After successfully installing a 2nd generation LPG on a car, and passing a test to ensure the functionality of its components and the absence of leaks of the propane-butane mixture (detected by “soaking” the connections or using a gas analyzer), the time comes for the need to adjust the equipment for further successful operation. The HBO adjustment is carried out sequentially in several steps, let's take a closer look.

Electronic gear adjustment procedure

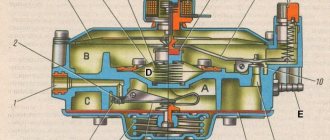

An electronic gearbox, such as Tomasetto, provides for two main gas adjustments on carburetor cars:

- pressure in the second stage (it can be called sensitivity);

- the volume of gases passing through the channel at idle.

The engine must be started on gasoline fuel and warmed up to the nominal temperature level. The idle speed is set to one thousand per minute. The supply is turned off and gasoline is produced. The adjustments are in the following starting position:

- maximum eversion of the dispenser (the gas channel is open to the largest cross-sectional area; with a two-section chamber, each chamber is adjusted separately: for the first - the largest opening, for the second - the minimum);

- the screw that determines the idle speed is screwed to the extreme position and unscrewed five turns;

- the screw adjusting the sensitivity is installed in an intermediate position.

First you need to set the idle speed. To do this, the car starts on gas fuel, using a choke, the speed is set to two thousand per minute. Then the choke is gradually removed, and by rotating the screw that determines the idle speed, the speed is set to the maximum. These operations are repeated until the choke is completely removed and the engine operates stable in idle mode.

The maximum speed is set using the idle speed screw. The screw that determines the sensitivity is gradually tightened. When the speed is lost, they are added by the screw that regulates the idle speed. If this does not work, then the sensitivity adjustment is tightened a couple of turns and the procedure is repeated.

At the end of the adjustment, this screw will be screwed in almost all the way, and the engine speed when idling reaches its maximum value - about 1.2 thousand per minute. After this, this indicator is reduced - slightly below the nominal value, by tightening the idle speed screw, then, unscrewing it slightly, it is set to about a thousand revolutions per minute.

Next, you need to adjust the sensitivity of this unit: the adjustment of the same name is gradually turned away until it affects the engine speed when idling, and it is twisted approximately one turn in the opposite direction. If everything is done correctly, when you press the gas pedal sharply, the power plant should respond responsively.

You might be interested >> Filter for gas equipment 4th generation

The third step is to set up the dispenser. With the engine running, the revolutions are set to three and a half thousand per minute, and the screw of the mechanical gas dispenser is tightened until they begin to change. Then this adjustment must be turned back half to three-quarters of a turn.

For a two-section dispenser that provides for separate settings in sections, the above applies to the first of them, the second is placed at a third of the previously configured ones.

If the pressure in your reducer is adjusted in the first stage, then turn off the motor and close the gas flow pipe. Then, using the control hole, which is closed with a bolt, connect a pressure gauge to the cavity of the first stage, allowing you to measure pressure up to one and a half kgf/cm2.

The power plant starts up, and at idle the pressure level is set to about 0.4 kgf/cm2. Then the idle speed and sensitivity of the gearbox are adjusted again. You should take into account the increased gas hazard of these works, therefore, if you are not confident in the reliability of the connection, you need to contact a service center.

Attention! Work on adjusting the two-section dispenser poses an increased gas hazard. Be careful.

Which system should you choose?

There are several leading LPG manufacturers in the world, one of which is Lovato. The equipment has a fairly high build quality, as well as high performance indicators. A particular advantage is the electronic control unit, which calculates all readings with excellent accuracy and very rarely fails. You can also note the compactness of this installation, in comparison, for example, with BRC equipment. It is worth choosing LPG for a specific type of gas, that is, either for liquefied propane or for compressed compressed methane. By the way, when using propane, gasoline injectors can be used, since the density and consistency of the gas is close to gasoline. When working with compressed gas, it is necessary to use special gas injectors.

Setting up the vacuum reducer

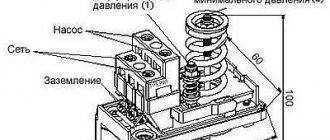

There are two types of vacuum reducers:

- providing separate adjustment at idle speed, as well as sensitivity;

- having a combined regulator of these two settings.

In the first case, the adjustment is carried out similarly to the adjustment of the electronic gear described above. If the regulator is combined, as in the 2nd generation Lovato LPG for cars with a carburetor, the adjustment is as follows:

- the car starts using gas, the speed is adjusted by suction, up to two thousand per minute;

- the choke is gradually removed, the speed is set to maximum by tightening the screw that adjusts the idle speed;

- The same adjustment adjusts the number of revolutions, about a thousand per minute or a little more;

- With a similar setting, the speed is further reduced below the nominal value, and then again rises to a thousand per minute.

This is how the 2nd generation Lovato LPG is configured for the carburetor.

Required materials and tools

To approach the matter correctly, you need to stock up on the necessary details in advance:

- USB adapter/chip;

- cable;

- connector (connection block);

- soldering iron and soldering materials;

- heat shrink tube of different diameters;

- insulating tape;

- multimeter or test light;

- side cutters (nippers).

If you have an unnecessary cord, for example from an old mobile phone that has a board marked PL2303, you can make this cord from it.

But we will make it simpler; online stores already have an almost ready-made solution at an affordable price. In particular, on Aliexpress (Aliexpress), you can buy an adapter for 4th generation HBO (TTL module PL2303) and all the necessary elements for assembling the cord.

It is worth noting here that such a wire (made in China) is not intended for too frequent use. In addition, due to its length (1 meter), it will not be convenient to use on all cars. But for private use it will work well.

It is best to purchase a copper wire with three cores, a soft, shielded wire at any electrical store. The length is 2-2.5 m. It is quite enough for convenient setting up of HBO directly from the car interior.

The chip will fit from a VAZ-2110 fuel pump.

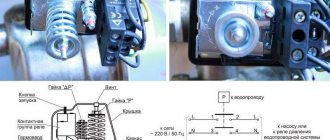

Adjusting the dispenser

The final step is setting up the dispenser. To do this, you need to start the car on gas fuel and set the speed to about three thousand per minute. There is no need to use suction, it is better to involve a partner. Then the screw that regulates the dispenser is tightened until the speed begins to change.

You need to fully verify the presence of this boundary by playing with the screw in one direction or the other. From this threshold, the adjusting screw is unscrewed by half to three-quarters of a turn. After a slight adjustment of the idle speed, the gas injection system for the carburetor can be considered configured.

You might be interested >> 2nd generation LPG high gas consumption

It is also recommended to check the correct settings of gas equipment for a carburetor engine based on the concentration of oxygen and carbon monoxide in the exhaust. The CO level should not exceed 0.45%. Adjustment is carried out using screws that supply air to the carburetor and regulate the idle speed of the gearbox. If the indicator is underestimated, you need to add it to the second of the specified settings; in the opposite situation, vice versa.

Checking the oxygen content in domestic conditions poses a certain problem. To do this, configure the HBO as follows:

- an oxygen sensor intended for injection modifications of the Lada is installed in the muffler behind the “pants”, this is done using a pre-welded adapter nut;

- contacts for heating are connected in the same way as a gas valve; for signaling, a shielded wire is used, connected to the dashboard and connected to the tester.

As a result, HBO adjustment occurs under your constant control. If the tester shows a voltage level of 0.2-0.8 V, then everything is normal, a lower level means there is not enough oxygen, a higher level means there is too much oxygen. However, depending on the load and operating mode of the engine, these parameters may change, so fine tuning is still necessary.

Note! The ability to adjust the oxygen level is achieved only after installing additional equipment.

An even more interesting option is to use a lambda probe emulator, which provides the possibility of color indication. Three LEDs, similar to a traffic light, indicate optimal operation. A microprocessor unit can be connected to this device, which allows you to control the adjustment of the electronic dispenser, but such work cannot be handled independently, and you need to contact a service station. Moreover, this pleasure is not cheap.

Is it worth installing HBO on your car?

Installing HBO on your car is a completely individual matter, but still, such a decision is justified.

Gas is much cheaper than conventional fuel and this is already one of the reasons to switch to it. The second is, of course, environmental friendliness.

The gas burns almost completely, leaving behind no harmful emissions or toxic substances, and significantly less carbon deposits are formed. Gaseous fuel does not harm the engine at all and does not cause frequent breakdowns, and most problems associated with valves and pistons are rather a problem of saving on fuel and maintenance. The only disadvantage of HBO is that it requires constant and timely adjustment, especially at the beginning of a new season.

Could it be that the coolant is not circulating through the gas reducer due to a broken thermostat?

If the thermostat breaks in the open position, then of course the circulation of coolant through the reducer will decrease, but not to such an extent that there is no circulation at all. Perhaps the tube leading the liquid into the gas reducer is clogged, there is air in the cooling system due to a burnt-out gasket under the head, a sign that the heater is not heating as well, bubbles are coming into the radiator, you can see by opening the radiator cap, the engine begins to overheat and boil. Or the system is simply poorly filled with coolant.

To fill the gas reducer with coolant, you need to disconnect the upper pipe from the reducer and wait until the liquid flows from the reducer, or blow into the radiator to quickly fill the reducer with liquid.

Injector with gas equipment

Gas is supplied to the injection engine through the air manifold. The injector runs on gas, the injectors and the fuel pump are turned off, only the gas damper, spark and knock sensor work. Therefore, if the injector works well on gasoline, but poorly on gas, diagnostics will not help (everything is fine with the injector), adjust the gas reducer.

There are injectors with installed gas injectors, these injectors are connected to a control unit (computer), but I think there is little point in installing such injectors on purpose, since it is expensive and you cannot set them up manually.

Another good thing about gas on an injector, I saw an injection car with dead injection equipment, there wasn’t even a gas pump in the tank. But on gas it worked perfectly; when running on gas, it was enough for this engine to have a spark and the gas damper control sensors worked during warm-up.