Preparatory stage

In order to unscrew a bolt or any other threaded fastener, you first need to prepare it. This stage can be summarized in 4 steps.

Let's take a closer look at each of them:

- Remove rust or contamination - this is the very first step, since without cleaning the contamination, you simply will not get to the threads.

- Tap the bolt - the knocks should be strong. This contributes to the destruction of the oxide layer. As soon as you feel that the bolt has begun to move out of place, you can stop trying.

- Heat the bolt - this stage is quite dangerous, since it involves direct exposure of the bolt to open fire. A torch, soldering iron or acetylene torch is suitable for heating. During heating, rust is removed from the hole and the fastener moves freely.

Use special products - we are talking about special anti-rust sprays or products that have high fluidity. The substance saturates the bolt well and helps to remove the bolt quite quickly.

The only drawback is that the product must be left for several hours for improved impregnation.

Self-tapping screws with stripped splines (asterisk)

If overheated screws are unscrewed/twisted a couple of times, their edges lose their sharpness, the screwdriver turns, but the screw itself remains in place. If it “sits” in wood, plaster, chipboard or other similar, not too hard materials, you can put a thin elastic band (for example, for hair) under the screwdriver. Due to the elastic force, a tighter fit is achieved to the remaining edges, which helps to move the self-tapping screw from its place. Other methods are more “traumatic”:

- Cut grooves inside the “licked” funnel using a flat-head screwdriver and unscrew. This method is quite dangerous: if the walls of the “funnel” are too thin, there is a chance that the screw head will simply crumble from the effort. All that remains is a screw that cannot be unscrewed.

It’s already difficult to unscrew such a self-tapping screw

Unscrew the self-tapping screw with torn edges (cross)

The remains of a bolt or stud without a head can be unscrewed as follows: cut a left-hand thread in the remaining body, drip “moment” glue, screw in the left-hand tap, and leave for an hour. Apply some oil to the main thread and leave for an hour. When the glue sets, unscrew it. If the remains of a self-tapping screw are stuck in the wood, it is easier to seal this hole and install another fastener nearby.

How to tighten a nut onto a stripped thread of a stud or bolt?

It is better, of course, to replace it, but the desire does not always coincide with the opportunity. Sometimes the thread at the end is damaged - knocked, tightened, but then it’s normal.

There are several ways to get out of the situation using improvised means or “in the field.”

If you have a file, grind the thread to 45 degrees.

Use a clamping lever that presses the nut against the thread from the end. Press and turn with the key. The main thing is that the nut is in an even position to the stud, otherwise it may not go “along the thread.” For leverage, you can use a large key, a plate, or a hammer handle. By securing the studs above with a rope, a chain, simply sliding it under something, and pressing below. Sometimes it is enough to press with the butt of a hammer to make the nut “go.”

If you “don’t do collective farming”, but really do everything efficiently, then you need to buy this set of dies with a knob,

A torn thread means that it is not there (licked threads).

Driving the thread with a nut is not the best option; there is a high probability that you will break the thread on the nut (internal), you will have to buy a tap, or use screwdrivers.

If you go the right way, then we clamp the bolt or stud in a vice (with the problematic thread facing up), lightly lubricate the thread with oil and drive it through with a die, then tighten the nut, you can even do it by hand.

If done incorrectly, then a certain load must be applied to the nut for it to move.

For example, press with a sledgehammer, and also clamp the bolt (or pin) in a vice.

Next, we work with an open-end wrench, the nut is under constant pressure, we push and tighten.

We make sure that the nut moves evenly, that is, distortions, especially during entry, are not permissible.

DON'T LEAN!

BE MORE DELICATE WITH YOUR CARVINGS

TEXT / SERGEY STASOV

In your car, the number of screws, bolts, and nuts goes into the thousands. The reliability of a car, its durability, convenience, and simply serviceability largely depend on the condition of the fasteners, primarily threaded ones.

There is no such thing as unnecessary fasteners. Ask experienced ones, everyone will probably remember something on this topic. Let's say how, while removing a panel, I lost a screw. I couldn’t find a suitable one and decided: it doesn’t matter, as long as I go without it. After some time, the panel began to rattle a lot, and then the speedometer “died.” They examined it - it turned out that it had crumbled! Shook him up. Silence in the cabin is not only comfort. Any “bounce” is vibrations, and they are not to be trifled with.

But this kind of “failure” is a mere trifle compared to the destruction of the suspension, steering, or the loss of a wheel while driving, when the driver has little chance of a successful outcome. Taking a closer look at old cars, you can “figure out” an optimist owner: one of the wheels is missing a bolt or nut. The reason is common - the thread is broken. Buying a new hub and replacing it seems expensive, your mouth is full of other worries, you need the car “on the go.”

Fortunately, God protects fools. Many people get away with this attitude. But not everyone. The wheel is now attached to the hub weaker, and even asymmetrically. When cornering, especially for speed enthusiasts, it seems to breathe, further loading the remaining bolts. The result is predictable: the metal is crushed at the fastening points, the tightening weakens - and the wheel begins to naturally dangle, threatening to break off the remaining fasteners.

HOW TO RIP A THREAD

There are many known ways. Often the mechanic applies excessive force to the key. What can you do, it is not customary for us to use a “momentary” key (exceptions are rare). Of course, the physical capabilities of people are not the same, but anyone can break the M8 thread, and even more so M6 and lower. Especially threads with fine pitch, of which there are many, for example, on the Volga. Usually the thread is not damaged the first time, but after several disassemblies of the assembly it “ends” naturally: the threads are deformed, moving more and more, and finally cut off. Therefore, in many cases, it is better to replace bolts, screws, and nuts that have already worked with new ones.

Premature thread wear and loss of strength are also caused by dry tightening without lubrication. Moreover, if the lubricant is “replaced” by sand, dust, and dirt.

Finally, an inexperienced person can ruin parts when trying to tighten a bolt, nut, spark plug, sensor, etc. not by thread. The result of inattention is especially sad if you damage the threads in critical, expensive parts - the cylinder block or its head, wheel hub, etc. Not everything can be easily repaired.

AND HOW TO SAVE IT

How to screw in a screw, spark plug, etc. to avoid them going in the wrong direction? The technique is ridiculously simple, although many people don’t know about it.

Let's say you insert a candle into a socket. Holding it aligned with the hole, press firmly and rotate smoothly counterclockwise. When the start of the thread (“start”) on the spark plug coincides with the start of it in the hole, you will hear a click and the spark plug will fall a fraction of a millimeter. Now, still with your hand, wrap it. Is it easy? So, by carving. What happens next is a matter of technique. We will use the key when it is really needed: during the final tightening. This technique is especially useful when dealing with small threads of large diameter. For example, when adjusting the “toe-off” on a Zhiguli. The threads of the steering rods and couplings are M16x1, moreover, there are both left and right.

Even if the screw or nut is screwed tightly, it is almost certainly a defect in the thread. Probably, as they say, it has already “pulled” - it has not yet been broken, but the finish is not far off. In some cases, this is easy to check: the nut is easily screwed onto the bolt with one side, but if it is turned upside down, it requires a wrench, which means that the thread is already wrinkled. When there is no other way out, it’s worth once again driving the threads: in the hole with a tap, on the screw with a die. If very little metal has been removed, the thread will still serve. A lot - it’s better to replace the parts.

Particular attention to screw jacks. The screw and nut have, one might say, a colossal responsibility here - tearing the car off the jack is unacceptable! One of the signs of excessive wear on the threads in the nut (which primarily affects it) is a clearly increased force on the jack handle, not only when lifting the car, but even when lowering it. Due to severe wear and distortion of the thread profile, the nut jams on the screw (Fig. 1) - using such a jack is at least unwise.

The edge of the fastener is damaged

It's time to look at the reasons that lead to the fact that you need to put effort into unscrewing the fasteners. Remember that how quickly you unscrew a bolt is influenced by many factors, from its location to the material from which the bolt is made.

Let's look at the tools that can be used to unscrew such a bolt:

- A sharp chisel is best used if a large bolt breaks. You need to apply a chisel to the place where the bolt head is located, always tangentially, and hit the structure with a hammer.

- Adjustment key - with this key you can tightly clamp the mestizo and move it out of place, thereby unscrewing it. It is better if the key is new, so it can fit more tightly to the head.

- A ring wrench is capable of performing the same functions as an adjustable wrench. To implement this method you will need a hammer.

- Hacksaw – Using this method, you can create a cut in the head so that it can be easily unscrewed with a screwdriver. You can create either a cross cut or a cross cut.

Types of spring threaded inserts

Wire inserts for repairing threaded holes have the shape of an elastic spiral, the turns of which form a high-precision rhombic profile on the inside, which is similar to the thread profile.

Most sold screws have a driving tongue that serves to screw them into the prepared receiving thread. After installation, it is easily separated along the cut using a special breaker. Spring sleeves have a different number of turns and, accordingly, different lengths, which are designated 1d, 1.5d, 2d, etc., where d is the diameter of the spiral. Special types of inserts are also available, for example, for spark plug threads or oxygen sensors. Threaded inserts are made from particularly strong, high-quality steel, mostly stainless steel, which makes it possible to obtain reliable threads that are resistant to wear, deformation and corrosion.

The thread on the fastener is damaged

A fairly popular problem that probably every second person has encountered. In this case, the bolt simply scrolls and does not come out. In this case, you need to use a screwdriver to pick up and lift the bolt.

It will be necessary to make an effort, since everything is not so simple and the bolt will rest.

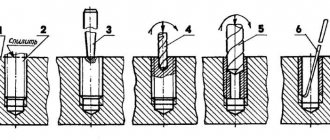

Procedure for unscrewing a bolt with a broken head

Threaded connections become a real test when the head of the bolt breaks off as a result of applying force. If the parts can be separated, then dismantling the hardware will not be difficult. Much more time and effort will be required when the head breaks off and the fasteners still do not protrude from the base.

The procedure includes the following points:

- Use an appropriately sized extractor. These tools are made from a cylindrical rod. One side of the metal blank contains a tapered thread of the opposite type of cutting. The second side is equipped with a square shank. The use of the element is possible provided that the bolt is pre-drilled. In this case, the diameter should be 3 mm less than the thread. Then you need to select an extractor and hammer the device into the finished hole. Unscrewing a bolt with a torn head is done by carefully rotating the extractor shank.

- An excellent solution to the problem is to use a tap with a left-hand thread. The accuracy of the diameter must be observed, which must correspond to the thread value. The method involves pre-drilling a new hole and cutting a new thread. The approach will be difficult for those who do not know how to unscrew licked bolts. This will remove all parts of the broken bolt to the outside.

Extractor

This tool is specially designed for unscrewing a spinning bolt, removing the remains of broken fasteners or any parts remaining inside the holes.

The principle of its operation is to drill a hole in the center and then jam the hole with an extractor. How deep it is placed depends on how worn the head and shank are, and how corrosion affects the threads.

There are several types of this tool:

- Blade;

- Kernel;

- In the form of a spiral;

- In the form of a screw.

All methods and instructions for use can be found in the instructions for the extractors.

Use of solvents

If the bolt has oxidized and because of this cannot be unscrewed, an excellent solution is to use a solvent. It perfectly clears out oxidation.

Most often, motorists encounter this problem.

- All you need to do is pour the oxidizer into the hole with the fasteners and wait about an hour.

- After this you can clean the top of the bolt and start removing it.

- An excellent option would be, if possible, to pry off the cap with a screwdriver.

Do not forget about safety rules when working with hazardous substances.

Heat

The set fasteners are heated with ordinary gas from a cylinder. | Photo: youtube.com.

If the previous methods did not help, then it’s time to take more effective measures. First of all, the stuck parts need to be heated, for this they use a gas burner. If you unscrew the nut, then you need to heat it. And if it’s a bolt, then the flame is directed at the part into which it is screwed. With a large increase in temperature, the parts expand, causing the gap in the thread to increase.

In addition, thread lockers are often used when assembling automobiles. When heated, they become fluid, “lowering” the bolt or nut and then it is easier to unscrew them.

Safety regulations

In fact, unscrewing a broken thread is quite a dangerous activity. Since the hole can be not only through, but also difficult to access.

Let's study the basic rules that need to be followed:

- Protect the skin of your hands and face - substances such as solvents, for example, contain many chemical elements. When mixed, they release substances that, upon close contact, can settle on the mucous membrane. In case of contact with human skin, there is a risk of burns. Be careful if you use this method, as the drops may get into your face or eyes.

- Use a respirator - the smell emanating from caustic substances can also enter the respiratory tract, which can also cause irrevocable harm to a person. But a respirator can trap the smell.

- Wear glasses - if dust and grains of chemical elements get on the mucous membrane of your eyes, they can cause burns or damage your eyes. Moreover, at the preparatory stage this will help you a lot.

If dust or paint does get in somewhere, follow these instructions:

- Rinse the area where the pollen has landed. If you find deep damage, immediately seek medical help from specialists.

- If you swallow dust, you should immediately leave the room for fresh air and try to cough. Be sure to rinse your nose. If you start to feel unwell or experience pain in your lungs, immediately call an ambulance and seek help from specialists.

Before you begin such manipulations, carefully consider your workplace and escape routes. This is necessary in case something happens. You will immediately know what exactly to do and what to get from where.

Useful tips

When performing work, you should use several tips:

- Before resorting to radical measures, it is worth inspecting the back side of the workpiece into which the screw is screwed. Perhaps the tip of the fastener is peeking out from the inside. In this case, you can grab it with pliers and try to unscrew it from the inside.

- When getting started, you need to make sure that the rotation of the fastener occurs in the desired direction. Some screws contain reverse threads. In such situations, to solve the problem you need to rotate clockwise.

- If a screw leaves a gaping hole in the workpiece, you can solve the problem by inserting a larger self-tapping screw here. An alternative is to use a bolted connection with a nut.

- When removing a screw using one of the above methods, all kinds of nicks and metal burrs are likely to form. To avoid injury during work, it is enough to put on thick gloves on your hands and protect your eyes with goggles.