The functioning of the internal combustion engine (ICE) of a chainsaw is based on the combustion of a fuel-air-oil mixture. To mix the gasoline-oil mixture with air and then feed it portionwise into the combustion chamber, a rather complex device in its design is installed on engines - a carburetor. When you buy a new chainsaw, the carburetor already has factory settings, but over time they get lost, and the device that controls the fuel supply needs to be adjusted again. Without knowing how the carburetor works and not understanding the operating principle of this module, it will be problematic to configure it correctly.

The design and principle of operation of a chainsaw carburetor

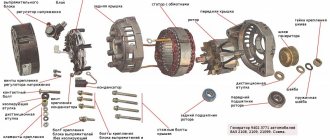

The chainsaw carburetor consists of the following main components:

- one-piece body made of light aluminum alloy;

- a diffuser located at the entrance to the carburetor;

- jets, special valves designed to regulate the supply of a combustible mixture;

- sprayer;

- float chamber.

Below is a diagram of a Walbro carburetor, which is very often equipped with chainsaws. Using this diagram, you can study in more detail the internal structure of the chainsaw carburetor.

The carburetor may have 2 or 3 adjusting screws with springs . The adjusting screws are designed so that there are needles (cones) at their ends. The screws have a right-hand thread, that is, they are tightened clockwise.

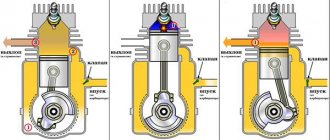

The chainsaw carburetor works as follows.

- After starting the engine, the air damper opens.

- In the diffuser (16), where there is a narrowing, the air flow accelerates and mixes with gasoline. The latter enters through jets (15) and (12), and the air purified by the air filter comes through the damper (7) located at the diffuser inlet.

- The damper (8), located behind the diffuser, regulates how much of the prepared mixture enters the combustion chamber.

- The volume of gasoline passing through the nozzles is regulated by screws (17) and (10) - these are, respectively, screws L and H on the chainsaw.

- The volume of the fuel mixture in the float chamber (14) depends on the needle valve (11). The functioning of the needle valve is controlled by a diaphragm (13).

- The membrane (4) controls the flow of the fuel mixture into the combustion chamber, and this depends on the number of revolutions of the internal combustion engine. Gasoline is purified through a filter (6).

Design features

Despite the possible differences in design, chainsaw carburetors operate on the same principle, so the adjustment sequence for different models does not differ significantly.

Prestigious chainsaws from leading manufacturers are equipped with technically advanced carburetors with built-in compensators and automatic choke control. Such modifications contribute to operator comfort, but do not affect fuel economy and other operating parameters.

The list of additional equipment includes a booster pump designed to enrich the mixture before starting the power unit. Many models of professional-class chainsaws are equipped with carburetor heating devices, which are turned on when the tool is transferred to winter operation.

When adjustment is needed

As already mentioned, the new chainsaw already has standard fuel supply settings. But for proper break-in, it is recommended to limit the maximum engine speed, and this is done using adjusting screws located on the carburetor body. Also, after running in, you will need to again make more precise adjustments to the supply of the combustible mixture.

In addition, the carburetor will have to be adjusted in the following cases:

- due to strong vibration, the factory settings were lost;

- The internal combustion engine does not start well and stalls immediately;

- The internal combustion engine starts, but the speed does not develop, and it stalls;

- the piston group is worn out - in this case, adjusting the chainsaw carburetor is possible as a temporary measure;

- the engine does not operate at idle speed;

- increased gasoline consumption, which causes the unit to produce a lot of smoke, contaminate the muffler and spark plug with soot, and reduce engine power.

Characteristics of the quality of the mixture at the carburetor outlet

A working mixture is formed directly in the carburetor, the composition of which can be adjusted within a sufficient range of operational adjustments. When the power unit operates on a rich mixture, the fuel does not burn completely, as a result of which the thrust drops and the engine burns fuel with less efficiency.

Combustion of a lean mixture is characterized by engine overheating, a drop in power, deterioration of the lubricating properties of the oil component of the fuel mixture, and the appearance of detonation phenomena that are unsafe for the design of the power unit.

Factory settings of fuel equipment are made on the basis of averaged data that does not take into account the influence of external factors, including air pressure and temperature, and the level of operational loads.

Periodic adjustment of the composition of the gasoline-air emulsion makes it possible to maintain the traction characteristics of the power drive at a given level and stabilize the economical consumption of fuel and motor oils.

Rules for setting up the carburetor

You should know that the carburetor can be adjusted correctly only if:

- cleaning filters (gasoline and air) are not dirty;

- the jets and the channels leading to them are clean;

- the membranes are not damaged;

- the needle valve is working properly and the required volume of fuel mixture enters the float chamber.

To adjust the carburetor of imported chainsaws, you must adhere to the following rules.

- Before adjustment, if possible, you should warm up the engine at idle or minimum speed for about 10-15 minutes.

- By rotating the “L” regulator, the engine is operated in such a way that it produces one and a half to two thousand revolutions per minute at idle. But you should pay attention to how the engine gains speed. When pressing the accelerator lever, acceleration should proceed quickly and evenly. If a “drop” in speed is detected, the screw should be slightly unscrewed until this phenomenon is eliminated, since it is caused by insufficient enrichment of the fuel mixture.

- When the mixture flow is adjusted at low speed, you should start tightening the screw “T” until you notice the rotation of the saw chain. After this, the screw should be unscrewed by half or a third of a turn, observing the behavior of the clutch mechanism. Normally, the saw should not rotate at idle speed.

Screw “H” compensates for under- or over-revving due to a change in fuel type, change in oil concentration or ambient air humidity.

Also, the “upper” setting can be lost if the low speed is incorrectly adjusted with the corresponding screw.

Without enough experience, it is better not to adjust the “H” screw. If the chainsaw carburetor is adjusted by an incompetent person, there is a great danger that a too lean mixture will enter the combustion chamber at high speeds, especially under load. Such engine operation will inevitably lead to rapid wear of its piston system and failure of the ignition system.

You can start adjusting high speeds if the person who will perform the adjustment has knowledge and skills in adjusting carburetor engines. The adjuster must have at his disposal a special device - a tachometer or a multimeter with an oscilloscope function.

Setting the carburetor of a chainsaw, namely, high engine speeds, follows a simple scheme.

- It is necessary to tighten or unscrew screw “H” until, at maximum gas, the engine develops about 15 thousand revolutions per minute (according to the tachometer) or the value indicated in the manual for this unit.

- When using an oscilloscope, the spark discharge frequency should be between 230 and 250 Hz. Please note that under load the frequency may decrease by approximately 10-15%.

We can conclude that for safety, the internal combustion engine should be configured at slightly lower speeds.

The carburetor of a Chinese chainsaw should be adjusted according to the same principle as described above. There are holes on its body into which you need to insert a flat-head screwdriver to adjust the engine speed. Each hole is signed with one of the three letters. As a rule, you can see the letter “T” near the top hole, and the letters “L” and “H” near the lower ones (shown by arrows).

The Chinese chainsaw Carver (CARVER) also has the same arrangement of screws. The following figure shows what a carburetor from a Chinese chainsaw looks like outside the unit body.

What you need to have to set up and adjust a chainsaw with your own hands

Each carburetor owner must have the necessary tools to adjust this system. There are three adjustment screws that are located on the body of the device. They have their own markings:

- L - screw for correcting low speeds.

- H - screw for adjusting high speed.

- T - regulates idle speed, in most cases used for experiments.

Chainsaw air filter

Before adjusting the carburetor, you need to prepare the device:

- The engine warms up, that is, it starts about 10 minutes before repairs, and turns off when starting work (see how to start a chainsaw).

- The air filter is checked and washed.

- The chain is stopped by turning screw T until it stops (see chain oil).

To carry out a safe repair, you need to prepare a flat surface where you can carefully place the device and turn the chain in the opposite direction. Need a tachometer. It determines whether there is a malfunction in the carburetor. When turning the screws, the sound should be perfect and absolutely smooth. If you notice squealing notes, the mixture is oversaturated.

How to troubleshoot carburetor problems

The main malfunctions of a chainsaw carburetor may be as follows.

- The engine starts with difficulty and stalls a few seconds after starting. This is often caused by incorrect low rpm settings. The fuel-air mixture is slightly enriched. It is necessary to unscrew the “L” screw half a turn, after which the adjustment should be completed with the “T” screw.

- Engine power decreases noticeably under load. This means that the carburetor excessively enriches the mixture with oxygen. Therefore, screw “H” needs to be tightened a little, about 1/8 of a turn. If after such actions the engine power is still insufficient, but there has been some improvement in its operation, then the regulator can be tightened a little more.

- The engine at maximum speed and without load begins to “sing”. This malfunction in the operation of the unit is caused by a lean mixture and high speed. The adjustment is made using the same “H” screw.

- No gasoline enters the combustion chamber. Failure can be caused by clogged fuel filter, channels and carburetor jets. To eliminate the malfunction, you need to completely disassemble this chainsaw module and blow out its channels with compressed air (a compressor is required). To properly clean the fuel channels, you can use a special carburetor flushing fluid. Also, the lack of fuel flow into the engine cylinder may be due to incorrect adjustment. How to do this yourself is discussed above.

- Overfills the carburetor. In 90% of cases, fuel overflow is caused by a dried out and roughened membrane, which puts pressure on the rocker arm connected to the needle. To change it, you will need to remove and disassemble the carburetor.

- The engine revs poorly, runs intermittently, and power decreases. These problems are often caused by a clogged air filter. You will need to remove the cover covering the filter and clean it, which involves washing with detergent.

In general, timely adjustment, as well as timely repair of a chainsaw carburetor can significantly extend the life of the entire engine piston system. Therefore, the adjustment of this component of the fuel system must be treated with great attention.

Preparation for self-tuning of fuel equipment

The sequence for adjusting the carburetor is outlined in the attached operating instructions. The factory kit includes a screwdriver for adjusting the screws marked with the letters L, H and T. Some manufacturers equip their chainsaws with carburetors, the adjustment of which requires a special adjustment key.

Correct tuning of the fuel system requires warming up the power unit to operating temperature and pre-cleaning the air intake filter element. The saw is installed in a position that provides convenient access to the fuel equipment.

How to properly adjust a factory saw

Carburetor adjustment is divided into two main stages. The first one is called basic. It is performed with the engine running. The second is performed when the engine is warm.

To carry out the carburetor setup procedure successfully, you need to read the operating instructions for a specific model in advance to identify additional features of setting up the device.

First stage

The adjusting screws for the highest and lowest speeds should be moved clockwise until the highest resistance is met. When the screws reach the stop, you need to move them in the opposite direction and leave them 1.5 turns.

Main stage

The engine is turned on at medium speed and warms up for about 10 minutes. The screw responsible for adjusting the idle speed should move clockwise. It is released only when the engine reaches stable operation mode. It is necessary to ensure that the chain does not move during this process.

Carburetor adjustment

In idling mode, the engine may stall (the reason is here). In this case, you must immediately turn the adjusting screw clockwise until it stops. Sometimes the chain starts to move. In this case, turn the adjusting screw in the opposite direction.

Checking acceleration operation

Need to do a little research. Acceleration of the device is initiated. It is necessary to evaluate the proper operation of the engine during maximum speed. When the engine is functioning correctly, it means that when you press the accelerator, the speed quickly increases to 15,000 rpm.

If this does not happen or the increase in speed is too slow, you must use the screw marked L. It turns counterclockwise. Moderate movements must be observed, since the turn cannot be more than 1/8 of a full circle.

How to adjust the maximum number of revolutions

To limit this indicator, you need to use a screw marked H. To increase the number of revolutions, turn it clockwise, and to reduce them in the opposite direction. The maximum frequency should not exceed 15000 rpm.

If you make this figure larger, the device’s engine will wear out, which will lead to problems in the ignition system. When rotating this screw, you need to take into account the ignition processes of the device. If the slightest malfunctions appear, then the maximum speed value must be reduced.

Final check at idle

Before this procedure, it is necessary to carry out a full adjustment of the carburetor components when operating at maximum speed. Next, you should check the functioning of the device in idle cold mode. When the correct adjustment parameters are achieved, you will notice that the carburetor design closely matches the following criteria:

- When the idle cold mode is activated, the chain does not move.

Chainsaw accelerator - When the accelerator is pressed even slightly, the engine accelerates at an accelerated pace. With gradual deepening of pressure, you can notice that the engine speed increases proportionately, reaching the maximum permissible values.

- When the engine is running, you can compare its sound to a four-stroke device.

If violations are noticed in the given parameters or the device has not been fully adjusted, you need to perform the main setup step again. Sometimes actions are performed incorrectly. In this case, the device may fail due to the loss of the correct node settings. In this case, you will have to contact a specialist.

Disassembling the carburetor if necessary to check or repair components

The design of different carburetor models is almost the same, so when working with them you can use the standard scheme. All elements must be removed carefully, and then laid out in the order given below , so that you can successfully place the items in place after the completion of the repair work.

Removing the Top Cover

- The top cover is removed. To do this, you need to unscrew the 3 bolts holding it in a circle.

- The foam rubber is also removed, since it is the upper component of the filter that conducts air.

- The fuel hose is removed.

- The drive thrust is output directly to it.

- The cable end is disconnected.

- The gasoline hose can be completely removed if you systematically pull it off the fitting.

To finally prepare the carburetor for major repairs or replacement of the smallest parts, you need to carefully disconnect it from the main system . Sometimes further disassembly is required. You should unscrew the components carefully and put the fasteners in groups, as these small parts are easily lost.

How to properly adjust a Chinese-made saw - adjustment instructions

To correctly configure the carburetor of a Chinese chainsaw, you must first remember the factory settings of the device, then turn on the engine. Subsequently, you will have to leave it running for several hours in order to accurately set your own parameters. Sometimes work is carried out only after ten minutes of engine operation, but many Chinese-made models require special handling.

Chinese chainsaw model

Adjustment procedure:

- Activities begin in idle mode . Using the adjusting screws, you need to achieve a systematic increase in engine speed, so you should first let it run at low speeds. A deviation from the norm is the movement of the chain along the bus. In this case, you need to adjust the outer screws to the optimal position so that the chain remains motionless.

- The transition to medium speed speed is carried out. Sometimes the engine starts to smoke. This defect can be eliminated by tightening the screw to supply a leaner fuel mixture.

In this case, the smoke will disappear, but the engine speed will increase. You need to adjust the settings until you reach a level where, when you press the throttle, the engine smoothly picks up speed, and no sudden jerks or interruptions are heard.

- The device's engine is being checked . The chainsaw is switched to minimum speed, and then the lever is quickly pressed. When pressed maximally, it is held for 3 seconds. If there are problems with the engine, you need to gradually loosen the screw until the optimal position is reached.

- The chainsaw should work for several hours in real conditions . You need to cut wood, and then inspect all the elements involved in this event. If there are deviations, they must be corrected using adjusting devices. When all defects have been eliminated and the optimal settings have been established to supply correctly concentrated fuel, the device setup process can be considered complete.

Before purchasing, we recommend that you familiarize yourself with the rating of chainsaws for reliability and quality. Take a look at the video:

Main cause of failure

During the sawing process, a large amount of small sawdust is formed, a very small amount of which still gets into the carburetor and clogs its channels and the fuel grid in it. Over time, this leads to unstable operation:

- Power reduction;

- Unstable operation - floating speed;

If the chainsaw stalls under load, then most likely this is also due to a clogged carburetor.

On a note! Many people will notice how sawdust can get into the carburetor if the saw has an air filter designed to prevent it from getting in. The answer is simple - this filter, due to its design, is not intended to filter very small particles.

If you have encountered such problems, then the first thing you need to do is remove the chainsaw carburetor, disassemble it and wash its parts in gasoline. After this you need to move on to configuration. In order to remove, you need to dismantle the top cover, remove the spark plug wire and unscrew the 2 mounting bolts. Read about what gasoline to use in a chainsaw here.

After washing, you can’t just start the saw ; to do this, you need to perform a certain series of actions, set the adjusting screws to the original “working” position:

- Screw in screw H until it stops and then back out 1.5 turns.

- Screw screw L until it stops, and then turn it out 2.5 turns.

- Start the saw and warm it up for 3 minutes.

- Now we move on to adjusting the carburetor, which consists of 2 stages.

Attention! Any carburetor adjustment should be made only with a warm engine. Those. Before the process itself, you must start the saw and warm it up at low and medium speeds for 2-3 minutes, and only after that you can start setting up a stable idle speed.

Initial adjustment and starting to use the saw

Most instruments come pre-configured by manufacturers.

During the running-in process, the correct operation is checked:

- When starting up for the first time, you need to ensure that the chainsaw operates in a gentle mode. A few hours after the start, it is recommended to cut small branches and trunks up to 10 cm thick.

- The chainsaw must start correctly, ensure a stable rotation speed of the sprocket and a smooth increase and decrease in power.

- Fuel consumption must correspond to the power used and in practice the saw should not go out, “sneeze”, smoke or run jerkily.

- There should be no extraneous knocks, pops or noises when the engine is running.

The following rules will help you stay safe:

- Mix gasoline and oil in accordance with the proportions specified by the manufacturers.

- Do not prepare the mixture in advance. The properties of gasoline and oil in a mixed state change over time. The exception is fuel for intensively used tools, however, even here the norm of 7 days should not be exceeded.

- Use oil designed for the chainsaw brand engine. A fuel mixture with a non-standard composition will damage it.

- When preparing the fuel mixture, take into account the influence of climatic conditions on the components.

Adjusting the carburetor after running in the chain saw

After running in the saws, only fine tuning of the UPT is performed. To do this, you will definitely need a tachometer and technical documentation for the sawing tool used. The fact is that almost optimal settings are already installed at the manufacturer's factory. Just to break in the engine and grind in other moving parts of the chain saw, the carburetor is configured to prepare a slightly richer air-fuel mixture than the calculated optimal one. Due to this, the maximum speed is slightly lower than that specified by the manufacturer and, in addition, the motor is better lubricated. Thanks to this, running-in of the engine and running-in of other moving parts are carried out in a gentle manner.

Therefore, if there is no tachometer and/or reliable information (passport data) about the maximum speed at idle, then you should not change the factory settings after running in, since it will not be possible to do this correctly. And in general, fine adjustments in this case are not necessary - the chainsaw will work just fine with the existing basic settings. And if you’re going to do it, it’s better to do it at a service center. It is recommended to entrust the fine tuning of the carburetor to a completely new instrument to specialists.

Fine adjustment

Before making fine adjustments yourself, it is strongly recommended that you mark the previous position of the adjustment bolts as accurately as possible. This will allow, in case of an unsuccessful attempt, to return them to their place - to the basic factory settings. We begin the adjustment with the “H” bolt. After setting the maximum speed, check the idle. If they differ from normal, we set them first using “L” and then “S” (“LA”, “T”). In doing so, we are guided by the rules and principles set out in the second chapter of this article. But we turn the adjusting bolts, focusing on the tachometer readings. Then we continue to adjust the carburetor as indicated in the same chapter. We turn the screws, watching the tachometer readings.

Summing up

Having sufficient experience, the setup is completed in 5-10 minutes. Provided all carburetor parts are in good working order, the adjustment process should not cause any difficulties. If something is faulty in the carburetor, then you won’t be able to adjust it, no matter how hard you try. To do this, before making adjustments, you need to eliminate all faults.

I will write about what kind of malfunctions there are, how to find and fix them, in the next article about repairs, provided that this is of interest to you. Therefore, if the article helped, rate it and write in the comments below whether the second part of the article is needed. Thanks to all.

Required Tools

Husqvarna special screwdriver

The main tool for adjusting the carburetor of a Chinese chainsaw is a medium-sized slotted screwdriver (flat type). Some saws require special keys, for example to set up the Husqvarna.

For more accurate and faster tuning, a tachometer is still required; it allows you to determine the engine speed, but this is not our case, our task is to learn how to tune by ear.

Read more about what tachometers are available, where to buy, how much they cost, and also how to set up a chainsaw with it.

For reference! This is the same as tuning a guitar. An experienced musician tunes by ear, while a beginner tunes using special instruments. In the case of a chainsaw, the opposite is true. An experienced person adjusts it with a tachometer, and a beginner tunes it by ear. In our repair shop, we use a high-quality and inexpensive tachometer from Aliexpress, which can be purchased at this link.

Buy tachometer on Aliexpress

User questions about chainsaws

The Husqvarna chainsaw started only on choke and then stalled. I bought a new Chinese carburetor, it looked exactly the same, it started idling smoothly and started without any suction. You start sawing and after 2 seconds it stalls. If you re-gear it, it still cuts for a little while, but then it still doesn’t hold high speeds. What's the matter?

First, check the fuel filter. If OK, back out the low speed screw (L) until it starts to pick up speed normally. Since X.X will increase, reduce it with the bolt (T) that is on top.

Chainsaw McCULLOCH MAC930 CC30 KW1.2 tire 35 cm, assembled in Italy in the 90s. Piston, seals are ideal. Doesn't hold idle speed or doesn't pick up speed when you try to accelerate it, it feels like it's choking on gasoline. Gasoline is pouring from the exhaust. What is the problem and how to fix it?

According to the symptoms described, gasoline is not flowing well, probably because the diaphragm has dried out due to long inactivity. You can fill the saw with gasoline, pump it manually and leave it for a while. From gasoline, all the rubber bands should get wet and start working. If that doesn’t help, then you can pick up a carburetor from some modern Chinese saw of similar cubic capacity (for example, from Shtil). After replacement, adjust the joint with the cylinder.

If I fill a Husqvarna chainsaw with Stihl oil or any other branded oil, should I follow the proportions of 1:25 as indicated in the instructions?

If branded oil for two-stroke engines is poured, then it does not matter which manufacturer it is from. High-quality fuels and lubricants from well-known brands are interchangeable, and recommendations are only a marketing ploy. You can safely fill a Stihl chainsaw with Husqvarna oil and vice versa, observing the proportions as for branded fuels and lubricants.

Why does a chainsaw cut crookedly, that is, it moves to the side?

The tire misaligned due to uneven wear. Don't forget to turn it over when working! If the tire is already worn unevenly, only replacement will help.

Why does the Taiga 245 chainsaw only work on suction and the carburetor cannot be adjusted?

Possible options: the carburetor diaphragm is broken, the gasket between the cylinder and the crankcase, the carburetor and the cylinder is not sealed, the crankshaft seals are leaking. In Taiga 245, when air is sucked into the crankcase from the outside, the functionality of the fuel pump built into the carburetor is disrupted due to the lack of vacuum. In this case, the saw will not work. The suction closes the air supply to the carburetor. This confirms the lack of tightness in the places indicated above.