- July 22, 2020

- Tools and equipment

- Andrey Sky

Almost any knife, especially for household use, requires regular restoration of the cutting edge. Due to constant mechanical impact, the tip becomes dull and deformed, which is why its performance is lost. Therefore, the sharpening process is a mandatory technological operation as part of the maintenance of this tool. This procedure can be performed with makeshift tools, but it is much more convenient to use special equipment like a sharpening machine. How to sharpen knives correctly on such a unit? Several aspects of the operation need to be taken into account at once - this applies to preparatory work and setting up equipment in compliance with safety rules.

When is it necessary to sharpen a knife?

If the tool is in good condition and fully ready for cutting operations, there is no point in adjusting its edge. On the contrary, performing this procedure may disrupt the initially correct edge geometry and reduce the quality of the cut.

But there are signs that clearly indicate that the use of an electric knife sharpener or other tool is required to restore the tip to working condition. For example, if small particles of metal are chipped off the edge. Some models of knives, depending on the material used, even pose a risk of injury in a dull state.

Another sign of a non-ideal state of the tip is the poor quality of the cut in principle. If the knife does not cut, but tears the product, it is necessary to correct it. The essence of the sharpening operation will be to restore the desired blade profile. In other words, the rounded edge of the tip must be given the shape of a cone.

Types of sharpening

There are several types of knife sharpening:

| Types of knife sharpening | Description | Example |

| Lenticular | The edge of the blade is sharpened, and the bend of the blade can also be processed. With such sharpening, blades are distinguished by a high level of cutting ability; they are able to “work” even on thick material, and, if necessary, serve as a chopping or piercing tool. Lens-shaped sharpening is carried out exclusively by hand, therefore it is used only in the production of professional knives - kitchen, hunting, tactical. | |

| Razor sharpening (flat) | It is carried out at a minimum degree (10-20) and is suitable for processing only surgical instruments, razor accessories, and blades for fine cutting. In everyday life, such sharpening is done for hunting knives for special purposes - for example, skinning knives, fishing knives. | |

| Wedge sharpening | It is rarely used, because after it the cutting ability of the tool increases, but the strength of its blade decreases. During the process, the side surfaces of the blade must be grinded and polished, but at home this is quite problematic. | |

| Pentagonal sharpening | It is widely used for kitchen and travel knives; even household devices for this process often perform just this type of knife sharpening. After it, the blade slightly loses its tactical abilities, but its service life does not decrease. | |

| Double-sided asymmetric sharpening | Combines enhancing the tactical and physical abilities of knives. The result will be ease of cutting even the hardest products, flawless chopping of material without any effort. This type of sharpening is often used in the manufacture of Japanese kitchen knives, which are of high quality. A special feature of knives with double-sided asymmetric sharpening is that the edge of the blade does not enter the cut on the product, but is constantly held on top. |

There are many ways to sharpen knives, they will differ depending on the tool used for this.

The technology of sharpening at home with a whetstone by hand

At home, sharpening can be done in the simplest way - with a whetstone by hand, step-by-step instructions for the process:

- The block is placed on the table in such a way that it does not slip or move. To do this, place a kitchen towel or any other textile napkin under the stone.

- Moisten the surface of the bar with water. There is no need to fill it, just spread a few drops and this will help not only to easily sharpen the knife, but also to completely clean the block of metal particles at the end of the work.

- Place the knife across the block and begin to move it away from you, imitating the movements when sharpening a pencil. In total, you need to perform about 50 movements on one side to achieve a slight roughness (burr).

- Turn the knife over and do the “procedure” for the other side of the blade, also moving along the block at least 50 times until a characteristic burr appears.

It is important to remember two nuances:

- as you sharpen, you need to maintain the angle of contact of the blade with the block;

- You need to continue the process until (changing sides of the blade) until the formed burr completely disappears.

Only after the last condition is met can you stop sharpening and proceed to grinding. To do this, you will need a stone/block with a finely abrasive surface; the movements are the same as before, but to achieve the desired result, it is enough to repeat them 20 times on each side.

How often should you sharpen?

It is believed that knives need to be sharpened as they become dull, but experts recommend this “event” be carried out at least once a week. In this case, it will be possible to maintain the cutting ability of the tool, and the sharpening itself will take place quickly and efficiently.

If we are talking about manual/mechanical sharpeners with wheels or musat, then they can be used at least every day - the knife will be sharp, but not for long. These devices are needed for straightening the knife, and not for fully sharpening it.

How to choose a sharpening machine?

For household work, it is best to use electric models for household use. Today these are universal units with a desktop installation method that cope with the restoration of blades not only of knives, but also of axes, chisels, all kinds of cutters and scissors.

It is advisable to give preference to knife sharpening machines with an adjustable angle, which will initially improve the quality of the operation. Moreover, it is important to pay attention to the configuration of the working equipment. Firstly, much more sharpening capabilities will be provided by a machine that allows the use of an abrasive disc and tape. Secondly, it is more convenient to use a setup with two circles on different sides. The fact is that the process of point correction may require the use of abrasives with different degrees of grain size. To avoid wasting time on reinstalling them when moving from one circle to another, it makes sense to take care in advance about the possibility of installing two elements simultaneously from different sides.

Professional sharpening of knives: how and what is better

While elementary, simple sharpening devices can be used for kitchen knives, professional sharpening of office knives, bread knives and surgical instruments requires a more serious approach. Most often, special devices are used for this manipulation, which are selected individually for each type of knife.

Hunter knives

In the field, hunting knives are best sharpened with mechanical pocket sharpeners, which can have different shapes and sizes, but are always of high quality materials. It is enough to run the knife several times along a special cut - and “at the exit” the edge of the blade will become sharp again.

Manufacturers of professional sharpening tools also offer hunters round or flat rods on a plastic/wooden handle - they are used for emergency knife sharpening. Round sharpeners are made of ceramic, flat ones have a diamond surface.

Among stationary tools, it is better to give preference to a case of sharpeners for hunting knives, which has a special clamp, numbered sharpening angles, and several stones with varying degrees of abrasiveness. Additionally, oil is included, which allows you to bring the hunting knife to perfection in terms of sharpness.

Scalpel

Surgical instruments, including scalpels, are sharpened using whetstones, emery and carborundum wheels. The sharpening angle is 15 degrees, and it must be strictly maintained throughout the entire process.

It is important to follow two rules:

- make movements during sharpening only with the blade forward;

- Both sides of the blade are processed on the sharpening device simultaneously.

This means you don't have to go through 50 strokes to sharpen one side of the blade and then the other - the sides have to be constantly changing. Scalpels are made of high-quality steel, so no burrs (roughness) are formed on their surface. It is necessary to periodically monitor the process and check the surgical instrument for sharpness.

Watch the video about sharpening a medical instrument:

Serving knives

Serving knives cannot be sharpened because they are made of a special metal - an oxidized or complex composition (alloy), which often contains precious metals. This type of knives is designed for cutting ready-made dishes, and they are a priori distinguished by their softness and pliability.

Boning knife

Boning knives can be sharpened with any equipment because they are made of durable steel and can withstand aggressive external factors. Since such knives are used for a long time, in addition to the main sharpening, periodic editing of the blade will be required. This can be done with a mechanical sharpener with wheels, musat, and a small whetstone.

Stationery knife

Stationery knives are made of thin metal, so you don’t need to use any special tools to sharpen them. But it’s worth taking a closer look at the structure and design of the blade – they have notches at a certain distance from each other. And if you take the edge of the knife with pliers and simply break it along the notch, then “sharpening” will take place instantly - the edge will become sharp again.

Thus, it will be possible to restore the cutting ability of a stationery knife 5 times for one replaceable blade.

You can break off a piece of dull metal using the back cover, it is located on the handle . To do this, remove the lid, insert a blade into the slot up to the line and turn it to the side. It will break off along this line.

Round knives

Round knives are used in the kitchen (for example, for cutting pizza, dough), in sewing workshops (for cutting pieces of fabric). It is almost impossible to sharpen them at home, because this process requires a professional tool such as a sharpening machine for hairdressing scissors.

In general, craftsmen avoid working with this type of knives and recommend purchasing new cutting tools as the blade becomes dull.

Flat knives

Flat knives are those used on woodworking machines and include chisels and plane blades. They can be sharpened with a whetstone, following the instructions:

- The blade is mounted on a whetstone (grindstone, whetstone) at an angle of 30-40 degrees.

- The chamfer is pressed against the whetstone with one hand (fingers), and the other holds the blade in the adjusted position.

- Move the edge of the blade along the block until a burr forms on the surface.

- Replace the whetstone with the same device with a fine abrasive surface and remove the burr using the usual sharpening movements.

It must be remembered that flat knives are sharpened only on one side . You can check the level of sharpness obtained on a wooden block - you need to remove the shavings from it.

Bread

A bread (serrated) knife is sharpened with a cone-shaped rod - it is placed in the space between the teeth. It is better if this sharpening tool is made of ceramic. Before starting the process, you need to determine the beveled side of the cloves - this is what needs to be processed.

The rod is inserted between the teeth at such an angle that it fits snugly against the edge, the movements are performed away from you and slowly, only 2-5 “pulls” are required to obtain the desired result. All nicks are processed in this way.

At the end of the work, you need to run your fingers along the back of the knife - small scale and burrs should be clearly felt on it, which indicate that the sharpening was carried out correctly. They are removed with fine abrasive sandpaper.

Watch the video on how to sharpen a bread knife:

Peeler

You don’t sharpen a peeler yourself, because given the low cost of this kitchen tool, it’s easier to buy it again to replace an already dull one. If the vegetable peeler is expensive, then you should take it to a professional, although he will most likely refuse such a service - the cutting parts in this device are too inconveniently located.

Japanese knives

Japanese knives are sharpened on water stones; you need several such sharpening tools with different levels of abrasiveness - from the smallest to the coarse. Before starting the process, the stones must be soaked in water (it covers them completely) for 3-5 minutes; the instructions for them indicate that this manipulation is carried out until air bubbles stop coming to the surface.

Japanese knives are sharpened in the usual way, but without even the slightest effort. The concave sides of kitchen tools are not sharpened; they are only passed over the stone a couple of times - this is necessary to remove burrs.

Features of professional sharpening machines

Such equipment has several technical and operational differences from household analogues. But it’s worth emphasizing right away that the cost of this machine can be 2-3 times higher than models for home use.

So, we are talking about more productive, functional and precise units that can confidently adjust the shape of an edge made of tool and high-speed steel. As a rule, professional electric knife sharpeners have a durable metal base, a balanced rotor, almost always the ability to install two wheels, and a powerful three-phase motor.

In terms of functionality, it is worth emphasizing the possibility of adjusting the reach, point-by-point adjustment to the dimensions of the tool being processed, and automatic wetting of the working equipment, which protects it from overheating.

7-step instructions for sharpening and finishing a kitchen knife

So, in sharpening a knife, one goal is to remove enough metal from the blade so that the cutting edge becomes sharp again. You need to start work with a coarse-grained abrasive and finish with a fine-grained one.

It is important to remember the following principles of sharpening knives:

- The most important thing is to choose the optimal sharpening angle and maintain it along the entire cutting edge while sliding along the block.

- Movements should be smooth, without pressure.

- All bars must be moistened with water, or better yet, with a soap solution: before sharpening (so that the blade glides better and metal dust does not clog the pores), during the process (to remove the resulting suspension) and at the end, to clean the bar.

Read also: Do-it-yourself cross stop for a circular saw

And one more important tip - the first time it’s better to practice on a knife that you don’t mind ruining. Especially if your main knife is too good and expensive. Well, let's start practicing.

Step 1. Rinse the stone with water, and then run over it, say, with a sponge with a drop of dishwashing liquid.

Step 2. Next, sit down at the table and place the stone on a wooden board, for example, a cutting board. You can place a towel under the stone. For some it is more convenient to place the block perpendicular to themselves, and for others at an angle of approximately 45 degrees. Over time, you will understand how it is more convenient for you to work.

Step 3. Now you need to decide on the sharpening angle and fix the position of the knife. What should the angle be? The general principle is that the smaller it is, the sharper the blade, and the larger it is, the longer the blade retains its sharpness.

- Regular kitchen knives are sharpened to an angle of 40-45 degrees. If you are sharpening a fillet knife (designed for cutting thin pieces of fish, poultry and meat), then you should sharpen it sharper - at an angle of 30-40 degrees. The selected value must be divided by 2, and then we will get the angle that should be between the blade and the surface of the block. That is, to sharpen a blade at 45 degrees, you need to sharpen each side at 22.5 degrees to the sharpening surface.

A simple technique shown in the photo below will help you fix the knife at an angle of 22.5 degrees.

- Remember, you should try to stick to the chosen angle throughout the entire work.

Step 4. Place the knife across the block so that the upper edge of the handle is above the lower edge of the stone. Holding the handle with one hand and the blade with the other, we begin to slide along the block away from ourselves along the trajectory shown in the picture below.

Watch a short and clear video:

- The point is that the cutting edge sliding along the stone should always be perpendicular to the direction of movement.

- At the bend of the blade, the knife handle needs to be slightly raised to maintain the selected angle.

- Remember also that you can’t put pressure on the blade, but you shouldn’t give it any slack either.

Thus, you need to pass the blade along the stone about 40-50 times, namely until a “burr” (burr, microsaw) appears along the entire length of the cutting edge. Its appearance will tell you that the excess metal has worn out and there is no point in grinding further. Then you need to turn the blade over and repeat the same steps. Clearly in the video:

- A burr is a small roughness that is difficult to see, but can be felt by carefully running your finger along the edge of the blade (but not along the edge, so as not to cut yourself).

During operation, a suspension will appear on the blade - metal dust, which must be periodically washed off with water.

Step 5. So, the burrs have appeared, now we proceed to finishing. To do this, we repeat the same manipulations on a stone with half the grain size. An alternative finishing method is using musat.

- Musat is a steel rod of oval or round cross-section with longitudinal notches. It is only suitable for editing and maintaining sharpness, but not for sharpening a knife. It is recommended to edit the knife with musat every time before and after work.

How to sharpen a kitchen knife with musat can be seen in the following video master class from the respected knifemaker Gennady Prokopenkov, who, by the way, specializes in making kitchen knives.

Step 6. If desired, you can bring your knife to a razor sharpness. To do this, take any leather or leather belt, treat it with GOI, Dialux or any other abrasive paste, and then do the same steps, but only in the direction from the cutting edge.

Step 7. Finally, we check the quality of sharpening. This is done very simply. It is enough to cut a tomato or cut paper. If you wanted to achieve razor sharpness, then you should try to shave the hair on your arm. The sharpest knives can even cut hair, as shown in the photo below, but in the kitchen such sharpness is not required for the most ordinary knife.

The best manufacturers of sharpening machines

In the budget segment, for simple sharpening tasks you can find good offers from domestic manufacturers. These are machines costing up to 3-4 thousand rubles. from brands such as “Vikhr”, “Kraton”, “Caliber”, etc.

The middle and most popular segment is represented by models with a price tag of approximately 5 to 10 thousand from Bosch, Metabo and Makita. According to reviews, one of the best knife sharpening machines in this group is the Bosch GBG 60-20 model. It has balanced characteristics and decent German workmanship.

Private craftsmen and industrial workers will be interested in professional models. This is a narrow, but technologically developing class of sharpening machines from companies such as Inforce and Proma in the BKL line.

Electric knife sharpeners

Modern electric sharpeners are a design with an electric motor, on the axis of which abrasive discs coated with diamond are located.

The components of the sharpener are placed in a closed housing with slots for the blades. There are models in which the angle of the blade is set automatically.

Electric sharpeners have the following advantages:

- compact dimensions;

- availability of sharpening and polishing modes;

- connectors for different types of knives and scissors;

- safety at work.

Before using the sharpener, you must read the instructions, which include:

- device description;

- work rules;

- sharpening direction;

- recommended implement angles.

To add sharpness, the blade must be inserted into the hole of a working sharpener and pulled towards you. The number of repetitions depends on the degree of edge wear (from 5 to 10). The blade is then polished.

The disadvantages of an electric sharpener include its relatively high price. It must be remembered that tools sharpened with this equipment quickly become dull.

Abrasive wheel selection options

This consumable material for a processing machine is available in a wide range. The sharpening wheel specifically for a knife should be designed for working with steel and the possibility of finishing correction.

The shape of the profile is fundamentally important for working with sharpening. In this case, equipment with a straight profile is used, which is optimal for straightening the blade.

The grit size will determine what type of finish a particular abrasive wheel can provide. For a sharpening machine used to correct a knife blade, almost all types of fractions can be used. Usually there are three ranges - from 400 microns, from 1000 microns and from 5000 microns. Accordingly, coarse, medium and fine sharpening is provided. Sometimes you can limit yourself to just finishing touches if the blade requires only minor editing.

The type of abrasive itself is equally important. Although knives are not overly demanding tools in terms of machining and dressing, today it is better to give preference to the more durable and efficient alumina blades. This material is hard and resistant to damage.

What to sharpen with?

Before you start restoring the sharpness of an edge, you need to familiarize yourself with all types of tools for work and their features. Not every device can sharpen a blade to working condition.

Sharpening stone

Sharpening stones, made from abrasive materials, are the most popular tools used for restoring cutting edges. Foreign companies indicate on the surface of the bars the number of abrasive grains per 1 square millimeter. There are stones with small, medium, and large grains on sale. With their help, you can perform both rough and finishing metal processing. Sharpening knives on sandpaper must be done carefully, making movements only in one direction.

Mechanical sharpener

Popular sharpeners that are purchased for sharpening kitchen knives. It is a structure that has two abrasive plates that are fixed at equal angles. It is enough to run the blade over them several times to restore sharpness. Cannot be used for sharpening special blades (hunting, sporting).

Electric sharpener

Expensive devices that are used for sharpening various blades. Allows you to achieve better results compared to mechanical sharpeners. This is due to the fact that this mechanism automatically selects the optimal sharpening angle.

Musat

A cylindrical file, sold separately, included with kitchen tools. Used to bring the cutting edge back to working condition after a short period of use with the blade. If there is serious damage to it, musat will not help.

Lansky sharpener

A special device that is used to restore sharpness to small blades. The main advantage of this sharpener is the ability to set any angles and maintain them throughout the working process. The sharpener is equipped with several bars for rough and finishing processing. The work is carried out manually.

Sharpening and grinding machines

In production, blades are often sharpened on machines. Using industrial equipment, you can accurately sharpen any tool. However, a master must operate the machines. This is due to the fact that the abrasive disc at high speeds can damage the cutting edge if moved incorrectly. We must not forget about cooling the metal during work.

Sharpening a knife on a machine

How to check the grinding wheel?

Whatever wheel is used in the work, it must be carefully checked before performing the operation. The audit must begin with a visual inspection. The item should not have the slightest crack or even chip.

Next, a check is performed on the machine. For this procedure, it is better to use a professional knife sharpening machine, which provides more effective safety features and customization options. On it, in particular, it will be possible to check the abrasive wheel for runout. This defect is expressed in vibrations, when, upon external observation, the outer edge of the disk moves away from the center to the sides. If such a flaw occurs, then the abrasive will need to be corrected with a special diamond device.

Sharpening methods

Knife connoisseurs often demonstrate a fanatical approach to the issue of sharpening. Possessing a large arsenal of devices, they achieve extreme sharpness from cutting tools, thereby turning sharpening into an art or a very expensive hobby. For household needs, the approaches they use are hardly justified, since the equipment used for these purposes can be many times higher than the cost of the knives themselves, while there are many inexpensive ways to obtain razor sharpness.

On the other side of the spectrum are users who have no idea how to properly sharpen a knife with a whetstone or using scrap materials. For people who are not keen on the intricacies of this matter, it will be a pleasant discovery that there are many inexpensive ways to obtain a razor-sharp blade that do not require complex devices or unattainable skills.

On the grinding wheel

An extremely undesirable method for processing. Due to the fact that it is difficult to properly limit the place of contact of the abrasive with the blade from heating, there is always a risk of steel tempering, and therefore loss of the original hardness of the cutting edge. Therefore, for routine sharpening of high-quality tools, rotating abrasives, without properly organized cooling, are unsuitable. In most situations, properly sharpening a knife means handling it by hand.

But in the case of very large chips on a blade without a circle, removing such a large amount of metal can be prohibitively long. If the knife is inexpensive, and the damage indicates that this is an exceptional case, then it makes sense to use an electric sharpening wheel or a grinding machine. The abrasive on the device should rotate without beating and at low speed. Numerous videos about the details of restoring edges using this method are easy to find on the Internet.

On abrasive stones

Sharpening metal tools using stone blocks is a classic method. The stones intended for this differ in shape and abrasiveness. From a geometric point of view, for household purposes it is enough to have flat rectangular bars. The vast majority of knives can be processed on such stones, with the exception of those that have crescent-shaped (concave) sections of the cutting edge or serrated sharpening.

Read also: Sanding wood with sandpaper

The technique itself looks like this: it is necessary to make smooth, repeated cutting movements along the plane of the stone, moving the entire surface of the edge along it. In this case, it is necessary to maintain a constant angle of inclination of the blade to the plane of the block. The issue of choosing the grain size of a stone or set of stones is very important. Grit is measured in grit. This unit of measure refers to the number of abrasive particles per square centimeter of stone surface.

If the knife is sharpened on a regular basis and just at the moment when it is still capable of cutting, then one 600 grit stone will be enough to maintain it. To restore a cutting edge or sharpen a very dull tool, you will need a stone of 200-300 grit. The ideal would be sequential processing on a set of several stones with a gradual reduction in grain size. The optimal set of bars looks something like this:

- 300-400 grit. For rough processing.

- 600-800 grit. Sharpening after the previous stone.

- 1000 - 1200 grit. Polishing.

Processing on the last stone on the list allows you to cut loose hair and paper. Although many experts recommend mirror polishing with ultra-fine abrasives of 1000-1500 grit, for most household knives the use of stones with an index higher than 600 grit hardly makes sense. It is also necessary to keep in mind that the price of stones increases with decreasing grain size. In terms of the materials from which the bars are made, they can be divided into natural and artificial by origin, dry and wetted (with water or oil) by method of use.

Sharpening devices

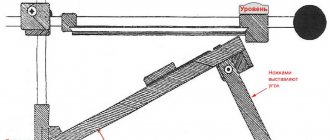

The greatest difficulty in manual sharpening is the need to maintain a constant angle of inclination to the plane of the stone. Various manufacturers offer devices that take over this operation. There are systems that involve mounting on a metal rod passing through adjustable holes. Thus, with their help, it becomes possible to move the abrasive relative to a rigidly fixed knife blade at a strictly defined angle.

No less popular are the so-called V-shaped devices. They look like two replaceable abrasive rods in a vertical plane at an angle to each other, fixed in a wooden or plastic base. To sharpen a knife, it is enough to make sliding movements with the blade along the stones perpendicular to the substrate.

Some manufacturers offer electric sharpeners with several stages of sharpening and even at different angles. These systems are generally designed for kitchen use and have the same disadvantages as a grinding wheel. In addition, even the most expensive models do not provide more than two sharpening angles. Their main advantage is speed. Many models allow you to restore the knife within a few minutes.

Sandpaper or cloth

This is a great way to get acquainted with sharpening simply and cheaply, without the risk of ruining expensive abrasives. There are many methods for conveniently securing a sheet of emery to a block or wrapping it tightly around a wooden block. Abrasive sheets are available in a wide range of grits at the appropriate stores. The home craftsman can only form them into a hard and smooth surface. Compared to stones, when sharpening with sandpaper it is better to use lighter and more frequent movements - strong pressure easily chips away the abrasive grain. Otherwise, the technologies for working with a knife are similar.

In such a matter as sharpening knives, it is important to remember that a sharp blade can cause a lot of trouble and therefore requires careful handling. But, paradoxically, people cut with dull knives more often in the kitchen. This is because an unsharpened tool requires more force and energy to operate, thereby increasing the likelihood of incorrect and unintended movements.

It is simply impossible to describe all the nuances of how to properly sharpen knives in one article, but this is not always necessary. Especially if an ordinary kitchen knife needs sharpening or you are just a beginner who needs to start somewhere.

- In fact, sharpening a kitchen knife to a sharp point at home can be done easily and quickly. But the difficulty is that this must be done in such a way that the sharpness of the blade is preserved for a long time, and at the same time too much steel is not removed from the blade.

In this material we will try to simply and clearly tell you how to properly sharpen a knife with a whetstone. After all, this method is not only basic and accessible to everyone, but also the most effective. In addition to step-by-step instructions for sharpening and finishing, here you will find a selection of training videos and an overview of alternative methods - from sharpening systems to the bottom of a ceramic plate.

General sharpening technology

First of all, you need to consider the operation from the outside. It is usually performed in two stages.

Initially, a smooth edge of the chamfer is formed so that it is sharp and without external defects. We can say that this is a rough sharpening, during which the general geometry of a sharp blade is simulated without the previous roundness. At this stage, wheels with a large grain fraction can be used.

The second stage involves performing a much more important operation to restore the blade. How to properly sharpen knives on a sharpening machine as part of the finishing edit? Much will depend on the experience of the performer, but in any case, you should focus on the existing shape of the blade, which was modeled during rough processing. At this stage, small irregularities and burrs are usually removed that cannot be carefully removed with large-format abrasive.

Sharpening or straightening knives

Before returning the knife blade to its original state using an electric sharpener, it is necessary to determine what actions are required for this tool - sharpening or straightening. When using a blade, the tip is often damaged and deformed.

It forms:

- edge bend;

- chips;

- wavy surface.

Electric knife sharpener.

Removing defects on a grinding machine will require the use of different attachments and changing the rotation speed. Otherwise, you can cut off the excess layer of metal.

To avoid this, you must first straighten the tool using mechanical straightening using a tool in the form of a round file (musat). It has a special surface made of durable steel, ceramics or diamond chips. The device is suitable for removing the bend of the blade at the edge.

Experienced craftsmen sharpen blades on a sharpening machine at minimum speed.

The wave-shaped deformation is cut off completely. There is no other way to remove it. Chips should be removed in the same way. Then you need to start sharpening the tip.

Technique for sharpening knives on a machine

Now you can move on to the most important stage - direct work with the knife.

It is advisable to position the blade against the direction of movement of the disk, which will prevent the metal from crumbling at the edge and minimize the risk of the same burrs forming. The only disadvantage of this method of positioning the knife is the risk of cutting it into a circle, which will ruin the tip at one point and may well deform the entire knife. Therefore, at first, beginners can experiment with positioning the knife in the direction of the abrasive stroke.

At the editing stage, additional devices will be required for sharpening the knife on a sharpening machine. We are talking about a whetstone with the finest grain, which will allow you to carefully trim the edge in certain areas. The process of fine-grained sharpening on a machine should be performed with a minimum number of movements. There is a high risk of knocking down a chamfer, which will ruin the entire result. You need to act carefully and balanced - along the entire length of the blade. Both sides are processed in this way so that the shiny surface of the knife is equally visible.

Blade sharpening

Proper sharpening of knives is carried out in the following order:

- Preparation. The sharpening block is placed on a flat surface; if necessary, a towel or cloth is placed under it so that when working, it does not slip on the table surface. It is also worth placing a container of water or oil on hand to wet the blade.

- The knife is placed with the blade on the leveled surface of the block at an angle of 40-45 degrees with the tip away from you; it is best to install an angle limiter on its blade. Stationery clips performed well in this regard. This will help maintain the sharpening angle.

- The blade is sharpened evenly by moving towards itself, the cutting edge should be smooth when exposed to light, without wavy bends. The wedge itself is symmetrical, the edges are the same in size.

- After rough straightening and creating slopes, it is the turn of a finer-grained block. The metal is periodically wetted with water. This is necessary to wash away any remaining abrasive and metal dust. After the blade slopes are ground, the bars must be washed in running water and soap, the knife itself must be washed and wiped thoroughly.

When editing, you should ensure that the sharpening angle is maintained; it is for this reason that it is recommended to use limiters.

They will help you initially maintain the angle, and later, as you gain experience, you can sharpen the blade “by eye.”

What is the correct knife sharpening angle?

The value is not universal, so you should focus on the specific type of knife and its application. It can be said that in the first stage of rough modeling of the geometry, some metal should be left for later removal for straightening purposes. When final sharpening knives, the angle is usually kept in the range from 7° to 45°. Moreover, average values of about 25° usually apply to kitchen tools, and the upper bar, up to 50°, applies to special models for tourist and hunting purposes.

Table of sharpening angles for different types of knives

In order to perform high-quality processing and maintenance of tools, it is necessary to maintain the basic sharpening angles of knives for various types of tasks with their use. To control the correct sharpening of corners, you can use a table that presents recommended values for various types of knives:

| Knife types | Sharpening angles |

| Dining rooms for serving | 55° — 60° |

| Kitchen household | 30° — 35° |

| Kitchen professional | 25° — 30° |

| Chefs professional | 20° — 25° |

| Cutting for fish | 25° |

| Cutting machines for meat and large fish | 30° |

| Vegetable cutters | 35° |

| Fruit | 10° — 15° |

| Cutting for root vegetables | 22° — 25° |

| Boning machines for meat | 25° — 30° |

| Chopping axes | 25° — 30° |

| Sirloin | 10° — 15° |

| Penknives | 20° — 25° |

| Tourist / hunting, priority is spiciness | 30° — 35° |

| Tourist / hunting, wear resistance is a priority | 40° — 45° |

| Shoe repair | 30° — 40° |

| Shoe cutting machines | 20° — 25° |

| Universal carpentry | 30° — 45° |

| Chopping (machete) | 45° — 60° |

Features of sharpening knives on a manual machine

Today there are many purely mechanical sharpening machines without an electric drive. They have a wide variety of design options and functionality. But when handling such a tool, it is important to consider several nuances. Firstly, a manual knife sharpener is usually mobile, which means that it will need to be well secured each time. This should be done on a workbench or other hard and stable table. Secondly, the sharpening process is performed with translational movements in only one direction. It should also be noted that with intensive use of manual sharpeners with a configuration of two V-directional abrasive stones, the knife will wear out much faster than when working with an electric machine.

How does the blade get dull?

We buy a sharp knife at the store, but over time it inevitably becomes dull if, of course, we work with it. Why does this happen, since the tool is made of good steel and sharpened at the factory? The process takes place at several levels:

- Microscopic, when particles of steel are ground off the cutting edge during friction with the material, making the edge less sharp. You can't see it, but you can feel how more and more pressure is required to cut over time.

- Macroscopic, when the tip encounters solid inclusions, such as grains of sand, particles of stone or metal. They are found in almost any material. The edge either moves the obstacle away or moves away itself, while crumpling.

- If the blade is used inappropriately, its blade can be damaged beyond recognition. This means unscrewing screws, digging soil, etc.

As a result, the working part of the blade is deformed, the edge loses its sharpness and the tool becomes less and less suitable for work. Gradually, hardened steels crumble, and softer and more ductile steels begin to curl.

Rice.

1. The process of blunting and sharpening a knife: 1. When working with a knife, the shape of the cutting edge changes randomly.

2. During the sharpening process, we return the specified shape of the cutting edge or change it. 3. And we give it smoothness, finally removing the burr. To return the knife to working condition, it is necessary to eliminate the resulting deformation and restore the correct shape of the blade.

What should you know about sharpening stones?

Comprehensive maintenance of knives, even if you have a machine with abrasive wheels, is unlikely to do without a touchstone. This granular block will allow, if necessary, to correct the result obtained on the machine, as well as support the operation of the tool in the field, if necessary.

In addition, some electric units are fully equipped with such bars as consumables. How to sharpen knives correctly on this type of sharpening machine? The principle is somewhat similar to mechanical and electrical machines on circles. The only difference is that the operator does not need to make any special efforts. The main work will be done by the device itself. The maximum that will need to be done is to ensure external control of the process.

Of course, a lot will depend on the sharpening stone itself. They are ceramic, abrasive and natural. If we are not talking about using the product as part of an electric machine, then before work it is better to moisten it with a soap solution. This technique will improve glide and prevent intense spraying of small particles from metal and abrasive.

What knives cannot be sharpened yourself?

To begin with, it is not recommended, in the absence of experience, to sharpen on your own at home those blades that are of some value or are especially convenient and necessary for work. If you sharpen them incorrectly, you can seriously damage the blade. In such cases, it is better to gain experience on some less valuable samples, and then, if you have the skill and appropriate tools, start processing other samples.

In addition, difficulties may arise with sharpening serrated knives - knives with a serrated or wavy cutting edge. Of course, there are household sharpeners designed for such blades, but there are many types of serrators; in other models, you can restore the sharpness of the edge yourself only with experience, specific skills and suitable tools, and even this is not always possible.

As you can see, the process of sharpening knives is not so simple. When taking it on, you need to imagine the procedure, the strengths and weaknesses of a particular sharpening tool, as well as the properties and purpose of the blade itself. If all this is available, there will be no problems with sharpening.

Safety requirements

Using a tool sharpening machine is a very reasonable and convenient way to solve the problem of dull blades. But we must not forget about safety. How to properly sharpen knives on a sharpening machine without harming your health? First of all, you can only work on proven and serviceable equipment, as well as on tested equipment, as already mentioned. During the operation, sudden manipulations and changes in the operating mode are excluded. All actions are performed smoothly and without jerking. Also, in the room where sharpening is carried out, there must be active ventilation. Small particles of abrasive and metal released during such operations must be removed immediately, as they pose a threat to the respiratory system.

How to test the sharpness

Checking the sharpness of the blade is carried out in several proven ways:

- paper - hold the sheet with one hand and strip the paper with the other. With sufficient sharpness, cutting will go like clockwork;

- tomato - place the vegetable on the table and cut horizontally;

- on hairs - carefully press the blade to the skin of your hand and lightly run through the hair on it. If the “epilation” is successful, then the blade is sharp.

Checking knives on tomatoes.

How to sharpen a knife?

We've come to the most important thing. Sharpening a knife involves placing its blade on a whetstone at a certain angle and running the entire cutting edge along it from the heel to the tip. Proper sharpening requires compliance with three conditions:

- The angle of inclination of the blade plane to the surface of the sharpening stone remains strictly unchanged (Figure 2).

- The edge line at the point of contact with the block must be perpendicular to the direction of movement (Figure 3).

- The pressure should be moderate and uniform; there is no need to “iron” the sharpener or remove chips from it.

- Figure 2

- Figure 3

So, we place the blade on the stone perpendicular to its long side, set the angle to 15-20˚, and begin to move the blade along the stone, gradually moving it from the heel to the tip. When turning the edge closer to its end, the handle should be slightly raised above the plane of the stone and pulled back, as if lagging behind the tip. This will allow you to maintain the same angle of inclination and perpendicularity of movement.

When the pass along the entire edge is completed, it is necessary to repeat it in reverse order, as when rewinding. This will make it easier to maintain the correct angle and overall the work will go faster. We perform these movements until a “burr” begins to appear on the opposite side of the edge.

The “burr” can be seen or felt with the skin of a finger when running it perpendicular to the tip. When the edge begins to scratch along its entire length, stop sharpening one side and begin processing the opposite side.

The knife is turned over and work begins on the other side. Gradually, a moment will come when, like last time, a “hangnail” will appear. This means the second side is ready. More precisely, almost ready.

Next, we take a thinner abrasive and start the process from the beginning. Similar to the previous stage, we achieve the appearance of a “burr” first on one side and then on the other side of the cutting edge. At this stage it will be much smaller and thinner.

Finally, the blade is polished to the finest abrasive. Here it is necessary to carefully polish the cutting edges, as if stroking them, and remove even the smallest “burrs.”

The position of the blade relative to the sharpening stone: When you lead correctly (position 1), the blade “drags” along the block flat, and when incorrectly, the blade “plows” along the block with its cutting edge (position 3) or the edge between the blade and the main descent of the blade (pos. 2).

In the video: one of the options for sharpening a kitchen knife on a Japanese water stone.

Alternative sharpening methods

If your kitchen knife is a simple and inexpensive “hard worker” and/or you just don’t want to delve into the “knife culture”, then we recommend using an electric sharpener, a roller knife or a sharpening system for sharpening at home. What are their pros and cons?

- An electric sharpener sharpens knives perfectly and quickly, but even the highest quality models remove too much material from the blades, thereby shortening their service life. Another disadvantage of an electric sharpener is that a good device costs more than $200.

- A roller knife is an inexpensive and easy-to-use option. With its help, you can quickly sharpen a kitchen knife, but, unfortunately, the sharpness of the blade will not last long and the knife will deteriorate over time. The most trusted tool among roller scissors is the one from Fiskaris (pictured). Do not confuse a roller blade with a V-shaped blade. The latter is an option for the most frugal.

- Sharpening systems are good because they allow you to more accurately set and maintain an angle. There are different types of such sharpeners - with blade fixation (manufacturers DMT and Lanski) and with fixation of the stones themselves at a certain angle (Spyderco Triangle Sharpmaker). Separately, we can highlight a sharpening system in which you can select the desired angle and control the position of the knife - this is the Edge Pro Apex Knife Sharpening System. Each system has its own pros and cons. For example, on sharpeners with a fixed blade it is inconvenient to sharpen wide chef knives, but on a triangle from Spyderco the knives are straightened rather than sharpened, and you can only choose an angle of 30 or 40 degrees. However, for kitchen knives these are the angles that are needed, and using a triangle is very simple. A detailed review and operating instructions for the Spyderco sharpener can be seen in the following video.

What are the disadvantages of Apex Edge Pro? Perhaps this is just a high price - $245. However, to sharpen kitchen knives, you can buy a Chinese copy of this sharpener (for example, on Aliexpress).

There is another clever way to sharpen a knife at home - using a rough mark on the bottom of a ceramic mug or plate. The principle of operation is still the same - maintaining the angle, smooth movements, maintaining the cutting edge (cutting edge) perpendicular to the direction.

The tool must be in working condition. In the case of a knife, the main characteristic of the working condition will be its sharpness. We will tell you how to sharpen a knife correctly, what tools you will need for this, and give you a number of useful instructions. "Knife sharpening. Basics" is a basic article for those who are just starting to get acquainted with this art.

Read also: What are left-handed and right-handed threads