A chainsaw is a necessary tool for household needs; it can find worthy use in the countryside. A chainsaw is easy to cut wood for a stove or fireplace. It also performs well when felling trees. Every owner of such an assistant should know the correct angle for sharpening chainsaw chains. Calling a specialist to your home, and especially to your dacha, costs a lot of money. Therefore, you have to make do on your own.

Although it is better to entrust sharpening to a professional, some lumberjacks have learned this craft on their own. If wood cutting specialists have to sharpen a chain 3-4 times a day, then an ordinary gardener does not have such a need due to the fact that he rarely uses the tool. How can you master the craft yourself? There are some recommendations for this.

Features of the chainsaw

Cutting wood is similar to working with a plane. In this case, the size of the cut depends on the thickness of the limiter. When the saw chain works hard, the teeth become dull faster. This is clearly manifested when the ground surface appears in the path of the chain. To completely dull the teeth, it is enough to “catch” on the ground for a couple of seconds.

If you sharpen it as often as possible, the chain will last much longer, since very little metal will be removed. In addition to the question of what angle of sharpening the chainsaw chain should be, you should also know this!

Working with a dull tool is undesirable for a number of reasons. First of all, this affects the quality of the cut, and not for the better. Fatigue also quickly sets in, which is felt not only in the hands, but also in the body.

Another reason is unjustified excess fuel consumption. All parts will work in increased mode, which inevitably leads to rapid wear. Performance drops seriously, which also happens when using a defective chain.

How to determine the tooth angle?

When buying a chainsaw, you need to purchase a special template that allows you to check and sharpen the teeth of the saw chain at the required angle. Templates are sold separately and are supplied with the chainsaw. It can be used to control the values of the back angles at the top and end blades, as well as the leading edge of the tooth edge. AliExpress

Figure 2

Visually determining and correcting the angle is highly not recommended, since different sharpening of the teeth will lead to rapid wear of the chain and saw mechanisms.

It is very important to determine the rear angle of the upper blade using a template, since the range of this angle varies from 50° to 60°, and any deviation can lead to increased wear.

In order to measure the sharpening angle, you must perform the following steps:

- Set perpendicular to the chain surface or the flat surface of the tooth edge.

- Align the template in relation to the tooth.

- Place a round file into the template and check the closure.

- If there are deviations of the tooth from the template, it means the angle does not correspond to the sharpening parameters and needs to be straightened.

Determining the angle using measuring instruments is impractical, since measurement methods without a template have a high error, which will affect the quality of the cut and the performance characteristics of the chainsaw.

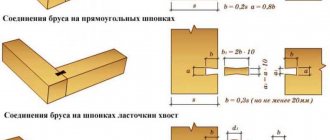

Features of the chain structure

To effectively be able to sharpen a chainsaw chain, you need to know the structure of its teeth. You can’t do without knowing the sharpening angle. Each tooth has a complex structure. Its geometry is represented by the following components:

- basis;

- spatula;

- depth limiter.

In this case, the blade consists of two blades: the end blade and the top blade. Moreover, between them there must be the correct sharpening angle of the chainsaw chain in order to provide it with the necessary performance.

As you can now guess, it is not the chain that cuts the tree, since it serves as the basis for securing the cutting links and moves them at high speed. The links themselves have sharp blades, with the help of which the wood is cut.

Circuit structure and parameters

Before starting work, you should determine the basic characteristics of the chain set. The choice of sharpening method, tool and the need for the procedure depends on this. What to look for:

- Features of the link . It consists of a base, a tooth blade, a depth stop, and two blades. You should carefully inspect each element, identify obvious defects and mechanical damage - they need to be dealt with first;

- Blade angle . It is this that allows the chain to cut wood and determines the volume and shape of wood chips. There should be no defects on it. The parameter of the upper blade varies from 50 to 60o, the end blade – from 60 to 85o;

- The tire profile height can be 0.625 mm or 0.762 mm . When processing limiters, you should fall within this range to reduce vibration of the tool during sawing.

Figure 1 - Types of saw chains

The second most important characteristics are the type of metal and chain pitch. For soft and medium-density materials, a regular file is suitable; it will do an excellent job of sharpening. For hard metal chains with frequent link pitches (from 0.36 inches), it is recommended to use only the machine straightening method.

Important ! The main parameters of the headset and its elements can be found in the operating instructions. Detailed technical specifications are always presented on the manufacturer’s website.

How do you know when sharpening is needed?

You can determine whether the chain teeth have been ground down or not by looking at some characteristic signs. Of course, it all depends on how intensively the chainsaw is used. It’s worth taking a closer look at what kind of shavings it leaves behind. Its uniformity and square shape indicate sharp teeth. If the chain is worn down, it usually leaves behind wood dust, and the sawdust itself resembles the needles that a hand saw “produces.”

If the cutting speed is reduced, then this is also considered a sign of a dull chain. You can feel an increase in the load on the instrument itself and the appearance of vibration. Beginners may not always be able to spot some of these signs. Therefore, they should pay more attention to the quality of the chips. Sometimes it can be brown, which is a guaranteed indication that it’s time to sharpen the chain.

How to sharpen by hand using a file?

Using a file is the easiest and most cost-effective way to correct the sharpness of a cutting edge. The procedure will also require a vice to securely secure the tire in a stationary state. The choice of file type and diameter depends on the characteristics of the chain and the technology of the procedure itself.

Determining the file diameter

It is easier to sharpen a chain with a round file with a holder, the diameter of which is selected depending on the pitch of the links. The table provides information for proper selection of tools.

| Step | File diameter |

| 0,25 | 2×2 |

| 0,325 | 2×2,4 |

| 0,375 | 2×2,6 |

| 0,404 | 2×2,75 |

File parameters

Despite the simplicity of the operation, using a file can ruin the quality of the tire. Useful tips for sharpening:

- primary sharpening is carried out with a round file of different diameters, and to correct the sharpness of the metal, a flat tool is used;

- it should not extend beyond the top of the cutting blade by more than 20%; the same clamping force should be maintained;

- movements are performed from oneself, the number of repetitions should be equal for all teeth;

- to correct the vertical plane, place the file strictly at a right angle;

- horizontal elements are sharpened at an angle of 20-30o.

Figure 5 – Set of files

How to carry out the process yourself at home - step-by-step instructions

You can straighten a chainsaw chain using a file even at home

It is important to choose the right tool and follow the technology. Step-by-step algorithm:

- Secure the tire with a vice so that its upper part is in a horizontal plane.

- Mark the shortest tooth with a marker or nitro enamel - it will serve as a reference point.

- Place the surface of the round file behind the main cutting edge and press it along the entire line. Due to the holder, it will automatically take the required position.

- Without changing the angle, run the tool along the beveled surface 3-4 times. If necessary, rotate the file around its axis to achieve the required sharpness.

- Check the height of the stopper with a special template and adjust the sharpening with a flat file.

Figure 6 – Do-it-yourself chain sharpening using a file

Repeat the manipulation with each link up to the marked reference point. Turn the chain over and sharpen all other teeth in the same way.

Sharpening methods

To sharpen a tool, you can turn to the services of craftsmen who not only know what angle of sharpening chainsaw chains is necessary, but also do all the work quickly and at a professional level. As a rule, the cost of such services is not so high, but the quality, on the contrary, is very high! This option is suitable for those who like to cut wood and have no desire to tinker with their tools.

Everyone else will be interested in trying their hand at this. Professionals in this regard always choose automatic equipment, which is characterized by maximum efficiency and accuracy. Of course, not every lumberjack can afford to purchase it, and therefore they manage in different ways. And here, among many amateurs, there are discussions about which technique is better to give preference:

- manual;

- alternative;

- modern.

You should not neglect the signs of dullness, and at the first need, begin the operation of sharpening the chainsaw chain. This will allow you to use it for as long as possible.

External signs of a dull cutting edge of a chainsaw tooth

Let us recall that a chainsaw tooth has a complex configuration (see Fig. 1), which also depends on the direction of movement of the chain. It has two working edges: a side edge, which is located perpendicular to the axis of movement of the links, and an upper edge, located at a certain angle to the direction of movement of the chain. In addition, a limiter is provided on each tooth, the parameters of which determine the height of the chips removed. Since the main cutting force falls precisely on the working angle, all subsequent work with the tool will depend on the angle to which the tooth is sharpened.

Figure 1 – Functional parts of a chainsaw tooth and their appearance

Before starting long-term work with a chainsaw, it needs to be inspected and test sawed, as a result of which:

- Visually determine the presence (or absence) of a conical section adjacent to the corner of the tooth, as well as a radius rounding on it - the main signs of blunting (see Fig. 2).

Figure 2

- Check the feed force at which the tool operates steadily and produces a quick cut. For sharp teeth, the initial moment of penetration of the tooth into the wood occurs quickly, and without significant resistance to the material.

- Find out the presence of chain vibrations during a steady cut - if they are noticeable, then the teeth need to be sharpened.

- Inspect the appearance of the newly cut end (especially if the tool is used for rip sawing). If there are rough chips and dents, the chainsaw chain must be sharpened.

Correct sharpening angle values

The sharpening angle of chainsaw chains is not a constant value and does not depend on the manufacturer or model of equipment. It is selected taking into account what kind of tree you will be dealing with. You can choose some average value, but the cutting efficiency may be ineffective. For this reason, it is necessary to choose the correct value, taking into account the specific type of wood.

If we are talking about solid wood, including those trees that have been “frozen” for a long time, it has a high resistivity. In this regard, the sharpening angle should be reduced. This will practically avoid the occurrence of vibrations, and the movement of the chain will be softer. The minimum value is 25°.

For soft types of wood, the sharpening angle can be increased, but not more than 35°. This will significantly improve productivity. As for the sharpening angle of the chainsaw chain for rip sawing, the value is 10°. In this case, the cut will be as smooth as possible, and equipment vibration will be minimized. Knowing these features, you can move on to considering different sharpening methods.

Working on the machine

The most convenient way to bring the tool into working condition is to sharpen chainsaw chains on a machine. For these purposes, manufacturers produce manual mechanical machines and electric machines for sharpening chains.

The first are a system of a round file, guides and stops. The device is designed in such a way that it is directly attached to the chainsaw bar. The operator only has to move the file along the guide a few times and move it to a new tooth, all this is done without rearranging the devices.

Using an electric special machine, working is even easier. The chain is removed from the saw and inserted into a special guide, above which a sharpening disc is already positioned at the desired angle. The operator lowers the disc onto each tooth, moving them one by one into the contact area.

We appeal to specialists and everyone who knows how to sharpen chainsaws: share your experience in the comments, write which machines and methods are best to use in this matter.

Manual method

This is the simplest and slowest method for sharpening chain teeth. However, the method is good when sharpening is done on site in the forest. Why not carry a whole machine with you all the time?! But here it’s worth being more precise - we don’t mean one tool, but a whole set, which includes:

- flat file;

- round file;

- sample.

Each of them performs their duties. The main purpose of the flat tool is to sharpen the depth gauge.

A round file already performs the main operation, making the cutting edges sharper. In this case, each chain requires a certain tool diameter:

- pitch ¼ inch - 4 mm;

- pitch 0.325 – 4.8 mm;

- pitch 3/8 inch - 5.2 mm;

- pitch 0.404 - 5.5 mm.

For Picco chains, which are equipped with Shtil 180 chainsaws with 3/8 and quarter inch pitches, a file with a diameter of 4 mm is also suitable. It is important to hold it correctly. With respect to the vertical plane, the file must be positioned strictly perpendicular to the chain, and with respect to the horizontal plane - at a slight angle (about 30°). The specific sharpening angle is selected depending on the needs, but within 25-35°.

Unlike sharpening a chainsaw chain on a machine, the angle here can be set using a template, which is considered a useful assistant. For this purpose, it is equipped with two slots: SOFT/S (for soft wood) and HARD/H (for hard wood). The template must be secured above the chain, which gives it the privileges of a limiter.

Just keep in mind that this method is not intended for permanent use, but serves only as a straightening of the blades. Using a file too often will wear out the chain over time, and the teeth themselves will be sharpened unevenly.

Chainsaw Chain Sharpening Angle Table

How to choose the right chain for a chainsaw?

- How to choose a chain step by step: main rules

- Taking into account the thickness of the tail

- Selection by depth of cut

- Chain length accounting

- Selection by link type

- Sequence of links

- Selection by type of sawing

- Taking into account the material from which the teeth are made

The chain is an important component of any chainsaw. It is she who takes most of the loads, and therefore wears out faster. Very often, the question of how long a chainsaw will last is followed by how to choose a chain for a chainsaw.

Chainsaw diagram.

Many people believe that the performance of a chainsaw depends one hundred percent on its power. But this is far from the case. Performance depends more on which chain you choose for the chainsaw. Specifically, she can find both the quality and speed of sawing. A discrepancy between the characteristics of the leading parts of the saw can make the tool virtually inoperable.

How to choose a chain by step: basic rules

Chain pitch is the distance between the centers of adjacent links. It is one of the main parameters of a chain for chainsaws. In practice, the pitch is measured as the distance between the centers of the first and third rivets, located in order.

The pitch determines the dimensions of the link: the larger the pitch, the greater the length and width of the link. As the pitch increases, the distance between the cutting teeth increases. These incidents lead to the fact that as the step increases, productivity increases, and the force required when sawing increases.

Thus, this parameter is directly related to the power of the chainsaw itself.

The main characteristics of a chainsaw chain.

Chainsaw chains are available in 5 different pitch options. For sharpening round file for sharpening chainsaw chains powermat sharpener for sharpening. This parameter is usually expressed in inches, and its value is indicated on the side of any product. The following steps are used:

- 0,25 (1/4);

- 0,325;

- 0,375 (3/8);

- 0,404;

- 0.75(3/4) inch.

For household chainsaws, chains with a pitch of 0.325 (for 3 hp chainsaws) and 0.375 (4 hp chainsaws) are widely used. A pitch of 0.404 inches is used in professional chainsaws with a power of more than 5.5 hp. Steps of 0.25 and 0.75 inches are currently used very rarely.

Bulgarian is a good alternative

Professional loggers consider this method primitive and labor-intensive. It is used as a last resort, since the angle grinder cannot be fixed to the template. For this reason, it is very difficult to achieve control over maintaining a constant sharpening angle and depth.

The tire is securely fixed in a vice to prevent its mobility during operation. You should not attach a new cutting disc to the grinder; it is better to use an old circle with a thickness of 1.5-2 mm.

It is better for beginners not to use this method at all - they will be safer. There is a risk of causing serious injury to yourself. In addition, there is no way to do this without skills in working with such equipment.

Application of special machines

It is not always possible to use a hand tool with a template. For example, if the cutting edge comes into contact with the ground during operation, there is a possibility of its deformation. In this situation, a special machine is used. The machine comes in two types:

- Mechanical.

- Electric.

The power saw has a design that looks like a bow saw, but with a round file. The machine can be used to level the length of all edges and restore the correct geometry. The machine in question has a complex system for setting processing parameters. Sharpening is performed in approximately 2-3 movements, after which the machine is installed in a new location.

The electric machine is easy to use. A special adjustment system allows you to correctly position the surface to be treated, as well as position the disc with high accuracy. Some models have an automatic vice clamping system when the disk is lowered. The cost of the electric version is slightly higher, but at the same time the performance increases significantly and the most accurate result can be achieved.

Modern method

Almost every non-professional is concerned with the question, what is the angle of sharpening the chainsaw chain on the machine? You won’t be able to use a file all the time, it’s difficult to use an angle grinder, and for beginners this procedure is downright dangerous. There’s nothing you can do about it; you have to use machines that can be either mechanical or electric.

You will have to work for an “eternity” with a manual machine, but you get pleasure from using an electric analogue. Today there are a wide variety of models to choose from that provide

- correct sharpening angle;

- high level of work quality;

- high sharpening speed.

It is also worth noting that sharpening is carried out evenly on all links. All you need to do is turn on the equipment, set the desired angle, enjoy the spectacle, or do other things. The cost of such machines varies from 2 to 4 thousand rubles. But the most important thing is that it will not be difficult to determine the sharpening angle of the Shtil chainsaw chain on the machine.

Although fiddling around with manual equipment is a very lengthy process, it costs several times less. In appearance, the machine resembles a bow saw, only instead of a blade there is a round file. The smallest tooth is also used as the basis. In this case, two or three movements are enough for sharpening, after which you can move on to the next link. If necessary, process the limiter - change the file (round is replaced by a flat one).

How is hand sharpening inferior to machine sharpening?

You can get the hang of it and sharpen a chainsaw chain by hand without much difficulty. But there are some nuances here, because first of all, it is not as effective as sharpening using a machine. The biggest disadvantages of the manual operation of sharpening chain cutting teeth are:

- Difficulty maintaining the required angle. You don’t need to think that you can sharpen a chainsaw chain with just one round file; for this operation you will also need at least a special guide and a second flat file.

- Low speed of operation. It is necessary to attach the guide to the tooth, manipulate it with a round file, check the compliance of the gap of the stopper, if it is necessary to correct it with a flat file, and only then proceed to the next tooth.

- The need to gain experience. Despite the various aids for sharpening a chainsaw by hand, you first need to feel the process, and this requires some experience.

Sharpening rules

Similar sections of each link must be treated uniformly. Otherwise, if there is an excessive selection of metal in any one area, then this ultimately leads to imbalance, unevenness and jerking during operation of the chainsaw. The load on the mechanism increases significantly, which in turn threatens to break the chain.

Therefore, the operation should be carried out at the required angle for sharpening the chain of the Shtil 180 chainsaw (as well as any other tool) with extreme caution, avoiding excessive force. The procedure itself is performed sequentially, that is, you need to start on one side, then finish on the other.

In some cases, you can observe that one cutting edge (or several) has become more sharply ground. This happens when the chain hits a knot on its way, which occurs when cutting hardwood. Then it is necessary to determine which of the teeth has worn down the most and use it to equalize all the other links.

After sharpening is completed, you should blow the chain with air from a compressor or pump, and then place it in a container with engine oil for a short time. Usually few people do this, but it will be useful for the chain.

How to sharpen a chain on a chainsaw with your own hands

Determining when a tool needs servicing is easy. This becomes clear during the work process based on the following signs:

the chips become small;

requires significant effort;

the saw jams;

strong vibration is felt;

cutting time increases.

Taking a closer look at the chain, you can visually verify that the edges do not have the necessary sharpness. Having discovered that the time has come to sharpen them, you cannot postpone this procedure. Firstly, the work becomes unsafe for the performer. Secondly, there is an unwanted load on the power unit. And thirdly, a lot of time is lost, some of which is better spent on sharpening.

The sharpening principle is based on the design features of the link. It consists of a body on which an L-shaped cutting edge is located. The vertical edge is straight, and the horizontal edge is made at an angle. There is a cut depth limiter in front of the tooth. All these elements need processing.

Grinding the cutting part reduces the height of the chain profile. If the height of the stop is not removed at the same time, it will not allow the tooth to sink into the wood to the required depth, so it is also ground down. Editing of the stop is done in significantly smaller volumes.

The cutting edge decreases in height by fractions of a millimeter when sharpened. This is the value you need to focus on when processing the limit stop. For work, you can use a file, an angle grinder (grinder), special mechanical devices and electric tools.

Useful tips

Some helpful tips will help keep your equipment in working order and eliminate the risk of injury. Of course, it is necessary to know the correct angle of sharpening the chain of a Shtil chainsaw. But timely tire care is also important:

- It is necessary to control the chain tension. Especially if the chainsaw tilts to one side during operation. Poor tension can pose a threat to humans.

- Conduct sharpening in a timely manner, without putting everything on the back burner. It may be expensive, but it is better to give preference to electrical equipment.

- Regularly lubricate the entire chain, otherwise it may fly off (its speed is about 100 km/h). Everyone will draw their own conclusions.

- Do not use used motor oil or any product of questionable quality. You should only choose specialized lubricants. As the best remedy - autol.

Before you start using a chainsaw, the chain should be broken in. Let it run at minimum speed for 40-50 seconds. The lubricant will reach every part, and the chains with the sprocket will heat up a little and rub against each other.

All this expert advice should not be ignored if you want to remain safe and sound!

Preventing the chain from becoming dull quickly

You can extend the life of the chain without periodic sharpening if you pay special attention to careful maintenance of the headset. In particular, it is required:

- The use of specialized oil, which must be added when refueling the chainsaw. To select the required concentration, it is recommended to read the instructions for the oil itself.

- All unused volume must be disposed of.

- During operation, it is recommended to periodically check the size of the gap between the stopper and the tooth edge. Ideally it should be 0.7 mm.

- In order to minimize the risk of tooth bending and one-sided abrasion, you can periodically rearrange the tire by 180 degrees.

- The drive sprocket must be lubricated systematically. This must be done before each use of the saw. You can choose the oil that is diluted with gasoline and added to the fuel tank. But the M8 brand has the best performance indicators.

- Monitor tension indicators. The chain should be positioned exactly along the grooves of the bar.

Choosing a tool class for use at home and in the country

A chainsaw is an indispensable assistant in the home and countryside. With its help, you can easily clear a log of knots, cut down a dried tree, take care of a garden, prepare firewood for the heating season, and perform other activities related to wood cutting.

In order to understand which chainsaw to choose, you need to know the operating principle of a technically quite complex tool, and navigate the variety of models offered on the modern construction market. In this case, it is necessary to decide on the expected scale of work, as well as with what intensity and frequency the unit will be used; even the gender of the employee should be taken into account.

So which chainsaw is best for the home? To choose the right unit, you should start by assessing the power of the tool and the duration of continuous operation. According to these parameters, chainsaws are divided into the following classes:

- Household tools. They are not designed to perform large volumes of work and are not very powerful. Using units of this class, it is possible to produce seasonal firewood in small quantities; thick logs cannot be cut. But they are light in weight and have minimal fuel consumption; they are easy to hold and carry. The duration of continuous operation is from forty minutes to an hour per day. This is the kind of chainsaw you can choose for your home.

- Semi-professional class units. With their help, you can saw fairly thick logs lengthwise and crosswise, but carrying the tool is already quite difficult. The engine is of average power and fuel consumption is not very high. The duration of continuous operation in a daily cycle reaches up to ten hours. Such a unit can be chosen for subsidiary farming.

- Professional grade devices. They are characterized by high power, weight and fuel consumption. With the help of chainsaws of this class, you can cut down forest for twenty hours without a break. The materials from which they are made are distinguished by their durability and quality. Such equipment is expensive, so for household work it is better to rent it.

How to sharpen cutting equipment using a grinder and a screwdriver

There are videos online that show the process of sharpening chainsaw chains using a tool such as an angle grinder or simply an angle grinder. The principle of the procedure is similar to the actions when using the machine. However, its only difficulty is that the master needs to independently choose the sharpening angle, and at the same time control the tool, holding it in his hands. It is quite difficult to do this, and even more difficult to carry out the procedure to obtain a high-quality sharpening angle. That is why it is not recommended to implement the process in this way, because it has many disadvantages:

- complexity - what is associated with holding the tool in your hands and simultaneously controlling the sharpening angle;

- there is a high probability of damaging the equipment, since if the teeth are incorrectly sharpened, the chain will cut with less efficiency, or will not cut at all;

- increasing the speed of tooth dulling - the disk on the sharpening machine rotates at a lower speed than the wheel on the grinder. With short contact with the edge, the metal manages to heat up significantly to high temperatures, which leads to its hardening and tempering, and therefore it is possible that a chain sharpened in such conditions will become dull faster (this will lead to accelerated wear).

Using a grinder to restore the quality of teeth sharpening is far from the best option. And resorting to its implementation is not recommended at all. You can watch the video to see how masters do this at home.

As an alternative to using a grinder for sharpening chainsaw accessories, a screwdriver is used. The principle of its implementation is to perform the following actions:

- Clamp a round file in the tool chuck (screwdriver).

- Perform movements with a file, as in the case of the manual method, only additionally rotate it using a screwdriver.

- Pass the rotating file several times, increasing the pressing force when moving away from you, and loosening it, returning it to its original position.

This method cannot be called effective, since there is no question of maintaining the sharpening angle. It has only one advantage - it takes half as much time to implement. It is suitable when you need to quickly complete the procedure. The video below shows how to sharpen a chain on a chainsaw using a screwdriver.

Based on the instructions presented, each sawyer can draw appropriate conclusions about the rationality of each method. Based on the description, you can always keep your instrument in good condition.