Cutting sheet material is an important technological operation, which is necessary when creating a significant number of profiles. In order to quickly and efficiently cope with the task under consideration, special equipment is required - a metal guillotine. You can buy this machine on the Metal Master website. The information presented here is a photo, video, detailed description, technical. The characteristics of each machine model will allow you to make a balanced and deliberate decision, to select the optimal equipment option that fully corresponds to the technological realities of your enterprise. When it’s difficult to make the right choice on your own, you can simply call the number listed on the website. Consultation with an experienced manager will help you choose the best equipment option.

The offered guillotine shears fully comply with European standards. Equipment must be tested in various operating modes before the machine goes on sale. Therefore, you can be 100% confident in the excellent quality of this equipment.

Convenient cutting of a wide range of materials: sheet steel, copper, zinc, brass, plastic. As a result, the output is workpieces of ideal quality without any defects (no dents, burrs, etc.). Depending on the modification of the equipment, it is possible to cut both rolled and sheet material.

Even work associated with a significant operational load will be done as quickly and efficiently as possible. Due to the high speed of completing assigned tasks, production efficiency invariably increases. The cost of finished products is reduced, and the enterprise becomes more profitable. The machine fully pays for itself within a few months, when the equipment is fully loaded.

Together with a reliable bending machine, guillotine shears allow you to perform tasks with the creation of additional roofing elements, elements of drainage and ventilation systems, as well as a significant number of other metal profiles. Guillotine for cutting metal is in demand in various fields of industry: construction, mechanical engineering, instrument making, manufacturing of advertising structures.

Before you start working with the machine, be sure to read the safety manual and also undergo a short briefing. With the task of those maintenance, the operator can easily handle it independently, without the help of a third-party specialist.

The choice of guillotine shears should depend not only on the workload of production (here the machine is selected based on the type of drive), but it is also important to take into account a number of technical characteristics: the thickness of the sheet material, the permissible length of the workpiece, weight and overall dimensions. Some parameters should be taken into account with a small margin. This approach will avoid overloading the equipment, which means the equipment will last much longer.

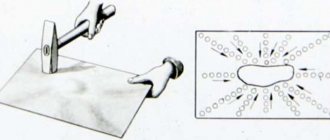

Manual guillotine saber type

This small-sized equipment has a relatively low weight - simple and convenient transportation of the machine from one production facility to another. The blades of the machine are made of alloy steel of the highest quality, resistant to corrosion.

The proposed technology represents the optimal solution for enterprises whose main field of activity is single or small-scale production. The machine can be installed in enterprises where production space is limited, for example in a small workshop or repair shop.

We invite you to pay attention to such equipment as Metal Master: MG 800; MG 500; MG 1000 (HS 1000); MG 1300.

Design features and advantages:

- The presence of a spring compensator allows for ease of lifting. Significant savings in worker effort, which generally has a positive effect on the efficiency of your enterprise.

- Increased wear resistance. The resulting vibration effect does not have a significant impact on the accuracy of solving the assigned tasks;

- Excellent stability. At the base of the guillotine shears there are special holes for attaching the equipment to the working surface using anchor bolts. During the process of cutting the material, the machine is not allowed to move;

- Possibility of processing sheet metal of unlimited length. There is a special method for attaching the blade (cantilever);

- Comfortable handle of the machine. The tip of the handle is made of non-slip material;

- It only takes a few minutes to set up the equipment to work with the required metal thickness;

- The machine is quite easy to use. Even a person who does not have significant experience working with similar equipment can understand the principle of its operation.

Mechanically driven guillotines

Hydraulic driven units

A distinctive feature of such machines is the ability to cut fairly thick metal workpieces. Equipment manufacturers note in their operating instructions that for structural steels the maximum thickness can be up to 40 mm.

Similar devices on the edge of the blades develop a force of 200...400 tons. In this case, it is important to use thick knives that can transmit forces in the cutting zone.

Installation with hydraulic drive. The pumping station is located outside the machine

To operate a hydraulically driven guillotine, you must have a special pumping station. From it, oil is supplied through reinforced hoses to the actuators. Liquid pressure can reach up to 135...150 bar. Hydraulic cylinders transmit force to the actuator through a system of levers.

The main advantage of such guillotines is their quiet operation. The knives move without impact.

On the control panel, the operator specifies a number of parameters, the built-in computer will make the calculations itself:

- what gap is required between the knives;

- where to set the emphasis;

- at what speed should oil be supplied to the hydraulic system?

If it is indicated that several parts of the same type will be cut, then this parameter is also indicated. Then the material will be supplied automatically.

The operator and assistant can only:

- place the sheet of metal on the work table;

- align it with the guides;

- align with stops;

- indicate the number of the program by which you want to cut metal;

- set the number of required parts.

At the end of the cycle, on the back side of the machine there will be chopped blanks or parts that need to be taken to the semi-finished product site. Other employees of the company use them in the following production processes.

The price for such machines is high, amounting to several tens or even hundreds of thousands of euros. Guillotines of this type are made to order. In the future, the equipment manufacturer maintains it throughout the entire life cycle of the process unit, provides it with programs and offers original spare parts. If necessary, even a fairly old machine can be modernized. After modernization, it is ready to serve on equal terms with new units for quite a long time.

Video: cutting metal with a guillotine.

Food for thought. In the thirties of the twentieth century, DIP-250 and DIP-350 lathes were purchased in Germany. More than eighty years have passed. This equipment continues to be successfully used at a number of enterprises. After major repairs, gun barrels for modern guns and tanks are processed on similar machines. Machines can last quite a long time.

Video: CNC hydraulic guillotine.

Electromechanical guillotine shears

The most common type of machine is the electromechanical guillotine shear. A shaft with a flywheel constantly rotates in them. Through the crank mechanism, torque is transmitted to the active knife.

To make a cut you need:

- place a sheet of metal on the table;

- set the focus to the specified size;

- fix the workpiece on the table and press it against the stop;

- press the control pedal.

The metal will be cut according to the markings. By moving the sheet again to the stop, you can repeat the operation.

Electromechanical guillotine

These machines are quite lightweight. They equip small workshops and fairly large enterprises. They are characterized by high performance. You can cut up to 60 parts in a minute.

The disadvantage is the noise during operation. Here the metal is cut with a strong blow. You often have to send knives for sharpening. Edges tend to chip when subjected to impact loads.

It is necessary to frequently check the condition of the edges of finished products. If the formation of bent edges and burrs is observed, then the knives are removed and sent to a sharpening machine.

Video: operating principle of electromechanical guillotine shears.

Pneumatic guillotines

If there is a developed system of pneumatic pipelines, the enterprise uses equipment powered by compressed air. Pneumatic guillotines use air compressed by compressors to carry out basic production activities. They are equipped with pneumatic cylinders.

Installations of this type require a receiver. The volume of air used in the cycle can reach several liters, so a supply of working fluid is needed.

Pneumatic guillotine

The operation of such devices is somewhat louder than when using hydraulics. But there are also advantages. On such machines it is easier to install computer control. Therefore, a number of European countries producing technological equipment are focusing on creating just such guillotines. It is easier to configure here; programs for managing production operations are written relatively simply.

Training operators for such machines is also easy. After just 2-3 days of work, workers master the basic techniques of working on a guillotine. All that remains is to issue them a production task, indicate the placement of workpieces and areas for unloading semi-finished products.

Video: guillotine shears.

Electromechanical guillotine

Reliable stationary equipment, which, depending on the machine model, allows you to process sheet metal with a thickness of 1.5 mm to 6 mm. Even complex tasks associated with a serious load will be solved as quickly and efficiently as possible, which becomes possible thanks to a powerful electric motor. The powerful body of the guillotine shears with an electromechanical drive makes the machine resistant to the negative effects of production vibrations. The cutting accuracy will always be at a fairly high level.

We offer you to make the necessary choice from a significant number of metalworking equipment, Metal Master: ETG 1330; ETG 2540; ETG 1315E; ETG 1530E; ETG 2030E.

Types of scissors for cutting metal:

- The manual guillotine is capable of cutting metal up to 3 mm thick.

- Hydraulic shears help achieve high cutting accuracy and process metal of maximum thickness.

- Mechanical guillotine models are considered very reliable and consume less energy.

- CNC guillotine shears have high efficiency.

The ck-stroyavto assortment includes guillotine sheet shears made in Russia and made in China. This TOP model includes the 10 best and most sought-after guillotines from domestic developers. They are made from high-quality components, are considered durable and unpretentious to climatic conditions.

The models are arranged by price (in ascending order), have a description and the main technical characteristics of the machines. For more detailed information, go to the product card of the model you are interested in.

Design features and advantages:

- Electromechanical drive with gearbox lubrication system. Low noise of the machine even under heavy load;

- Special desktop layout. Extremely precise positioning of the processed sheet material;

- High-precision adjustment of gaps between knives. A clean cutting surface is guaranteed;

- For convenient operation, the equipment is equipped with a foot drive. With free hands, the operator can easily and quickly place the metal sheet on the work surface;

- The machine is attached to the working surface using anchor bolts. During the process of cutting metal into workpieces of the required overall dimensions, equipment movement is not allowed;

- The occurrence of scratches on the surface of the processed material is excluded. The presence of polymer pads ensures accurate clamping of sheet metal;

- The equipment allows you to cut not only metal, but also cardboard and plastic;

- Reliable protection of the operator’s fingers eliminates the occurrence of force majeure circumstances.

Applications of manual guillotine shears

As a rule, small companies, individuals, car service owners, as well as construction companies performing tin and roofing work prefer to buy a manual metal guillotine.

An indispensable machine for cutting stainless steel, aluminum, copper and galvanizing in housing and communal services organizations when carrying out various types of repair work. Manual guillotine shears for cutting sheet metal are the optimal choice of metal-cutting equipment for cutting thin-sheet material if you do not plan to perform large volumes of work, but in the metalworking process you need to ensure a high level of cutting accuracy of sheet steel or other materials without spending money on more advanced models of machines with a higher price.

In addition, it is beneficial to buy manual guillotine shears if you need to process other types of sheet material, cardboard of various thicknesses, plastic, and organic glass.

Buying mechanical guillotines for cutting and chopping metal at a competitive price from the Avangard company is a profitable purchase. With sufficiently high physical and mechanical parameters in the process of metal processing of sheet material, a metal-cutting machine does not require additional costs for electricity, maintenance of drives, other components and assemblies and quickly pays for itself.

Hydraulic guillotine shears

The rigidity of the guillotine design is ensured by a durable, welded frame. The resulting vibration load does not affect the accuracy of solving the assigned tasks. Availability of powerful hydraulic cylinders and a reliable hydraulic system with components supplied by the world's leading manufacturers.

The CNC has an intuitive control system. It is possible to record up to 40 programs. Excellent positioning, cut counters, and clamping time settings - all this can provide a significant increase in labor productivity.

We offer a significant selection of machines, Metal Master: HCJ 2060; HCJ 2540; HCJ 2560 and others.

Design features and advantages:

- Sufficiently powerful equipment intended for mass production. Low operating noise even in very busy conditions;

- The optimal ratio of favorable price and decent quality. For a long time, the machine will work as efficiently as possible, coping even with a significant load;

- Built-in pressure gauge and force regulator. Metal cutting will be carried out in strict accordance with established requirements;

- Ergonomics. Intuitive control panel. Wide choice of sizes and functions. Full compliance with almost any production requirements;

- Electrical equipment from Siemens and Schneider is characterized by increased performance and wear resistance;

- Sheet support brackets with an adjustable crossover stop are located on the front part of the machine. Thanks to the shadow cutting line, marking work can be done.

In general, the proposed technology is an excellent choice for mass production when a durable machine with significant functionality is required. This is a reliable assistant that makes your work much easier.

Manual machines

Many people think that manual machines are inconvenient for production. In fact, these installations are quite in demand in small enterprises. In conditions of small-scale production, it is important to ensure product quality:

- It is more important to ensure the exact dimensions of all parts.

- Proper edge processing. Deburring.

- Parallelism and perpendicularity of cut straight lines.

When a significant volume is required, quality is often relegated to the background. We need mechanical devices capable of producing several blows and cutting off a certain number of workpieces within a limited time.

If the workshop produces single products, then the speed and number of blows of the device are not so important.

Attention! Today in the construction market it is not difficult to buy metal Chinese doors at a relatively low price (2000...4000 rubles). But if you want to have a more durable and reliable door, you turn to workshops where a product with the specified characteristics will be made to order. It will have armor plates in the area where the locks are placed; the manufacturer will additionally provide its product with additional options that will prevent unwanted persons from entering.

Several metal fire doors with options to prevent the spread of smoke and fire are manufactured by small businesses. They use simple and reliable manually driven guillotines.

Professional manual guillotine

These installations provide the following:

- the sheet of metal is placed on a special table;

- with the help of additional side tables, the workpiece can have significant dimensions (up to 2500 mm in length and 2500 mm in width);

- regulation of the cutting depth is limited by a special stop located behind the movable knife;

- special guides allow you to ensure perpendicularity of the cut;

- other guides will precisely position the workpiece at the desired angle or allow it to move only in a parallel direction;

- Before cutting, to prevent possible vibrations in the active work zone, the workpiece is pressed against the table. Now it will not move in any direction.

Video: guillotine for cutting metal.