Metal processing is a process aimed at changing the shapes, sizes and appearance of products. To implement the project, a certain set of tools is used. Regarding metal, various types of machines and additional devices may be needed.

- Methods and stages First stage. Creating a mold or blank

- Second phase. Parts processing

- Third stage. Assembly of the structure

Types of plumbing tools

Measuring

- Rulers, tape measures - length measurement, quality and accuracy of metal rulers justifies their price

- Feeler gauges are a set of steel plates used to determine the thickness of the gap

- Vernier calipers - allows you to measure the internal size, external size and depth, like a ruler, a very accurate and high-quality tool

- Micrometer - allows you to measure distances with an accuracy of hundredths of a millimeter

- Protractor - measuring angles

Marking

- Scribbler - a steel rod with sharp, hardened ends

- Marking compass - for drawing circles and roundings on the marked workpiece

- Punch punch - for making small indentations on the workpiece marking lines

- Articulated pliers tools - pliers, forceps, pliers and their varieties

- Vice - for clamping and further processing of workpieces

- Clamps - allow you to tightly press parts together, for example when gluing

- Hammer - a device for bending, straightening and hammering

- A sledgehammer is the same as a hammer, only 10 times heavier

For cutting metal

- Side cutters - cutting through thin materials

- Hacksaw for metal - cutting metal, sawing

- Scissors - cutting metal sheets

- Chisel - cutting metal

- Kreitsmeiseli - for cutting keyways and grooves

For metal processing

- Files and needle files - removing a layer of metal by filing

- A scraper removes thin layers of metal from a part.

For machining holes

- Reamers - precision hole machining

- Countersinks - they are used to make chamfers and recesses for the heads of bolts, screws, rivets

- Countersinks - they are used to increase the diameters of holes

Assembly tool

- Screwdrivers - Phillips, slotted, hex, torx

- Wrenches - open-end, box, socket, hinge, adjustable, ratchet

- Torque wrenches - have adjustable torque

As you can see, locksmith tools have a very wide variety.

Measuring tools

In addition to universal measuring instruments, there are special ones that are used exclusively for working with metals.

Metal Measuring Tools

Forging calipers - this measuring tool comes in many sizes, which allows you to obtain several sizes of forging. This makes it much easier to check the dimensions of parts during forging.

Shrinkage ruler - used to identify shrinkage of a part during cooling or heating. Its scale ranges from 0.01 to 0.015 and allows you to calculate shrinkage even by eye, without any formulas.

Shaped hammers

A handbrake is an ordinary hammer that is used in blacksmithing, plumbing and many other types of manual work (hence its term). Its forms are determined by the targeted tasks. In every forge there are handbrake handles with longitudinal, transverse, wedge-shaped and rounded strikers. A small ordinary hammer, usually used to give a signal and indicate a specific location and force of impact.

Types of shaped hammers

A sledgehammer is perhaps the most important tool in the hands of a hammerman. With its help we give the workpiece the shape we need. The weight of a sledgehammer is on average 8-9 kg, in exceptional cases it can reach 15 kg.

Depending on the work performed with metal, three forms of sledgehammers are used - sharp-nosed with a transverse or longitudinal wedge-shaped end, and blunt-nosed, in which both striking ends are flat. Working with a sledgehammer is done with the help of a hammer hammer. If there is no need for high impact force, you can get by with an impact hammer weighing no more than 2-4 kg.

Shaped hammer , also a tool for working metals. It is necessary for artistic functions and can have completely different shapes of the butts. Craftsmen use shaped hammers to carve out the relief and background on the bottom (metal lining for the workpiece). Shaped hammers are very different in shape from handbrake hammers. The head of these hammers has two heads: slightly curved and very wide or flat, and the other is rounded.

When striking with a wide striker, all attention and energy is focused on the working plane of the coin. And the other firing pin usually serves instead of the fire hammer.

The handle of shaped hammers is made of hard special wood and has a characteristic shape. The dimensions of the handle are chosen so that it does not interfere with exercise, and the blow is strong enough.

When working with softer metals, wooden hammers made from especially durable types of wood, for example, birch or oak, are used. With their help, the softest silhouettes are obtained.

Metal tools

Coins for metal

Embossing is the most important tool for metal processing.

Embossing tool

The base of the coinage is usually made octagonal. With this form, the location of the working surface at the time of embossing is easier to control by hand, looking less at the tool itself.

The impact part has a wide variety of sizes and shapes, which are determined by the type of purpose and dimensions of the part.

According to the type of work and the shape of the striking part of the coin, there are several types of it, of which the main ones can be distinguished: boboshniks, loshchatniks, consumables and kanfarniks . With their help, important elements of metal processing and relief creation are produced.

Hook and ratchet are arc-shaped coins for basting embossing on bulky items.

A chisel is a hammer with a sharpened striking surface, used to create openwork work. They are divided into straight lines, and with the help of them straight lines and semicircular ones are carved, which are used for carving curved lines.

Tips for choosing

When choosing a set of plumbing equipment, the main thing is to know for what types of work it will be intended. If a kit is chosen for home use, then its main feature should be simplicity, quality, and safety. Don't skimp on price. Low quality materials fail faster. When choosing equipment for narrowly focused types of work, you need to purchase only those tools that are really needed. No need to buy extra. High quality is the main criterion. It is necessary to pay attention to the quality of the handles and their design. They should not slip or turn. It is especially worth remembering that when using, the main thing is safety, and it largely depends on the kits used.

Manufacturers of metal processing tools

There are manufacturers who have been making high-quality equipment for metal blanks for several decades. At the same time, both domestic and imported companies are represented.

Domestic

The equipment of JSC NIR is most widespread in Russia. To produce equipment, the company uses alloys of special hardness. The main advantages of their products:

- high wear resistance;

- it is possible to quickly change tools;

- there is a nano-coating;

- low sharpening costs.

The Moscow Tool Plant is not lagging behind in terms of performance. Products have been based on world standards for several decades. Using such equipment, you can easily create the most non-standard threads, machine a coupling, pipe and any other part on a lathe.

Imported

Foreign factories produce high-quality tools that are used all over the world. One of the leaders is the Israeli company ISCAR, which produces tools for turning, drilling, and milling.

For processing titanium, aluminum, stainless steel, cast iron, you can use strong and reliable German tools from ARNO.

The top five includes the Japanese company SUMITOMO. They make their equipment from hard alloys, diamonds and CBN. The products are used for turning and milling work of various levels of complexity.

Size differences

When choosing any tool, it is important to pay attention to its size. Files come in 6 classes, which differ in processing accuracy.

Good to know. There are more than 20 types of turning tools. They are divided into left-sided and right-sided.

The dies or dies used to cut threads differ in their measurement system. It can be in millimeters or inches.

Methods and steps

The entire path from raw materials to the finished product can be divided into 3 main stages.

First stage. Creating a mold or blank

Methods:

- casting involves filling a mold with molten raw materials;

- mechanical impact on the material: forging, rolling, stamping, bending.

Second phase. Parts processing

Includes many different processes:

- milling;

- turning;

- grinding;

- cutting;

- drilling;

- thread formation;

- planing.

Third stage. Assembly of the structure

Can be implemented in the following ways:

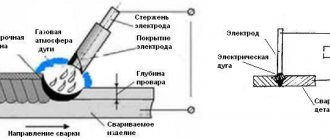

- welding;

- soldering;

- gluing;

- connection using fasteners.

At each of the listed stages, manual metal processing is allowed. Achieving results on your own takes longer and requires patience, skills and, of course, a tool.

It is not easy to organize a metallurgical enterprise at home. Building a forge is an expensive undertaking, but not difficult. This makes sense if you have a desire to engage in forging on an ongoing basis. Accordingly, it will be cheaper to purchase blanks for future products in a store or order from a company.

Existing technologies for manual metal processing involve turning and metalworking.

Homemade workbench made from used metal pipes

RatexFORUMHOUSE user

I need a universal table for working in the workshop. I decided to make it from various trash. I took frames from old greenhouses. They are based on pipes with a cross section of 3x6 cm. The wall thickness is 3 mm. Boards with a cross-section of 15x5 cm were used for the tabletop. I bolted the boards to metal corners. To work with clamps, I will make the tabletop with a 5 cm release on all sides. Having sketched out a plan, I got to work.

The base of the workbench is scrap metal.

The user cut up used frames. I welded a frame from pipes. Then I painted it.

Table size: 2900x800x830 mm.

Ratex welded M16 nuts to the legs from below. Screwed the bolts into them.

This way the workbench can be adjusted in height, and the tabletop can be adjusted to suit your height.

The user assembled the tabletop from six boards 3 m long.

Tabletop width 900 mm.

I assembled the base from old chipboard sheets.

The plates are connected to each other by metal plates 30x30 mm. Mounting points - in the center at the bottom and one at the joints.

RatexFORUMHOUSE Member

I figured out what the table looked like. The height of the workbench is 840 mm. Just right for me.

The height of the working surface of the workbench was 5 cm lower than the plane of the drilling machine. That's how it was intended. By placing a block under the workpiece, you can drill something long, with the part supported on the workbench.

I fastened the boards to the Ratex frame with round head bolts for an internal hexagon.

At the end of the work, the user painted the tabletop. According to him, the best option is to cover the boards with a metal sheet. But there was no such leaf lying around in the bins, and it was expensive to buy.

Ratex

To avoid damaging the wood, I will place a small metal sheet on the table. At least something. Then I will attach the vice to the workbench. I will attach a block with sockets for connecting electrical tools. I'll put some sandpaper on it. Below I will put grinders, a welding machine, drills, a hammer drill, fasteners and parts. Agree that such a workbench is better than working on a concrete floor, as I did before.

Sanding machine LANNERET

An angle grinder with a power of 220 W will be a very useful device. The machine is made taking into account the latest safety requirements, therefore it is equipped with a two-way switch with a lock. The body of the tool is made quite ergonomically, so it fits comfortably in your hand during operation.

For convenience and safety, a soft start and speed control device is installed, and it is also possible to lock the side handle in two positions, choosing the most suitable one for yourself. The maximum rotation speed of the machine is 7500 rpm.

Overall, the device is good and does its job well.