Heavy operations for working with multi-ton objects, without discussion, imply the use of special lifting devices. Among the variety of types of jacks, the title of the smoothest and most accurate is deservedly attributed to screw-type lifts. This group includes a wide range of representatives of different sizes and capacities, used in many areas: from household tire fitting to lifting multi-storey buildings. In this topic, we will cover: what kind of screw jacks there are, how they work and where they are used. At the end of the acquaintance, we will explain what requirements to put forward and what parameters to choose a lift for your needs.

Rack and pinion

Finally, let’s take a look at some of the best rack and pinion jacks for cars.

This category of lifting devices is not very common among ordinary car enthusiasts, since it is used primarily for work in extreme conditions, or in services and specialized garages.

- Matrix 505175. High-quality mechanical rack-and-pinion lift costing about 3.5 thousand rubles. With minimal physical effort, it lifts the car to an impressive height. The device is designed to work with loads weighing up to 3 tons. The lifting mechanism allows for a maximum lift of 1016 mm. At the end of the support rail, the manufacturer has provided for the installation of a towing loop, thanks to which the jack can be used as a winch.

- Skyway S01803005. A rack and pinion lift will cost approximately 5.5 thousand rubles. Widely in demand in the professional field, it is often recommended by experts as one of the best representatives of its segment. The peak lift height is 1350 millimeters. In this case, the pick-up begins at 130 millimeters. The total weight of the structure does not exceed 14 kilograms, which does not interfere with lifting loads up to 3.5 tons.

- Matrix 505155. Another hijack from a trusted manufacturer. Allows vehicles to be raised and lowered smoothly and evenly. The model is characterized by increased strength and wear resistance. Lifts a load weighing 3-4 tons. At the same time, the lifting height is only 700 millimeters, which is slightly less compared to the previous product from Matrix. But the price has also been reduced to 3 thousand rubles.

Matrix 505155

Choosing a car jack is an important and responsible event for every car owner and driver.

The experience and practice of most motorists shows that it is optimal to have a pair of jacks at your disposal. One will serve as a traveling tool, capable of helping out in a difficult situation and helping to simply change a broken tire in the field. The second tool is intended for storage and use in garage conditions. With its help, more complex repair and restoration work is performed.

At the same time, it is not necessary to spend a lot of money on purchasing jacks. There are a number of inexpensive, but very high-quality, reliable and effective tools. Decide on priority tasks and required characteristics. Trust trusted manufacturers.

The best companies

Encyclopedia of Mechanical Engineering XXL SEARCH

AE&T. This is one of the Russian companies that specialize in the production of car accessories. The Automotive Equipment & Tools brand was founded in 2005. Today its products can be purchased in almost all regions of Russia. It is almost impossible to find fault with the quality of this company’s products, since customer reviews are only good.

AIRLINE. This brand produces a huge number of different products intended for motorists: tool sets, luggage systems and, of course, jacks with a lifting capacity from 1 to 16 tons. All AIRLINE products are painted in the signature orange color.

Forsage. Mainly hydraulic jacks are produced under this brand. Their body is painted blue-gray. These products are manufactured in China, but this in no way affects their quality. Products can serve customers well for many years.

Varieties

Encyclopedia of Mechanical Engineering XXLSulfation of battery platesSEARCH

Before talking about the rating and naming the names of the best models, you need to understand what types of jacks there are, how they differ from each other, and what their strengths and weaknesses are. Then we’ll look at the top best jacks, which will allow you to make your final choice. Based on the type of drive, these devices are divided into several categories.

- Mechanical. They are driven by human physical efforts, which is why not every car can be lifted independently. They are used mainly for passenger cars whose weight does not exceed 1.2 - 1.5 tons. They are morally outdated because they were replaced by more advanced and modern solutions.

- Hydraulic. Based on the principle of hydraulics, communicating vessels and incompressible fluid. Very effective, simple and easy to use devices. But they have more stringent requirements in terms of transportation, since they cannot be transported in a horizontal position.

- Pneumatic. They operate using compressed air. Their use requires a compressor. Portable models are not very productive, and they still cannot do without a compressor. Some devices are connected to the exhaust system of the car, due to which they inflate and lift the car.

- Electrical. They work from a household or car network. In extreme conditions they cannot always help out, since they require a power source. But with stationary use they perform well.

Among all these types, the most attractive, in terms of performance and ease of use, are mechanical and hydraulic models. But pneumatics are too dependent on additional factors, which is why they are preferred to be used in stationary rather than traveling conditions for cars.

Devices are also distinguished by type of design. The most outdated of them are vertical screw models. They used to be equipped with Soviet and domestic cars. To use them, the machine must have special grooves. Energy-intensive to operate because you have to put in a lot of effort. They gradually faded into the background, and are now used less and less.

Therefore, car owners generally give preference to the following designs:

- Bottled. These are hydraulic devices that are great for off-road vehicles, large trucks and heavy vehicles. Also easily copes with more compact and light-weight vehicles.

- Rack and pinion. They definitely require a strong fixation on a hard surface. The main advantage is the ability to lift the car to a height of about 150 centimeters. None of the competitors are capable of this.

- Roll-on. Such designs are based on a hydraulic mechanism. Most often used for working with cars at service stations or in garages. Not the most convenient as a camping jack.

- Rhombic or screw. The most common devices among car owners. The main structural element is the screw. When it turns, the diamond base expands or contracts, raising and lowering the car. Convenient to use, easy to maintain and compact devices.

Such a variety of designs and the emergence of new companies on the market has led to the fact that it is now extremely difficult for a car owner to make a choice. To make this task easier, we have selected the best jacks of different designs. This will facilitate the selection process and allow you to take a closer look at the most optimal tools that suit your criteria. But the final decision still has to be made by you.

Pneumatic jacks

Pneumatic jacks are also considered a common type of rolling jacks, often used in large auto repair shops. The device consists of a pneumatic cushion that is inflated with compressed air. Inflatable lifting devices are made independently using a tube from a truck, together with a ball valve to gradually release the air.

Pneumatic jack device

For ordinary car owners, a type of pneumatic design is used that can be inflated from a hand pump or exhaust pipe. Such a mechanism will easily lift even the heaviest car to a height of more than half a meter and allow you to replace a wheel or diagnose the chassis.

Vertical mechanical devices

Encyclopedia of Mechanical Engineering XXL Dry cylinder liner SEARCH

The design of vertical screw jacks was developed 30 years ago and has remained virtually unchanged since then. The main structural elements of these devices are a screw and a housing made of steel. Their carrying capacity is small - up to 1 ton.

The main advantages of vertical devices:

- Application of slight force on the handle, stability of the load.

- Significant work progress.

- Significant lifting height.

- Small mass.

- Low cost.

Disadvantages of vertical structures:

- small support area and, as a result, low stability;

- large sizes;

- Can only be used when lifting vehicles equipped with special lugs.

To insure against the “breaking” of a vertical jack, experienced car enthusiasts recommend additionally placing logs, bricks or other suitable objects under the body of the lifted car.

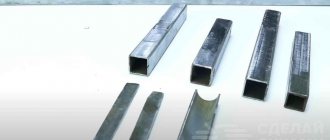

Rack mechanical jacks

Rack-and-screw structures are available with one or two screws and are capable of lifting loads weighing up to 3 tons. The operating principle of single-screw products is identical to vertical ones. And for double-screw ones, the body serves as a support nut.

The first screw, with a larger diameter, is screwed into another screw with a large thread. When the handle rotates, a screw of a larger circle is removed, and a screw with a smaller diameter is removed from it, which increases the height of the load.

Rack screw structures have excellent stability and a rigid structure. The disadvantages include serious weight, and for jacks with one screw - also a relatively low lifting height.

Lever-screw devices

Lever-screw jacks are multifunctional devices and are used for lifting vehicles weighing up to 1 ton. The main structural elements are a screw, upper and lower arms.

The upper lever has a catch and a nut, and the lower one has a screw stop and a support pad. The angle between the lever with a pick-up and the lever with a support platform is changed by rotating the handle.

The advantages of such devices are considered to be relatively low weight, low starting height and significant stroke. The disadvantages include low stability and low structural rigidity.

Screw mechanical rhombic devices are used for lifting machines weighing up to 2 tons. The load-bearing component kit includes four levers, which are connected using hinges arranged in a diamond shape.

Lowering and raising the device is carried out by changing the angles of the diamond. Screw jacks have a rigid structure and a large support surface and are universal in use. There is only one drawback - it is a small working stroke.

Diamond jacks

Rhombic mechanisms are produced not only with mechanical, but also with hydraulic electric or manual drive. These devices are capable of lifting loads weighing up to 1.5 tons.

Their design is distinguished by their reliability, small size and significant lifting height. The only drawback is the fairly high cost.

Combined lever-screw products are a unique combination of lever and rhombic jacks. Such jacks are small in size and have a low initial height. There are two disadvantages - low stability and insufficient structural rigidity.

The described types of screw mechanical products can be classified as devices primarily for domestic use, however, for each variety you can select models that differ in their power. Thus, the screw mechanism used in construction has large dimensions and is capable of lifting tens of times more weight.

You need to choose a suitable device based not only on the planned volume of work, but also by making the necessary calculations.

How to choose a screw jack

The choice of jack is made for each type of specific work. It is necessary to accurately determine whether it is possible to use a manual mechanism, or whether it is necessary to use an electric drive. Manual devices do not require preliminary calculations; when working with electromechanical devices, the mass of loads lifted by a jack is accurately measured. The calculation is made to calculate the power of the structure, taking into account the factors of maximum lifting height, working stroke and initial height. Hydraulic mechanisms will require calculation of the force exerted on the handle and the power of the electric motor.

Basic requirements for mechanisms:

- The load capacity is selected according to the type of car; if the design is used as a universal device, it is important to pay attention to more powerful models.

- The lifting height varies, so it’s worth looking at the numbers; the higher, the better.

- The presence of special grooves or cells for lifting on a car requires the use of a device of the appropriate type, otherwise stability is lost.

The most popular type of lifting equipment is mechanical screw designs, which are characterized by low cost and ease of operation. The rhombic type of mechanisms comes complete with almost every modern car, but there are times when you have to select a device for certain jobs.

When purchasing a jack, you should refer to the technical documentation of the car, where the curb weight is precisely indicated. A power reserve is necessary, but you should not be overly insured, because... more lifting devices have increased weight and dimensions.

Conditions under which the purchase will be correct

If we talk about jacks, then there are numerous torments of choice.

Which one to choose: rolling or bottle, rhombic or hydraulic.

Of course, the crux of the matter lies in the question itself.

If you plan to use the device when lifting weights up to 2 tons, then this is one unit, but if you have to lift it up to 3 tons, then these are completely different loads and here it is better to approach the issue more carefully.

After all, if in the winter, outside the city, and even at night, you are left without a jack, and there is a need to replace a wheel due to a puncture, then the driver will not envy such grief.

First you need to understand which specific jack is needed for a particular case.

There are several types of lifting capacity of jacks up to 1.5 tons, up to 202.5 tons and up to 3 tons. How to choose car jacks. If you are using a regular sedan or hatchback, a jack with a lifting capacity of up to 1.5 tons is quite suitable.

When using a small SUV, a car jack with a lifting capacity of up to 2.5 tons is suitable. If you are using a fairly large SUV, you will need a full-fledged rolling jack with a lifting capacity of up to 3 tons.

The video tells you which car jack is best to choose:

Design and types of screw jacks

A huge number of people believe that mechanical screw jacks are necessary only for changing car wheels, and do not even realize that bridge spans are moved using such devices.

The bodies of heavy vehicles are held in the required position, powerful springs are compressed, and steel pipes are moved through the ground. The design of screw devices is simple, they are distinguished by their reliability.

According to the type of force applied, screw products are divided into the following:

- manual;

- equipped with electric drive.

By design:

Hydraulic. Screw. Rack and pinion. Pneumatic.

Screw jacks are simple and powerful mechanisms. The principle of their operation is to convert torque into translational movement. The main elements of these devices are a “screw-nut” pair and a worm-type gearbox.

The gearbox supplies torque to the nut, where it, transformed into translational motion, lifts the load. In a more advanced modification - jacks with a ball screw drive (ball screw), additional balls or rollers are added to the screw-nut pair.

Adding additional elements allows you to increase the efficiency of such a device by reducing frictional resistance, increasing the operating time and speed of lifting the load. However, the cost of such a mechanism is slightly higher than that of a conventional screw device.

Screw and ball screw mechanisms have their advantages. First, a screw jack was developed. Then, when it became necessary to lift loads with increasing mass, devices were invented based on a group of electrically driven jacks.

The installation of a group of such products, working simultaneously and synchronously, makes it possible to lift large loads, moving them through a symmetrical transmission.

Types of screw mechanical jacks

There are many types of lifting devices for cars, the most popular is the diamond screw jack. A screw jack, the price of which is at an average level, is the most stable and compact.

Car jack

The main advantages are:

- The car is lifted along a vertical plane, without pushing in different directions.

- If the maximum permissible loads are observed, it is durable and does not break.

- It is characterized by increased stability.

- Repairable, folds compactly.

Repair of this type of mechanism occurs without difficulty; the screw part often fails, which can be replaced with a screw-type construction pin. If you have the necessary plumbing skills, it is enough to cut the stud in accordance with the size of the jack and weld a nut on the fastening side. It is possible to make the device yourself, but the time spent is not worth the savings, because the price of a screw mechanical jack starts from 400 rubles.

Mechanical jack

The mechanical jack of the lever-screw type is reliable during operation, thanks to the smallest number of moving elements. The price of such a device on the market is not high, but there are a number of disadvantages. The stability of the device is not at a high level; when lifted, it pushes the car body away from itself. Increased effort is required to lift equipment with such a device, which is not very convenient for women, as well as for long-term work.

In the domestic automobile industry, vertical screw jacks have been used for a long time. The design features a long stroke and smooth force applied to the handle. The lifting height, sufficient for any type of work, made the unit attractive to car enthusiasts.

Vertical screw jacks

Rack-mount screw mechanisms are used less and less due to the high cost and specific purpose of the work. They require the object to be lifted to have special holes for guides. If installed incorrectly, it is easy to damage the car's paintwork.

Bottle devices differ from competitors in having a greater load capacity. There are varieties that can lift up to 5 tons; this solution will help owners of SUVs or minibuses. The design consists of persistent threads with impressive internal elements, which allows you to not worry about durability. The price of the device is high, which makes it difficult to choose between a conventional design; such jacks will help for construction purposes and other purposes.

Bottle jacks

In households, special screw construction jacks are used, which allow you to hold the load at a certain height. Under conditions of frequent use and a larger mass of objects, an electric jack, also of a screw configuration, is used.

The best rolling car jacks

Roll-on lifts are great for garage use. They are stable, compact, but have an impressive load capacity and do not require much effort.

Wiederkraft WDK-81885 – low profile jack with high lifting capacity

4.9

★★★★★ editorial assessment

97% of buyers recommend this product

The compact German-made model is equipped with two working cylinders, which significantly increases the reliability of holding the working part. And the large plastic support pad does not leave scratches on the car’s paintwork.

The main feature of this jack is its impressive lifting height, and this significantly expands the range of serviced vehicles. The only weak link in the chain of all Wiederkraft advantages is the heavy weight of the device, which reaches up to 34 kg. The price of the lift is 9 thousand rubles.

Advantages:

- Reliable design;

- High-quality execution;

- Low pick-up;

- Two working cylinders.

Flaws:

Impressive weight.

Wiederkraft WDK is suitable for both amateurs and professionals. But it’s only convenient to use in a garage—you can’t roll one in the trunk.

Kraft KT 820002 - compact and inexpensive model

4.8

★★★★★ editorial assessment

94% of buyers recommend this product

The jack can be used for both passenger cars and SUVs, if they fit into the load capacity parameters specified by the manufacturer. The lift is supplied in a plastic case and costs only 3,200 rubles.

Advantages:

- Reliable and durable;

- Qualitatively assembled;

- Affordable price with excellent technical characteristics.

Flaws:

Low lifting height.

KT 820002 is perfect for a garage, cottage or small auto repair shop.

Matrix Master 51040 – semi-professional jack

4.7

★★★★★ editorial assessment

87% of buyers recommend this product

This jack is equipped with only one working cylinder. But despite this obvious reduction in the cost of the design, it is practically not inferior to its two-cylinder counterparts in terms of load capacity and reliability of holding.

Moreover, Matrix lifts the machines to a fairly decent height - sufficient for the master to be able to easily reach the desired place under the bottom and work there. The price of this model is 5000 rubles.

Advantages:

- Reliability;

- Good load capacity;

- High lifting height;

- Relatively low price.

Flaws:

Weight 21 kg.

Matrix Master 51040 is a good choice for a small service station or private tire service.

Screw type mechanical jacks

Often, when selling a car, the buyer is given a gift in the form of a spare wheel, a wheel wrench and a jack - this is a screw mechanical lifting device. Most passenger cars are equipped with such jacks, whose ground clearance allows the installation of such a lifting mechanism. Its design is quite simple: four movable steel arms with a clamp are based on a stand (movable diamond-shaped horizontal structure). At the top of such a device there is a support platform for holding the car.

Screw jacks can be of a vertical design: a movable screw is located inside the housing. It should be noted that the lifting capacity of such lifting devices directly depends on the pitch of the screw thread, and the larger it is, the higher the lifting capacity of the jack. In both cases, the vehicle is raised and lowered by rotating the drive handle. This type of car jack can be used to lift cars that are not too heavy. Vertical lifts are superior to diamond lifts due to the fact that they are more powerful and much more durable.

Mechanical jack test

General advantages of screw jacks:

- Lightweight and compact

- Easy to use

- Doesn't require much effort

- Have a low pick-up height

- Made without soft materials

- They are inexpensive

The traditional disadvantage of screw jacks was considered to be low stability due to the small support area, but this applies more to high vertical jacks. Due to their low height, horizontal screw jacks are much more stable. Plus, over time, designers have found various solutions to make the device stand on its feet more confidently.

At the same time, you need to keep an eye on the mechanics. From time to time, lubricate the hinges and screws, remove dirt, and keep the jack clean.

Most screw jacks come with a 1-year warranty, as manufacturers are confident in the reliability of the time-tested design.

Screw jack

Screw jacks have significant disadvantages.

| Screw jack for large diameter pipes. |

Screw jacks have significant disadvantages. These include: slow tension of the coupling, the need to unscrew and tighten the clamping screw when securing the jack to the pipe, and soil contamination of the tension screws with worm threads. A number of construction organizations have developed designs for lever-type tension jacks.

| Screw jack for large diameter pipes. |

Screw jacks have significant disadvantages. These include: slow tension of the coupling, the need to unscrew and tighten the clamping screw when securing the jack to the pipe, and soil contamination of the tension screws with worm threads. A number of construction organizations in Russia have developed designs for lever-type tension jacks.

| Screw jack. |

A screw jack (Fig. 46) consists of a body, a screw, a head, a nut and a drive handle. Jack screws have trapezoidal (GOST 9484 - 60) or persistent (sawtooth) (GOST 10177 - 62) threads.

The screw jack (Fig. 14, b) consists of the following elements: a steel body 2 with a hole in the upper part, in which there is a rectangular or trapezoidal thread; screw 4 and head 6 freely rotating on it to support the load; lever 7 with ratchet. To raise or lower the load, a lever with a ratchet is pumped, and in some jacks the screw is turned in the desired direction using a rod inserted into the screw holes.

Screw jacks have the property of self-braking, as a result of which self-lowering of the screw under the influence of the mass of the lifted load is excluded, which increases the reliability of the jacks.

Screw jacks are not subject to periodic testing, but must be inspected once every 1 month.

| Scheme of lifting a load with two jacks. |

Screw jacks are used for various installation work, especially when it is necessary to ensure the accuracy of installation of the lifted load to a given height. The main advantage of this type of jack is self-braking, which is ensured by the fact that the lifting angle of the jack screw thread is made smaller than the friction angle. Screw jacks are reliable and safe in operation, providing smooth lifting and lowering of the load. The jack (Fig. 5 - 4 a) consists of a cast iron or steel body, in the upper part of which there is a nut.

Screw jacks (Fig. 22), unlike rack and pinion jacks, do not require special locking or braking devices. The screw jack consists of a cast frame and a steel self-locking screw with a rectangular thread ending in a head. The frame has a fixed nut in the upper part, along the thread of which a screw moves. The screw is turned using a ratchet handle. Depending on the direction of rotation, the screw, and with it the head, rises or falls.

| Roller chains.| Roller crowbar. |

A screw jack (Fig. 24), unlike a rack and pinion jack, does not require special locking or braking devices. It consists of a cast frame / and a steel self-locking screw 3 with a rectangular thread, ending with a head. In the upper part of the frame there is a fixed nut 2, along the thread of which the screw moves. Turn it with handle 4 with a ratchet. Depending on the direction of rotation, the screw, and with it the head, rises or falls.

How does a screw jack work?

The principle of operation of a screw jack for a passenger car is to move the frame structure in a given direction under the action of the displacement of the screw gear nut.

For example, in a diamond jack, the screw on one side is fixed in a sleeve with the possibility of rotation. On the opposite side there is a nut, which is rigidly fixed at the connection point of the posts. As the screw rotates, it moves the nut and changes the distance between opposite points of the rhombic structure. If the horizontal opposite points are approaching, then the vertical ones are moving away, which is the working movement to rise.

Other jacks operate using approximately the same algorithms, the only difference being that the direction of the working movements in the kinematic diagrams and the lever systems are different.

The exception is the bottle type jack. It does not use a lever system in its design: the telescopic principle of a screw drive works here. But the limited range of working heights makes this jack unsuitable for an ordinary passenger car.

Hydraulic lifts

In such lifting devices, hydraulic oil, which is located in the housing reservoir, is used as the driving force for moving pistons (plungers). When the drive handle operates, oil is pumped through the pump, resulting in the movement of the piston inside the cylinder, and the car is raised.

Special valves are used to retain oil inside the cylinder and, accordingly, the piston. Hydraulic lifts can have either a fixed support or be based on a rolling platform. This type of jacking device is capable of reliably and rigidly holding the weight of the machine, providing the necessary level of immobility.

It is best to choose a rolling hydraulic lift for yourself, since it has a number of features:

- the use of a rolling platform with wheels makes it easy to move the device to the desired location;

- the piston is easily extended by a special lifting foot (heel), which is driven by the handle without much effort;

- The portable rolling lift easily fits into a special case that can be carried in the car or placed in the garage.

Its carrying capacity can be from two tons.

What type of lifts should you prefer?

When purchasing a jack, it is necessary to take into account, as we have already said, the load capacity depending on the weight of the car, as well as the operating conditions of the car. All types of lifts on a rolling platform are perfect for auto repair shops, which will ensure convenience and speed of work. Portable hydraulic and mechanical devices are no less effective in operation, and they are compact and do not take up much space, so they can be easily transported in a car. Their support capacity and stability on various surfaces should also be taken into account. Don't forget about the carrying capacity.

Hydraulic jacks

A common type of hydraulic jacks are bottle jacks. The main differences are in dimensions and working load capacity. The larger the jack body, the higher its characteristics and ability to lift loads, and, accordingly, the price. Durability and stability make this type of lifting equipment the most used in car repair shops. The design provides a safety valve that does not allow work to continue if the object weight exceeds 25% of the declared one.

Hydraulic jack and its structure

Repairing hydraulic devices is a simple process in which the main thing is to replace the seals and replenish the fluid level. The disadvantage is the increased initial height, heavy weight, and the ability to work only in a vertical position. A type of hydraulic device is a rolling one, which can often be found in auto repair shops.

Bottom line

A jack is a necessary element of a car, which is selected as a useful thing. More than once he will save the owner on the road or help another person in trouble. Don't spare money on your purchase. A correctly selected jack will definitely please the owner.

- Next How to choose a DVR for a car: types of devices and their features

- Back Do-it-yourself heated mirrors: step-by-step instructions and installation

- Aug 6, 2019

- Aug 5, 2019

- Hyundai crossovers / News

Aug 5, 2019

- Aug 3, 2019

- Legislation / Taxes and fines

Aug 2, 2019

- Aug 1, 2019

- April 13, 2019

- March 12, 2019

- Feb 17, 2019

- April 11, 2019

- July 27, 2017