Characteristics of steel grade St2sp

St2sp - Structural carbon steel of ordinary quality, welds well, welding is carried out without heating and without subsequent heat treatment, welding methods: manual arc welding, automatic submerged arc welding and gas protection, KTS, ESW. For thicknesses greater than 35 millimeters, heating and subsequent heat treatment are recommended; it is not prone to flake sensitivity and there is no tendency to temper brittleness. Cutting machinability in the hot-rolled state at HB 137 Kυ hard alloy. = 2.0 and Kυ b.st. = 1.6, has found its application in the production of non-critical parts of structures and mechanisms that require increased ductility or deep drawing; used in lightly loaded elements of welded structures operating under constant load and at positive temperatures; St2sp steel has relatively high toughness and ductility, slightly higher than St2ps steel. Forging at temperatures from 1300 to 750 0C, cooling is carried out in air. St2ps steel is not prone to temper brittleness and is magnetic.

Buy 2PS steel in Moscow and the Moscow region

2PS steel is widely used in various fields of industry, used in mechanical engineering, involved in the manufacturing industry, covers a wide range of construction, shipbuilding, and is partially used in aircraft production and many other areas of industry. There are a large number of steel grades, a huge part of the alloys are made to order, and those steel grades that are in great demand are partially stored for regular customers. The Metallpro company carries out wholesale and retail sales on the territory of the Russian Federation; 2PS steel is partly in our warehouse in the form of rolled metal products, and partly we ship directly from the metallurgical plant. With constant demand, we are ready to offer mutually beneficial cooperation, delivery directly from the factory by carriage standards, as well as by motor vehicles. You can buy 2PS steel in Moscow and the Moscow region at a favorable price from the Metallpro Trading Company under a mutually beneficial contract for a long partnership period.

Interpretation of steel grade St2sp

Decoding of steel: The letter at the beginning indicates a group of steel which defines the criteria for the ultimate strength for the chemical composition; if there is no letter, then such steel belongs to group A, and is supplied to consumers based on mechanical properties (such steel may have a high sulfur or phosphorus content). Letters St. indicate that the steel is of ordinary quality, although most steels are high quality. The numbers from 0 to 6 are the conventional brand number depending on the chemical composition and mechanical properties. Typically, the higher the number, the more carbon and the greater the strength. In our case, 2 indicates the carbon content in the alloy is 0.09–0.15%. The letters after the brand number indicate the degree of deoxidation: cn - calm. In terms of price, calm steels have become more expensive than semi-calm and boiling steels. Mild steel is steel obtained as a result of deoxidation. It is obtained by deoxidation with aluminum, manganese and silicon. The level of oxygen in it is so reduced that during metal processing no reaction occurs between carbon and oxygen, and the presence of non-metallic slags and their inclusion is reduced to a minimum. Calm steel has a dense structure and good mechanical properties. It is less prone to negative reactions to welding heat and to aging. The features of a homogeneous microstructure give the alloy maximum corrosion resistance and ductility.

Price for steel 2PS

The favorable price for the 2PS steel grade is explained by the presence of a competitive environment, low markups and loading from leading metallurgical plants directly, sometimes bypassing storage at transshipment points. Metalpro company bears full responsibility for the chemical composition of the supplied products and guarantees the quality of delivery. The cost of 2PS steel in warehouses in Moscow and the Moscow region is determined by the costs of warehousing and logistics. The Metallpro Company can also supply 2PS steel directly from the metallurgical plant, which gives our partners an advantage to consistently save money and develop their business in a broad format.

The price for 2PS grade steel is determined personally with each company, monthly needs are individually negotiated and the form of payment is discussed. Warehouse services for custom-made items and logistics to the production site also form the cost of 2PS steel. The Metalpro company maintains an open dialogue personally with each of its clients; each transaction is accompanied by a personal manager from the production stage to the delivery of rolled metal to the customer. Full control at any stage from payment to delivery to the customer’s site gives the latter a complete picture.

Supply St2sp

Supplied in the form of long products, including shaped steel according to the regulations of GOST 2590-88 Hot-rolled round steel , GOST 2591-88 Hot-rolled square steel , GOST 8239-89 Hot-rolled steel I-beams , GOST 19771-93 Equal-flange bent steel angles, GOST 19772 -93 Bent steel angles, unequal flanges , GOST 8278-83 Bent steel channels, equal flanges , GOST 8281-80 , unequal , GOST 8283-93 steel trough equal flange profiles , GOST 380-94 Carbon steel of ordinary quality , GOST 85 09-93 Steel corners hot-rolled equal flange , GOST 8510-86 rolled steel angles unequal-flanged , GOST 8240-97 Hot-rolled steel channels , GOST 535-88 Rolled bars and shaped carbon steel of ordinary quality , GOST 2879-88 Rolled hot-rolled hexagonal steel, GOST 19903-2015 Hot rolled sheet products , GOST 19904-90 Cold-rolled sheets , GOST 16523-97 Rolled thin sheets of high-quality and ordinary quality carbon steel for general purpose, GOST 503-81 Cold-rolled low-carbon steel strip, GOST 103-76 Hot-rolled steel strip , GOST 82-70 Hot-rolled steel Wide-band universal, GOST 3282-74 Wire Steel low-carbon general purposes , GOST 17305-71 Carbon structural steel wires, GOST 10705-80 steel power steel pipes , GOST 10706-76 Pipes steel eight-dimensional , GOST 3262-75 Pipes steel water and gap-pipes .

| Classification, nomenclature and general norms | GOST 380-2005; |

| Long and shaped rolled products | GOST 2590-2006; GOST 535-2005; GOST 5422-73; GOST 8239-89; GOST 8240-97; GOST 8510-86; GOST 8509-93; GOST 30136-95; GOST 9234-74; GOST 2879-2006; GOST 2591-2006; GOST 11474-76; GOST 30565-98; GOST 19425-74; GOST 19240-73; |

| Sheets and strips | GOST 14918-80; GOST 14637-89; GOST 16523-97; GOST 19903-74; GOST 8568-77; GOST 103-2006; |

| Ribbons | GOST 6009-74; GOST 3560-73; |

| Ribbons | GOST 19851-74; |

| Steel pipes and connecting parts for them | GOST 24950-81; GOST 53383-2009; GOST 8642-68; GOST 20295-85; GOST 8644-68; GOST 12132-66; GOST 8646-68; GOST 8696-74; GOST 8645-68; GOST 10706-76; GOST 13663-86; GOST 3262-75; GOST 8639-82; GOST 8731-87; GOST 8732-78; GOST 9567-75; GOST 10707-80; GOST 8638-57; GOST 10705-80; |

| Low carbon steel wire | GOST 3282-74; |

Chemical composition

| Standard | C | S | P | Mn | Cr | Si | Ni | Fe | Cu | V | Mo |

| GOST 398-96 | 0.57-0.65 | ≤0.04 | ≤0.035 | 0.6-0.9 | — | 0.22-0.45 | — | Remainder | — | ≤0.15 | — |

| GOST 5257-98 | 0.57-0.67 | ≤0.04 | ≤0.035 | 0.5-0.9 | — | 0.2-0.45 | — | Remainder | — | — | — |

| GOST 398-2010 | 0.57-0.67 | ≤0.02 | ≤0.03 | 0.6-0.9 | ≤0.2 | 0.22-0.45 | ≤0.25 | Remainder | ≤0.3 | ≤0.15 | ≤0.08 |

Fe is the basis. According to GOST 398-96, the allowed content of molybdenum is not more than 0.08%, nickel is not more than 0.25%, chromium is not more than 0.20%, copper is not more than 0.30%. The total content of sulfur and phosphorus should be no more than 0.065%. In finished bandages, maximum deviations in chemical composition are allowed in accordance with the requirements of GOST 380. According to GOST 5257-98, nickel content is allowed no more than 0.30%, chromium no more than 0.25%, copper no more than 0.30%. According to GOST 398-2010, the total proportion of sulfur and phosphorus in steel should not exceed 0.040%. In bandages, maximum deviations of the chemical composition are allowed: for carbon +0.030/-0.020, for manganese +0.050/-0.030, for silicon +0.030/-0.020, for chromium +0.020, for vanadium +0.010%, for phosphorus +0.0050% , for sulfur +0.0050%. The mass fraction of hydrogen in liquid steel should not exceed 0.00020%.

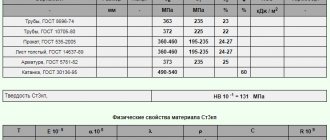

Mechanical properties of St2sp at normal temperature

| Type of delivery | Size | Eg. | sв | sT | d5 | y | KCU | Heat treatment |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Pipes, GOST 8696-74 | 334 | 225 | 24 | |||||

| Pipes, GOST 10705-80 | 333 | 206 | 24 | |||||

| Rolled goods, GOST 535-2005 | 335-430 | 195-225 | 29-32 | |||||

| Thick sheet, GOST 14637-89 | 330-430 | 195-225 | 29-32 | |||||

| Wire rod, GOST 30136-95 | 420-470 | 60 |

Designations

| Name | Meaning |

| Designation GOST Cyrillic | St2ps |

| Designation GOST Latin | Ct2pc |

| Translit | St2ps |

| By chemical elements | 2 |

| Name | Meaning |

| Designation GOST Cyrillic | VSt2ps |

| Designation GOST Latin | BCt2pc |

| Translit | VSt2ps |

| By chemical elements | 2 |

Foreign analogues of steel grade St2sp

| USA | A192, K02502 |

| Germany | 1.0034, RSt34-2, S185, St35, St37-2 |

| France | A34-2, A34-2NE |

| England | 1449-3420HR,, 3420HS, S360 |

| European Union | E195, S235JR |

| Italy | Fe330BFN |

| China | Q215, Q215A, Q215A-Z, Q215B, Q215B-Z |

| Bulgaria | ASt0, BSt2sp, WSt2ps, WSt2sp |

| Hungary | Fe310O |

| Poland | St0S |

| Romania | OL34.1 |

| Czech | 10000 |

- Structural steel

- Tool steel

Pros and cons of steel

We will consider the advantages and disadvantages using knives made of D2 steel as an example. It is no coincidence that it is extremely popular in the manufacture of blades. So:

pros

- The cutting edge of products made from D2 holds its edge for a long time. Despite frequent and intensive use of the knife, it will remain sharp for a long time;

- high hardness of the product is achieved due to carbon and chromium in the alloy. The metal blade is optimal for use in field conditions;

- Knives made from this steel have a rather aggressive cut. The blade will do an excellent job of cutting branches and will cut rope or rope fibers without any problems. Also, such a knife can easily help cut a carcass, cut bones and tendons;

- this steel is not afraid of temperature changes. The blade will be in working order in both heat and cold;

- Knives made of D2 steel have high wear resistance. The blade will serve its owner for many years;

- The homogeneous structure of the alloy prolongs the service of the knife. This prevents the appearance of microcracks, which eventually lead to destruction of the blade;

- a high percentage of chromium content has a positive effect on the corrosion properties of the product;

- knives made from this grade of steel are low in cost. The products occupy the average price range on the market.

Minuses

- high but insufficient chromium content affects the blade. If the product is in contact with water, acids and salts for a long time, then there is a high probability of corrosion;

- To prevent the appearance of corrosion foci, the blade requires constant care. After work, it must be wiped with a dry cloth and dried;

- Using the product as a nail puller will not work. The blade is afraid of lateral loads, it can break;

- The high hardness of the product is characterized by problematic sharpening. It will not be possible to sharpen a blade while traveling. Special tools and sharpening stones are required;

- It is not recommended to make throwing weapons from D2 steel. Impact loads are detrimental to the blade;

- You will never be able to polish a blade to a shine. It has a matte surface, which affects the appearance of the product.

D2 steel knives

Blades for various purposes are produced from tool steel: tourist, hunting, fixed blade and folding products. Also knives for survival and for every day. Kitchen and cutting blades will delight their owner with their sharpness for a long time. Let's look at several options for knives made of D2 steel.

Touring knife – Kizlyar Supreme Maximus

The blade belongs to the Outdoor knife family. These knives are reliable and designed for outdoor activities. They can perform various tasks. Blades are also in demand by hunters, rescuers and ordinary tourists. The blade has slightly concave slopes and a small false blade. The handle is made of G10. Blade characteristics:

- Knife length: 272 mm;

- Blade length: 143 mm;

- Handle length: 129 mm;

- Blade width: 31 mm;

- Butt thickness: 3.9 mm;

- Blade material: D2;

- Handle material: G10;

- Country of origin: Russia;

- Manufacturer: Kizlyar Supreme, Kizlyar, Russia;

- Weight: 288 grams.

Knife of the Outdoor family.

Folding knife – Ganzo Firebird FH61-BK

Folding product from the Ganzo company. The knife has an aggressive, recognizable design. D2 steel will provide reliable cutting edge retention and efficient cutting. The blade is opened using a flipper. The handle is made of G10, which will provide a non-killable coating. Blade characteristics:

- Knife length: 180 mm;

- Blade length: 80 mm;

- Blade width: 30 mm;

- Handle length: 100 mm;

- Butt thickness: 4 mm;

- Blade material: D2;

- Handle material: G10;

- Manufacturer: Ganzo, China;

- Weight: 100 grams.

Folding knife from the Ganzo company.

Knife – Bumblebee

The “bumblebee” blade is a small fixed knife that will become a universal assistant for a hunter, fisherman or a simple tourist. The knife is made in the best traditions of Russian knife making. The geometry of the blade follows the contours of Russian northern knives. The handle is made of wood and has a hole for a lanyard. Blade characteristics:

- Knife length: 222 mm;

- Blade length: 107 mm;

- Handle length: 115 mm;

- Blade width: 35 mm;

- Butt thickness: 4 mm;

- Blade material: D2;

- Handle material: Birch;

- Country of origin: Russia;

- Production: Sander A.;

- Weight: 150 grams.

Heat treatment of D2 steel

The production of D2 steel begins with the electroslag remelting (ESR) method. The hot alloy is passed through a special flux. This way harmful impurities are removed. Further steel production continues through heat treatment.

D2 steel blanks.

During hardening, it is important to ensure uniform heating of the entire mass of metal. A short delay is enough for this. The process is carried out in an oxidizing environment, which ensures decarburization of the surface layer of the workpiece. It is removed during mechanical processing.

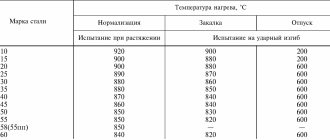

Conventional heat treatment is carried out as follows:

- The initial hardness of steel is achieved when hardened at 1000-1010 °C. Exposure at temperature is carried out for 5-7 minutes;

- tempering is carried out at 175-200 °C, holding for 2 hours.

This achieves an alloy hardness of 61-61 HRC. When making special knives for certain dynamic loads, the steel hardening mode changes:

- the workpiece is heated to 1020-1040 °C and hardened;

- tempering is carried out within two hours at 310-340 °C.

Sharpening knives made of D2 steel

Recommendations for sharpening blades made from D2 steel grade are practically no different from other powder steels. Aluminum abrasives are ideal; the most popular are Boride T2 or PC series stones.

Silicon carbide stones also work well, but be aware that they require soaking in water.

The work will be done in a damp environment. And as has already become known, D2 steel does not tolerate long-term contact with water very well.

If you come across a product of increased hardness, then it is best to use diamond bars with an organic bond. They are produced by the Venevsky Diamond Factory. It is recommended to use Dialux paste on a leather blank and diamond paste on an oak blank as finishing agents.

Thermo-mechanical treatment conditions

Hardening is a mandatory and necessary process to impart hardness to steel. An oxidizing atmosphere is used when processing parts not intended for the manufacture of blades. Making knives from D2 steel requires a different approach. To properly process knife steel, it must go through all the important stages:

- forging;

- annealing;

- shaping processing;

- re-annealing;

- correction of curvatures;

- hardening;

- vacation.

To produce cutting blades that are designed to withstand dynamic loads, a different temperature and time of exposure to the workpiece are required. The most common method is the use of low tempering and quenching in oil, under a stream of air or in hot environments.

A mandatory requirement is uniform heating of the workpiece.

The absence of oxidation prevents decarburization from occurring. This ensures that the product remains strong and sharp. Here the alloy is heated to 690-850 °C.

After a few minutes it is cooled and doped with vanadium and molybdenum. After processing, the steel is tempered and undergoes final machining. At this stage, the workpiece is ground and the blade is sharpened.