A jack is a device that no driver can do without when repairing their car. It is needed to lift loads to a small height. It should be stored in the trunk of a car or in a garage. When purchasing such a device, you need to pay attention to the load capacity, which should be as high as possible, as well as the universal functionality. Many car enthusiasts prefer a hydraulic jack, which you can build with your own hands. But before that, you need to study information on how to make a homemade car jack with your own hands at home.

Types of jacks

Today, the assortment of stores for car enthusiasts includes several types of jacks from both domestic and foreign manufacturers. Popular varieties:

- hydraulic;

- mechanical;

- electrohydraulic and electric;

- pneumatic.

The operation of a hydraulic lift is that it pumps brake fluid or hydraulic oil into the working cavity. Single-valve models have a valve that prevents oil from flowing back, and the two-valve type has a built-in bypass safety valve that prevents minor damage to the structure if the permissible load is exceeded.

Example of using a jack

A homemade mechanical jack is a lifting device for completing passenger cars. The principle of its operation is that the screw pin is moved by mechanical force.

As for the electro-hydraulic design, it is activated by an electric drive. There are some lift models that have a manual drive.

With pneumatic devices, air is pumped into the cylinder, due to which the mechanism begins to operate. A homemade tool is also powered by the exhaust gases of any vehicle, which cannot be said about the industrial version, which requires powerful compressor equipment to operate.

Note!

The material used to make a jack depends on its load capacity and type of construction. Rolling devices for repairing passenger cars are made of aluminum, and hydraulic cargo options are made of cast iron and steel. The load capacity and the mechanism as a whole directly affect the type of material and its thickness.

Rolling jack made of steel

Skills required to make your own jack

Making such a device for repairing vehicles is a rather difficult task and requires a lot of money. A novice mechanic’s “arsenal” should have a number of specific skills, which include cutting, welding, painting, turning and machining.

You might be interested in this About Matrix jacks: torque, hydraulic - what to choose

The main skill that is needed to work with metal is welding, because the structure will need to be assembled from scratch, and you can’t do it without a welding machine. To cut iron, you will definitely need a grinder or an oxygen torch, and you need to process the future product with a grinder or file.

Important!

You can do without turning skills, but in this case you need to be prepared for the fact that it will be much more difficult to manufacture and process some parts.

The finished item must be covered with several layers of paint. If the master has all the above skills, making a lift will not cause any difficulties.

What is required for this

Assume that the main part of the structure is the jack. It can be screw, linear, manual, pneumatic, but the hydraulic option is more reliable.

It is better to make the rod retractable. It will require a metal profile of two sections: external - 32 mm, internal - 30 mm. If pipes are found, then the outer one should be within 63 mm in diameter, and the inner one should be 58 mm.

The platform is made of sheet iron or a metal profile. You need reliable rollers: it’s better to buy them, but if you don’t expect a lot of weight. Or you can use wheels from an office chair.

Tools: grinder, welding machine, electric drill with drills of different diameters, bolts, nuts.

Tools and materials you will need

To make a jack at home, you will need suitable tools, the main one of which is a welding machine. First you need to acquire a semi-automatic device with carbon dioxide - this way, the release of excess slag will be eliminated, and the seams will be smooth. The second important tool is a small and large grinder, which are necessary for cutting blanks from steel sheets.

An example of making a bottle jack

The holes should be made with a drill, and to process iron parts you may need a sharpener, preferably an electric one. In addition, experienced specialists recommend acquiring the following tools:

- sledgehammer;

- file;

- bars and hammer;

- a vice and a screwdriver;

- needle files.

The more devices there are, the easier the work of processing steel parts will be. A great help in the process of making a jack is a lathe and a homemade jack vice that can be placed in the garage or workshop. The milling machine makes processing and tuck-out of a rod or bolt several times easier.

As for the material for the structure, it can be purchased at a specialized store or on the market. It is strictly not recommended to buy steel from scrap metal collection points, as it may end up battered and rusty. Depending on the type of jack you plan to manufacture, you may need additional fasteners and mechanisms that are physically impossible to make yourself. In any case, you need to be prepared for the fact that some components need to be purchased on the market.

Powerful bearing puller

If you need a powerful bearing puller (for example, you need it to disassemble large electric motors), you can make one from a car bottle jack.

From a piece of thick key made of hardened steel, the author cuts two blanks 200 mm long.

After this, one hole with a diameter of 16 mm must be drilled in each workpiece.

DIY hydraulic rolling jack

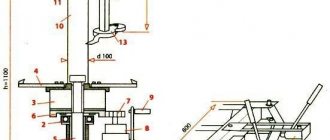

It is very easy to make a rolling jack with your own hands. The base of a hydraulic jack, consisting of a lifting platform and a lifting lever, can be made independently from a channel. A homemade rolling jack is used as a lifting force, and in order for the structure to move, rollers, bearings or ordinary wheels should be attached to it.

Scheme of the finished jack

The installation of the jack must be carried out on a movable type of platform, which is usually called a “swing”. This is necessary in order to compensate for the movements of the jack caused by a slight change in angle. The swing platform should perform swinging movements, and for its manufacture it is recommended to use the same channel. First, a through-type hole should be drilled in the lifting base of the channel, and then place the “swing” on the screw so that there is a gap of 1.5 cm in diameter between the platform and the base.

Note!

In order to increase the strength of the finished hydraulic structure, it is recommended to build braces on the sides using rods for these purposes. The greater the thickness of the rods welded to the base, the stronger the product will be.

Recommendations

Nowadays, it is advisable to make homemade jacks of a complex type with your own hands only in cases where there is enough material and old devices collected in the garage for this purpose, which will ensure their creation practically free of charge. A rolling version of the lift can be built without hydraulics - using a pneumatic jack.

You should also not forget about such an important negative side of the rolling lifting device as its significant dimensions. This product is more likely a garage type, and not for transportation in the trunk. However, for those mechanics who are seriously involved in car repairs, such a lifting unit is an indispensable assistant in their work.

To learn how to make a rolling jack with your own hands, see below.

How to make a pneumatic jack at home: description

To make a pneumatic lift with your own hands at home, you must first acquire an air cushion and two bolts. The air cushion is the main working part, which is sold on the market or in specialized stores. It is also recommended to give preference to an ordinary rubber cylinder, which is located on the air suspension of any vehicle.

Important!

It is advisable to use a cylinder from a truck, since its strength allows it to withstand strong pressure and significantly increase the lifting moment. But these cylinders are distinguished by their large height, due to which it is not always possible to place such a device under a car with low ground clearance.

To make the cushion and valve, you need to prepare two bolts in advance. The pillow must be equipped with a factory threaded hole into which a high-pressure tube is screwed. This tube needs to be replaced with a bolt of the same diameter, and then select another one that will act as the top cover. The products must be drilled in such a way that a cavity is formed during their connection.

You might be interested in this About low hydraulic jacks: rolling and hook-on

Arrangement of cushions in a pneumatic jack

You need to place a strong fitting for inflation in the top bolt, as well as a ball from the bearing. The final stage is welding the structure and screwing it into the hole of the pillow.

Common mistakes and how to avoid them

Many car enthusiasts often wonder whether it is worth making a jack lever or other structure with their own hands in order to carry out repair and installation work, lift cars or other loads. It all depends on the cost of materials. In 2022, the price of a finished factory jack can reach 5,000 rubles, but the cost of tools and parts for homemade products can significantly exceed this amount. The most common mistake is that inexperienced car enthusiasts prefer to make a hydraulic mechanism rather than a pneumatic or rack and pinion mechanism, which are much cheaper and simpler.

Today, the price of jacks is not so high, and there is no point in wondering whether it is worth wasting your time and making such a device at home. If there is no desire, then it is better to purchase a ready-made lifting structure in a store, but if you want to make it yourself, you can test your abilities. Some experts claim that by making a simple lever jack yourself, you can save a couple of thousand rubles.

It is necessary to carefully study the homemade drawing, safety regulations, as well as the dimensions of the homemade rolling jack. In inexperienced hands, any material, press or tool can act as a dangerous weapon that can cause serious injury. In order to cut and sharpen parts from steel sheets, you should acquire safety glasses to prevent possible eye injuries. Any mistake in the manufacture of jacks can lead to irreversible consequences, the result of which is very difficult to correct.

FakeHeader

Comments 39

oh, this will come in handy now, thanks)

I respect people with hands! yyyy

Yes, this is not for you to make a rake out of chairs on the press.

yyyy not rakes but daisies yy

“Lovely”! What about painting?