Welded mesh is rolled metal made by welding rods or wires laid perpendicularly. The guides always form a right angle, making the cells extremely regular in shape, square or rectangular. The production technology does not limit the diameter of the rods and wires used, it allows the use of light rolled metal as raw materials and heavy reinforcement, which determines the supply of metal products in rolls or cards. The cell sizes are also not limited: from small 3-6 mm long to 200 mm, which provides a wide range of possibilities for the material and its use in various branches of production, farming, and construction.

Externally, the standard “classic” grille is characterized by visual permeability and correct geometry, which allows it to be used for external, facial structures, for example, fences. And its strength and reliability make it a good reinforcing frame for concrete, block, and cement structures.

What are welded mesh and how are they produced?

Welded mesh is a high-quality metal structure of specified geometric dimensions. Welded mesh is made using a special technology from steel rods perpendicularly connected to each other by spot contact welding. This technology ensures maximum reliability of fixation of all elements, guaranteeing strength and durability, as well as the ability of the welded mesh to withstand various harsh conditions.

Certain types of steel are used to make welded wire mesh. Most often, low-carbon steel or stainless steel is used in production, since these types of steel make the welded mesh resistant to water and corrosion. Steel is used because it is cheap and easy to bend and cut.

Workmanship

Before purchasing, a mandatory check of workmanship is required. This approach will maximize the service life and reduce the number of maintenance operations. Main stages of quality control:

- Checking welds. Properly performed resistance welding should not damage the wire. The connection must be strong and the surface must not have visible damage.

- Estimation of cross-section constancy. If high-quality wire is used, there should be no noticeable deviations in thickness. If deviations are observed, the wire may have hidden internal defects.

- Test of strength. The wire must withstand repeated bending. It is not necessary to bend the mesh specifically. All you have to do is start unwinding the roll. If the weld is not damaged, the connection is good.

- Checking documentation. It is recommended to buy a mesh that has a quality certificate. The product passport is not a guarantee of quality. The complete absence of documents is a serious reason to refuse to purchase.

Buying welded steel mesh for building a fence is a successful and affordable purchase. A fence made from such a mesh is highly reliable and does not spoil the landscape. A responsible approach to choosing the type of coating and checking the quality of the product is the key to long, trouble-free operation.

Application options for welded mesh

Welded mesh has a huge range of applications. Despite their lightness and flexibility, welded mesh has a robust design and is durable. This means that welded wire mesh systems are ideal for applications where installation with less flexible wire systems may be difficult, and where meeting the highest standards of durability is paramount. Ready-made welded mesh is much more convenient to use than bar reinforcement, which requires a bundle, which saves time and money when carrying out work. You can use welded mesh when:

- Carrying out plastering work.

- Screeding of floors, ceilings, foundations. When welded mesh is used in this way, it prevents cracking, shedding, and helps maintain the geometric integrity of the building element/structure.

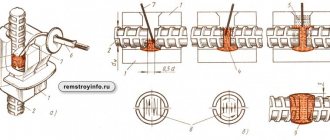

- Installation of brick and block masonry. Reinforcement with welded mesh can significantly increase the strength of the structure, resistance to loads and various adverse effects.

- Road construction to strengthen foundations.

- Laying sidewalks and paths.

- Installation of fencing, fencing.

- Use in agriculture. Welded mesh can be used in the manufacture of cages and pens.

Features and Benefits

A number of features determine the advantages of this type of material over others. These differences actively contributed to the growing popularity of such a grid. When constructing fences, the following advantages are most important:

- Does not degrade the appearance and does not block the surrounding area.

- Not subject to deflection and sagging. During long-term use, the chain-link mesh may sag, which reduces its protective properties and significantly spoils the appearance of the fence. The occurrence of such a defect requires periodic restoration of the fence.

- Ease of installation. Rolls unwind without the use of significant effort. For mounting on poles, use special fastenings available on sale. The chain-link mesh requires preliminary assembly, bending and twisting the ends of each piece of wire, and high-quality tension before fixing it on the posts. The welded structure is immediately ready for installation.

- Relatively small mass. The necessary protective properties are also ensured when using a sufficiently thin wire. Light weight not only simplifies installation, but also has a positive effect on the durability of the structure, since the load on the supporting poles is reduced.

- Acceptable price. The enterprises have established mass production using automation at all stages. Reducing labor costs during manufacturing allows us to maintain an attractive level of retail prices for the product.

- High strength. The rigidity of the structure is achieved not only by the use of steel wire, but also by the use of welding to connect the elements of the material.

Advantages of using welded mesh

- High strength. Welded mesh is resistant to deformation, stretching, and tearing. Due to the increased diameter of the steel rod, it is able to withstand significant loads while maintaining the specified cell geometry. The strength of the welded mesh is affected by the steel core and its thickness. The strength of welded mesh is proportional to the diameter of the wire and inversely proportional to the mesh size - large cells make the mesh “weak”.

- Resistance to various weather factors and temperature changes. These characteristics make it possible to use welded mesh outside buildings (on the street), inside wet, unheated rooms.

- Moisture resistance. The galvanized coating protects the masonry mesh from corrosion.

- Compatibility and excellent adhesion with any mortar mixtures, including concrete. Reliable adhesion ensures the durability of the reinforced structure, the absence of peeling and destruction.

- Compliance with sanitary standards, environmental friendliness.

Do-it-yourself mesh installation

To construct a chain-link structure, it is recommended to use one of two methods: tension or sectional.

Based on the experience of specialists, it can be argued that the simplest method is tension. To make a fence using the tension method, you should purchase chain-link in rolls. Posts for future fencing can be wooden, iron, reinforced concrete or asbestos-cement. And, of course, we must not forget about the wire.

Welded mesh coating options

Welded mesh differs in cell sizes, wire diameter and metal processing method. In other words, the choice of welded mesh for different tasks is carried out based on the type of surface treatment and cell size. The presence of a protective coating extends the service life of the welded mesh and allows long-term use in open spaces.

- Non-galvanized welded mesh is a simple and cheap option and is used where aesthetics are not required. For example, when pouring a floor, in masonry, when equipping entrances. But when used in conditions exposed to atmospheric precipitation, non-galvanized mesh requires painting, otherwise it will rust and lose its characteristics over time.

- On the contrary, welded galvanized mesh is protected from corrosion, durable, and has a high degree of aesthetics, which is why it is often used in the construction of fences. Stainless steel is considered durable, aesthetically pleasing and reliable, even when used in damp conditions. Buying welded mesh of this type will be more expensive, but you are guaranteed to get quality and durability.

Welded stainless steel mesh is produced using special production technologies:

- galvanic galvanizing is the process of applying a protective layer up to 20 microns by electrochemical action on the workpiece.

Hot-dip galvanizing is a complex technological process that allows you to achieve protection of 60 microns. This technology provides a high degree of corrosion protection even in the event of mechanical damage.

For additional protection, the mesh is not only galvanized, but also covered with an additional layer of polymer protection, which is done after welding. This not only adds aesthetics, but also extends service life, increasing the degree of corrosion protection. Welded mesh with a polymer coating is not afraid of a chemically active environment. Using this material, you can equip a fence made of welded mesh, as well as partitions in warehouses and enterprises. The production process involves dipping the mesh into a polymer solution, which creates a layer on its surface of about 0.5 m.

Advantages and disadvantages

It is easy to judge the pros and cons of metal structures due to their popularity.

Advantages:

- Price – low compared to other fencing;

- Easy and simple installation;

- Possibility of use for large areas;

- Good strength;

- Can be painted;

- Durability;

- After dismantling, the mesh remains reusable;

- Does not interfere with air circulation;

- Does not create shade for plants;

- Reliability. You can put barbed wire or an electric fence along the top;

- Convenient territory marking;

- Can be used as a frame;

- It is convenient to clean off dirt with water.

Flaws:

- It is difficult to create high fences;

- Through such a fence, the entire site becomes visible, which not all owners like;

- Many people consider metal mesh to be an outdated fencing option.

Types of welded mesh

The production of welded mesh involves several options for the production of finished products. It is possible to purchase welded mesh in the following formats.

Welded mesh in roll

Welded mesh in a roll has maximum flexibility, which allows it to be rolled into rolls due to the smaller wire diameter. Due to the fact that welded mesh in rolls allows for quick installation and also meets many requirements and construction standards, this material is often used for the construction of fences.

You can view the welded mesh in rolls available for sale or compare them here.

Welded mesh in cards

With this option, the welded mesh is made in a rectangular shape. The diameter of the wire used here is larger, so the rigidity is higher.

The grid in maps is often used at various stages of construction:

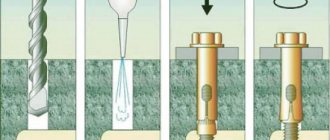

When pouring the floor. In order to prepare rough and finishing bases in the form of a floor screed, reinforcement is necessary; this is where welded mesh is used, which is an inexpensive and durable material. When laying building blocks and bricks. We are talking about building houses. Here it is customary to reinforce every fourth row using 8 mm reinforcement or masonry mesh, which is selected according to the thickness of the block. It is easier to work with masonry mesh, the wire diameter of which is 1.6-1.8 mm, since it is equally suitable for both glue and cement mortar. During road construction. The use of welded mesh allows you to increase the strength of concrete and paths on the territory of private houses.

You can view the welded mesh available for sale in maps or compare them here.

Masonry nets

Reinforced mesh for masonry walls or masonry mesh is used in construction as a reinforcing element when creating reinforced concrete structures, erecting walls, pouring floors and foundations to strengthen the structure. The use of masonry mesh allows you to increase the strength of the wall without increasing its thickness. The reinforced mesh with high tensile strength can be bent without damage, and also has anti-corrosion properties and a long service life.

You can view existing masonry nets for sale or compare them here.

Expanded metal mesh TsPVS

All-metal expanded metal mesh (TSPVS) is a metal sheet, evenly cut and stretched into diamond-shaped, staggered cells. Cold-rolled sheet metal with a zinc coating is used for the manufacture of CPVA. TsPVS mesh is a relatively new material on the market, but has already established itself as a cheaper analogue of chain-link mesh and welded wire mesh. The TsPVS mesh is easy to cut, has a lower specific gravity, and is visually aesthetic. TsPVS meshes are used for:

- Reinforcement when performing plastering work.

- Reinforcement when laying tiles, stone and similar building materials.

- Reinforcement during facade work and application of thermal insulation coatings.

- Fencing garden plots, making cages for pets.

- Production of screens for heating radiators and ventilation grilles.

- Manufacture of fencing for electromechanical devices, thermal insulation of pipes.

- Guards for bins, trailers, conveyors, etc.

- Cutting off concrete at the stage of roof installation.

- In interior design.

The special shape of the TsPVS mesh gives it rigidity, and the absence of welds eliminates the presence of vulnerable areas in which the process of structural destruction begins. Due to its shape, moisture and foreign contaminants do not accumulate in the mesh fabric, which eliminates the appearance of pockets of corrosion.

You can view the commercially available CPVA meshes or compare them here.

Welded mesh with PVC coating

PVC coated welded mesh with plastic coating is made of high quality galvanized iron wire. A smooth plastic coating is attached to the anti-corrosion coating using strong adhesive, which increases the service life of the wire. Welded mesh with PVC coating is used for fencing residential and public buildings, such as gardens, parks, and other buildings. You can buy PVC-coated welded mesh in the form of rolls and panels, as well as in various colors.

Areas of application

Welded mesh is used to solve a wide variety of industrial problems. And the number of applications will only expand over time. Here are just a few of the areas:

- Construction. The material is used for reinforcing walls and facades of buildings, and is used for the construction of reinforced belts in order to evenly distribute the load from load-bearing structures and walls. Pools have strong and durable walls using reinforcement. A powerful mesh is laid under heavy stone flooring.

- Men at work. Laying a massive mesh under an asphalt concrete pavement allows you to increase the service life of the roadway due to a significant increase in resistance to increased mechanical loads. The material will not allow the road surface to collapse as a result of impact loads and natural soil movements. The mesh is also used as a base for laying paving slabs in urban pedestrian areas and paths in suburban areas.

- Agriculture. The durable welded structure is not only ideal for fencing pastures and fields, but can also be used as a building material. It is used to make both large pens and small cages for keeping animals and birds.

- Arranging fencing is the most popular method of use. Welded mesh for fences is most widespread among owners of summer cottages. This type has become a good alternative to the use of traditional Rabitz mesh.

Welded mesh sizes

The overall dimensions of the welded mesh depend on the type of product selected. For example, the most popular welded mesh widths in cards are 0.25m, 0.5m, 1m, 1.5m and 2m. The length of the masonry mesh is usually 2m or 3m.

A roll of welded mesh is usually 50m long and 1m or 1.5m wide.

CPVA mesh is packaged in rolls 4m, 8m or 10m long. The roll width is 1.25m.

Regardless of the type, the following welded mesh cell sizes (mm) are distinguished: 15x6, 25x10, 25x25, 50x20, 50x25, 50x50, 100x100, 150x150, 200x200. The diameter of the welded mesh wire also varies and has values of 0.5, 1, 1.6, 3 or 4 millimeters.

Marking

XC d/d1 bxL –

structural formula shows how mesh products are labeled.

X

is a designation for one of five types (listed above).

WITH

– welded mesh,

Wed

– rolled product.

Designations d, d1 –

dimensions of the diameters of the rods located lengthwise and transversely.

B, L

show the dimensions of the map.

Where to buy welded mesh in Voronezh at wholesale prices

To perform certain construction work, you will need the appropriate types and sizes of welded mesh. When purchasing welded mesh, you must consider:

- Intended use of welded mesh.

- Effective permanent and temporary loads.

- Dimensions.

- Regulatory requirements for the placement of welded mesh.

Depending on the purpose and overall dimensions, as well as the cell size of the welded mesh, the price varies significantly. You can choose a suitable welded mesh at low wholesale retail prices in the EVERYTHING IN THE HOUSE online store. We guarantee low prices for welded mesh, and our offers contain cheap prices for welded mesh.

You can also clarify the possibility of reducing the price of welded mesh by contacting the manager by phone or ordering a call back. Delivery options for welded mesh can be selected during the ordering process or interaction with the manager.

Direct link to compare the characteristics of different types of welded mesh here.

What factors to consider when purchasing?

Before building a house or any structure, design calculations are first drawn up, where the required dimensions and diameters of the reinforcement will be laid down. And this is correct, but if there is no project, then when purchasing you can pay attention to approximate calculations and general patterns.

- The minimum total cross-sectional area of longitudinal prestressing reinforcement will be equal to 0.1% of the sectional area of the concrete structure. It's minimum. For example: the height of the reinforced concrete tape is 500 mm, the width is 300 mm, which means the area of the working rods is 150 mm2.

- We divide the resulting total area of the reinforcement by their number (4, 6,

we obtain the size d of the prestressed reinforcement.

we obtain the size d of the prestressed reinforcement. - The rods in each direction must have the same section size.

- If the product is assembled from rods of different diameters, then their difference should not be too great, the diameter ratio should not be more than 0.25.

- According to GOST 23279-2012, if the product is mounted from smooth, non-profiled A240 (A1), then all cross-shaped joints must be welded. If the steel is profiled, in a rod or wire version, it is allowed per 1 sq. meter of product no more than 2 intersection points without welding.

Find out also about choosing a mesh for a dog's enclosure and choosing a mesh for concrete.

Necessary materials

Before installing the fence, you need to know exactly how much mesh you will need. To do this, arm yourself with a tape measure and walk around the perimeter, measuring it. This way, you will accurately determine the amount of material you need to purchase.

How to calculate the number of pillars so that the fence is as strong as possible? Remember: one post should be installed for every 2.5 m. Plus add more posts for installing gates and gates.

The height of the fence and posts must match. And the value of the height is a matter of choice for each site owner.

Choose fencing material that is durable, reliable and corrosion-resistant. But here it is more about the financial side. Each person chooses a mesh fence according to his capabilities.

Wooden poles are considered to be the most budget-friendly option. Hooks intended for hanging chain-link are attached to them. It is better to make sure that the columns are slightly higher than the grid or are the same in height.

We recommend giving preference to a mesh made of wire 2 mm thick. And don't forget about the anti-corrosion coating.