Heat treatment of cast iron

Low Temperature Annealing

To eliminate internal stresses and restore the size of a gray cast iron workpiece, natural aging or annealing at low temperatures is used.

The natural aging method is unpopular because it involves prolonged aging of the metal after final cooling, which can be 3–5 months, and in some cases, several years. This approach is determined when the necessary equipment for annealing is not available.

Nowadays it is almost never practiced; instead, the low-temperature annealing method is used. It consists in the fact that the castings, after complete solidification, are placed in a cooled oven or in an oven heated to 100 - 200 degrees (°C). At the same time, unhurried heating is carried out, gaining 75 - 100 degrees every hour until the temperature reaches 500 - 550 degrees.

After this, the metal is left for 2 - 5 hours, after which it is cooled to 200 degrees with a temperature decrease every hour by 30 - 50 degrees. Then cooling is carried out in the open air.

Graphitizing annealing method

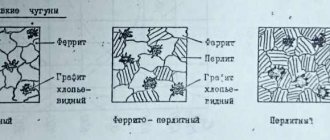

During casting of products, partial bleaching of gray cast iron on their outer part is possible, and sometimes the entire cross-section is affected. To prevent this process and increase the machinability of cast iron, graphitizing annealing is carried out at high temperature, holding it at 900 - 950 degrees for 1 - 4 hours. This is followed by cooling to 250 - 300 degrees in the oven and transferring the cooling process to the open air. This type of annealing allows the cementite in the bleached areas to break down into ferrite and graphite, after which white and cast iron, consisting of a mixture of variable proportions of gray and white, are transformed into gray cast iron.

Strengthening heat treatment of product blanks

Workpieces that have simple shapes with small cross-sections are subjected to this process. Strengthening heat treatment is carried out by maintaining a temperature of 850 - 900 degrees and holding for 1 - 3 hours. This is followed by the process of cooling the products in air. Such temperatures lead to the splitting of carbon and graphite in austenite. As a result of air cooling, the metal base acquires the structure of troostite perlite with slightly greater hardness and improved wear resistance. The hardening process is practically not used for gray cast iron; quenching and tempering are more often used.

Hardening

To increase the strength characteristics of gray cast iron, they resort to hardening, which is done by heating it to 850 - 900 degrees, followed by cooling in water. Pearlitic and ferritic cast irons can be hardened. This process makes it possible to obtain a hardness HB of the order of 450 – 500. The products subsequently acquire a martensite structure with sufficient inclusion of retained austenite and graphite precipitation. An excellent way to increase the strength and wear resistance of gray cast iron is isometric hardening, which is carried out according to the principle of hardening steel.

On high-strength cast irons with nodular graphite, flame and high-frequency surface hardening can be used. Products after this treatment acquire greater surface hardness and a viscous interior, which allows them to withstand significant impacts and abrasions.

Alloy gray cast irons and high strength magnesium cast irons are subject to nitriding from time to time. The surface hardness after this process is HV 600 – 800, resulting in high wear resistance. The process of sulfidation of cast iron is very effective. A piston ring, for example, after this exposure quickly breaks in, does not wear out so quickly, and its service life can increase significantly.

Vacation

To eliminate stresses resulting from hardening, tempering is carried out. Parts that will experience high wear loads in the future are tempered at temperatures of 200 - 250 degrees. On cast iron workpieces that will not be intended to work under significant friction, high tempering is carried out at 500 - 600 degrees. During this process, in cast irons that have previously been quenched, the hardness does not decrease as much as when steels are tempered. This happens due to the fact that the composition of hardened cast iron consists of a large volume of retained austenite. In addition, the presence of a significant proportion of silicon, which enhances the tempering resistance of martensite, has an effect.

To obtain soft cast iron, annealed white cast iron is used with an approximate composition: 2.5 - 3.2% - carbon (C); 0.6 – 0.9% – silicon (Si); 0.3 – 0.4% – manganese (Mn); 0.1 – 0.2% – phosphorus (P); 0.06 – 0.1% – sulfur.

Two methods of annealing for soft cast iron have been developed:

• graphitizing annealing under neutral conditions, which consists of splitting cementite into ferrite and small graphite particles; • decarbonizing annealing, accompanied by oxidative processes, consisting in the combustion of carbon.

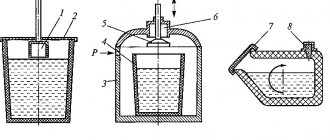

Producing soft cast iron by annealing using the second method requires 5–6 days, which is why the graphitization method is mainly used. The blanks, after removing sand and fragments of channels for filling casting molds, are packaged in metal containers or placed on a pallet, after which they are annealed in methodical, stone and other annealing furnaces.

Annealing consists of 2 stages of graphitization. The first consists of evenly heating the castings to 950 - 1000 degrees, followed by holding for 10 - 25 hours, after which the temperature drops to 750 - 720 degrees at 70 - 100 degrees per hour. The second stage consists of holding the workpieces at 750 - 720 degrees for 15 - 30 hours, followed by cooling them in the oven to 500 - 400 degrees. At these temperatures, they are transferred to the air, where final cooling takes place. Thanks to this sequence, cementite splits within 950 – 1000 degrees. After such annealing, the structure of soft cast iron takes the form of ferrite grains with the addition of nests of small graphite particles.

To increase viscosity, pearlitic soft cast iron undergoes spheroidization. To speed up annealing on soft cast iron, white cast iron is hardened, and then graphitized.

Thermal effect on soft cast iron

To enhance the strength characteristics and wear resistance, soft cast iron is normalized or quenched followed by tempering. Strengthening heat treatment involves holding cast iron at 850–900 degrees for 1–1.5 hours, after which it is cooled in the open air. Workpieces with increased hardness are subjected to high tempering at 650 – 680 degrees with 1 – 2 hour holding.

There are cases when it is necessary to harden cast iron to obtain increased strength and wear resistance at the expense of ductility. The temperatures used are the same as in the normalization process; cooling occurs in water or oil. Tempering, based on the needs for hardness, is most often carried out at 650 - 680 degrees. Accelerated cooling is carried out immediately after the first stage of graphitization, when the temperature reaches 850 - 880 degrees, after which high tempering is carried out. For soft cast iron, hardening is carried out using high-frequency currents or an oxygen-acetylene flame. Hardening brake pads using this method consists of heating the parts with high-frequency currents up to 1000 - 1100 degrees and holding them for 1 - 2 minutes, after which accelerated cooling is carried out. The structure of the hardened layer includes martensite and graphite particles HRC 56 – 60.

Soft cast iron is very often used in mechanical engineering, various industries, agriculture and other industries. Machine parts are made from it. This cast iron is preferred due to the fact that it is cheaper than steel, yet it has excellent mechanical characteristics and is very resistant to corrosion and wear.

Etymology[ | ]

The Russian word “cast iron” is considered a direct borrowing from Turkic languages[1]:

ČOƔ [chog] shine, radiance; flame, heat

[2]

;

kritsa [3]

→ ČOƔÏN, ČOΔÏN [chogun, chodun] copper

[2][4]

, cast iron

[3]

The borrowing of the Turkic term is directly related to the mass production of iron, cast iron and steel in the cities of Volga Bulgaria, Bolgar and Dzhuketau, in the 14th-15th centuries.[1]

The origin of the Turkic term is also associated with whale. trad. 鑄, pinyin zhù, palla. zhu, literally: “to pour; cast (metal)" and whale. trad. 工, pinyin gōng, pal. gong, literally: “deed”[5]. However, the path of penetration of the Chinese term into the Russian language is not indicated. In addition, phonetic processes in Chinese such as initial shift and vowel shift are not taken into account. In other words, the Chinese term 鑄工 adopted its modern pronunciation quite recently, not earlier than the 17th century.

In Finnish the word for cast iron is Valurauta.

, which has two roots and is translated as cast iron (

rauta

);

similarly in English ( cast iron

).

Gallery[ | ]

- Cast iron products

- Cast iron staircase

- The Severn Bridge - the world's first cast iron bridge

- Cast-iron pan

- Cast iron stove - potbelly stove

- Cast iron charcoal iron

- Cast iron manhole cover

- Cast iron bridges

- Iron Bridge over the River Severn at Coalbrookdale, England (completed 1779)

- Eglinton Tournament Bridge (completed c. 1845), North Ayrshire, Scotland, built of cast iron

- Original bridge over the Tay from the north (completed 1878)

- Fallen Bridge over the Tay from the North (1880)

Notes[ | ]

- ↑ 12

Wegman et al., 2004, p. 41. - ↑ 12

ANCIENT TURKIC DICTIONARY, Second edition, revised / Edited by D.M. Nasilova, I.V. Kormushina, A.V. Dybo, W.K. Isabekova. — Astana: “Gylym” Baspasy, 2016. — P. 162. - ↑ 1 2 R. G. AKHMETYANOV.

ETYMOLOGICAL DICTIONARY OF THE TATAR LANGUAGE, Volume II. - KAZAN: MAGARIF - VAKYT, 2015. - P. 451. - Mahmoud al-Kashgari.

Divan lugat at-turk (dictionary of Mahmud al-Kashgari). - 1074. - P. 206-9. - Start of iron foundry

- Karabasov et al., 2012, p. 54.

- Wegman et al., 2004, p. 39.

- Numismatic Legacy of Wang Mang, AD9-23 by Henz Hratzer, AMFishman, 2022. 中国古钱大集华光普着甲册 2008年版. January 2009

- Chinese coins

- Archaeologists have found a 14th century Golden Horde cauldron on the Kulikovo Field

- Terekhova N. N. Iron foundry technology of the ancient Mongols

- What are bells made from?

- ↑ 12345678

Cast iron / Milman B. S., Kovalevich E. V., Solenkov V. T. // Chagan - Aix-les-Bains. - M.: Soviet Encyclopedia, 1978. - P. 248-249. - (Great Soviet Encyclopedia: [in 30 volumes] / chief editor A. M. Prokhorov; 1969-1978, vol. 29). - ↑ 12

Korotich, 2000, p. 178. - History of firearms from ancient times to the 20th century

- Artillery gun (history of invention)

- About tsarist artillery and cannon casting

- Wegman et al., 2004, p. 40.

- History of the locomotive

- Cast iron for Russian stove

- Wegman et al., 2004, p. 51-52.

- Wegman et al., 2004, p. 53.

- Karabasov et al., 2011, p. 138-140, 144-153.

- L. G. Beskrovny.

Army and Navy in the 18th century.. - M.: Military Publishing House of the Ministry of Defense of the USSR, 1958. - P. 361. - 662 p. - Domain revolution

- Victorian and Georgian style and fireplace design (unspecified)

(inaccessible link). Retrieved October 15, 2022. Archived October 15, 2022. - A. N. Grablev.

Machines and foundry technology. - M.: MGIU, 2010. - P. 14. - 228 p. — ISBN 978-5-2760-1857-7. - Underground London: Water and Sewerage

- Zimmerman, Gunter, 1982, p. 245, 253.

- Zimmerman, Gunter, 1982, p. 246.

- Zimmerman, Gunter, 1982, p. 245.

- Lenin. Imperialism, as the highest stage of capitalism, ch. 7.

- World production of pig iron in 2009 decreased by 3.2% (inaccessible link)

- The world's production of cast iron is growing.

Production volumes[ | ]

Cast iron cast into ingots

Play media

Release of pig iron from a blast furnace

In 1892, Germany produced 4.9 million tons of pig iron, against 6.8 in England, and in 1912 it was already 17.6 against 9.0[32]

World production of pig iron in 2009 amounted to 898.261 million tons, which is 3.2% lower than in 2008 (927.123 million tons)[33]. The top ten pig iron producing countries looked like this:

| Place in 2009 | A country | Pig iron production, million tons |

| 1 | China | 543,748 |

| 2 | Japan | 66,943 |

| 3 | Russia | 43,945 |

| 4 | India | 29,646 |

| 5 | South Korea | 27,278 |

| 6 | Ukraine | 25,676 |

| 7 | Brazil | 25,267 |

| 8 | Germany | 20,154 |

| 9 | USA | 18,936 |

| 10 | France | 8,105 |

For four months of 2010, global production of pig iron amounted to 346.15 million tons. This result is 28.51% more compared to the same period in 2009.[34]