Home » Reviews » Guillotines for metal cutting: types and applications

To cut metal sheets or rods, enterprises use special equipment. Guillotines and guillotine shears are needed in construction, mechanical engineering, manufacturing, car service centers and home workshops.

Similar scissors for cutting and chopping metal are produced in various variations. The types of this equipment will be discussed below. Devices with different types of drive differ in cutting accuracy, operating speed and other characteristics.

Russian metal cutting machines (guillotines) are selected based on technical characteristics. The most important of them is the maximum thickness of the sheet material that is planned to be cut. The weight of the scissors is equally important. These parameters and other technical parameters are indicated in the description of Guillotine shears in our catalog.

Pneumatic guillotine shears

Pneumatic scissors are distinguished by high cutting accuracy due to the increased rigidity and strength of the frame.

Pneumatic models are equipped with a compressor and operate using compressed air. Guillotines of this category are distinguished by a large working surface. The equipment is very economical and is suitable for large enterprises that require constant operation of the metal cutting device.

Pneumatics perfectly cut thick sheets and cope with alloy steel.

The lubrication and electrical system of pneumatic shears of the HA series operates even at low temperatures, which is impossible when working with a hydraulic analogue.

Electromechanical machines for metal cutting

Mechanical guillotine shears are in demand at enterprises that specialize in cutting sheet metal. Equipment of this class is characterized by a low price, optimal performance, and is used to perform the entire range of tasks associated with cutting rolled metal in production.

The system is powered by an electric motor. The machine is connected to the network to supply energy. Such devices are distinguished by high speed, efficiency, and cutting accuracy. When cutting, the knife acts evenly on both sides of the sheet. The service life of electromechanical type guillotines is long.

The length of the table and the size of the sheet workpiece depends on the model and assumes a width of 2000, 2500 and 3000 mm.

Principles of classification

Guillotine shears are distinguished by the following characteristics:

- By type of drive. In industrial production, as well as when cutting thick sheets, driven metal guillotines are more common. In this case, the control can be mechanical or hydraulic. In individual business practice, as well as in private workshops, manually driven machines are found.

- According to the execution of the main actuator. An electromechanical guillotine is most often equipped with a crank mechanism, while manual machines often have a lever mechanism.

- According to the method of pressing the workpiece to the supporting surface of the table. Guillotine shears can have mechanical (spring) or hydraulic clamping.

- According to the control method, cutting shears with non-automated feeding and removal of cut strips are distinguished, and automated complexes based on sheet shears, where all technological operations are carried out without human intervention.

Despite all the design and technological differences, these machines have one thing in common: the angle of inclination of the knives at which they cut. The fact is that at a zero inclination angle, penetration is carried out simultaneously across the entire width of the sheet, which causes increased energy costs and becomes the main reason for the increased drive power. Since the schedule of the technological operation of separating sheet metal has a peak of effort only at the beginning of the introduction of knives, and then rapidly decreases, it is much more profitable to ensure the gradual introduction of the tool into the workpiece. The force is significantly reduced, and the working displacement, although increased, is not much (due to the small thickness of the processed rolled profiles). Therefore, the knives of equipment for cutting sheet profiles are always inclined. The tilt angle ranges from 1.5...3.5°; it is larger for more powerful equipment. When cutting a harder product, for example, stainless steel, the gaps, on the contrary, are reduced. Increasing the gaps for ductile mild steel or copper degrades the quality and accuracy of the cut because the material being cut is pulled into the gap between the blades and forms burrs. Burrs are also a sign of a dull tool.

According to the classification accepted in our country, mechanically driven guillotine shears have the symbol H31__, H32__, H34__ or H33__ (the last two digits of the designation indicate the maximum thickness of the sheet metal being cut). Hydraulic shears are designated H37__. In practice, there is also marking of drive units for cutting sheet material according to its thickness and width. A typical example would be German-made machines, designated, for example, as follows: ScTR16×3150 (the first number is the maximum thickness, the second is the greatest width).

Hydraulic guillotine shears

Hydraulic guillotines are used by large enterprises. These devices are used in the automotive industry and in the production of roofing materials.

Machines in this category are the most modern and productive. They are distinguished by their long cutting length, high power, productivity and efficiency. If you need a system that can easily cut a sheet 2.5 cm thick, then you should pay attention to these machines. Their cutting length reaches 3 meters.

The guillotine can be equipped with pedal and manual control, graduated stops for cutting high-precision workpieces, CNC and a number of additional options. A distinctive feature of this equipment is its high cutting accuracy and the absence of nicks and dents. Hydraulic guillotine shears are used for cutting without defects or damage the covering layer of metal with a polymer or paint coating.

Guillotine for cutting metal: manual, hydraulic, electromechanical, pneumatic

Cutting metal products on a guillotine is a straightforward method of cutting rolled steel sheets into rolls, strips and rectangular and square pieces.

There is practically no waste when cutting with a guillotine (a small amount of small chips may remain on the knives). Cutting accuracy - 0.05-0.1 mm. Work speed - more than 10 workpieces per 60 seconds (depending on the type of equipment).

Metalworking technologies such as chopping and cutting should not be confused, because they have significant differences.

Chopping and cutting metal

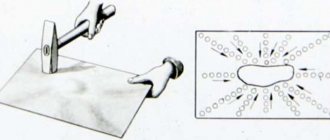

Steel blanks are cut by the impact of a chisel (sharp cutter), which is located at a slight angle or strictly perpendicular to the rolled metal. The tilt of the working tool is controlled by the master, since the presented method is carried out manually.

The manual cutting method is familiar to people working in production, private craftsmen, and car owners. It is applicable in cases where it is necessary:

- adjust the workpiece to the required size;

- process the edges of metal products;

- level a flat surface;

- remove the formed burrs;

- form edges for further welding of rolled metal;

- separate the resulting scale;

- punch a hole in the workpiece;

- cut off the heads of fasteners (for example, bolts).

The chisel has a sharpened tip. It allows you to cut metal, make grooves, recesses, and holes in the workpiece.

It is made from tool alloys or carbide structural plates. Outwardly it looks like a steel bar, on one side of which there is a cutting edge. Depending on the purpose, it varies in shape, width of the working part and sharpening angle.

Traditionally, tools with a width of 2-2.5 cm are used. The cutting edge is flat or slightly rounded. When working with steel raw materials, the sharp part of the chisel becomes dull over time. The cutting element is sharpened taking into account the required angle. For work:

- with bronze and cast iron the parameter of 70 degrees is observed;

- ordinary steel - 60 degrees;

- copper and brass - 45 degrees.

An analogue of a chisel is a crossmeisel. Usually its cutting part does not exceed 1 cm, the shape of the working surface is teardrop-shaped. It is more often used to create grooves and grooves on the surface of a metal product, while the chisel is used more for through cutting through rolled metal.

When chopping by hand, a hammer acts as an additional tool. For work, select a standard locksmith tool weighing 0.4-0.8 kg and handle length from 35 to 45 cm.

The process of cutting metal using a chisel consists of the following steps:

- the workpiece is placed on a flat and durable surface or an anvil (more often it is clamped in a vice);

- a marking line is made;

- A chisel is placed vertically at the cutting site;

- the master applies light blows with a hammer to the top of the chisel, which in the process moves slightly along the marking line;

- the steel billet is turned over;

- all actions are repeated on the reverse side.

But cutting can be not only vertical, but also horizontal. In this case, the workpiece is clamped in a vice at an angle of 35 degrees or less relative to the table. This method allows you to chop off the excess part of the rolled sheet protruding from the vice.

As an alternative, hand held metal shears have recently been used instead of chisels. But in both the first and second cases, the edge of the workpiece may have roughness, burrs, and unevenness.

But cutting metal with a guillotine gives an even cut. But this type of metalworking no longer refers to cutting, but to cutting. The workpieces are cut using sawing and cutting tools (scissors, saws, automated modern equipment). This is a more modern method, used mainly in small and large enterprises.

How to cut metal on a guillotine

A guillotine for cutting metal is a machine that is equipped with a static cutting element located at the bottom, as well as an upper knife (it moves along a certain path: arc-shaped or just straight, depending on the type of machine). Some types are equipped with an additional press, which allows you to fix the workpiece on the bed.

A characteristic feature of such installations is the oblique knife beam located on top. This helps it gradually move towards the cut line while applying pressure to the rolled metal sheet.

This type of knife also affects the power of the mechanism, which is capable of cutting through steel up to 20 mm thick with one blow. But the recommended parameters for workpieces are still sheets from 0.1 to 2.5 mm. In this case, the strength of the metal can reach 500 MPa.

Knives are produced in one piece. They are made mainly from steel grades U8A and U10A (after heat treatment they should have a hardness in the range of 56-58 HRC), as well as X12, 4ХС, 6ХС, 5ХВ2С, Х12Ф1 (their hardness is 56-62 HRC).

The cutting process consists of the following stages:

- the workpiece is fed to the work table. This is done manually or automatically (depending on the type of machine);

- the steel sheet is fixed to ensure high quality cutting;

- the dimensions of future tapes or strips are determined;

- the locations of the incisions are indicated;

- a steel knife sharpened at an optimal angle (on average from 86 to 89 degrees) is lowered onto the laid rolled metal;

- with its own weight or with the help of a hydraulic, electromechanical drive, it acts on the workpiece with the force necessary for cutting;

- once the cut is made, the knife is raised.

In industrial conditions, equipment with long knives is used, which increases cutting speed, increases productivity and makes it possible to cut rolled metal with a width of more than 3 meters. At large enterprises, machines with guillotine shears are installed, which are capable of cutting 6-meter rolled products.

What metal is cut on a guillotine?

The guillotine machine is used for cutting cold-rolled and hot-rolled metal. You can also chop:

- galvanized steel;

- blanks made of stainless alloys;

- composite materials;

- smooth and corrugated aluminum;

- non-ferrous types of metals (copper, titanium, brass).

As we said above, the thickness of the workpieces can be in the range of 0.2-1.5 mm. The guillotine cuts steel with a strength of up to 400 MPa. In industrial conditions, workpieces 2 meters long are cut as standard. At large enterprises it is possible to cut sheets 3-6 meters long. The cutting accuracy does not exceed 0.1-0.2 mm.

Equipment Features

A standard guillotine for cutting sheet metal consists of:

- from a fixed frame (work table);

- right and left racks;

- clamping beam part;

- knife type beams;

- back stop;

- crank;

- shear plate;

- knife feed lever (can be manual or automatic).

Depending on the type of equipment, this equipment can be supplemented.

Guillotine for cutting metal is:

- manual. Used in small workshops. The workpiece is cut by two installed knives. The lower one is fixed in one position, and the upper one moves strictly vertically downwards. The manual guillotine does not require adjustment. It is only important to install the equipment on a flat surface and align the knives according to the factory diagrams. Cuts relatively small workpieces (cut width usually does not exceed 1200-1500 mm). Used for steel up to 0.5-0.7 mm thick. Popular models: Mazanek GR 2000, Schechtl HT 200, Q01-1.25×2000;

- hydraulic. They are equipped with a hydraulic drive system. Performs both piece and serial processing of metal sheets. The hydraulic guillotine works with sheet metal up to 2 cm thick and no more than 6 meters long. The knives can move in a straight or arcuate path. Control over their location is carried out in manual, automatic, and semi-automatic mode. Particularly popular: Stalex HQ, Stalex THS, MelalMaster HCJ;

- electromechanical. It is used in large enterprises where high productivity and the ability to cut thick sheet metal are important. The knife works thanks to a crank mechanism. The equipment can be equipped with CNC. This allows you to create templates for the production of large batches of workpieces of the same type and increase cutting accuracy. An electromechanical guillotine cuts metal with a cross section of 4-8 mm. The knife makes up to 60 moves in one minute. Popular models: Fabtec Q11, RAS SMARTCUT, RAS PRIMECUT, SAY-MAK SRGM-H;

- pneumatic The entire mechanism operates on a compressed air line. The productivity of this type of equipment is higher than that of a hydraulic machine. Most often, the pneumatic guillotine is used in enterprises with large-scale production of metal products. The knife cuts metal with a thickness of 12 mm or more. The TGSP machine model is especially popular.

Industrial guillotines

Productivity and minimization of time costs when cutting with a guillotine play a major role when choosing equipment for large enterprises. Therefore, in industrial settings, pneumatic, hydraulic or electromechanical equipment is mainly used. Large producers place emphasis on complete automation of the process. The main part of the machines is equipped with CNC.

Among the popular types of guillotines for cutting metal, we highlight:

- MetalMaster hydraulic units;

- Stalex electromechanical guillotines;

- Inanlar hydraulic shears;

- pneumatic machines TGSP;

- electromechanical scissors TKS, etc.

Hydraulic shears Inanlar

Comparative table of all types of guillotines, GOST standards, types of defects

| Guillotine type | Thickness of metal products | Type of metal product | Maximum strength of the metal workpiece | Sheet width | Number of moves in 60 seconds | Availability of CNC | Cutting accuracy |

| Manual | 0.2 – 1.5 mm | Galvanized and profiled sheets, fittings, ordinary sheet metal | 400 MPa | 0.1-2.5 m | from 2 to 5 | — | 0.05-0.1 mm |

| Hydraulic | 0.4 – 40 mm | Fittings, corrugated sheets, steel made of aluminum, titanium, galvanized, stainless and ferrous metal | 500 MPa | 1-3 m | from 8 to 20 | + | 0.05-0.1 mm |

| Electromechanical | 0.25 – 12 mm | Fittings, corrugated sheets, steel made of aluminum, titanium, galvanized, stainless and ferrous metal | 500 MPa | 1-3 m | from 1 to 60 | + | 0.05-0.1 mm |

| Pneumatic | 0.2 – 12 mm | Fittings, corrugated sheets, steel made of aluminum, titanium, galvanized, stainless and ferrous metal | 500 MPa | 1-2.5 m | from 1 to 60 | + | 0.05-0.1 mm |

Work with guillotine equipment is controlled by GOSTs 6282-88, 11647-75.

Among the possible types of marriage, we highlight:

- oblique cut and crescent shape (explained by the blade moving to the side due to weak tension in the frame);

- formation of a sharp edge on a metal product. Reasons: poor quality of sharpening of the guillotine knife or incorrect location of the upper cutting element on the machine;

- curvature or twisting. This can happen due to poor quality or incorrect clamping of the workpiece.

Advantages of guillotine cutting

- Fast payback.

- Complete readiness of the workpiece for further processing after the cutting process;

- Versatility (you can work with rolled sheets of various alloys, including cold and hot rolled steel, stainless steel, galvanized).

- Economical. Cutting metal using a guillotine results in minimal losses of the starting material (no more than 10%). This method allows you to cut sheets with virtually no sawdust or shavings.

- Cut quality. The edge is smooth, without burrs, creases or chips. The knife is lowered strictly perpendicular to the workpiece.

- No heating of the material.

Application

In industrial conditions, other types of metal cutting are also used. It could be:

- waterjet method. Cutting accuracy – 0.1 mm, cutting width – 0.8-1 mm, minimal material loss (possible tolerances 0.1-0.3 mm);

- band saw cutting. Accuracy - 0.1 mm, width - about 1.5 mm, material loss is minimal (possible tolerances 0.1-0.3 mm);

- laser cutting method. Accuracy – ±0.05 mm, width – 0.2-1 mm, material loss is small (possible tolerances 0.1 mm);

- plasma cutting. The cutting accuracy is ±0.1 – ±0.5 mm (depending on the type of material), the cutting width is 2-7 mm, the loss of material is relatively high (possible tolerances are 0.2–0.5 mm).

Guillotine cutting is used primarily to create steel sheets, strips and strips of specific sizes.

These metal products are subsequently used in construction and in the production of parts for cars, work machines, and industrial machines. The resulting metal products are also used in aircraft, ship, and car construction.