The basic set of guillotine shears usually includes blades designed for processing soft, low-carbon steels and non-ferrous metals. However, if cutting high-alloy materials is required, then it is necessary to use a cutting tool of a completely different quality, since ordinary knives will very quickly lose their sharpness and may even break.

Therefore, for the manufacture of products and blanks from stainless steel, special, especially durable blades are purchased, and the knives are replaced on the machine. This operation is not so complicated, but it has certain specifics and requires some skill.

Parameters affecting the quality of guillotine cutting

Cutting a steel sheet on a guillotine occurs as a result of the relative displacement of two strong metal knives in a vertical plane. In this case, the upper knife can be installed parallel to the plane of the sheet being cut or at an angle to it. The second blade arrangement requires less force to do the job. The angle of inclination of the knife to the horizontal is called the cutting angle and is set depending on the thickness and strength of the material being processed.

The second parameter that ensures a high-quality cut is the gap between the knives . This is the horizontal distance between the vertical planes of movement of the cutting edges of the blades. The size of this gap is usually 6-9% of the thickness of the metal being cut and, in addition, depends on its strength, that is, the type of steel or non-ferrous alloy.

Setting up guillotine shears

For high-quality and productive operation of guillotine shears, it is necessary to configure them as accurately as possible. And the most important setting on which the productivity of the machine depends is setting the gap between the knives. If the gap of the working parts is set correctly, the quality of metal cutting will increase significantly. Therefore, it is extremely important, before you buy such an absolutely important machine as guillotine shears, that you familiarize yourself with the rules for adjusting the gaps on the model of the machine you have chosen.

Our article will discuss adjusting gaps on machines such as mechanical guillotine shears and hydraulic guillotine shears from PJSC Dolina.

The gap between the working bodies must be set in a ratio of 1/20-1/30 of the thickness of the metal sheet. The quality of the cut line depends on the correct setting of this indicator, so this indicator must be constantly checked when cutting metal of different thicknesses. The gap is changed by moving the working bodies using a special mechanism. It is important that you should not cut metal whose thickness has a maximum value and whose length is equal to the length of the working parts of this machine model. You should also ensure that when cutting a workpiece of the maximum permissible thickness, the pressure on the metal does not exceed 50 kg/mm2. Working at the maximum permissible values leads to maximum load on the power units of the machine and working parts, and contributes to their rapid wear and reduction of the service life of the machine.

If the strength of the workpiece exceeds 50 kg/mm2, then it is necessary to determine the maximum permissible thickness of the workpiece using a special formula δ X = δ√ 50/σBP, mm, where:

- δ—permissible thickness;

- σВР is the maximum permissible thickness of the workpiece for a certain machine model, as indicated in the documentation;

- 50 - strength of the workpiece.

To set the required gap between the working bodies, it is necessary to adhere to the following ratio: the thickness of the sheet has an indicator of 1, 3/3, 3/6.3, 6.3/12.5 - then the gap between the working bodies of guillotine shears should be respectively - 0.15, 0.35, 0.5.

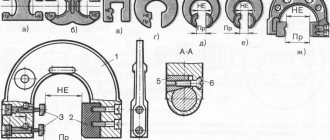

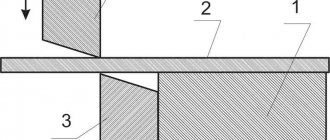

To set the required gap between the upper and lower knives on guillotines produced by PJSC Kuvandyksky, it is necessary to loosen the bolts pos. 1 and pos. 3, figure 1, which secure the table to the frame. By manually rotating the flywheel according to the arrow indicated on the casing, lower the knife beam down until the table knives and knife beam overlap (10 mm - overlap of the knives).

Move the table forward and set the required gap, then, lowering the knife beam down, measure the gap along the entire length of the knives from left to right. After setting the gap, tighten the bolts. The movement of the table back relative to the knife beam is carried out with bolts in position 2, figure 1. The gaps between the guides and the knife beam are secured with spacers, position 4, figure 1.

Figure 1. Gap adjustment

Make sure that the blades of guillotine shears are always sharp and well sharpened - the quality of cutting and the efficiency of the machine depend on this.

Devices for improving cutting quality

Hydraulically driven guillotine shears ensure smooth movement of the upper cutting knife and, thanks to the presence of additional devices, ensure high cutting accuracy and cannot be overloaded during operation. Such devices include:

- front and back stops for quick sizing;

- hydraulic or mechanical clamps for securely securing the sheet and obtaining a cut without the formation of burrs or bends;

- light illumination of the shadow marking of the cutting line;

- possibility of automation of the technological process.

Using the front stops, you can quickly determine the size of the protruding part of the metal sheet by reading the readings from the surface of the movable ruler between the lower knife and the stop.

The position of the back stop is regulated by the operation of an electromechanical drive from the control panel or CNC commands. The rear stops are manually set by rotating the adjustment wheel on the left front of the machine. Under the wheel there is a mechanical counter for the actual distance from the cutting line to the back stop.

On most guillotine machines, two lamps mounted on a lowering crossarm ensure that the shadow is cast strictly along the line of the future cut. This helps to visually control the entire process and accurately determine dimensions.

As a result of the use of these devices and mechanisms on high-tech equipment, it is possible to produce products and workpieces from various grades of steel, of any size and in a wide range of metal thicknesses.

Where to buy a hydraulic guillotine

If you need a good and inexpensive hydraulic guillotine for cutting metal, you can find it in the catalog. The company offers different categories of this equipment, including:

- budget models like Stalex HQ01-1.6x2500B (price from 527,150 rubles, sheet thickness up to 1.6 mm, cut length up to 2500 mm);

- industrial automated installations, such as Stalex THS 2030x4 (cost from 1,136,200 rubles, workpiece thickness up to 4 mm, cut length up to 2030 mm);

- industrial CNC machines, for example, Stalex QC11K-4x3200 (price from 2,857,400 rubles, sheet thickness up to 4 mm, cutting length up to 3200 mm).

Return to list

Setting the gap between cutting edges

An absolutely even cut without burrs or bends on hydraulically driven guillotine shears can only be obtained with a correctly set gap between the knives. If the gap is too small, the metal will have an uneven edge, and if it is large, it will begin to bend during cutting.

Adjustment of the position of the cutting edges must be carried out even on high-quality equipment. It is done using control levers for the lower guide rollers of the scissors. The levers have several fixed positions, of which the uppermost one corresponds to the minimum clearance. When operating with numerical program control, regulation is carried out automatically using two horizontally located hydraulic cylinders.

Features of metal guillotines

Guillotines have the following main advantages over other methods of separating sheet blanks:

- low force due to the simultaneous creation of excess pressure along the entire length of the cutting zone;

- minor loss of metal in the form of shavings;

- absence of severe overheating in the processing zone, which eliminates excessive tempering or hardening of the metal when cutting it.

The most common types of guillotines are:

- manual, in which the source of effort is the physical strength of the operator;

- electromechanical, in which the force is created by an electric motor;

- hydraulic;

- pneumatic, in which the knife moves under the influence of compressed air.

According to the degree of automation, there are manually controlled options, semi-automatic and automatic models, some of which are equipped with CNC.

Guillotine for cutting metal

The first installations were manually driven. In order to perform cutting, it was necessary to install not only the knife itself, you also need to have a counter plate (fixed knife).

General view of a modern manual guillotine for cutting metal: 1 – table; shear plate; 3 – knife; 4 – crank; 5 – knife feed lever

A manual metal guillotine allows you to cut relatively small workpieces; the cutting width rarely exceeds 1200...1500 mm. In this case, the thickness of the cut parts depends on the material used for manufacturing.

Typically, small industries use similar machines for steel with a thickness of up to 0.5...0.7 mm. You can cut off plastic or different types of films. Flooring factories cut vinyl tiles.

In printing houses, before binding books, brochures and other publications, blocks are formed using manually driven guillotines. Subsequently, they are sent to the press, where printed products are created.

The cutting process on a guillotine machine: 1 – table for feeding material; 2 – metal sheet; 3 – anti-cutting blade; 4 – knife

Gap adjustment

When working, try to reduce the distance between the edges of the blades. The smaller it is, the cleaner the cut. However, when working with metal, operators are forced to move the fixed blade to increase clearance. As the thickness of the metal being cut increases, the distance becomes necessary to increase.

If you do not do this, the edges of the blade will crumble. The metal undergoes deformation changes. It behaves like a plastic substance and is squeezed out between the edges.

Gap δ between cutting edges

The thinner the workpieces, the closer the blades should be placed relative to each other. Table 1 presents recommendations for clearances depending on the thickness of 08 sp steel.

Table 1: Gaps between cutting edges for a manual guillotine when cutting 08 sp steel

| Sheet thickness, mm | Gap between knife and shear plate, mm |

| 0,08…0,095 | 0,02 |

| 0,100…0,195 | 0,03 |

| 0,200…0,295 | 0,04 |

| 0,300…0,395 | 0,05 |

| 0,400…0,495 | 0,06 |

| 0,500…0,595 | 0,07 |

| 0,600…0,695 | 0,08 |

| 0,700…0,800 | 0,09 |

When working on installations with a hydraulic or crank drive, the speed of movement of the knife is higher. Therefore, it is necessary to slightly increase the gap (Table 2).

Table 2: Clearances between cutting edges for mechanical guillotines

| Sheet thickness, mm | Gap between knife and shear plate, mm |

| 0,080…0,095 | 0,04 |

| 0,100…0,195 | 0,06 |

| 0,200…0,295 | 0,08 |

| 0,300…0,395 | 0,10 |

| 0,400…0,495 | 0,12 |

| 0,500…0,595 | 0,14 |

| 0,600…0,695 | 0,16 |

| 0,700…0,800 | 0,18 |

At a high speed of metal displacement (mechanical knives), heating occurs. If you do not increase the gap, then after several consecutive cuts the edges can heat up to such an extent that the metal can weld to the knives.

Oblique cut

When creating the first machines for mass executions, poor-quality cutting sometimes occurred. The straight blade did not cut skin and bone tissue from the first blow. Louis XVI, who was present during the testing of the installation, suggested that the inventor improve the device by making a falling blade with an angle. Sliding entry allows you to optimize the cutting angle and redistribute the load in the device.

When cutting occurs, the meeting of the edge with the material being cut does not occur simultaneously along the entire length of the knife. It gradually penetrates into the metal. Therefore, even a slight tilt, just a few degrees, can significantly reduce the amount of cutting resistance.

Installing the active blade at an angle of inclination β: 1 – active knife; 2 – passive knife; 3 – material to be cut

Modern small guillotine shears work with significant β angles. This is how the designers achieved a noticeable reduction in the forces on the knife. In some enterprises, even women work on such small-sized machines. They cope with the task of cutting metal.

Guillotine shears for cutting metal with manual drive