical damage and cracking.

- After annealing, it acquires another undeniable advantage - increased hardness and ductility to calcination.

- Has high thermal stability.

- The alloy is resistant to flocking during finishing.

Thanks to these advantages, 9ХС steel is a popular and practical tool alloy.

Minuses

There are also disadvantages to this alloy, which also need to be taken into account in the production of tools and cutting products.

- Specific requirements for heat treatment.

- Not suitable for welding work.

- When processing, strict adherence to temperature conditions is required.

- Complicated mechanical processing.

Only highly qualified specialists need to work with 9XC alloy, as there are conditions and nuances that must be met.

Blade made of 9ХС steel.

Pros and cons of 9ХС steel

9ХС steel is suitable for making knives due to its properties:

- Hardness. A knife made of steel with a hardness of 63 units can cope with any task without any problems. It can easily cut even hard materials: tree branches, bones, veins. - Corrosion protection. Due to the chromium content in the composition, such knives are not afraid of water. After contact with different types of liquid, rust will not appear on them. - Elasticity. — High quality cutting edge. — Holds an edge for a long time. — High resistance to mechanical damage and cracking. — Carbides are evenly distributed over the cross section, which improves the performance of the finished product. — Increased hardenability. — High thermal stability. During processing, the likelihood of flakes appearing is minimal.

This brand also has some disadvantages. These include:

- Appearance. The blade is made of 9XC steel and does not shine and has a peculiar pattern. - High price. Due to the nature of production, which requires increased temperature control during hardening, and the need for hand forging, knives made from 9XC steel are not cheap. - Difficulty in processing. Even a slight violation of the steel manufacturing process can lead to a decrease in its quality. During heat treatment, it is very important to maintain a certain temperature regime. If the steel is overheated, it will become hard, and if it is underheated, the blade will quickly lose its sharpness. Therefore, electric ovens with automatic temperature control are most often used for this purpose. — Loses its positive qualities at high temperatures. When heated above 200°C, the cutting properties of the tool decrease. - Requires care. Chromium contained in 9ХС prevents the development of corrosion, but it is not enough for full protection. To prevent rust from appearing, the knife must be thoroughly dried after contact with water or other liquids.

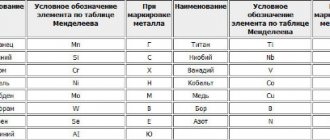

Chemical composition

To create 9ХС steel, 13 substances are used, the combination of which in the right quantities results in qualitatively better physical, mechanical and operational characteristics.

Here are the components that make up 9ХС steel:

- iron (Fe) – 94%;

- silicon (Si) – up to 1.6%, but not less than 0.9%;

- chromium (Cr) – up to 1.25%, but not less than 0.95%;

- carbon (C) – 0.9%;

- manganese (Mn) – up to 0.6%;

- nickel (Ni) – 0.35%;

- copper (Cu) – 0.3%;

- molybdenum (Mo) – 0.2%;

- tungsten (W) – 0.2%;

- vanadium (V) – 0.15%;

- sulfur (S) – 0.03%

- phosphorus (P) – 0.03%;

- titanium (Ti) – less than 0.03%.

Percentages may vary slightly among different manufacturers. Deviations should not exceed 1/10 of a percent, otherwise the properties of the resulting alloy may differ.

Application

Widely used in industry, it is used to create such products:

- knives;

- knife blades and other cutting tools;

- drills of different diameters and purposes;

- cutters for industrial and household equipment;

- stamps that are used in cold-type work;

- parts for equipment.

Steel can be used in other areas if the technical and operational characteristics meet the requirements for the products being manufactured.

Knife “Mushroom picker” – hand forged, steel 9ХС, walnut.

What is 9XC steel for knives?

Steel grade 9ХС – tool carbon steel. It uses chromium and silicon as alloying additives. They give the alloy strength and reliability, as well as good elasticity, bending resistance and wear resistance.

9ХС is mainly used in industry. It is made from:

- drill;

- taps;

- incisors;

- cutters;

- machine stamps;

- stamps for cold work.

It is also quite popular among knife manufacturers.

The best kitchen knives in the world - top 10

Reviews of knives from 9ХС

For the needs of the food industry, hunting, tourism and other activities, knives made from 9ХС steel are often used. Impressions of use are mostly positive. Users note difficulties in sharpening and the possibility of nicks. In general, owners of 9XC knives are satisfied and note the high strength of the products, long-term retention of the original sharpness after sharpening.

9ХС is a specialized alloy used for durable cutting tools, threaded components, and abrasion-resistant parts. If the technical requirements for processing are met, this metal alloy is quite good in operation.

At the moment, metallurgical enterprises produce many grades of tool steel. One of them is 9xc steel. A characteristic feature of such steel is that its alloy includes silicon and chromium alloy additives. This steel is mainly used in the production of measuring and cutting instruments, and knives are also made on its basis.

Knives made of this steel can easily be called an excellent option for fishing, hunting and tourism. Although they have not become widespread and popular when compared with other varieties, they still have a number of advantages. Forged knives made of this steel are faithful and reliable helpers, which are mainly used for hunting or fishing.

Price

9ХС is an expensive type of steel. This is due to the peculiarities of its production. Such blades are not stamped. They require hand forging. This significantly increases the cost of the product, but on the other hand, exclusivity attracts buyers. The average price for a knife made of this steel grade ranges from 6,000 to 25,000 rubles.

A knife made of 9XC steel is reliable, has a huge margin of safety and excellent cutting qualities. With proper care, it will last for many years and will not break or corrode.

Peculiarities

This tool steel contains many alloying additives . One of them is chromium , the content of which in the alloy ranges from 0.95-1.25%. Thanks to chromium, a higher level of hardness is achieved, strength and corrosion resistance are increased. Silicon, which is also present in the composition of this steel, demonstrates similar qualities, and its amount in the alloy exceeds 1%.

The properties of silicon help to increase the strength threshold, while the level of ductility and toughness decreases slightly. At the same time, the fluidity of the material and cold brittleness increases.

In addition to the above-mentioned properties, one can note the traction of the material to the tempering ability of processing by cutting the workpiece in a hot state. Interestingly, this tool steel does not have such a drawback as a tendency to be damaged by flakes - defects in the internal structure that negatively affect the strength characteristics.

When choosing knives based on the steel in question, you need to be aware of one important nuance - 9xc is not very suitable for the production of welding-type structures. It is recommended to use such workpieces exclusively in the case of resistance spot welding. Products based on this brand should only be used on cold surfaces.

The procedure for heat treatment of the steel in question for knives is carried out using electric furnaces with a sealed casing, equipped with automated control of the heating temperature and atmosphere. At the same time, during the heat treatment process, it is still necessary to regularly monitor the temperature and constantly check the hardness.

In addition, structural metallographic control and X-ray analysis for the presence of defects in the structure are required.

Advantages

- The advantages of the material include outstanding technical characteristics . For this reason, it is generally a suitable choice for the production of parts or individual elements that must have properties such as wear resistance, elasticity and bending resistance.

- When it is necessary to make cutting-type elements or any components, experts in this matter mainly choose the 9xc brand. The choice in favor of this particular brand is due to a number of aspects. In the case under consideration, one can note the uniform distribution of carbides over the cross section. Thanks to this feature, a significant advantage is provided when using this material in the manufacture of thread-cutting tools with a fine thread pitch.

- Billets made on the basis of this steel, used in the manufacture of certain products, are characterized by a high level of resistance to cracking.

- In addition to this, another property deserves special mention - a high level of hardness in the annealed state . This material can be easily calcined and at the same time demonstrates excellent resistance to heat. All these advantages also apply to knives made on the basis of 9xc.

Flaws

In addition to a number of significant advantages, steel also has some disadvantages. As an example, during heat treatment the material behaves quite capriciously; compliance with a specific temperature regime is required.

Another fly in the ointment is that the chemical composition of different batches can vary significantly. Given the complexity of mechanical processing, to obtain the desired result you will need to attract a highly qualified craftsman. However, even under the supervision of specialists, not every product is able to withstand final inspection.