Types of grinding machines

When working closely with wooden parts and objects, the craftsman needs to know what types of wood sanding machines there are in order to select the most optimal device for himself.

Based on the design principle, types of wood sanding machines are divided into 3 types: belt (grinder), disk, drum.

- The band press is considered the most common. The abrasive coated belt is mounted on two shafts, which are driven by an asynchronous motor. In this case, the grinding element can be located in a horizontal or vertical position. During operation, the tape does not sag, but processes the wood without generating a large friction force. This design can be used when processing long parts.

- The disk unit, or as it is also called a disc grinding machine, is equipped with an axis to which an abrasive wheel is attached. During operation, the disk begins to rotate around its axis. During operation, you can adjust the speed of the wheel with an abrasive coating without reducing the speed of the axis itself.

- The disk unit, or as it is also called a disc grinding machine, is equipped with an axis to which an abrasive wheel is attached. During operation, the disk begins to rotate around its axis. During operation, you can adjust the speed of the wheel with an abrasive coating without reducing the speed of the axis itself.

- The drum machine is designed in such a way that abrasive belts in the form of a spiral are wound onto adjacent rollers. In turn, these elements are spaced a certain distance from a flat surface (table top). By adjusting this distance, you can calibrate the wooden parts.

There are other types of portable sanders. Drills and screwdrivers are often equipped with special attachments with abrasive coating.

The device and principle of operation in each version is different from each other. At the same time, the wood will be processed differently.

The easiest way to create a disc sander. But a homemade sharpening and grinding machine, based on a belt design, will be much more functional and in demand in the home workshop than any other.

Submersible evaporator for chiller

A plate evaporator is used for more powerful installations, usually with a cooling capacity of 10-15 kW, since with such powers a submersible (twisted) evaporator will be too bulky and will require a large container, which must be completely filled with cooled liquid, which is often the case in a production line not provided. Or the container should be inside the chiller, which, compared to a plate heat exchanger, will increase the dimensions of the chiller several times.

And in the production of industrial chillers with capacities over 150-200 kW, as a rule, shell-and-tube evaporators are used.

To a client wishing to buy an industrial chiller, the chiller manufacturer recommends one or another type of evaporator, indicating the pros and cons of its use.

The compressor-condensing unit for the production of a chiller can be taken in fact, almost any one in which the compressor corresponds to the temperature regime and the required cooling capacity (medium or low temperature). If this is a former air conditioner (or rather a split system), then you can unsolder the three-way valve and connect everything directly, if you do not need a heat pump function, as in a standard refrigeration unit - KM-KD-Receiver-TRV. And instead of an electronic board with a remote control designed for a split system, install conventional automatic motors and starters, block pressure switches, as well as a microprocessor controller with a temperature sensor.

The Internet is replete with various manuals and videos on how to make a chiller yourself; there are two main points that are often not mentioned anywhere, although their understanding is critical for high-quality assembly of the chiller.

Most often, those who want to assemble a chiller themselves use a submersible - twisted evaporator, as the cheapest and simplest option that can be made independently. The question is mainly about the correct manufacture of the evaporator, regarding the power of the compressor, the choice of the diameter and length of the pipe from which the future heat exchanger will be made.

To select a pipe and its quantity, you need to use a thermal engineering calculation, which can be easily found on the Internet. For those who do not want to make an accurate thermal calculation of the evaporator, for some reason, fixed power values will be given below. For the production of chillers with a power of up to 15 kW, with a twisted evaporator, the following diameters of copper pipes are most applicable: 1/2; 5/8; 3/4. Pipes with a large diameter (from 7/8) are very difficult to bend without special machines, so they are rarely used for submersible evaporators. The most optimal in terms of ease of use and power per 1 meter of length is a 5/8 pipe. Under no circumstances should an approximate calculation of the pipe length be allowed. If the chiller evaporator is not manufactured correctly, then it will not be possible to achieve either the required superheat, the required subcooling, or the freon boiling pressure, as a result the chiller will not work efficiently or will not cool at all.

Below are data on the thermal power that one meter of pipe can transmit. The data are not reference data, they were obtained by a combination of thermal engineering calculations and an empirical method, but at the same time they have been successfully used in the calculation of submersible evaporators for many years. The power values include a margin of ~3%.

Chiller evaporator data:

— Pipe 3/8 ~ 0.14 kW/1 meter of pipe = 0.029 m2 of heat transfer surface.

— Pipe 1/2 ~ 0.19 kW/1 meter of pipe = 0.039 m2 of heat transfer surface.

— Pipe 5/8 ~ 0.25 kW/1 meter of pipe = 0.049 m2 of heat transfer surface.

— Pipe 3/4 ~ 0.29 kW/1 meter of pipe = 0.059 m2 of heat transfer surface.

— Pipe 7/8 ~ 0.33 kW/1 meter of pipe = 0.069 m2 of heat transfer surface.

In practice, we have not used pipes with a diameter of more than 7/8 in the production of industrial chillers.

Also, one more nuance, since the cooled medium is water (most often), then the boiling point when (using water) should not be lower than -9C, with a delta of no more than 10K between the boiling point of freon and the temperature of the cooled water. In this regard, the low pressure emergency relay should be set to an emergency level not lower than the pressure of the freon used, at its boiling point -9C. Otherwise, if there is an error in the controller sensor and the water temperature drops below +1C, the water will begin to freeze on the evaporator, which will reduce and, over time, reduce its heat exchange function to almost zero - the water cooler will not work correctly.

Grinder and sharpener: a brief comparison

A belt grinder and a sharpener are analog devices, as they perform almost the same functions. But there are also differences in the quality of processing and design. The grinder has several advantages that a regular sharpening machine cannot boast of. This:

- precise processing geometry;

- simple replacement of abrasive tape;

- versatility of use.

Please note that due to the presence of a shaft and rollers, the tape becomes perfectly level. This makes it possible to more accurately position the workpiece for processing. As a result of cleaning parts, defects, nicks and burrs do not appear (this often happens when processing metal parts with a grinding wheel).

The grinder belt is made from strong sandpaper. For belt grinders, many belt options are sold with different abrasiveness. Having a whole set of them on the farm, you can perform work of varying complexity.

Direct assembly process

You can assemble a tire changing machine as follows:

- To make the frame you will need durable profile pipes. They will serve as an excellent basis for the machine.

- A distance of at least 700 millimeters must be maintained between pipes. This ensures the stability of the structure during operation.

- The parallel arrangement of pipes is ensured by using an angle. In addition, they are used to strengthen the structure.

- If desired, you can complement the design with adjustable legs. You can make the device mobile by installing wheels or rollers; in working condition, fixation is carried out using stoppers.

- After creating the base, the metal pipe is fastened. It is recommended to choose a version with a diameter of 20-30 millimeters. A flange is installed at a height of 40–60 centimeters before welding work.

- The next step is to attach the fastening element, which is represented by a steel plate. It will be used as a base when attaching the lever.

- The lever is represented by a design consisting of a shoulder and a paw. The paw is used for direct tire removal.

It is practically impossible to assemble a structure without a welding machine. In addition, the metal should be protected from environmental influences by painting the surface.

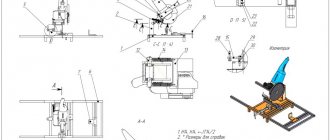

Schematic diagram of the grinder design and the principle of its operation

In order to correctly understand the structure and operating principle of the grinder, let us turn to its structure. The main task is to find a powerful motor that will need to be equipped with a drive.

Important! The torque is transmitted to the rollers, which drive the abrasive belt.

Appearance of the grinder

So, the main elements of the grinder, in addition to the engine, are:

- Straight roller with pulley.

- Tension rollers.

- Abrasive tape.

- Base.

- A device that fixes the tension of the belt and rollers.

- Table for fixing the part (in some models it can be rotary).

After connecting the device to the network, the rollers set the abrasive belt in motion. Moreover, the position of the rollers can be shifted to control the tension of the abrasive belt.

In some cases the table can be rotated 180°

When assembling the grinder yourself, it is important to position the rollers strictly perpendicular to each other to avoid distortions of the belt, which can lead to its breaks.

Advice! Before deciding on the size of the belt and the width of the rollers, figure out what surfaces you plan to process, their dimensions and volume of work.

Using Sandpaper

You can also quickly sharpen scissors using sandpaper. To carry out the work, you only need paper with any size of abrasive. The sharpening process in this case is quite simple.

A sheet of sandpaper should be folded in half. The abrasive surface must be outside .

The folded paper is placed between the two separated parts of the scissors, after which several cuts should be made.

This method is only suitable for cases where there is not enough time to fully sharpen the surface. After some time, the cutting part will become dull again.

Advantages and disadvantages

The advantages of grinding machines include:

- Quality and speed of processing.

- High performance.

- The ability to obtain the surface of the desired roughness.

- The ability to process not only the wood itself, but also pre-grind the finishing layer.

The disadvantages are:

- Release of a large amount of dust, requiring the organization of a dust removal system.

- Large quantities of consumables (abrasive) of several sizes.

- Difficult to manufacture and maintain (this especially applies to belt installations).

Considering the existing shortcomings, before starting assembly, you need to decide how necessary the machine is. If it will be used only occasionally, it is not practical to spend time on manufacturing - you can get by with hand tools.

Sharpening methods

Before sharpening scissors, you need to understand the features of their use. The methods used for knives are not suitable in this case. This is due to the use of the edge cutting method, which requires sharpening angles of 300 or more.

Smaller edge angles are bad because the blade becomes dull faster and the cutting process is simplified. An important feature of the tool is the need to maintain the factory angle, since the design is adjusted to it.

You can sharpen the blades of the tool using the following methods:

- On a special machine. High quality processing, productivity.

- On the grindstone. The method is painstaking and difficult to implement due to the low accuracy of the sharpening angle.

- Sharpening stone. Simplicity and accessibility of the method. Turning is only possible on a perfectly flat surface, angle control is difficult, and grinding speed is low.

To quickly sharpen scissors, you can use the following tools and methods:

- foil;

- bottle;

- with a pin;

- by sharpening with a needle.

Sharpening scissors on a machine

Advantages of a homemade machine

A belt grinder can be purchased at any hardware store, but a hand-assembled machine has many advantages for the owner:

- Minimum costs for labor and materials.

- The ability to independently prepare a drawing (or use a ready-made project) with the proper dimensions, type of design and principle of operation.

- Most consumables are available in every craftsman's household; you just have to search in your own barn, pantry, or garage.

- The missing elements and accessories can be purchased at a construction supply store (fastening clips, guide and drive rollers, sanding belt). You can also make rollers for the grinder yourself.

- A large collection of videos on assembling a grinder with your own hands from scrap materials.

Masters are always presented with web portals with a large number of step-by-step instructions on how to make a grinder with your own hands, diagrams and ready-made drawings, and practical advice.

Drawing of a belt grinder tensioner for DIY assembly

Drawing of a belt grinder tensioner mechanism for DIY assembly

The support table and thrust platform of the Host belt grinder are made of 6 mm thick steel using welding and subsequent grinding of the seams. You will also need an M8x1.2 tap; the holes for this thread are marked with a diameter of 6.8 mm. As a thrust element of the grinder, we recommend using porcelain tiles; they have proven themselves better than high-alloy steel or cast iron, because... its density and durability are higher.

Possible uses of the grinder

An installation of this type, industrial or homemade, has several main areas of practical use. A well-assembled structure can be used in the following cases:

Processing of metal sheets after cutting (for example, additional processing of sheet iron before assembling a certain structure). Using a grinder belt allows you to get rid of sharp nicks, scale, and irregularities.

Sanding wooden surfaces in the manufacture of furniture (or its restoration), picture and mirror frames. All wood parts can be processed with a plane, but the quality of sanding in this case depends entirely on the skills and practical skills of the craftsman.

When using a grinding machine, a belt moving evenly along the axis produces high-quality processing, removing all roughness, nicks, and sharp knots.

Sharpening knives and scissors. Very often you have to deal with the problem of a dull kitchen knife or textile scissors. This issue is especially relevant for seamstresses who operate from home. In such cases, having a sanding machine on hand will be an obvious advantage.

Today there is a wide variety of professions and hobbies. Most of them require specialized tools, including a grinder.

You can assemble a machine of this type with your own hands, using step-by-step instructions and a series of video tutorials. Drawings with dimensions and videos on assembling a grinder with your own hands can be found on practical construction web portals.

What is a grinder

A homemade grinder, assembled with your own hands, is a stationary machine that has a main belt for grinding parts. With the help of two rollers (drive and guide), the tape rotates around a certain axis.

The number of revolutions depends on the power of the design, the motor (drive) used and the quality of self-assembly. On the lower contour, such accessories have several clamps, with the help of which the machine is secured to a workbench or other working surface.

Often, clamps for fastening are additionally mounted on the side contour (reliable fastening allows for optimal processing, without gross defects).

Drawings with the dimensions of a simple grinder for do-it-yourself work will allow you to optimally observe the basic principles of the design, ensuring the further operation of the machine.

Grinder “from Chapai” - a brief overview

Grinders from Andrey Chapai have already become a household name. Hundreds and thousands of samples of grinding machines “from Chapay” have settled in the workshops of craftsmen in Russia and neighboring countries. The peculiarity of GCs (grinders from Chapai) is that they are universal and are created based on the needs of the customer: for sharpening knives or processing wood, with or without a certain type of engine. There are both mobile versions for home processing of products, and professional models.

Grinder “from Chapaya” is a universal machine for processing complex-shaped products made of metal, plastic and wood

You can buy a product, as they say, “turnkey”, or you can choose a modest set of tools and equipment.

At the moment, the most popular models of MGs are: GC-10, GC-12, GC-16 (professional series), as well as new mobile versions of the grinder 610 series GC610-63 and GC610 -71" - manufactured with zinc coating

General points characteristic of all machines:

- All mating surfaces of the grinder are polished. This helps to eliminate distortions during the running of the belt.

- Grinders come without painting or coating. The surfaces of the MS (short for grinder from Chapai) work for sliding. To prevent corrosion of the product, it is enough to periodically wipe it with a special oil or silicone spray.

- Unique pressure pad design.

I would like to dwell on the last point in more detail. The master came up with a unique design for this platform with the same size of 165x50 mm, there are 2 rotation positions for the base and two stop positions for the frame.

Options for rotating the pressure table and attaching it to the stop

Additionally, the set of tools and equipment includes a wheel for installation instead of the drive roller. It is recommended to be used when working on metal, when large amounts of paint or rust have to be removed.

Turning wheel with polyurethane coating, it is very convenient when adjusting and grinding concave slopes of products

Let's take a closer look at one of the professional models. The GC-16 is made on a reinforced rotary frame with 2 racks made of 12 mm thick sheet, which provides the necessary rigidity and allows you to quickly move the grinder to a vertical or horizontal position.

Grinder “from Chapai” – GCH -16. Appearance:

The design uses an enlarged sanding belt - 1600−1800×50 mm. And a fairly powerful engine - 2.2 kW. The machine has higher productivity and is ideal for continuous work in large industrial production. The price of such a product currently varies from 55,000 to 60,000 rubles.

Description of industrial chiller

Chiller (water-cooling machine) is a device for cooling liquid through a vapor-compression or absorption refrigeration cycle. After the temperature has decreased, the liquid is used to cool the air in the heat exchanger (fan coil) or to remove heat from equipment.

Operating principle of an industrial chiller

The device is used in various industries. A cooling unit in a connected system with a fan coil is used in some models of air conditioners.

Operating principle of an industrial refrigeration plant

In production, special absorption chillers are used as a rapid heat removal unit. It is necessary to ensure the operation of various industrial equipment that generates heat. The chiller selects and removes excess heat and maintains the optimal temperature and thermal conditions of the equipment. Lithium bromide in water is used in industrial installations as a liquid that absorbs gas in full.

During the cooling process of water, excess heat is released, which is released into the environment.

The industrial installation consists of two blocks:

- top - generating hot container with relatively high pressure;

- lower - includes an evaporation tank and a section with an absorbent.

Nature of operation of the installation:

- The heat from the generator affects the absorbent, which releases water vapor.

- The steam is transferred to the condenser and turns into a liquid state, giving off heat to a special reservoir of water.

- Having lost heat, water from the condenser is supplied to the evaporator.

- Here the water evaporates under pressure, absorbing heat from the refrigerated circuit (chiller).

- By pumping boiling water through a pumping unit, heat transfer is enhanced.

- At this time, the remaining absorbent concentrate is transferred to the absorber, where gas is absorbed from the evaporator and heat is released.

- The exhaust circuit removes heat from the absorbent container outside the installation.

- After the heat is removed, the resulting water and absorbent are again transferred to the generator.

Advantages of chillers over compression refrigerators:

- small amount of energy consumed;

- low noise emission during operation;

- environmental friendliness, because the working substance is plain water, not freon;

- absorb the released energy;

- long period of effective operation;

- industrial safety;

- ease of control.

Flaws:

- price;

- the need for a source of hot energy;

- heavy weight;

- high water consumption of the system.

Chiller for beer production

Water cooling machines are actively used in beer production. It is used to cool the wort. When receiving malt liquor, you need to quickly reduce the temperature. The quality of the drink depends on this. This broth contains beneficial and harmful bacteria. Beneficial elements are preserved at temperatures above 60°C, and all harmful bacteria die. But with slow cooling after 60°C, the likelihood of the appearance of harmful microorganisms increases. Therefore, it is necessary to reduce the temperature quickly.

The importance of the speed of the production process is also reflected in the fact that the fermentation process and the addition of yeast can only be carried out at a favorable temperature of about 20°C.

When the broth cools slowly, a large number of bacteria are formed. Yeast, when added, will not be able to absorb excess microorganisms. The drink will be spoiled. Slow cooling also impairs the commercial quality of the product.

Do-it-yourself grinder at home - text and video instructions

Now let’s look at step-by-step instructions for making a grinder with your own hands.

Homemade grinder with a washing machine engine

| Illustration | Description of action |

| To operate, you will need a regular asynchronous motor from an old washing machine. | |

| To operate, you will need a regular asynchronous motor from an old washing machine. | |

| We weld two steel plates to the motor, with washers on them. The fasteners will help us install the motor firmly and safely on the frame. | |

| To work, you will also need an abrasive belt, in our case - 610x45 mm (the width was cut to fit our rollers). | |

| To work, you will also need an abrasive belt, in our case - 610x45 mm (the width was cut to fit our rollers). | |

| We will need lugs, a bolt and a roller to create a regulating mechanism to control the position of the rollers during operation. | |

| We begin welding the roller fastening mechanism. | |

| We begin welding the roller fastening mechanism. | |

| We weld a metal sheet with a slot for the motor to the frame. | |

| On the other side of the structure we attach a metal corner to firmly fix the engine. | |

| On the other side of the structure we attach a metal corner to firmly fix the engine. | |

| We install a bowl-shaped pulley on the motor shaft; it will be fixed to the keyed phase. | |

| We grind the rollers with spacer bushings in advance and install bearings in them. | |

| We grind the rollers with spacer bushings in advance and install bearings in them. | |

| Based on the tension of the tape, we try on the installation location of the retaining mechanism for the driven roller, mark the fastening points, and align the structure so that the tape is sufficiently tensioned. | |

| We drill a hole for fastening the bolt, which will hold the entire structure in the future. | |

| We drill a hole for fastening the bolt, which will hold the entire structure in the future. | |

| The bolt will allow for more precise adjustment of belt tension in the future. | |

| Our bolt allows the structure to function like a pendulum, which means it is easy to control the tension of the sanding belt. | |

| Our bolt allows the structure to function like a pendulum, which means it is easy to control the tension of the sanding belt. | |

| And with the help of this handle with a bolt, we can adjust the position of the rollers relative to each other, and this can be done even while the machine is running. | |

| To adjust the tension of the tape, furniture gas pressure is used. |

A grinder of this type will easily help sharpen dull drills or small ones.

Grinder for drill

A grinder for a drill is a special attachment that can be made in several stages. There are hundreds of options for what it could be. We chose a non-standard model.

| Illustration | Description of action |

| To work, you will need a shaft with gears, bearings and sheet metal. | |

| To work, you will need a shaft with gears, bearings and sheet metal. | |

| We cut out two plates measuring 110x250 mm. | |

| We drill the necessary holes on each of the plates. | |

| We drill the necessary holes on each of the plates. | |

| In this part the bearings will be fed for adjustment. | |

| Next, take the “hairpin” and cut it into 120 mm pieces. | |

| Next, take the “hairpin” and cut it into 120 mm pieces. | |

| We install homemade rollers on the studs and secure them with bolts. | |

| We stretch the tape and fasten it on the other side. | |

| We stretch the tape and fasten it on the other side. | |

| We make a base for attaching the grinder. | |

| We attach the grinder to the frame, and fix the drill with clamps. | |

| We attach the grinder to the frame, and fix the drill with clamps. | |

| Don't forget to sharpen the corner for convenient fixation of the knife during sharpening. |

Such grinders can help sharpen knives or any flat parts.

Do-it-yourself grinder from an angle grinder: drawings

Grinder drawing with dimensions for self-assembly

Grinder for an angle grinder: appearance and main elements

This is one of the simplest grinders that you can make yourself. The design of such a mechanism is intended primarily for cleaning weld seams. However, if it is firmly mounted on a table, it can be successfully used as a sharpening machine for straightening cutting tools or sharpening knives, axes, etc.

Do-it-yourself grinder from a grinder

| Illustration | Description of action |

| All you need to do is find a grinding machine, for example, like this one. | |

| All you need to do is find a grinding machine, for example, like this one. | |

| Next, we assemble the structure - the base for stable and safe mounting of the machine. Below we strengthen the structure with corners. The main thing is not to forget to provide a hole for the wire. | |

| The top is not very important, however, a dust canopy can be attached here in the future. | |

| The top is not very important, however, a dust canopy can be attached here in the future. | |

| And so our grinding machine turned into a grinder for sharpening knives and metal structures. |

Video: scrap metal grinder

Wood lathe in home workshop

The availability of lathes for free sale has allowed many craftsmen to use their skills and potential to manufacture various products.

Previously, and it’s true, it was almost impossible to buy a machine for your home. Currently, there are many different models on sale from Russian and foreign manufacturers. These are mainly Russian-Chinese (idea and patent Russia, manufactured in China) and Swiss-Chinese machines. These are brands such as Kraton, Zubr, Enkor, related to desktop machines, with a power of about 350 W and a price from 7,400 rubles to 9,000 rubles. Machine ENCOR Corvette-73s with a power of 350 W

Jet JML machines have a higher price, but they also differ in quality with the same difference as comparing prices. There are options for both tabletop and floor-standing machines, with good build quality and an excellent cast frame. The average price with a power of 500 W, which is quite enough for working with wood, starts from 25,000 rubles.

Working on a Jet JML lathe

The price is for a good machine and well worth the money. But rather than buying an inexpensive Bison-type machine and finishing and improving it with your own hands, many people wonder whether it’s easier to completely make a wood lathe with your own hands. Moreover, it is very easy to find drawings on the Internet, the rest is skill and intelligence.

Drawing of the simplest DIY wood lathe

We take several diagrams and drawings for the simplest machines, select what it can be made from, if possible, add details to improve the quality and accuracy of the work.

Where do we start making a woodworking machine with our own hands?

Making a homemade wood lathe with your own hands is not as difficult as it might seem at first glance.

Each of us has a compartment in the garage for such parts - “maybe they will come in handy.” From them you can make a machine that will not be inferior in quality to the factory one. The main thing is a drawing chosen by you and edited according to your capabilities for a wood lathe, which you will make with your own hands, drawings and accurate calculations of geometry.

We take as a basis a factory-made machine

It’s better to take the design of a factory machine and make it in its likeness.

The machine starts with a frame. It can be made from a profile pipe, channel or angle. It is important here to prevent distortion and maintain right angles. It can be made by welding, or by using a threaded connection. If there is no metal, it is quite possible to make a wooden base for the machine.

Homemade mini woodworking machine with a wooden frame.

The only drawback of such a machine is that it will not last as long as one made of metal, since the bolts will have to be tightened during operation. In the process they will begin to loosen and give play. The metal frame is much more durable and if you do turning work seriously, try to use it.

Headstocks, both front and rear, as well as a motor and speed control, a stop for the cutter, as well as clamps, both driven and driven - this is a set without which the machine will not work.

When starting to make a simple machine with your own hands, you need to think about what you will install on your machine and what you will use to make the necessary components. The electric motor is usually used from a washing machine or vacuum cleaner. If you don’t have any in stock in your garage, you can go to a scrap metal dealer or buy it on Avito for pennies.

If necessary, rewind it. The headstock is more difficult to find; it can be found from a decommissioned factory machine. You can do it yourself, as shown in the photo of a wood lathe, which shows how the user made the headstock with his own hands.

Homemade headstock Side view of the headstock

To do this, 6 holes with M6 threads were cut on the pulley, securing a circle of plywood 20 mm thick with threaded pins (4 pieces). The remaining two holes have a special trident for fastening.

It is quite possible to make the tailstock yourself. The guides and its body are welded from the same rolled metal: angles, channels, profile pipes. The cone can be turned on a metal lathe, the handle for it was made of 20 mm plywood, the fasteners were made of studs and nuts plus welding. See examples of homemade products for a do-it-yourself wood lathe in the photo.

Tailstock assembly Example of cone mounting Finished tailstock

A tool rest for cutters can also be made by welding.

An example of making a handicraft

This is one of the options for making a simple wood lathe with your own hands, which has small overall dimensions along the frame: 100 cm x 20 cm.

A belt drive system can be used as the gear shift unit necessary for a good machine.

How to make a mini wood lathe with your own hands

This mini wood lathe can be made with your own hands from a wooden base. Since small parts can be processed on it, high engine power is not required and vibration will be minimal.

An example of making a handicraft

Therefore, all the necessary parts can simply be made of wood, which completely simplifies the work.

The frame is usually made from metal parts, but this is not necessary; there are many examples of design solutions. If you don’t want to use a drill, you can use an electric motor from a pump or other equipment. A sharpener can also be used as a headstock. The tailstock is part of an old used drill.

If we use a wooden frame, be sure to fasten its corners to reduce loosening during operation. Internal guides are made of wooden slats along which the tailstock moves.

Mini machine made almost entirely of wood

The carriage moves along guides, which are made in the shape of a prism. The most important thing is to maintain geometric dimensions and parallelism.

The headstock, or as its second name is the spindle headstock, transmits movement from the electric motor through the shaft. In its kit there are usually the following:

- headstock body;

- spindle;

- bearings, if possible of good quality;

- a device that will control the movement of the spindle in the desired direction;

- a device that controls the speed of the spindle;

- start button.

The tailstock can be either factory-made or made independently. It can be either on a wooden base or on a metal one. The cone for a homemade headstock needs to be sharpened.

Approximate manufacturing diagrams for a lathe

Tailstock diagram

Or a completely wooden base.

Manufacturing diagram of a tailstock with a wooden mount

The speed is adjusted using pulleys and a belt drive; the belt can be taken from a car, the pulley can be carved from wood. It is not difficult to make a handrail and install it on the rail.

Turning and milling machine, manufacturing examples

The number of operations that are performed on it is much greater than that of a simple lathe, for example, cutting grooves, grooves, making cones. First, we draw a diagram and make a list of necessary materials.

During installation, the front or spindle headstock is fixed motionless, and the rear one moves along the panel.

The difference in such a machine is that a small disk is put on the shaft coming from the engine, while on the shaft from the spindle head the disk size is much larger. For milling work, we use a milling cutter, a six-piece cutter, and a base for it made of 6 mm thick plywood. This sole, together with the router, should move along the guides. This router will perform both milling and turning work. It is placed on a platform that we make ourselves, at the top support point of the machine.

Example of a turning and milling machine

There is another type of woodworking machine made by hand, this is a lathe and copying machine. This type of machine is used to make identical products, for example, candlesticks for sale, legs for tables or chairs, and similar products. In this case, you can use those parts and assemblies that are simply not needed for use.

Unlike an ordinary lathe, the difference is that a copier is added to a copying lathe.

It is mainly made from an old milling cutter, which can be purchased inexpensively on sites such as Avito. It is placed on plywood 12 mm thick and measures approximately 20 x 50 cm.

Holes are cut in the center of the plywood, both for the cutter and for fasteners. The cutter is secured using clamps and stops. The guide is made of a pipe along which part of the platform with the cutter located on it will move.

Installation of a plywood platform

Like the cutter, another important part of the copier will be a specially installed block, which can be removed when not needed. It is mounted horizontally and its best size will be 7x3 cm, the upper part of which should be parallel to the axis of the machine.

The stop, which plays the role of a copier, is made of thick plywood, for example 15 -20 mm, and is attached vertically to the working surface directly on the transition beam. Templates, which are also made of plywood, are installed using fasteners to the block, that is, to its front part, and the upper part is aligned with the axis of the desired template.

Drawing of a turning and copying machine

A much better result would be to use a circular saw instead of a router.

You can watch the video: making a lathe, lathe-milling, lathe-copying machine for wood with your own hands below

Turning and copying:

Turning and milling machine:

Lathe:

| Attention Bearing Buyers Dear customers, send your questions and requests for the purchase of bearings and components by email or call now: Delivery of bearings throughout the Russian Federation and abroad. Bearing catalog on the website |

Attention Bearing Buyers

Dear customers, send your questions and requests for the purchase of bearings and components by email or call now: +7 [email protected] Delivery of bearings in the Russian Federation and abroad. Bearing catalog on the website

themechanic.ru

Rotary table for grinder

For accurate and uniform grinding, the part must be rigidly fixed in relation to the moving abrasive belt. Therefore, any grinder includes a rotating support table (or, as turners call it, a “handle”).

Usually this is a flat metal plate 15÷30 cm long, 5÷10 cm wide and 5÷10 mm thick. The table should have a recess at the end to fit the width of the belt, an adjustable tilt towards the grinding plane, and also move back and forth and up and down.

Some support tables have the ability to rotate 90 degrees to the right and left, but the master must decide how necessary this option is. Moreover, its implementation on home workshop equipment can be quite complicated.

In foreign videos, craftsmen widely use rectangular pipes and various shaped profiles to make homemade grinders. This simplifies both the design and manufacture of the machine. Our craftsmen use such materials much less often: they mainly use channel, strip and corner.

Of course, you can refer to the difference in price, but the grinder requires very little metal, so this explanation is questionable.

Bonding tape

Modern manufacturers of abrasive materials offer ready-to-use belts. They can be in rolls of a given size or glued into a ring. Usually there is a need to make an abrasive belt for a grinder to specific sizes. This is done by gluing strips to a specific size. To solve this problem you will need the following materials:

- tape for gluing abrasive materials;

- glue;

- degreasing liquid (gasoline or white spirit);

- a clamp or weight for compressing glued parts.

The tape should be applied in the following sequence:

- Mark the strip of abrasive along its length, taking into account the joint, which is made at an angle. The larger it is, the longer the contact length.

- The backing of the required length is cut out of the braid. It ensures reliable gluing.

- The surfaces are prepared for applying glue: they are cleaned with sandpaper and degreased.

- Cover the substrate and part of the tape with glue.

- Gently press the substrate against the abrasive tape and fasten them together using the available tools.

If the gluing is done carefully, the homemade tape will last quite a long time. In terms of its consumer characteristics, it will be no worse than the samples produced at the enterprise.

How to make videos

Preparing videos for the grinder is one of the most labor-intensive stages of work. For a grinding machine, most often, four rollers are made with different sizes - from 70 to 150 mm. Typically steel, titanium or duralumin are used. It is also possible to turn parts from wood.

Drawing of a homemade turnkey grinder

Important! When turning, it is necessary to give the rollers a “barrel” shape so that they do not fly off the belt.

Homemade pulley

This structural element is the most difficult to manufacture. A ready-made pulley for a grinder is quite an expensive part. To make it yourself, you need certain knowledge in the field of mechanics and turning. You can get a high-quality pulley from steel or duralumin. In this case, the workpiece must be processed on metal-cutting machines. In a simplified version, it can be made from plywood. It must be FSF or FB. The thickness is selected based on the width of the tape used.

The diameter of the drive shaft is calculated based on the characteristics of the selected motor and the required belt speed. You can make this calculation yourself or use existing tables.

How to choose a ribbon

There are a lot of grinder models, but the most popular option is the band grinder. When choosing a sanding belt, you should focus on a number of criteria:

- The purpose of the grinding machine (processing wooden surfaces is very different from processing metal parts, artificial or natural stone).

- Required belt stiffness.

Carefully choose not only the type of sanding belt, but also its width. Videos, drawings, tips on choosing a belt and assembling a grinder with your own hands will help you optimally carry out your independent work.

How do scissors work and work?

The scissors have a symmetrical design, consisting of two moving parts, which are connected to each other by a bolt or rivet. Each part is a ring connected to a cutting edge. The parts of the structure fit tightly together.

Cutting is carried out due to the presence of a minimum gap between the two blades, which are driven like a lever mechanism. Fingers are threaded through the rings and the lever is activated.

Blade geometry

The blades have the following shapes:

- spicy;

- rounded;

- combined.

Cutting force

Cutting tools are produced for use in various fields. The difference lies not only in the size and geometry of the blades, but also in the amount of cutting force.

The force increases depending on the distance to the axis of rotation: the closer to the axis, the higher.

How to position the machine correctly

After a final check of the operation of the grinding machine, it should be optimally placed in a workshop or garage. In this case, you should pay attention to a number of parameters:

- Convenient working area near the machine. The processed part needs to be placed somewhere.

- Distance to the outlet and length of the network cable.

- Convenient tabletop height for long-term work of the master.

- Possibility of protecting children from the working structure (height, protective casing and screen).

- Availability of light sources and their location (above the grinder or on the side of the structure).

When choosing an installation location, they also focus on fire safety requirements. There should be no flammable liquids or surfaces near the installation.

Useful tips

When performing tire fitting work, the following recommendations should be taken into account:

- The extreme part of the lining should not be subject to serious mechanical stress. This is due to the fact that if you make a mistake, you can create serious problems for yourself in the future with the installation of tires. The most difficulties arise when installing tubeless tires.

- The edges are lubricated with grease to eliminate the possibility of damage to the rubber. It is worth considering that the tire should be lubricated every time it is installed. By using a lubricant, the likelihood of a rupture in the rubber is significantly reduced.

- At the time of installation, it is recommended to use a soap composition or another with lubricating properties. Their use greatly simplifies the installation process.

- When installing rubber on the disc, you need to ensure that there is no gap between them. This can lead to the tire starting to flatten or the outer part of the rubber to become damaged.

- On sale you can find quite a few different special kits for installing tires. Their use allows you to significantly simplify your work. Special kits include sealing harnesses and mounts of various sizes.

On the Internet you can find a variety of drawings according to which tire changing machines are made. In most cases, improvised materials are used in construction.

The design of a homemade tire changing machine allows for high-quality removal and installation of tires on almost any rim. At the same time, the machine is assembled practically from scrap materials, that is, it will cost a low cost. Considering that the cost of a service station is constantly growing, a homemade machine in the garage will be useful.

Setting up and checking the grinder in action

After completing the assembly of the entire structure, we begin to tension the tape. When rotating, it can move along the rollers to the left or right. To eliminate this phenomenon, we rotate the driven roller around its axis by both nuts until the tape stops moving to one or the other edge. Thus, we will find a position when all interacting elements are in place. Now we can safely turn on our homemade product and process the metal object. We make sure that the processing proceeds normally, without jerks or impacts, and we are quite satisfied with the result.

Other recommendations

You can find just a huge number of different recommendations related to the processing of nail scissors. In order to significantly increase the service life of the product, you should pay attention to the recommendations below:

- Do not boil scissors for the purpose of disinfection. This kind of impact causes active formation of corrosion on the surface. Inexpensive disinfectants can be purchased to kill germs.

- It is recommended to treat the scissors layout mechanism with oil once every six months. To extend its service life, just a few drops are enough. Oil not only reduces wear on the damaged element, but also prevents the formation of corrosion.

- It is not recommended to disassemble the scissors, since many mechanisms cannot be reassembled.

- The product should be used exclusively for its intended purpose. In other words, hairdressing scissors cannot be used to trim plant branches.

- You cannot grind metal over the entire surface. If the sharpening angle is observed, the service life of the product can be significantly extended.

Thus, sharpening of professional tools should be carried out by a professional . An example is thinning scissors, which cannot be sharpened at home using conventional tools.

Ready-made machines from the store

Grinder "Lefty"

Characteristics: motor – 1.5 kW, belt length – 1250 mm (up to 1600 mm); The model is interesting for its additional equipment (wheel, contour), which is included in the kit.

Appearance of the “Lefty” grinder

Grinder-sharpener “Kraton” BG 14-05

Characteristics: the device is used for sharpening metal tools and wooden parts; power consumption – 2 kW, movement of the sanding cloth – 14 m/s; disc diameter – 150 mm; tape width – 50 mm. Features: rigid cast base, adjustable stops and protective screen.

Model cost from 6,000 rubles Grinder-sharpener “Kraton” BG 14-05

Grinding machine BISON ZShS-330

Characteristics: machine type - disc-and-belt; circle – 125 mm; speed – 2950 rpm; tape size 762 mm × 25 mm; power - 330 W; belt speed – 810 m/min. Cost – 5490 rubles.

Grinding machine BISON ZShS-330Grinding machine BISON ZShS-330

Sharpener METABO DS 125

Characteristics: sharpener type - with sanding belt; circle - 125 mm × 20 mm × 20 mm; circle diameter - 125 mm; circle thickness - 20 mm; landing diameter – 20 mm; speed – 2980 rpm; power - 200 W. The cost of the model is 7679 rubles.

Sharpener METABO DS 125Sharpener METABO DS 125

Sources

- https://lesoteka.com/instrument-i-oborudovanie/shlifovalnyj-stanok-svoimi-rukami

- https://m-strana.ru/articles/chto-takoe-grinder-i-dlya-chego-on-nuzhen/

- https://homius.ru/grinder-svoimi-rukami-chertezhi.html

- https://tehno-gid.net/sad/shlifovalnyj-stanok-po-derevu-svoimi-rukami.html

- https://svoimirykami.guru/grinder-svoimi-rukami/

- https://HouseChief.ru/kak-sdelat-grinder-svoimi-rukami-chertezhi-s-razmerami.html

- https://vopros-remont.ru/elektrika/grinder/

- https://WikiMetall.ru/oborudovanie/grinder-svoimi-rukami.html

- https://SdelaySam-SvoimiRukami.ru/5627-samyj-prostoj-grinder-bez-svarki-i-tokarki-iz-dvigatelja-stiralki.html