Home / Electrodes

Back

Reading time: 2 min

0

6506

The choice of electrodes is huge; they are produced by many manufacturers. Some are more famous, others less.

Of those that are well-known, we can primarily note such as ESAB, LEZ, Kobelco, Spetselektrod.

However, there are still many quite worthy manufacturers who have not yet managed to become as popular. We would like to introduce you to one of these companies.

- Information about the company

- ANO-4

- MR-Z

- Finally

Types of electrodes

The manufacturer of Arsenal electrodes, a plant under the same name "Arsenal", presented them in only two versions - MRZ ARS and ANO-4. However, each of them deserves close attention, including for home welding.

Arsenal welding electrodes have the following advantages:

- easy arc ignition;

- the constancy of its combustion;

- easy re-ignition of the arc after it has died out;

- minor metal spattering;

- melting uniformity;

- formation of an even seam;

- easy removal of slag.

In addition to electrodes, the plant produces filler wire. Arsenal electrodes, like all manufactured products, comply with international standards, which is combined with their low cost.

Welding electrodes MEZ

Magnitogorsk Electrode Plant produces high quality electrodes that meet all international standards. “MEZ” is a full-cycle enterprise. The entire range of work is carried out here - from the selection of raw materials to the production of finished products. The company's product range includes a huge number of electrodes that are suitable for any grade of steel. During the welding process, completely different electrodes are used. Thanks to this, it is possible to obtain high-quality, durable seams, and make the welder’s work easier and more convenient. The most popular electrodes of the MEZ brand. The products of this manufacturer have a very affordable price and at the same time meet the requirements of all international standards. The MEZ plant produces a huge number of different electrodes. The assortment includes more than 35 items. Among such a variety, you can easily find the most suitable option for yourself.

At least 1000 tons of products are shipped monthly. There is a constant search and development of new items and ways to reduce the cost of existing ones. The plant has been operating stably and producing quality products since 1949. Electrodes from this manufacturer are in great demand in the market.

You can purchase the following electrodes from this manufacturer:

- for steel welding;

- for welding of high-strength metals;

- electrodes for welding low-alloy steel;

- electrodes for welding hydrocarbon types of metal;

- electrodes for welding damaged metals.

MEZ electrodes are widely used in many areas of life. They are used in any welding process. It depends on what work needs to be done, what metals will be used and, of course, on the professionalism of the welder. Electrodes are already selected based on these parameters.

Electrodes ANO-4

Arsenal welding electrodes of the ANO-4 brand are used for welding work using the manual arc welding method. Can be used by professional craftsmen and beginners. They are most suitable for welding carbon steels. Welding electrodes Arsenal brand ANO-4 have different diameters - from 2.0 to 6.0 millimeters, which allows you to weld products from 3 to 20 millimeters.

Their main advantage is the rutile coating. It ensures rapid ignition of the arc and its further stable combustion. This makes the job easier and results in a high-quality seam.

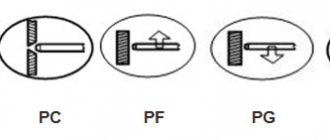

The possibility of being in space depends on the size of the diameter of the consumable. Electrodes having a diameter of less than four millimeters can provide the ability to weld in a variety of existing positions. If electrodes whose diameter exceeds this value are used, then the limitation is the direction of movement of this consumable element during vertical welding - it should be carried out from the bottom position to the top, and not vice versa.

When welding, alternating current is used. To use a permanent one, you will have to use a transformer. No preliminary preparation is required. The undemanding nature of the surfaces being welded allows for rust residues and minor contamination.

When using ANO-4, the seam is of high quality and durable. There are practically no defects such as cracks and pores. Welding of critical structures is acceptable. Before starting welding, it is recommended to calcinate the electrodes for at least one hour, especially if they were stored in a damp room.

Rutile coated electrodes

ESAB-SVEL OK 46.00

ESAB-SVEL OK 46.00

The prefix SVEL means a Russian manufacturer using Swedish technology. In Russia there are representative offices of the Swedish company ESAB itself, which independently sells the products of the world-famous Swedish concern.

Rutile-cellulose coating. Also used for low alloy steels. And for galvanized sheets. Welding occurs at a lower current strength than other rutile electrodes. This allows you to cook thin-walled products and parts. High stability of the welding arc and easy ignition allow even inexperienced welders to obtain a high-quality seam. For comparison, only experienced welders can handle OK 48 and OK 53, working on a short arc.

An advantage over the main electrodes is the possibility of high-quality welding in places where it is difficult to clean the welding edges. In turn, in critical cases, preference is given to the main electrodes.

Another plus is the ability to work with heavily contaminated and rusty metal, without preliminary cleaning. The slag is easily separated, leaving an excellent seam. No metal splashing.

Calcination before starting work is required for an hour, but a temperature of 70-950 is sufficient.

Due to the ease of ignition (and re-ignition), it is recommended for welding with short seams, tack welding, and with arc breaks.

The main advantage is the best price/quality ratio, although the price is higher than others with rutile coating.

Note: the price also depends on the size of the package, for example, the price indicated in the table is 225 rubles for a kilogram package and 199 for a 5.3 kg package.

Reviews

- There is no consensus on which production is better - Leningrad or Tyumen. Some people think – Belarusian;

- Among other shortcomings, the high price is very rarely noted;

- The ease of ignition and work on rusty iron are often noted;

- high-quality steel inside;

- noticeably better than mp 3;

- do not go out during work;

- re-ignition is also easy.

Lincoln Electric Omnia 46

Lincoln Electric Omnia 46

Brand of Lincoln Electric - an American company. On the Russian market you can find products with this brand in a wide price range: from 170 to 305 rubles/kg.

Like Swedish products, it is good for beginners - easy ignition, even cheap inverters do not require a lightening function. It is performed by an ionizing coating on the end.

But more importantly, the arc requires almost no control. Also low sparks, low spatter - no stripping required for great looking seams. Easy slag separation, which allows you to weld steel with a surface of any degree of purity. Also rutile-cellulose coating.

Due to the high strength of the deposited metal, they are even used to weld pipelines under pressure.

The downside compared to ESAB-SVEL OK 46.00 is lower resistance to dampness.

Reviews:

- marked with a plus price;

- the rest is basically the same as about ESAB-SVEL OK 46.00.

OZS-12 (SpetsElektrod, Moscow)

OZS-12 (SpetsElektrod, Moscow)

Domestic products. The coating is rutile.

Special properties:

• possibility of an extended arc; • welding on an oxidized surface; • ability to operate at extremely low currents.

Pros:

- high-quality seam, accessible to a not very experienced welder

- price.

Minuses:

- mandatory cleaning of the welding area;

- very sensitive to dampness - mandatory calcination for an hour (150-1800).

Resanta MP-3

Resanta MP-3 electrode

Type MP-3 is the most common type of electrode in the country.

In terms of quality they are close to ESAB-SVEL OK 46.00. But there are many manufacturers; knowledge of them and careful selection in the store are required. Generally the authority is low. But with the Resanta brand, the model is successful.

There are practically no differences from the Swedish model, except for greater sensitivity to dampness.

Electrodes MP-3

In terms of their advantages, MRZ and ARS electrodes are similar to ANO-4 brand electrodes, but there are still some differences that make them even more popular. The welding workflow with this type of electrode is much easier than when using other models. Arsenal MP-3 electrodes can be used in industrial production and for domestic use.

One of the main features is that there is no need to remove slag residues from the surface of the seam, since it separates on its own. All that remains is to remove him from the place of work.

Another undeniable advantage is the ability to use MP-3 Arsenal electrodes for surfacing metal with gaps of a sufficiently large size. Their use allows welding not only on a short arc, which is still difficult, especially for beginners in this matter, but also on a long one.

The rutile coating, which includes titanium dioxide, provides strength and resistance to the formation of defects such as pores and cracks, and also reduces the susceptibility to corrosion. The coating has a slightly greenish color.

Arsenal 3mm electrodes allow you to work with a long arc, which is important when the surface is of poor quality and there are oxides on it. Arsenal 3 mm electrodes allow you to fill cracks and gaps of any size. The resulting seam is of high quality and even. The average consumption of electrodes for one hour of welding work is 1.7 kilograms, that is, in order to weld one kilogram of metal, 1.7 kilograms of MP-3 welding electrodes will be required.

The diameters are as follows: 2.5; 3.0; 3.2; 4.0; 5.0 millimeters. Such a large selection simplifies the welding conditions. Depending on the diameter of the electrode, the current value is set. If you have to work with structures that have walls of medium and large thickness, then the mode is set to the maximum, and the electrode is moved along the welding process with a slight inclination. You can weld using the short tack method.

If thick-walled parts are welded, then a reinforced seam is applied and the current size is increased. Electrodes with a diameter of 5.0 millimeters are used for work in the lower and vertical positions. Ease of use allows you to perform various types of welding work.

MR-Z

The MR-Z brand is present in the assortment of many manufacturers. This brand is in many ways similar to ANO-4, we will not repeat the advantages, we will dwell on the characteristic differences of this brand from others.

One of the main features is that there is no need for a long time to remove slag from the surface of the weld. The slag crust separates on its own; all that remains is to remove it from the seam.

Another advantage of these welding rods is that they can be used to weld gaps of any size. This is convenient for beginners who sometimes find it difficult to use a short arc; with this brand you can weld on a long arc.

Electrodes ANO-21

Arsenal ANO-21 electrodes are used for welding parts with a thickness of one to four millimeters made of low-alloy and carbon steels. This model is available in diameters 2.0; 2.5; 3.0 and 4.0 millimeters.

For their manufacture, wire is used containing additives that increase the value of the surface tension coefficient of the formed deposit. This makes it possible to work on seams located in the ceiling and vertical positions without fear of metal leaking out of the weld pool.

The advantages of ANO-21 electrodes include: easy ignition of the arc, stability of its combustion, formation of easily removable slag, strength and durability of the seam, which is sealed. However, they cannot be used when it is necessary to weld parts of large thickness and pipeline joints under high pressure. If vessels operate under low pressure, then it is possible to use this type of electrodes.

Electrodes with basic coating

Kobelco LB-52U

Kobelco LB-52U electrode

Manufactured by a Japanese subsidiary of a metallurgical concern in Japan.

High-performance welding in any spatial position. An excellent seam in stationary conditions, but in the external environment the electrodes quickly absorb moisture. Stable arc and low spatter.

Careful calcination is necessary: for 30-60 minutes at a temperature above 3000. Important: be sure to withstand the rated current strength.

Reviews:

Minuses:

- good cleaning of the welding surface is required;

- secondary ignition is unrealistic;

- Not everyone can afford the price.

Experienced welders attribute these disadvantages to the lack of experience of those who say so. The first minus goes away simply with gaining experience. For the second disadvantage, there is an explanation and advice: explanation: contact disappears when the electrode is torn off, and the rod seems to be enveloped in coating; tip: clean off the coating from the tip of the electrode.

Pros:

- these are the best electrodes;

- it's a pleasure to work with them.

OZL-8 (LEZ)

OZL-8 (LEZ) electrode

Melting products. Only direct current of reverse polarity with a short arc. The use of alternating current sharply reduces the quality of seams.

They are considered indispensable in frame structures made of any stainless steel. This versatility is especially appreciated. Used in aggressive environments and at high temperatures.

Slags are easily separated. Avoid sudden cooling of the seam. Calcination to 3000 is mandatory.

Reviews:

- For its price, the seam is quite normal, does not rust.

SSSI 13/55

UONI 13/55

Of the main ones, the most common ones when welding carbon steel products.

They are distinguished by a coating resembling a resin, which effectively removes all slag from the seam. But it is precisely because of this coating that there is a problem with ignition. An inexperienced welder does not succeed at this on the first try. Secondary ignition is possible only by cleaning the tip of the electrode.

Reviews:

- They are considered a thing with character - if you know how to deal with it, then everything will be fine.

See also our electrode rating for 2022.

Commenting system SigComments

ESAB welding electrodes

ESAB brand electrodes are wildly popular on the market. This is due to their undeniable quality and affordable price.

Main advantages of ESAB electrodes:

- quite resistant to burning cracks;

- Using such electrodes you can make long seams and tacks. ESAB OK 46 electrodes are best suited for this;

- Smooth seams are obtained when welding high-alloy and carbon steels. It is also good to weld galvanized metals with such electrodes. For these purposes, it is best to use ESAB electrodes;

- Even beginners and inexperienced welders can handle these electrodes. They are very convenient for igniting and maintaining an arc;

- Great for large gaps.

If you have little experience as a welder, or you find it difficult to make a choice, you can turn to our company’s specialists for help. They will help you make the right choice and select the right consumables.

You can purchase electrodes for any type of welding work from us. The catalog contains all possible variations of consumables that are only available on the market at very affordable prices. Here you will find excellent value for money. You can select the necessary electrodes and place an order in just a few minutes. If you have any difficulties making a choice, please contact our managers for advice. Qualified staff will easily help you select consumables. On our website you can place an order for electrodes of these brands. To place an order, just call the numbers provided or write an email. You can purchase goods both wholesale and retail. Delivery throughout Russia is possible.