Powered by gasoline | 03/22/2017

When actively working on trimming dead wood or expanding the area of a personal plot, the home workshop must have a chainsaw. Chainsaw teeth, even from a trusted brand (for example, Stihl), periodically wear out and therefore require high-quality sharpening. In the absence of special devices, a properly selected file for sharpening a chainsaw chain will help solve this problem.

External signs of a dull chainsaw tooth

Among the most popular chainsaws are rightfully the tools of the Austrian company Stihl, in particular, Stihl-180 (to be precise, Stihl MS-180-14''). A 150 mm flat file is suitable for sharpening. For chain storage. With such a chainsaw you can trim branches and deal with medium-sized branches - a power of 1500 W allows this quite well. Despite the high-quality steel that this brand (we don’t consider Chinese counterfeits!) uses to make the teeth, self-sharpening will require skill and time.

You should pay attention to the following external signs of a dull cutting chain:

- A conical section appeared on the working angle of the tooth.

- When moving from the working corner to the top edge, the radius rounding is visually different.

- At the moment of the initial feed, even at a relatively low intensity, the penetration of the working edge of the tooth into the thickness of the wood is carried out with great resistance.

- At the stage of a steady cut, the chainsaw chain begins to vibrate, and the noise level of the chainsaw increases noticeably.

- When sawing in the longitudinal direction, the cutting surface has rough cuts and chips of wood. When and how to sharpen a chainsaw chain. What tools are used for self-sharpening at home with a file. The chips themselves become significantly smaller in size.

The trial test is carried out on dead wood, and in no case on wood with high humidity. The frequency of sharpening depends on the main cutting direction. If it is performed predominantly in the axial direction, then sharpening will have to be performed much more often.

Related Posts

Do-it -yourself chainsaw

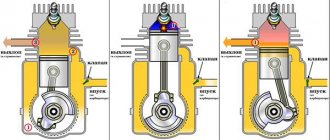

The chain tooth planes wood like a plane, and the thickness of the chips is adjusted by the height of the stop.

The intense work of the saw leads to rapid dulling of the chain. Several sharpenings may be required during the first day. The problem is also made worse by the fact that the tooth quickly becomes dull when it meets the ground. Saw chain sharpening is a sharpening device - a sharpening device. Chain sharpening machine sadko scs-85pro, delivery. It is enough to hook the tire into the soil once or twice, and you can stop working. the chips become small and the saw stops going deeper into the tree.

The earlier dull teeth are sharpened, the less material must be removed during sharpening, as a result. The service life of the saw chain is longer. Finding the moment when sharpening is required is quite easy. The main feature is the feed force. A correctly sharpened chain is pulled into the cut even with a slight pressure. If, on the contrary, the chainsaw is forced to cut by increased feed force, then the teeth have become dull. A dull chain can also be recognized if, instead of large thick chips, only small chips fly out of the cut.

In this situation, the chainsaw must be sharpened urgently. Do not cut with a dull or defective saw chain. the result is high tension in the body, high repetitive load, and poor cutting results. In addition, this means a decrease in productivity, high fuel consumption and increased wear on all components of the chainsaw.

Read also: Stepper motor connection diagram

What is included in the sharpening kit?

In the absence of a special machine, you will have to make do with a file to sharpen the chainsaw chain (more precisely, not one, but two). The video of sharpening a chainsaw chain shows that you should regularly turn the file to avoid. File for sharpening chains dolmar 5.2mm reviews. File for sharpening chains stihl 4.8mm reviews. You also need a special template with which you can check the current value of the sharpening angle. Thus, the basic set of sharpening equipment includes:

- Round file with a cross-sectional diameter of 4.5…5 mm.

- A holder with special positioning lines, with the help of which the tool can be placed on the top face with the required accuracy. The holder is equipped with a section that rests on the surface of the cutting depth limiter.

- A flat file used to sharpen the limiter itself.

- A hook that removes sawdust generated during the sharpening process.

Features of the chainsaw

Cutting wood is similar to working with a plane.

In all this, the size of the cut depends on the thickness of the limiter. When the saw chain works in a saturated mode, the teeth become dull faster. Chain sharpening. File diameter 5 chain file. This is clearly manifested when the ground surface melts in the path of the chain. To blunt the teeth one hundred percent, it is enough to “catch” on the ground for a couple of seconds. If you are able to sharpen it frequently, the chain will last even longer, since very little metal will be removed. In addition to the question of what angle of sharpening the chainsaw chain should be, you also need to know this!

There is no need to work with blunt equipment for a number of reasons. At first, this affects the quality of the cut, but not for the best. Lethargy also quickly sets in, which is felt not only in the hands, but also in the body.

Another reason. unjustified excessive consumption of fuel. All parts will work in increased mode, which inevitably leads to rapid wear. Performance drops seriously, which also happens when using a defective chain.

To be able to sharpen a chainsaw chain perfectly, you should know the structure of its teeth. You can’t do without knowing the sharpening angle. Each tooth has a complex structure. Its geometry is represented by the following components:

- basis;

- spatula;

- depth limiter.

With all this, the blade consists of two blades: the end blade and the top blade. At the same time, there must be the correct sharpening angle of the chainsaw chain between them in order to provide it with the required performance.

How can you figure it out now? It is not the chain that cuts the tree, since it serves as the basis for securing the cutting links and moves them at the highest speed. The links themselves have sharp blades, with the help of which the wood is cut.

How to choose the right file sizes for sharpening a chain?

The main difficulty is deciding on the size of a round file, because work performed with a flat tool is much simpler. For Stihl saw teeth, the top end of the file should protrude 20% of its height onto the surface of the working angle. However, you should also remember about the saw chain pitch, which is usually taken at 0.325 inches.

The next stage of selection is to clarify the length of the round file. It depends on its size. Let's learn how to choose a saw chain file for sharpening. Power saws. Chainsaw chain file file for sharpening chains. GOST 1465 establishes five numbers for this tool, but only No. 4 or 5 are suitable as a file for sharpening a chainsaw. Files No. 4 have a working length of 200 mm, and No. 5 - 250 mm and 300 mm. As the length increases, the amplitude of the operator’s hand movements increases, so the quality of guiding the file along the tooth also increases accordingly. File for sharpening chainsaw chains and various. Therefore, a longer file is better for sharpening.

Alternative options

The Russian market has a wide range of auxiliary equipment that allows you to select a file or device for sharpening chains of different configurations and price levels. The products of leading manufacturers of chainsaw equipment are of the best quality.

A significant part of the offers consists of branded components for various models of sharpening machines. Such files do not have shanks or handles, so they are not suitable for manual sharpening. Piece products may be sold individually or as a set with templates, mandrels, holders or other additional equipment.

Sequence of operations when sharpening

High-quality sharpening of teeth requires strict adherence to the following rules:

- A file for sharpening a chainsaw should be placed strictly perpendicular to the direction of movement of the saw teeth in the vertical direction, and at an angle of 15...20 0 in the horizontal direction. The latter is controlled using a holder.

- The round file in the tooth mouth must be located slightly above its edge (for file No. 5 this is approximately 1...1.5 mm).

- A holder is installed on the tooth, the lines of which will show the exact direction of movement of the file in the horizontal plane.

- After several movements of the file, the sharpening surface is covered with magnetized shavings, which should be immediately removed with a hook.

- Sharpening begins in the direction away from you, without using excessive force: the notches should gently enter the metal of the tooth. It is recommended to make several movements and then turn the file by 20...30 0 so that the wear of the notches occurs more evenly.

- It is recommended to sharpen “through the tooth”: first sharpen the teeth in one direction, and then in the other.

- The pressure on the file during sharpening should be constant, as should the number of reciprocating movements on the tooth being sharpened.

When sharpening the depth limiter, proceed as follows. Properly sharpened chain for a chainsaw, what file for sharpening a chain. A template is applied to the limiter. A file for sharpening a chain: how to use a file to sharpen a chainsaw chain. When the stopper slot fits into the template groove, set the height of the worn area, which is removed using a flat file. The template is installed on one of two sides - Hard or Soft, which corresponds to hard or soft wood.

Sharpening will be easier if the chainsaw bar is clamped in a bench vise. The intervals between sharpenings can be increased if you promptly monitor the correct chain tension, monitor the condition of the limiter, regularly lubricate all moving elements, and periodically replace the drive sprocket.

The chain is considered an important part of any chainsaw, because with its help all work with trees is performed. Therefore, when using a chainsaw frequently, the chain needs periodic maintenance, and one of these points is sharpening the chain with a round file.

Features of care and maintenance of saw sets

Despite the efficiency, autonomy and other advantages of manual sharpening, experts recommend periodically sharpening chains on special machine equipment. Even a one-time operation has a positive effect on the calibration of cutting links.

On the other hand, mechanized sharpening significantly affects the service life of the saw chain, since all cutting links are subjected to standard processing, regardless of their condition.

- In order to sharpen a chain yourself in the field, you need to have strong skills in working with the existing tool. The best option is to keep several chains in stock that can be changed with minimal loss of working time.

- To properly sharpen the cutting edges of the headset, in addition to a good eye and a steady hand, you need a special sharpening kit, which includes a flat and round file.

In any case, the best result can be obtained by using a branded chain sharpening tool, the capabilities of which are an order of magnitude higher than their cheap analogues.

The practice of working with brand tools shows that the products of leading manufacturers Shtil, Husqvarna, Oregon and a number of others do not differ in quality characteristics.

The service life of removable equipment equally depends on the quality of the material, the design features of the lubrication system, and the qualifications of the workers and maintenance personnel.

During operation, it is recommended to periodically check the tension of the saw chain and the supply of chain oil to the working cutting area. Filling the system with waste and cheap oil substitutes is strictly not recommended.

The wear rate of the chain and bar increases sharply with excessive tension, sand and other abrasive materials getting into the set, or poor condition of the drive sprocket crown. A nail not detected in the wood in a timely manner can ruin a new chain beyond any possibility of repair.

After work, the headset must be cleaned of sawdust; during long breaks in work, it must be dismantled, lubricated and stored in a dry place.

How to sharpen a chainsaw chain with a file

Although the file is inexpensive and easy to use, for chainsaw chains you will have to acquire a special type. To work, you will need two types of files - round and flat. The standard work kit looks like this:

round file with a permissible diameter of 4.5-5 mm;

flat file for changing the limiter;

a holder with lines, the task of which is to position the chain on the permissible upper edge;

hook, needed to remove sawdust and working shavings.

Please note that the diameter of the file is selected so that it corresponds to the rounding of the working part of the saw tooth. If you use chainsaws for domestic purposes, round files with a diameter of 4 and 4.8 mm will be the most optimal. More powerful and professional chainsaws will require a round file with a diameter of 5.2 or 5.5 mm.

Important: in order for the chainsaw to cut correctly in the future, in addition to sharpening the cutting edges of the teeth, you will have to change the limiter responsible for the depth of cut. Otherwise, the chain will not be able to cut to the proper depth, which will result in longer, harder work with the wood. The limiter is adjusted using a flat file described above.

Chain teeth parameters

To achieve good cutting parameters, the tooth blades are given certain angles. The back of the tooth sloping backwards at an angle forms the rear corner of the upper blade. This is a tool for sharpening the edge of the cutting tooth of a chain. Depending on the parameters of the chain, a file with a diameter of 4.0 mm to 5.5 mm is used for a chainsaw. This angle is needed to cut the upper blade into the wood.

The tapering blade of the tooth forms the rear angle of the end blade. This angle is needed for side cutting of chips.

The edge of the end blade forms a frontal angle with the sliding surface of the cutting link. Front angles for different types of chains vary from 60 to 85°.

The back angle of the upper blade describes the backward tilt of the upper blade.

Files for sharpening chainsaw chains Shtil 180

First, it is important to buy the right file for the job, if you are using the Stihl 180 model, the round file will have to be selected based on the chain pitch (0.325 inches), the presence of notches and the length of the file itself. Based on the GOST 1465 standard, round files are classified by length by number. The following files are ideal for the Shtil 180 brand:

No. 4 - working length 200 mm;

No. 5 - working length 250 and 300 mm.

The second option is more suitable, because the longer length will make the sharpening procedure convenient and effective.

Notches on round files can be of two types - notched and cut. We recommend choosing notched ones due to the smaller cutting angle range. The most suitable files are those made from tool steel; we recommend products from the Zubr brand. The manufacturer creates them specifically for handmade work and offers many different sizes.

Chain sharpening procedure

First of all, place the chainsaw on a flat surface; at home it can be a table; when working in the forest, a large block of wood is perfect. It is important that the chain is tensioned when sharpening, otherwise the procedure will be a failure. Sharpening takes place in the following stages:

A round file is installed in a perpendicular direction when moving the teeth on the chain in a vertical position; if the teeth are in a horizontal position, the file is installed at an angle from 15 to 200 degrees. For horizontal teeth, you can use a holder.

For the procedure to be successful, when installing the file into the tooth throat, make sure that it is installed just above the edge; 1 mm is enough;

The third stage is installing the holder on the tooth. The lines on such a tool will show the correct direction of movement of the file in a horizontal position.

Once positioned correctly, you can make a couple of strokes with the file until metal shavings form. The shavings are removed with a previously prepared hook;

You need to sharpen the chain in a position away from you; with the correct choice of file diameter, the notches should fit smoothly into the tooth.

Modern method

This is the simplest and slowest method for sharpening chain teeth. However, the method is good when sharpening is done on site in the forest. Why not carry a whole machine with you all the time?! But here it’s worth being more precise - we don’t mean one tool, but a whole set, which includes:

- flat file;

- round file;

- sample.

Currently reading: Proportions of oil and gasoline for a Husqvarna chainsaw - novaso

Each of them performs their duties. The main purpose of the flat tool is to sharpen the depth gauge.

A round file already performs the main operation, making the cutting edges sharper. In this case, each chain requires a certain tool diameter:

- pitch ¼ inch - 4 mm;

- pitch 0.325 – 4.8 mm;

- pitch 3/8 inch - 5.2 mm;

- pitch 0.404 - 5.5 mm.

For Picco chains, which are equipped with Shtil 180 chainsaws with 3/8 and quarter inch pitches, a file with a diameter of 4 mm is also suitable. It is important to hold it correctly. With respect to the vertical plane, the file must be positioned strictly perpendicular to the chain, and with respect to the horizontal plane - at a slight angle (about 30°). The specific sharpening angle is selected depending on the needs, but within 25-35°.

Unlike sharpening a chainsaw chain on a machine, the angle here can be set using a template, which is considered a useful assistant. For this purpose, it is equipped with two slots: SOFT/S (for soft wood) and HARD/H (for hard wood). The template must be secured above the chain, which gives it the privileges of a limiter.

Just keep in mind that this method is not intended for permanent use, but serves only as a straightening of the blades. Using a file too often will wear out the chain over time, and the teeth themselves will be sharpened unevenly.

Almost every non-professional is concerned with the question, what is the angle of sharpening the chainsaw chain on the machine? You won’t be able to use a file all the time, it’s difficult to use an angle grinder, and for beginners this procedure is downright dangerous. There’s nothing you can do about it; you have to use machines that can be either mechanical or electric.

You will have to work for an “eternity” with a manual machine, but you get pleasure from using an electric analogue. File for chain. The most important parameter of a file for sharpening a chain (shank 180). Today there are a wide variety of models to choose from that provide

- correct sharpening angle;

- high level of work quality;

- high sharpening speed.

It is also worth noting that sharpening is carried out evenly on all links. All you need to do is turn on the equipment, set the desired angle, enjoy the spectacle, or do other things. The cost of such machines varies from 2 to 4 thousand rubles. But the most important thing is that it will not be difficult to determine the sharpening angle of the Shtil chainsaw chain on the machine.

Although fiddling around with manual equipment is a very lengthy process, it costs several times less. In appearance, the machine resembles a bow saw, only instead of a blade there is a round file. The smallest tooth is also used as the basis. In this case, two or three movements are enough for sharpening, after which you can move on to the next link. If necessary, process the limiter - change the file (round is replaced by a flat one).

Important features when sharpening

If you work with a file and are ready to sharpen it yourself, pay attention to the following nuances and recommendations:

A standard file will sharpen a chain a maximum of 2 times;

Cleaning up shavings is most convenient with a crochet hook;

Mechanical sharpening with a file is faster and cheaper than using a grinder or a machine;

To determine the height you will need a template;

You can buy a file for sharpening a chainsaw at chainsaw stores;

It is advisable to sharpen teeth from problem areas first.

At first glance, the procedure seems complicated, but after the first successful attempt, you will understand how to properly sharpen a chainsaw chain right at your workplace.

Video

Carburetor Sthil MS180 (Shtil 180). Adjustment - no, I haven’t heard...

The Shtil MC 180 chainsaws produced at the moment and in the last couple of years are equipped with Chinese-made carburetors, which have only one adjustment screw . Such membrane-type carburetors are practically impossible to disassemble, since it is completely sealed and filled. So to say: “Adjustment - no, I haven’t heard...” In this case, it is easier to buy a Shtil 180 chainsaw carburetor, and both original carburetors (also made in China, but at a plant owned by STIHL ) and from third-party (also Chinese) manufacturers are available for sale.

It should be noted that despite being made in China, the original Shtil 180 carburetors are very reliable and rarely let their owners down. The price of an original carburetor for a Stihl 180 and a non-original one differs quite significantly. For example, if a non-original carburetor on the Internet costs from 700 rubles, then the original one costs 2500 rubles, that is, almost 4 times more expensive.

For chainsaws manufactured for 5 years or more, it is possible to purchase repair kits. The price of a repair kit for the Shtil 180 carburetor ranges from 200 to 400 rubles.

Sharpening methods

To sharpen a tool, you can turn to the services of craftsmen who not only know what angle of sharpening chainsaw chains is necessary, but also do all the work quickly and at a professional level. As a rule, the cost of such services is not so high, but the quality, on the contrary, is very high! This option is suitable for those who like to cut wood and have no desire to tinker with their tools.

The round file holder has stripes that allow it to be positioned correctly relative to the chain. The holder is installed on the tooth being sharpened in accordance with the orientation lines. In this case, the plate itself rests on the upper edge of the tooth and the depth stop, and the ratfil is placed under the cutting edge.

The insertion of the holder ensures that the file is attached to the tooth at the correct height. Chainsaw chain sharpening, buy everything for chain sharpening. There are different holders for different pitches of the saw chain. The correct choice of holder, coupled with the correct diameter of the file, ensures that the file protrudes above the back of the tooth by 1/5 of its own diameter. Use only special grinders for sharpening saw chains.

What kind of file is needed to sharpen a chain?

How to choose a file

for

sharpening

chainsaw JOIN VSP GROUP PARTNER PROGRAM: .

How to set up the carburetor of a Shtil 180 chainsaw?

We only have access to idle speed . Why is this necessary and how do you understand when you need to adjust the idle speed of a Shtil 180 chainsaw? This is necessary if the chain does not stop at idle, which can lead to injuries and unstable operation of the saw as a whole.

Why does the chain break?

The owner of a chainsaw may have to face a problem such as a rupture of the saw blade. If this happens, it is necessary to find out the causes of the breakdown.

Most often, the main reason is unfavorable external factors:

- tension beyond measure;

- wear of the guide bar or discrepancy between the shanks and the width of the working groove;

- operation of the saw set under high loads for a long time;

- overheating of the part due to lack of lubrication;

- the part does not match the tire type and drive sprocket crown configuration.

Currently reading: Circular sawing machines

Chain saw sharpening template

To significantly simplify the procedure, it is recommended to purchase a special template, which greatly simplifies the procedure for setting the required angle. Such a tool allows you to check the indicator of the rear angles of the conical and top blades, as well as the leading edge of the cutting edge.

Experts point out that the most important thing is to use a template to control the clearance angle. This is due to the complexity of changing this indicator, and it must be maintained within a strict range

Too high a material hardness determines the need to reduce this indicator. Experts indicate that the optimal value varies from 10 to 12°.

How to choose the right angle?

Cutting hardwood is characterized by low productivity and a large load on all components of the chainsaw (we recommend reading in more detail about the structure of the chainsaw). The most popular hardwoods are ash, beech, birch, elm, maple, oak and hazel.

The photo shows a special sharpening device that allows you to securely fix the file.

In order to effectively cut these rocks, it is necessary to maintain a sharpening angle of 25°. This value will ensure optimal operation of the chainsaw with average performance characteristics.

Softwoods include all conifers, with the exception of larch - spruce, pine, fir, cedar, as well as deciduous trees - alder, linden, aspen, willow and poplar.

For rip cutting

As already mentioned, the recommended sharpening angle is 10° with a possible deviation of up to 2°. This is due to the need to quickly cut deep into the tree when making a longitudinal cut.

For working with soft wood, the optimal angle is 25°. The fibers of soft wood are distributed unevenly, that is, hard ones alternate with soft ones. A value of 25° allows cutting of alternating fibers without periodically increasing the engine speed.

For cross cutting

For cross cuts in soft and hard wood, a value of 35° is recommended. This value allows you to achieve optimal power characteristics and load on the chain when cutting.

Angle table

The sharpening angles for saw chains are presented in the table below. From the table you can even understand which file will be needed to sharpen a particular chain.

Table of sharpening angles for all types of saw chains, as well as cutting depths. To enlarge, click on the photo.

Useful tips

Some helpful tips will help keep your equipment in working order and eliminate the risk of injury. In addition to the question of what angle of sharpening the chainsaw chain should be, you should also know this! Of course, it is necessary to know the correct angle of sharpening the chain of the Shtil chainsaw. But timely tire care is also important:

- It is necessary to control the chain tension. Especially if the chainsaw tilts to one side during operation. Poor tension can pose a threat to humans.

- Conduct sharpening in a timely manner, without putting everything on the back burner. It may be expensive, but it is better to give preference to electrical equipment.

- Regularly lubricate the entire chain, otherwise it may fly off (its speed is about 100 km/h). Everyone will draw their own conclusions.

- Do not use used motor oil or any product of questionable quality. You should only choose specialized lubricants. The most important parameter of a file for sharpening a chain is the diameter of the file. As the best remedy - autol.

Before you start using a chainsaw, the chain should be broken in. Let it run at minimum speed for 40-50 seconds. The lubricant will reach every part, and the chains with the sprocket will heat up a little and rub against each other.

All this expert advice should not be ignored if you want to remain safe and sound!