In order for the chainsaw to work properly and perform its functions efficiently, it is necessary to use suitable chain oils. The service life of the sawing machine depends on the choice of consumables. How to replace oil for a chainsaw chain if it is not possible to purchase expensive options?

An alternative is a lubricant that has good adhesive properties. Compounds with low adhesion rates accelerate wear of the unit, since the lower part of the tire remains without lubrication. There are also options that are prohibited for use with saw chains.

Volga Oil M-8V

Universal motor oil, which is suitable not only for cars with gasoline and diesel engines, but also for chainsaws. The product, known as Avtol, contains a mineral base and multifunctional additives. Inexpensive option for working at sub-zero temperatures.

Properties:

- excellent adhesion performance;

- high level of heat resistance;

- increases the service life of the unit;

- freezing temperature - 25-35 degrees below zero.

The average price per liter is 150-200 rubles.

Popular brands of oils for chainsaw chains

Stihl

The Germans traditionally offer several solutions:

- Forest Plus

Inexpensive for a branded product, but very effective. There will be no problems with it down to -15 degrees. Packaged in 1 and 5 liter containers. It retains its properties for three years, so when purchasing it, you need to consider how tightly you will use the saw.

- BioPlus

The name hints at the environmental friendliness of the lubricant. Plant origin makes the product completely safe for forests and water bodies. Biodegradable lubricants are at the peak of popularity in Europe, although in Russia they are still reluctant to shell out money for them.

- Synth Plus

Professional oil for real tough lumberjacks from countries with harsh climates. Although such forests are cut down mainly in Russia and Finland. The formula of the components allows it to work at -25, and the high price makes its use in household saws pointless.

Husqvarna

The Swedes have not remained aloof from “chain” lubricants. This segment offers two options:

- Bio Advanced

A universal solution, both for amateurs who value their efforts and tools, and among professionals for whom maximum speed and durability are vital. Biodegradation is a must.

- Vegoil

A more budget-friendly solution for the amateur sector. Positioned as an oil with reduced consumption. In practice, it is almost no different from competitors in terms of the speed of emptying the tank.

Other manufacturers

The oil is produced by many companies that also make chainsaws. Their products are less popular than Shtil or Husqvarna, but are also in demand among owners of gasoline units.

- Polar Lube

Mineral lubricant from the Italians Oleo-Mac.

- Champion

An adhesive lubricant that the manufacturer of the same name recommends for its power tools.

- Biotop

Following the global fashion for ecology, the Japanese company Makita decided to keep up.

If you have a saw that you don't want to lose, don't put car engine waste into the oil tank. Although this liquid still has lubricating properties, there is practically no adhesion. Everything around will be worked out. In addition, small particles of metal that accumulated in the waste while it was inside the 4-stroke internal combustion engine act on the chain, sprocket and tire like an abrasive.

For an expensive instrument, it is better to take high-quality consumables. For an inexpensive one, they are still of high quality, if the saw is not purchased for the purpose of a one-time job. Chain and engine oil is a way to both extend the life of a chainsaw and “kill” it faster.

Caliber

A budget substitute for expensive chain oil. Due to the presence of functional additives in its composition, it has a number of unique properties. In particular, the use of “Caliber” allows you to increase the service life of the chain and the entire unit as a whole. There is a special scale on the side of the canister showing the amount of lubricant available.

Peculiarities:

- mineral base;

- protects against corrosion;

- low evaporation rates;

- reduces chain vibrations;

- It is used sparingly.

The cost of 1 liter is 275 rubles.

Universality problems

Universal oil for lubricating chainsaw chains has relatively unattractive performance properties. It is worth considering that even lubricant manufacturers do not indicate their 100% versatility.

An incorrect choice leads to the fact that the wear of the structure increases by approximately 10% and the working life of the saw set is reduced.

The information above indicates that there are no universal options for oils. That is why when choosing, you need to pay attention to operational properties, in particular, temperature conditions.

Carver

Suitable for all types of saw chains. Increases the efficiency of using the tool, while reducing the friction force in places where the chain comes into contact with the bar and sprocket. Thanks to the formation of a durable oil film, the unit works perfectly under heavy loads.

Characteristics:

- reliably protects against wear and corrosion;

- reduces the coefficient of friction;

- can be used regardless of the season.

A canister with a volume of 0.946 liters costs 260-280 rubles.

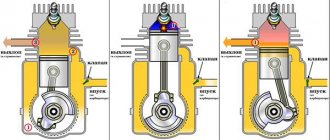

Basic malfunctions and repairs of the chain lubrication system

Let's look at common malfunctions and repairs of the chain lubrication system of modern chainsaws.

If the chain is not lubricated

The tank is full, but the oil does not flow to the chainsaw chain. There could be several sources of the problem here.

- Oil pump drive failure. Quite a common malfunction. On Stihl chainsaws, it is common to cut off the flange of the plastic drive gear. Or the splines are worn out. The gear does not rotate at all or rotates but does not engage the pump drive.

Uneven supply of lubricant

The chain receives too much or too little lubricant. When oil does not flow to the chain or is poured too much, it causes discomfort during operation and can damage the saw. This problem is a little less common, but also quite widespread. There may be several reasons.

- Incorrect adjustment. It is better not to touch the oil supply adjustment screw on some saws without understanding the adjustment process.

- Use of lubricants of unsuitable viscosity. The pump pumps lubricants that are too thick less readily, and they are less easily distributed by the chain along the tire. With liquid oils the opposite is true.

- Reduced tightness in the chain lubrication system. Sometimes the oil supply tube to the pump comes off or is damaged. This causes oil starvation. A similar problem manifests itself in lubricant leaks at the bottom of the chainsaw.

Overheat

Despite the abundant supply of oil to the chain, overheating or jamming is still observed. There is only one reason here - the use of a material that is absolutely unsuitable for lubrication. This can often be seen when pouring into the mining system.

Anchor

Mineral-based oil with adhesive additives that positively affect the functionality of the tool used. Lubrication helps reduce friction where the chain meets the bar and sprocket. The product is completely biodegradable after use.

Properties:

- increases the service life of the chainsaw;

- reduces wear rates;

- is consumed moderately;

- excellent adhesive properties.

Price 1 liter - 250 rub.

Features of chain oil

If the engine arsenal must have such properties as purity and low ash content, then chain oil must have completely different basic characteristics. It does not burn, so it is not required to be carbon-free after use.

The design of the saw set includes a bar with a driving and driven sprocket and a chain. Lubricating the blade facilitates its movement along the tire channel, the passage of the drive links along the sprockets, reducing wear on the rubbing pairs. Since the oil is applied to the surface of the chain in special holes or grooves, it must adhere well to the blade, since when the sprockets rotate, the centrifugal force will cause it to fly apart.

At maximum speeds such spread is inevitable. There is even an experiment to check the lubrication on the chain:

Apply full throttle, holding the tire over the fresh cut. Drops of oil that appear will indicate that there is enough lubrication.

Based on this, we can outline two most important characteristics of “chain” oils:

- Good adhesive ability . This means that the oil should stay as tightly as possible in the grooves and holes of the chain. At medium speeds it doesn't even leave the surface. Such indicators are related to viscosity - it is quite high for lubricants. At the same time, excessive thickness also harms the chain - the oil does not have time to envelop the chain in the required amount.

- Highly environmentally friendly . Chain oil ends up in nature almost unchanged, like from a bottle: it drips onto the ground, remains on wood, bushes, and grass. Once on the snow, in the spring it flows into a reservoir. Its impact may seem insignificant, but there are thousands of chainsaws operating all over the world. Large companies are very concerned about environmental issues. Therefore, they try to make their oils safe for the environment. Many of them are made from plant-based ingredients and disintegrate in a few days. Therefore, high-quality products have a limited shelf life.

Nanotek 2T Standard

If the question arises about what kind of oil to lubricate the saw chain, you should pay attention to the product of a domestic manufacturer. The lubricant has a mineral composition and excellent performance characteristics. Reliably protects parts from wear.

Peculiarities:

- contains mineral oils;

- can be used at temperatures no higher than -20°C;

- prevents jamming of rubbing parts;

- increases tire and chain resources.

The cost of a 1-liter canister is 185 rubles.

Types of engine oil

Among the wide variety of lubricants, three large groups can be distinguished, which differ in both composition and characteristics:

- Mineral.

- Semi-synthetic.

- Synthetic.

- Mineral oils

One of the cheapest and most common. They are obtained during the refining of petroleum products. Many saws are kept in mineral oil for quite a long time. Its main advantage is price and availability. True, you can’t buy a good pure substance for pennies either. Mineral water can smoke the inside of the engine over time. However, if the owner is good with his hands, he can clean out all the “insides” himself. According to experienced “pilot operators”, with rare and not too intensive use of the unit, the mineral component is quite enough for normal operation.

- Synthetic oil

For two-strokes, it is made from artificially created components.

Industrial synthesis gives indicators unattainable with mineral oils. Synthetics are not afraid of cold, heat, or temperature changes. In addition, it forms much less soot. Recommended for use in professional equipment. in a logging site, where tools work for 8-10 hours almost without a break, the highest quality is the only way to maintain productivity. Semi-synthetics are a compromise solution for those who cannot afford pure synthetics, but the class of the tool does not allow them to add mineral water to gasoline. It is made on the basis of petroleum products, but contains special additives that improve the performance of the substance.

Oregon

Semi-synthetic product that is suitable for all types of chain saws. The composition is represented by a complex of purified mineral oils and special additives. The latter help to increase the viscosity of the material, which allows the unit to be used at high temperatures and high speeds.

Characteristics:

- retains quality regardless of the season;

- stable adhesion at temperatures from -20 to +240 degrees;

- no pungent odors;

- reduces wear at high speeds;

- protects against corrosive processes;

- profitable in terms of consumption.

1 liter costs on average 350 rubles.

Champion 2-stroke

Two-stroke mineral motor oil made in Russia. Its use allows you to reduce the heating of the unit during operation. Due to good viscosity indicators, it extends the service life of parts and tools as a whole. Despite the low cost, the product is manufactured in compliance with quality standards.

Properties:

- perfectly lubricates the chain;

- economical consumption;

- protects against wear;

- mineral composition;

- not suitable for sub-zero temperatures.

The average price of a liter canister is 350 rubles.

Rules for preparing the fuel mixture

Gasoline and oil must be diluted in containers that are resistant to petroleum products (plastic or metal cans). It is not recommended to use plastic water, juice or milk bottles for these purposes, since food-grade plastic decomposes when exposed to gasoline. As a result of this process, the fuel mixture will change its properties, and it is difficult to predict what effect it will have on the engine.

The combustible mixture for a chainsaw is easy to prepare.

- Take the required amount of lubricant and pour it into the prepared container. You should not pour all the prepared gasoline into the container with oil; half the required amount will be enough.

- Rock the container slightly until the lubricant is completely dissolved in the gasoline.

- Now you can fill in the remaining gasoline, mixing it well with the mixture in the container. This completes the preparation of the fuel mixture for the chainsaw.

Before each refueling of the chainsaw, the combustible mixture must be shaken. Also, do not forget to tighten the cap of the fuel tank well, otherwise this will lead to a lean mixture and engine failure.

It is better to use the prepared fuel mixture immediately. Therefore, it needs to be prepared in such quantity that it is enough for the expected amount of work. If the mixture remains, then it cannot be stored for more than 1-1.5 months. During this time, it will lose a significant part of its lubricating properties.