Based on their purpose, oxygen cutting is divided into separation and surface cutting. Dividing cutting is intended for cutting blanks, cutting sheets and performing other work related to cutting metal into several parts. Surface cutting is intended for cutting grooves on metal, removing surface defects on castings, rolled products and welds, removing rivet heads, removing the surface layer of metal and a number of other works.

According to the method of execution, oxygen cutting is divided into manual and machine. Manual cutting is performed with a special cutter, machine cutting is performed using special gas-cutting semi-automatic machines and automatic machines.

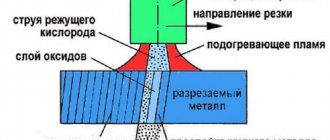

Oxygen cutting is based on the combustion of metal in a stream of technically pure oxygen. When cutting, the metal is heated by a flame that is formed by the combustion of any flammable gas in oxygen. In some cases, gasoline or kerosene vapor is used as a flammable gas. Oxygen that burns heated metal is called cutting oxygen. During the cutting process, a stream of cutting oxygen is supplied to the cutting site separately from the oxygen used to form a combustible mixture to heat the metal. Touching the heated metal, the cutting stream of oxygen intensively oxidizes and burns its upper layers. The process of oxidation of the upper layers of the metal is accompanied by the release of a large amount of heat, which goes to warm up the lower layers of the metal. The combustion process of the metal being cut spreads over the entire thickness, the resulting oxides are blown out of the cut site by a stream of cutting oxygen.

The metal subjected to cutting with oxygen must meet the following requirements: the ignition temperature of the metal in oxygen must be lower than its melting point, the metal oxides must have a melting point lower than the melting point of the metal itself and have good fluidity, the metal must not have high thermal conductivity. Copper, aluminum and their alloys, as well as cast iron, do not meet these requirements and cannot be cut with oxygen. Low carbon steels are easy to cut. Medium carbon and high carbon also cut quite well, but in some cases they require preheating.

The tendency of steels to harden when they contain some alloying impurities, as well as when the carbon content is more than 0.3%, leads to the formation of cracks when cutting without preheating. Alloying impurities in combination with carbon have different effects on the ability of steel to be oxycutable. The influence of various elements on the cutability of oxygen cutting steels is indicated in Table 6.

For oxy-fuel cutting, flammable gases and vapors of flammable liquids are suitable, giving a flame temperature during combustion in a mixture with oxygen of at least 1800ᴼC. The purity of oxygen plays a particularly important role in cutting. For cutting, it is necessary to use oxygen with a purity of 98.5-99.5%. As oxygen purity decreases, cutting performance decreases greatly and oxygen consumption increases. Comparative data on a decrease in cutting productivity and an increase in oxygen consumption with a decrease in its purity are given in Table 7.

Types of gases for metal cutting

To begin with, let’s define that we call nitrogen and oxygen and air gas; air is also a gas.

When cutting with a laser (either CO2 or fiber), gas is supplied through the nozzle along with the laser in order to remove combustion products from the cutting zone or to help the laser process the material.

Nitrogen

If we are talking about nitrogen or oxygen, then there are many ways to store and supply gas to the machine, the most basic is a gas cylinder, we screw a reducer onto the cylinder to regulate the pressure and from the reducer we run a hose to the machine.

Air

A compressor is an AIR supply device. That is, only air. Air can be used to cut small thicknesses, on average up to 2-3mm. A filtration system is needed to ensure that the air that goes through the compressor to the machine is clean, without water or oil.

If the filtration system is bad, then small particles of water and oil fly out of the compressor along with the air, they settle on the protective glass of the laser head and the glass quickly fails. Also, the entire air path of the machine and head is polluted.

But that’s not all, in some machines air is also used to operate pneumatic systems, so it is worth distinguishing between the air supply to the cutting machine and for the operation of pneumatics.

Most often, the necessary cleaners are already installed inside the machine; nothing additional is needed.

Advantages and disadvantages

The gas burner is designed for cutting products in production conditions, with a large volume of tasks. Before using the device, it is important to understand what key features metal cutting with propane and oxygen has:

- The mechanism of action is convenient when making curved cutting lines. Stable power allows you to separate metal products of various thicknesses into parts. In situations where it is impossible to use a tool such as an angle grinder, a gas torch is used. The task of making a round product or a blind hole is performed with a gas torch without requiring much effort.

- A gas cutter has an advantage over gasoline models. In addition to being lightweight, the mechanism does not produce excessive noise during operation and is also compact.

- The use of a device based on the influence of flammable gas makes it possible to double the speed of execution, which is beyond the power of mechanical tools.

- Propane, as a liquid gas, has a low price. Therefore, it is used not only when processing products for production needs, but also when recycling metal and other activities.

- The use of propane as a flammable mixture allows for high-quality cutting. Cutting is carried out along a narrow line, which is the main factor in quality work.

The disadvantages are that some materials cannot be processed with a propane cutter, such as cast iron and high-alloy steels.

Oxygen or nitrogen for cutting metal?

Oxygen cutting is the cheapest. Nitrogen cutting is much more expensive, but when processing almost all metals except ferrous metals, we use nitrogen if we want to preserve the properties of the metal.

You CANNOT cut stainless steel with oxygen . If we cut it with oxygen, the material will essentially burn, because combustion is nothing more than oxidation at high temperature, and oxygen is a combustion catalyst. Thus, we make rust from stainless steel, oxidize it, that is, we simply remove all its stainless properties.

And nitrogen is a non-flammable gas, it is inert, nothing burns in it, it performs another function - it protects the metal from oxidation, cools it and removes combustion products from the cut zone.

Ferrous metals are usually cut with oxygen.

Chernukha can also be cut with nitrogen, but this will be too expensive and unprofitable, and since it does not have stainless properties, there is no point in preserving them.

One more nuance - we use nitrogen to cut everything except titanium , which during laser cutting reacts with nitrogen, crumbles, and loses its structure and properties. To cut titanium you need argon .

Scope of application

Oxygen-arc cutting is most in demand during a complex of assembly and construction works, during which it is necessary to use the cutter in a repeated short-term mode, as well as on objects where the use of oxygen cutting is undesirable or completely unacceptable. In particular, this method is relevant for cutting metal under water. The technology is used for manual cutting of steel; it can be used for separating non-ferrous metals and alloyed alloys with small thickness, cast iron, and for batch cutting of similar products.

Manual oxygen-arc welding allows you to create a cut that is characterized by relatively low quality. Surfaces and edges have irregularities, deposits and roughness. Possessing high productivity and efficiency due to additional sources of thermal energy, the technology is often used during dismantling work, as well as work on grinding scrap metal for its subsequent processing.

Metalworking ordered from our company is carried out in the shortest possible time!

Why do you order oxy-fuel cutting from us:

- Creation of products from 1 hour

- Deferred payment to regular customers

- Payment upon delivery is possible

- Product quality complies with GOSTs, TUs and is confirmed by certificates

Gas pressure when cutting metal with a laser

So, the machine has two auxiliary gas connection sockets - an unregulated path for nitrogen or air and an oxygen path with a pressure regulator.

The first goes directly to the working head: that is, just as you set the pressure on the cylinder on the reducer, that’s how it works.

And the second - the oxygen path requires very precise pressure regulation, which is why there is a special regulator made by the Japanese company SMC. It allows you to set precise cutting pressure parameters directly from the program.

When we cut a material, it must first be punched. At the moment of this breakdown, the pressure should be 0.15-0.2 MPa, and during the cutting process, 0.5-0.6 MPa is enough and the machine must regulate this discrepancy in pressure.

If you pierce a material with oxygen at the same pressure as you use to cut it, then splashes of molten metal will fly, because... oxygen, as we found out above, is a combustion catalyst. There are no such problems with nitrogen; you can set the conditional 2 MPa and punch and cut at the same pressure.

Gas pressure regulator in a metal cutter

Returning to the pressure regulator - you cannot apply more than 1 MPa to it; in the best case, it will simply release excess pressure and you will have an excess consumption of oxygen; in the worst case, it will simply fail.

For cutting with nitrogen, the normal pressure is 1.6-1.8 MPa, and with oxygen - 0.5-0.6 MPa, i.e. gas consumption is almost three times less.

However, despite the fact that oxyfuel cutting is cheap, it is complex and requires experience in setting parameters.

A slight deviation in pressure, the wrong nozzle diameter - and you will have a bad cut.

But if you know how to work with oxygen, it turns out more efficiently and cheaper than nitrogen or air.

Speaking of air: what's the catch here?

Oxygen cutting equipment

Cutters

For oxygen cutting using acetylene, equipment for acetylene welding is used, but instead of a welding torch, a gas cutter is used, usually of the injection type, Fig. 6.

Oxygen flows through a hose placed on oxygen nipple 1 into the cutter. Part of the oxygen, passing through valve 2 and injector 10, goes into the mixing chamber 9. The rest of the oxygen (cutting oxygen) is sent to head 5 through valve 3 and tube 4. From the cutter head, cutting oxygen passes through the central channel of the internal nozzle 6 and arrives at the cutting site.

Acetylene is supplied to the cutter through a hose placed on nipple 12. Then acetylene passes through valve 11 and through the grooves of the injector located on its outer surface, enters the mixing chamber 9. Acetylene is sucked into the mixing chamber by oxygen passing through the central hole of the injector. A combustible mixture is formed in the mixing chamber, which passes through tube 8 into the cutter head, from where through the annular gap between the outer nozzle 7 and the inner

mouthpiece 6 comes out. At the exit, the combustible mixture is ignited, and a heating flame is formed.

For manual separation cutting, cutters of the “Flame -62” and RGS -60M types are widely used. The RGS-60M cutter is plug-in; it is attached to the barrels of the Moscow and GS-3 welding torches. Technical characteristics of the “Flame -62” cutter are given in Table 8.

For cutting using gases that replace acetylene, the RZR-62 cutter is used.

In addition to these cutters, the RU-66 universal cutter is also used. The universal cutter is designed for manual cutting using a preheating flame formed by a mixture of acetylene or gases that replace acetylene with oxygen.

The RU-66 cutter is available in three versions: RU – for cutting steel using acetylene and substitute gases as fuel; RUA - for cutting steel using only acetylene as fuel; RUZ – for cutting steel using acetylene substitutes as fuel.

In addition to cutters designed for separation cutting,

There are special-purpose cutters for surface cutting, for example cutters of the RAP-62, RPA-62, and RPK-62 types.

Cutter 321(RAP), Table 9, is used to remove sagging roots of welds, as well as minor defects on castings. Acetylene is used as the fuel gas for this cutter.

RPA-62 and RPK-62 cutters are used to remove defects in welds, for cup-shaped preparation of sheet edges for welding and for removing local defects on castings and rolled products (Table 10).

To cut off the heads of rivets, a RAZ-60 insert cutter is used, which is attached to the barrels of the Moscow and GS-3 burners.

For cutting thick steel (up to 700 mm), a special installation URR-700 is used. This machine is designed for oxygen cutting of castings, rolled products, forgings, cutting off steel castings and cutting large steel scrap.

The installation kit includes: a PP-700 injection cutter, an oxygen ramp of ten cylinders, a ramp oxygen reducer and an acetylene three-cylinder ramp with a conventional cylinder reducer. For heated flames, acetylene is used as a combustible gas.

Portable and stationary machines are designed for separating steel cutting; they are characterized by high productivity and cleanliness of the resulting cut.

The portable Sputnik machine is designed for cutting steel pipes with a diameter of up to 1100 mm. The machine can cut pipes perpendicular to the generatrix or obliquely with beveled edges at an angle of up to 35°. By installing two cutters on the machine, rings can be cut. The machine has a self-propelled trolley with an electric motor and is equipped with a rectifier unit with a magnetic amplifier.

The magnetic amplifier control is located outside the machine.

The ASH machine is stationary, designed for oxygen cutting of steel up to 100 mm thick. The machine is mainly used for cutting parts and blanks of various configurations from sheet steel according to special templates - copiers. Templates can be used to cut blanks for wrenches, flanges, rough flat gears and other parts with a tolerance of 0.3-0.5 mm.

The cutting modes for the AShS-2 machine are listed in Table 11.

The universal gas cutting machine SGU - 1-60 is designed for separation cutting in stationary conditions. This console-type machine with automatic magnetic copying on a steel copier allows you to cut out shaped parts and straight-line cutting of sheets.

Air for metal cutting

If you are going to cut in air, you need to take care of a good filtration system, the cost of which can sometimes reach the cost of the compressor itself.

People think that I’m now going to grab God by the balls, not pay for gas, pay once for a compressor and that’s it – cheap and cheerful. But actually no, air cutting also costs money.

Disadvantages of Using Air to Cut Metal

It’s just a one-time and large investment. And the compressor also needs to be serviced - the oil needs to be changed. And it happens that the filters also fail, it works fine for three months, then suddenly it starts spitting. Condensation is flying from the receiver, that's all. And if you once clogged the duct, then installed air with normal filters, it still won’t help, because you will have to clean the duct itself, blow it with alcohol.

When working with air, you need to very thoroughly clean and dry the air path, because any moisture and oil that flies from the compressor will settle on the protective glasses and you will have to change them several times an hour.

For normal cutting with air, a pressure of 1.6-1.8 MPa is needed, but in order to achieve such an output pressure after all dryers and filtration systems, there must be 20-25 atmospheres before the filters. And such a compressor already costs normal money. Therefore, the cost of a compressor with a good dryer system will be quite expensive.

Think, maybe it’s more profitable for you to take a gasifier with nitrogen and just fill it once a month?

Let's summarize by air

Air is only relevant if you are cutting no more than 1.5 mm and if you are not chasing the color of the edge.

If you cut stainless steel with air, the end will not be white, but will be slightly yellow, since air contains 8-10 percent oxygen.

Air is not free. It's difficult and expensive. For this whole system to work properly, it is worth investing well in it. If you are cutting chernukha, then stainless steel, then one, then the other, then it is better to work with gases.

Security measures

Oxygen-arc cutting of metal belongs to the category of work with an increased fire hazard, which is performed by a cutter from among the electrical or electrical technological personnel. To ensure safety, the equipment is inspected at least once a year, and the work site is provided with primary fire extinguishing equipment. The performer must use a protective mask and special clothing during the technological operation.

see also

- Oxygen flux cutting

Gas equipment and workplace equipment at a metal cutter

- Gas can be supplied in 40 or 70 liter cylinder This is not very convenient, since they have to be changed frequently and additional time is spent on this.

- There is a matrix of cylinders - 25 cylinders tied with hoses. The cylinder matrix lasts longer, but it takes up more space and is more difficult to refill and transport.

- Maybe a gasifier is a large cylinder that contains gas in liquid form. This is why the gas from the gasifier is very pure. Moreover, it is more economical.

You should not chase gas purity three nines (99.999%), four nines (99.9999%). Ninety-nine hundredths (99.99%) is already enough. The rest is redundant, it is not financially feasible and will cost a fortune. OCH (very pure) or OSCh (extra pure) is enough, test it and decide what suits you best.

In the next article we will talk about the control system, software and show you the coolest functions of a metal cutter that greatly simplify the work process.

Basic design of a cutting torch

Design features of the cutter.

Injection or two-pipe cutter

This is the most popular model due to its design. The name “two-pipe” comes from the division of technical oxygen into two streams. This is done to functionally separate the work of oxygen.

The upper flow of oxygen flows at high speed through the nozzle of the internal mouthpiece. This is an extremely important part of the device - it is directly responsible for the metal cutting phase. This flow is regulated by a special valve, which is usually placed on the outer panel.

The second flow of oxygen goes straight to the injector. The operating procedure in the injector chamber is as follows: oxygen enters the chamber under high pressure and at high speed, as a result of which a rarefied pressure zone is formed in this space. Oxygen is injected in this case.

Nominal gas flow.

Through special side holes in the walls of the chamber, flammable gas is drawn into it - in this case it is ejected. The gases are mixed, the velocities are equalized, and as a result, a flow of a mixture of gases is formed at the exit from the chamber, the velocity of which is lower than that of the injected oxygen, but higher than that of the ejected combustible gas.

At the next stage, the formed mixture of gases enters the tip - first into its head, and then exits through the nozzle between the mouthpieces and forms the same flame in the form of a torch, which heats the metal to its combustion temperature. All gas flows are regulated by their own valves on the outside of the housing - for supplying oxygen and separately for supplying flammable gas to the injector.

Injectorless or three-pipe gas cutter

In this case, the device of the gas cutter is more complicated. Oxygen enters it through two tubes, and the third tube is rightfully occupied by flammable gas. In this welding torch, gases are mixed inside the head; there is no chamber here. This system is safer than the two-chamber model.

The fact is that there is no risk of the so-called “reverse strike”, which consists of a very unpleasant and dangerous phenomenon: the penetration of burning gases in the channels and tubes of the device in the opposite direction.

This model has a significantly higher cost. In addition to this drawback, the three-pipe cutter has one more nuance: when working with it, a very high pressure of flammable gas is required - higher than with an injection apparatus.

Service and repair of a metal laser machine

Many people can sell metal cutters, but not everyone has the same experience and knowledge as our managers and service employees.

Perhaps this article contained many terms that were unclear to you, do not be alarmed, we will clearly tell you about all the nuances and teach you how to operate the machine correctly. Our training lasts three days, during which time you will learn everything you need about the structure of the machine and its maintenance, we will teach you how to select settings for different types of materials of different thicknesses and show you how to work with cutting modes that simplify your work and help save time and materials .

We have successful experience working with various industries and therefore can teach you a lot, share our experience and give you unique advice on how to optimally set up your production.

Cutting steel with a gas cutter

The handle of the gas cutting valve is slowly released down - a stream of oxygen is supplied, igniting the molten metal. If a violent reaction immediately begins to occur, then the steel has caught fire and you can continue to gradually increase the oxygen pressure until its stream cuts right through the material. When the reaction does not proceed, the metal is not heated enough to ignite in a stream of oxygen. It is necessary to add oxygen to the heating flame and allow it to heat the steel.

When the oxygen stream begins to cut, the cutter mouthpiece begins to slowly move along the cutting line. In this case, almost all processing products (molten slag, sparks) are blown away by a jet to the rear side of the cutting zone as shown in the video. If this flow comes back or slows down, then you need to reduce the speed of the cutter or stop it and heat the material even more (it is better to work very slowly than to try to cut too quickly). Cutting continues until the intended cut or separation of metal is completed.

How it works

The device for implementing this technology has a very simple structure. This is a steel tube of suitable diameter through which oxygen is supplied. One end of the lance tube is connected through a valve and a flexible hose to an O2 source, and the other is applied to the surface to be treated. To activate the flame, the working end is heated to 1400 °C (an auxiliary heat source is used for this, for example a gas cutter), after which it begins to rapidly oxidize (burn), raising the temperature to 2000 °C and maintaining it without external heating. To ignite the flame, O2 is supplied at low pressure (about 1 atm), which, after the formation of a stable process, rises to operating parameters (5-6 atm).

As noted above, oxygen lance cutting of metals and concrete structures is often used in the metallurgical and construction industries. Using this method, the following operations are performed:

- drilling of metal and reinforced concrete products;

- scrap cutting;

- removal of casting profits;

- separation of thick slabs.

Since working with O2 carries a certain danger, such cutting must be performed using protective equipment: a shield, a mask and special equipment. Read more about the operating features of this gas and precautions in the article: Technical oxygen: production, operation and use in industry.