Among the types of rolled metal, construction fittings occupy a special position - they are always in high demand, and the need for them does not decrease. This is due to the growth of the housing market and the active construction of industrial and public facilities. The wide range of applications places a number of demands on reinforcement products and requires a wide range of them. The features and types of construction reinforcement will be discussed in this article.

Main purpose

Construction mounting fittings are intended for the manufacture of frame products to strengthen concrete used for the construction of objects for various purposes. As a rule, these are periodic profile rods with different diameters.

Volumetric and flat frames are calculated structurally. They are made from individual rods by welding or wire tying.

The need to use reinforcement in reinforced concrete structures is due to the weakness of concrete to bending and compression. Such loads are experienced by floor slabs, wall and foundation blocks, lintels and other structural elements. Without reinforcement, products crack and collapse. The frame solves the problem - rigid reinforcement works in tension and compensates for the destructive stress in the concrete. Moreover, the frames are necessarily located in the lower stretched part, where the maximum deformation force occurs, as well as throughout the entire volume to stabilize and redistribute the load.

Disadvantages of composite products

Despite the large number of advantages, composite building reinforcement also has several disadvantages. For this reason, before purchasing reinforcing elements, a careful calculation of the reinforcement should be carried out.

- Low modulus of elasticity. Metal and fiberglass products of the same cross-section have different elastic modulus. For the latter, the figure is 4 times lower.

- Exposure to high temperatures. When heated to 90-100 degrees Celsius, the connecting elements of composite reinforcement melt, making the product more fragile. In this regard, you need to take care of additional thermal protection.

- Inability to use electric welding. To solve this problem, reinforcing bars are installed at the ends of the rods on which welding can be done.

- Cannot be bent. If you need to give the rod one or another curved shape, then it will be impossible to do this on the construction site. The only way out is to manufacture the required shape at the factory.

Sources

- https://WikiMetall.ru/metalloobrabotka/chto-takoe-armatura.html

- https://dompodrobno.ru/armatura/

- https://GidFundament.ru/materialy/vidy-armatury.html

- https://regionvtormet.ru/instrumenty/kakie-byvayut-vidy-armatury-klassifikatsiya-po-osnovnym-priznakam.html

- https://stroy-podskazka.ru/armatura/klassifikaciya/

- https://pobetony.expert/armirovanie/dlya-chego-nuzhna-armatura

- https://www.syl.ru/article/355522/chto-takoe-armatura-vidyi-armaturyi

[collapse]

Similar posts:

- The best welding inverters for home and garden...

- How to work with an angle grinder correctly: step-by-step instructions

- FBS GOST blocks: foundation blocks 13579 78

- Diameters of steel pipes - table of external and...

- How to cut a round pipe lengthwise into exactly 2 parts using a grinder

- List of logs to be filled out during construction...

Kinds

The widespread use of construction reinforcing bars dictates the need for a wide range of rods, so that for each design, according to calculations, the most suitable blanks for the manufacture of the frame can be accepted. According to the characteristics of the fittings, products can be divided into several types.

According to the material of manufacture:

- Mounting fittings made of steel of various qualities are the most common and well-known. High-carbon and low-alloy steel are used for manufacturing.

- Construction reinforcement made of composites is a relatively new reinforcing product for concrete structures. These are rods made of basalt, fiberglass and hydrocarbon with polymers. They are close in characteristics to metal products, and in many cases serve as a worthy replacement for a steel frame.

The cross-section of the reinforcement base is round; the surface of the bar can be of two types:

- Ribbed. This redistributes the load in the concrete structure.

- The smooth one serves as a dressing for making a frame. Rods without relief can also be used as a redistributing frame; then their ends are bent to prevent slipping.

According to the conditions of use:

- Non-tensioned is the usual rigid reinforcement from which the frame is knitted and installed in the formwork before pouring the mortar. Used to strengthen products intended for use under normal conditions.

- The prestressing reinforcement is pre-stretched in factory settings, where the structures are formed. These are used in conditions of increased bending loads: floors in industrial premises, public buildings with wide spans between load-bearing walls, etc.

According to their functional purpose, building reinforcement can be:

- Longitudinal prevents the formation of cracks in tension zones - usually in the lower part of reinforced concrete products;

- Transverse rigid reinforcement is located in the compression zone.

Selection rules

The reinforcing rods at the base play an important role - they create rigidity, thereby preventing crashes. To perform this function, it is necessary to produce a high-quality reinforcing frame that will ensure the safety of the foundation.

During construction, it is necessary to select the material based on the diameter and type of reinforcement.

And although manufacturers of fiberglass materials talk about the possibility of replacing steel, experienced engineers are distrustful of the statement and are strongly testing notched steel rods.

An important point when choosing a material is the diameter of the rods. For frame structures, you can purchase reinforcement with a 10-12 mm cross-section, and for the construction of powerful structures, denser ones - 14-16 mm.

You should also choose a metal that has anti-corrosion properties. This will ensure resistance to aggressive external environments.

Classes and markings of building reinforcement

The use of reinforcement in construction is carried out in accordance with the requirements that are determined structurally. Specialists calculate structures and accept rods with markings containing the necessary information about the reinforcing product.

Classes are a designation of parameters not of the rod itself, but of the steel from which it is made. Based on this criterion, construction reinforcement is conventionally divided into 3 classes:

- A – grade of ordinary hot-rolled or cold-drawn rod steel;

- At – heat-treated (reinforced) steel;

- Ac - steel can be assembled into a frame by welding;

- Ak – corrosion-resistant with a protective coating (galvanized or galvanized).

The designation of hot-rolled rod reinforcement contains a digital index. General marking contains some properties of metal products:

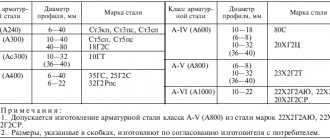

| Strength class | Diameter | Steel for manufacturing | Description |

| AI (A240)* | 4…40 | Carbon St3KP, St3PS, St3SP | Smooth rod |

| A-II (A300) | 10…80 | Low alloy St1G2 or carbon St5SP | Corrugated rod or wire in coils |

| A-III (A400) | 6…40 | Alloyed 35GS, 25G2S, 32G2R | Ribbed for foundation |

| A-IV (A600) | 6…40 | Low alloy cold rolled 80С, 20ХГ2Ц | Corrugated Crescent Reinforcement |

| AV (A800) | 6…40 | Low alloy 23Х2Г2Т | Ribbed Rods |

| A-VI (A-1000) | 6…32 | Low alloy 22Kh2GAYu, 22Kh2G2R, 20Kh2G2SR | Corrugated blanks for welding |

* designation/marking of old and new samples.

Steel classification

To understand the markings, you need to understand how steel alloys are classified according to their intended purpose. It is customary to determine properties according to several parameters:

- The chemical composition determines the strength indicators. Here the properties are determined by the compositional ratios between iron and carbon. Along the way, changes in characteristics depend on the presence of alloying elements or substances that impair performance.

- The structure changes depending on the production methods. Forged products are stronger, cast ones may form pores or other defects. When rolling through rollers, hardening is achieved and the desired shape is obtained.

- For proper use, certain brands are determined by their intended purpose. Such information is especially important for special-purpose steels. In them, even small changes in the chemical composition can significantly change the behavior under load or operation in an aggressive environment.

- The quality of steel ingots depends on the content of harmful components. Sulfur and phosphorus lead to cold brittleness and red brittleness, so metallurgists try to remove deteriorating ingredients from the alloy.

- Oxygen in steel products changes the structure. To remove it, deoxidizers are added to the molten mass; they form oxides and do not cause negative changes to the metal.

Classification of steels according to main indicators

Classification by structure

The structure is studied on special thin sections. They are examined under a microscope, having previously treated the polished surface with sulfuric acid. It is customary to define the following states:

- Hypoeutectoids are characterized by a high ferrite content. Low carbon content does not allow the metal to exhibit sufficient resistance under mechanical loads;

- eutectoid correspond to the best ratio between strength and plastic properties;

- hypereutectoid steels are used in the manufacture of tools. They are distinguished by high surface hardness, as well as resistance to loading;

- ledeburite contain carbides. The metal exhibits excessive fragility;

- Ferritic indicators correspond to the properties inherent in pure iron.

Eutoctoid steel

Hypoeutectode steel

Ledeburite. Iron carbide inclusions are visible

To improve properties, normalization is carried out. It consists of relieving stress from parts that have had heat treatment associated with improved properties. Prolonged heating and holding at temperatures above 720...750 °C, and subsequent cooling leads to annealing. Metal grains change their appearance.

The top row shows the sections before normalization, and the bottom row shows them after

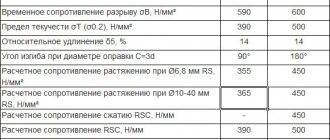

Technical characteristics of construction reinforcement

GOST 5781-82 defines the basic technical requirements for fittings of each class (Table 8):

| Steel grade | Yield strength st | Temporary tensile strength sв | Relative elongation d5,% | Uniform elongation dr, % | Impact strength at -60 °C | Bend and cold test | |||

| N/mm2 | kgf/mm2 | N/mm2 | kgf/mm2 | MJ/m2 | kgf m/cm2 | ||||

| No less | |||||||||

| AI (A240)* | 235 | 24 | 373 | 38 | 25 | — | — | — | 180°; c = d** |

| A-II (A300) | 295 | 30 | 490 | 50 | 19 | — | — | — | 180°; c = 3d |

| Ac-II (Ac300) | 295 | 30 | 441 | 45 | 25 | — | 0,5 | 5 | 180°; c = d |

| A-III(A400) | 390 | 40 | 590 | 60 | 14 | — | — | — | 90°; c = 3d |

| A-IV(A600) | 590 | 60 | 883 | 90 | 6 | 2 | — | — | 45°; c = 5d |

| AV (A800) | 785 | 80 | 1030 | 105 | 7 | 2 | — | — | 45°; c = 5d |

| A-VI (A1000) | 980 | 100 | 1230 | 125 | 6 | 2 | — | — | 45°; c = 5d |

**с – sending thickness, d – rod diameter.

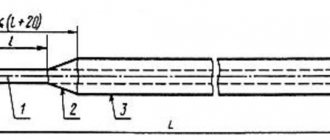

The construction length of the rods according to GOST is from 6 to 12 meters. The document also regulates the composition of steels for the manufacture of building rods and their other properties.

To make it easier to distinguish between the rods, their ends are painted in different colors:

- A-IV – red;

- AV – red and green;

- A-VI – red and blue.

A little about decoding steel

For the manufacture of different fittings, different types of steel are used:

- Alloyed (with impurities of other metals);

- Carbon (its strength characteristics are determined by the amount of this chemical).

Carbon steel is marked as St with digital indices from 0 to 6. This value hides the average amount of carbon in the alloy as a percentage. The higher the value, the stronger and less flexible the rod.

St3...St4 can have different degrees of deoxidation:

- Boiling (“kp”);

- Semi-calm (“dog”);

- Calm (“sp”)

St5-St6 are produced:

- Semi-calm;

- Calm.

Various chemical elements are added to alloy steels, which affect different properties of the alloy:

| Element | Designation in steel grade | Tensile strength | Yield strength | Relative extension | Hardness | Impact strength | Fatigue strength | Weldability | Corrosion resistance | Cold resistance | Red brittleness |

| Carbon | U | ++ | + | = | ++ | — | — | — | 0 | 0 | 0 |

| Manganese | G | + | + | — | + | — | + | 0 | + | 0 | 0 |

| Silicon | WITH | + | + | — | + | = | 0 | — | — | 0 | 0 |

| Nickel | N | + | + | 0 | + | + | 0 | + | ++ | 0 | 0 |

| Chromium | X | + | + | — | ++ | 0 | 0 | — | ++ | 0 | 0 |

| Copper | D | 0 | 0 | 0 | 0 | 0 | 0 | 0 | ++ | 0 | 0 |

| Niobium | B | ++ | ++ | — | + | 0 | + | + | 0 | 0 | 0 |

| Vanadium | F | + | + | — | + | 0 | ++ | + | + | 0 | 0 |

| Vanadium nitride | AF | ++ | ++ | — | + | 0 | + | 0 | + | 0 | 0 |

| Molybdenum | M | + | + | — | + | 0 | ++ | + | + | 0 | 0 |

| Bor | R | ++ | ++ | — | + | — | + | + | 0 | 0 | 0 |

| Titanium | T | + | + | 0 | + | — | 0 | + | 0 | 0 | 0 |

| Aluminum | YU | 0 | 0 | 0 | 0 | — | 0 | 0 | 0 | 0 | 0 |

| Sulfur | No | — | — | 0 | — | — | — | = | 0 | 0 | ++ |

| Phosphorus | P | + | + | = | + | = | 0 | = | — | = | 0 |

| Arsenic | No | — | — | — | 0 | — | — | — | 0 | 0 | 0 |

| Nitrogen | A | ++ | ++ | = | ++ | = | — | — | 0 | 0 | 0 |

| Oxygen | No | = | = | = | + | = | = | = | — | — | + |

Designations in the table: (+) - increases; (++) - significantly increases; (-) - reduces; (=) - significantly reduces; (0) - does not have a noticeable effect.

The marking of construction reinforcement made of alloy steel 22Х2Г2Р, from which products of class A1000 are produced, is deciphered as follows:

- 22Х – 0.22% chromium;

- 2G – manganese 0.02%;

- 2P – boron 0.02%.

The remaining volume is iron (Fe).

Assortment of fittings

GOST 5781-82 contains a conditional range of frame reinforcement (Table 1):

| Profile number (nominal rod diameter dн) | Cross-sectional area of the rod, cm2 | Weight of 1 m profile | |

| Theoretical; kg | Maximum deviation, % | ||

| 6 | 0,283 | 0,222 | +9,0 |

| 8 | 0,503 | 0,395 | -7,0 |

| 10 | 0785 | 0,617 | +5,0 |

| 12 | 1,131 | 0,888 | -6,0 |

| 14 | 1,540 | 1,210 | |

| 16 | 2,010 | 1,580 | |

| 18 | 2,540 | 2,000 | |

| 20 | 3,140 | 2,470 | +3,0 |

| 22 | 3,800 | 2,980 | -5,0 |

| 25 | 4,910 | 3,850 | |

| 28 | 6,160 | 4,830 | |

| 32 | 8,010 | 6,310 | |

| 36 | 10,180 | 7,990 | +3,0 |

| 40 | 12,570 | 9,870 | -4,0 |

| 45 | 15,000 | 12,480 | |

| 50 | 19,630 | 15,410 | |

| 55 | 23,760 | 18,650 | +2,0 |

| 60 | 28,270 | 22,190 | -4,0 |

| 70 | 38,480 | 30,210 | |

| 80 | 50,270 | 39,460 | |

The theoretical mass of products may vary - it depends on the brand of alloy used and has an error, usually within the specified range.

Calculator

Reinforcement weight © metcalc.ru

Classification by structure

The structure of steel refers to the internal structure of the metal, which can vary significantly depending on heat treatment conditions and mechanical influences. The shape and size of grains depend on the composition and ratio of alloying additives and production technology.

The basis of steel grains is a crystal lattice of iron, which includes atoms of impurities - carbon, metals. Carbon can form solid solutions in the crystal lattice, or it can create chemical compounds, carbides, with iron.

The structure of steel changes with temperature changes. These changes are called phases. Each phase exists in a certain temperature range, but alloying additives can significantly shift the boundaries of the transition of one phase to another.

The following are the main phases of the state of the metal:

- Austenite. Carbon atoms are located inside the iron crystal lattice. This phase exists in the range of 1400-700 °C. If the composition contains from 8 to 10% nickel, the austenite phase can persist at room temperature.

- Ferrite. Solid solution of carbon in iron.

- Martensite. Supersaturated carbon solution. This phase is characteristic of hardened steel.

- Bainite. The phase is formed by rapid cooling of austenite to a temperature of 200-500 °C. Characterized by a mixture of ferrite and iron carbide.

- Perlite. Equilibrium mixture of ferrite and carbide. It is formed when austenite is slowly cooled to a temperature of 727 °C.

Steel structure

The phases of the metal structure characterize its physical properties, depending on which the class of steel is determined - structural, foundry, and so on.