When carrying out welding work, physical and chemical processes take place that have a negative impact on the human body. For example, ultraviolet radiation burns the retina of the eyes, the skin of the face and hands. Just a few minutes of such ultraviolet welding radiation level is equal to several tens of hours of exposure to the scorching tropical sun.

But that's not all. The fumes contain microparticles of molten metals, which can cause poisoning, affecting the welder’s respiratory system. There is always the possibility of getting burned from splashes of molten metal. Therefore, it is very important to follow safety rules that are specially developed and take into account all the nuances of welding work.

At manufacturing enterprises, welders are allowed to perform their duties only after instruction. All of them are informed about the impending danger and know perfectly well how to protect themselves from it. Hobbyists working at home should take exactly the same precautions.

Hazardous factors

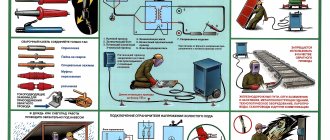

Regardless of the type of welding, the welder himself and those nearby are negatively affected by a whole range of factors. The safety measures used during work are aimed primarily against the following main consequences:

- sparks flying in all directions can burn through other workpieces, clothing and shoes, as well as ignite flammable materials and cause burns of varying severity (if they come into contact with open skin);

- when welding, you can get a burn on your face and hands from hot and heated surfaces; the fumes can burn your mucous membranes and eyes;

- saturation of the body with metals and other compounds that accumulates over time, leading to diseases of the respiratory system;

- Electric shock is a common danger, most often based on failed insulation or poor contact at the connection point;

- hearing impairment - from constant noise at the work site;

- fire and explosion when ignited near a flammable gas cylinder, or even when a flame forms directly on it;

- fall of technological equipment and workpieces;

- fall of the welder himself - in the absence of order under his feet or during welding work at height.

Welding safety considers the following reasons as the causes of these negative situations:

- ultraviolet and infrared radiation (from which “welding bunnies” appear, familiar to every welder);

- high level of chaotically generated sound – from equipment and workpieces;

- critically high content in the air of the working area of substances hazardous to humans (primarily lead, chromium, zinc, cadmium, etc.);

- high local temperature: the weld pool generates heating of surrounding objects to dangerous levels.

To preserve the health of workers, welding safety procedures are developed and applied.

Why is it important to follow labor safety rules in the welding area?

Welding work is considered dangerous and harmful for a reason. At welding sites, potential hazards are everywhere. These may be dangerous flammable substances, high temperatures of objects, flammable and explosive substances, or a fire. Therefore, labor protection during welding work plays a key role.

Safety rules and regulations for welding activities are established by adopting a local regulatory legal act at the enterprise or organization - the Labor Safety Instructions (hereinafter referred to as the Instructions). Depending on the specifics of the enterprise’s activities, there may be one general security instruction. If an enterprise has significant production volumes and combines several areas of activity, then there may be several instructions on labor protection, each for a separate area.

Safety precautions for manual arc welding

A decent number of rules and recommendations have been written for safety precautions during welding. Occupational safety and health is constantly strengthening its position and detailing its initially brief provisions. Here are the basic requirements set out in each instruction and which should be taken into account by every welder (including amateurs):

- the workplace must be cleared of flammable objects and kept clean;

- It is recommended to enclose the welding station with a high screen;

- the welder must use PPE and wear a protective mask while the welding arc is burning;

- labor safety rules for electric and gas welders indoors necessarily require the use of forced ventilation;

- moving and reconnecting welding equipment is carried out only after removing power from it;

- Safety precautions for electric arc welding include an element of worker attentiveness - it is important to carry out the process without distraction, which is why the welder often works with an assistant;

- Cables should not be kept twisted and preferably without crossing them.

These are the basic safety regulations when working with welding equipment. Most of the requirements are added according to the specifics of the work performed - for example, for welding pipes and pipelines or for operations at height.

To be allowed into the site, an employee must

- Meet all statutory qualification requirements.

- Complete initial and introductory safety training and other necessary types of training.

- Have sufficient skills in handling welding equipment, use it only for its intended purpose and with the knowledge of management.

- Use personal protective equipment and keep it clean and in proper shape. It is not allowed to wear a jacket with an open collar, roll up the sleeves, or weld in oily clothing or mittens.

- Be able to provide first aid to injured colleagues and other people until the medical team arrives.

- Know how to use fire-fighting equipment in the event of a fire for its intended purpose. Know the signals of fire safety devices, ensure free access to fire safety equipment and emergency exits.

- If you feel unwell or feel unwell, stop working, consult a doctor, and immediately inform your immediate supervisor. If your colleagues are not feeling well, you should immediately inform the doctors, provide first aid if necessary, and inform management. The employee must know the location of the first aid kit, know its contents and be able to use it in practice.

- Clean the welding machine at least once a month.

- Ensure that at the welding site there is a special partition made of fireproof material with a height of at least two meters, the distance between the floor and the walls must be at least 50 mm.

- In the event of a technical malfunction of equipment or wiring, immediately inform your immediate supervisor.

- Comply with internal labor regulations.

- Ground the electric welding installation.

- Install identification marks for the welding location or mark them in another visible way.

- Degrease surfaces with special non-flammable solutions. Do not use kerosene, gasoline or other flammable substances.

- Do not use equipment whose operating instructions are not familiar to you.

- Maintain rules for storing hazardous substances.

- Maintain cleanliness and order in the welding area during all working hours, do not clutter the workplace with garbage and waste.

- Undergo a medical examination in accordance with the established procedure.

- Carry out only the assigned task, do not allow arbitrary operation of the equipment.

- Do not use faulty equipment.

- Operate devices in a safe manner.

- Transport gas cylinders only on special carts, avoiding sudden shocks.

- Is sober at work. If you identify colleagues, people in a state of alcoholic, drug or toxic intoxication, or drinking alcoholic beverages, immediately stop them from performing work, ensure their removal from the work site and report to superiors.

- Do not eat food at your workplace.

- Bear responsibility for failure to comply with safety regulations (disciplinary, civil, administrative, criminal).

Gas welding and cutting - safety precautions

Safety requirements are also available for oxygen gas metal processing methods. Thus, carrying out gas welding operations requires attention to the following points:

- the position and safety of gas cylinders is the key to the health of workers, therefore their storage and transportation require maximum attention;

- protective caps on the valves of the cylinders must be on at all times - unless the container is currently connected;

- Before connecting the burner and starting to supply the gas mixture, it is important to check the condition of the unit - technical condition and the absence of oil on the burner and fittings;

- connection of gas communications is carried out in a certain order - as is the supply of flammable gases;

- when performing gas welding work, it is better to hang the supply hoses rather than lay them on the floor;

- It is better to keep the gas pressure constant;

- When a backfire occurs (characteristic popping noises are heard), it is important to shut off the supply of flammable gases as quickly as possible, and first it will be acetylene, and only then oxygen.

When working, it is important to keep the burner flame under control and not leave a lit burner lying down or unattended.

Useful article - what is Tig welding

Absolutely forbidden

Safety precautions at different stages of electric arc welding necessarily take into account points that cannot be performed under any circumstances. They are regularly overlooked by “relaxed” workers and not taken into account by newcomers:

- Welding outdoors is not allowed in the presence of precipitation and heavy fog;

- It is prohibited to work in oiled PPE;

- parts cannot be held by hand - only with the help of mechanical devices;

- It is forbidden to cook without an influx of fresh air for breathing - from a window or a special hose;

- Do not cook near flammable materials and fuel;

- Maintenance of power supplies and cables is prohibited until the voltage has been removed and disconnected from the network.

The crown of this list and the cause of eye pain is welding without a protective mask or with damaged glass on it.

Welder personal protective equipment

ESAB Heavy Duty Worker

Quick view

Canvas apron

Quick view

Mask BARSVELD MS 107

Quick view

Before starting welding

The initial stage determines safety precautions for arc welding in terms of preparation of conditions:

- checking the equipment planned for use - its serviceability and protection from water;

- checking the grounding and correct installation of all connections, as well as the integrity of the cable insulation;

- absence of dirt, oily fabrics, water on the floor and parts;

- Fire extinguishing equipment is available within walking distance;

- the working area is fenced (including with signal signs), there is only one entrance to it.

Organizational factors - obtaining technical specifications and conditions for creating a result.

Preparing equipment for operation

Before you start welding, it is important to check the functionality of the equipment and prepare the required components. This will subsequently eliminate the occurrence of unforeseen difficulties and will allow you to complete the planned task efficiently.

Sequencing:

- Carefully inspect the unit, auxiliary elements, and consumables for integrity.

- Check the availability of the necessary protective equipment and their condition.

- If work is planned to be carried out in particularly hazardous conditions, an appropriate design should be prepared.

- Pay attention to grounding to eliminate the possibility of electric shock. When the body of the welding unit is reliably grounded, the risk of a short circuit is significantly reduced.

- Be sure to check the cables. During the working process, they should not be located in liquid, as this reduces the reliability of the insulation.

With proper preparation for such an important procedure, most problems can be avoided.

Cylinders with oxygen or acetylene must be transported, stored and operated strictly in accordance with the instructions Source xn--b1ae4ad.xn--p1ai

In progress

If you do not take into account the degree of compliance of the weld with the required parameters, the main leitmotif of welding work is to protect yourself and others from exposure to radiation, high temperature, particularly harmful aerosol, flying sparks and electric shock:

- ventilation must be constantly on;

- contact with metal surfaces is not allowed - felt or rubber mats should be placed;

- It is important to keep the cables straight and not intersecting;

- when using other equipment and machines, it is important to ground them and turn off their power systems;

- electrodes and other consumables should be used in prepared form - dry and without obvious defects;

- if possible, work with an assistant;

- The welding power source may only be manipulated after it has been disconnected from the network.

When an arc occurs, it is important to wear all recommended PPE.

Useful article - Types of welding machines

When carrying out welding work, it is prohibited

When cooking, some prohibitions must be taken into account. Let's take the following points as an example:

- Welding should not be carried out if the safety helmet is broken or cracked.

- If the hood is not working or there is poor ventilation, it is prohibited to perform various welding works. In addition, cases with high humidity are prohibited.

- In all cases, the part must be secured; you cannot cook, for example, hanging or holding it by hand.

- Do not cook in areas with flammable gases or liquids.

- Do not cook under pressure.

- The electrodes should not be kept closed for a long period. This leads to breakdown of the element, due to which the parameters of the supplied current are adjusted.

List of prohibited actions when welding

In addition, equipment with serious mechanical damage or defects, or in a faulty condition, should not be used. The condition of the equipment should be checked from time to time.

Upon completion of the process

Safety precautions for the welder at the end of the process come down to simple points:

- disconnecting electrical equipment, winding cables to a prescribed place (usually near the power source, in a locked cabinet);

- putting things in order, cleaning tools and putting items in their places;

- the cylinders are locked, their valves are covered with caps;

- consumables (electrodes, carbide, wire) and valuable (blanks and parts) materials are described in a general manner and locked.

If deviations or malfunctions are detected, you should immediately inform your supervisor.

Welding completion procedure

The welding process must be completed correctly. This will avoid unwanted consequences.

Sequencing:

- Turn off power.

- Wait until the created seam has completely cooled. Safety precautions do not allow working with hot metal.

- Thoroughly clean de-energized welding equipment and check it for integrity.

- Inspect the formed seam for quality.

At the final stage of welding, you need to collect all the equipment and move it to a permanent storage location.

Checking the quality of cooled welds is carried out using special equipment Source dsnspb.ru

Basic rules of labor protection in emergency situations

Welding safety precautions also include information about the actions of personnel in the event of an abnormal or emergency situation:

- stop work immediately;

- disconnect the equipment from the network, extinguish the flame, shut off flammable gases;

- find out what is happening or inform others;

- if possible, make attempts to eliminate negative phenomena.

If necessary, first aid should be provided to victims - by calling doctors or sending someone to call. In any case, you should notify your supervisor about everything that is happening.

In this article:

In case of injury at work:

When working as a private master

- a commission was appointed to investigate the causes;

- management will lose bonuses this month;

- Perhaps someone from middle management will be fired indicatively.

- explosions of flammable gases are possible;

- harmful fumes are released;

- the welder is in close proximity to hot objects or flames;

- possible electric shock;

- there are harmful effects of UV rays and bright light.

But for you without eyes or with a damaged heart from an electric shock, this is unlikely to make you feel any better. And if you are partly to blame for what happened, you will also be punished financially. Therefore, the welder himself should be interested in observing safety regulations and demand from management everything necessary for this.

Safety precautions when performing welding work at height

Work above ground level above 1.5 meters is called work at height. In addition to standard PPE, the welder must also wear a helmet and safety belt.

All tools are secured against falling; it is recommended to take the minimum necessary with you. It is recommended to use compact welding equipment, and cables that are as flexible as possible and of sufficient length.

It is important to protect the area under the operations being performed from people accidentally passing under it. This will protect everyone from accidental drops of workpieces, tools, scale and sparks.

Useful article - How to check NAKS in the registry by last name

Requirements for labor protection during welding work

- It is not allowed to place flammable substances near the welder’s workplace. Materials subject to combustion must be within five meters of the workplace, explosive, flammable substances - no closer than ten meters.

- The welder cannot repair or turn equipment on or off. This is entrusted to electricians. The welder only monitors the serviceability of the device.

- Gas cylinders should not be located closer than five meters from heat sources.

- The welder carries out work outdoors during rain or snow only under special fireproof canopies.

- Welding of closed tank structures must be carried out by three welders. One is located directly inside the tank, two should be outside for insurance. The welder inside must be wearing a special belt with a rope, which the other welders must hold on top. These structures should not contain harmful gases or other substances that adversely affect welders.

- 12W lamps are used as artificial lighting in welding areas.

- You only need to clean slag from welding seams with a special metal brush and safety glasses.

- It is necessary to weld elements located at height only if scaffolding is available.

- If welding is carried out in dangerous, enclosed spaces, or in rooms at depth, then it is necessary to use devices that automatically turn off when the electrode with the part being welded is disconnected.

- The gearbox valve opens smoothly, without jerking. You need to stand on the side opposite to the direction of the gas. There should be no strangers in front of the jet.

- If there is a long break in work activity, the valve on the oxygen cylinder must be closed.

- If the cutter overheats, you need to stop working and cool the cutter in a container of cold water.

Means of protection

Safety regulations necessarily regulate the availability and maintenance of PPE - personal protective equipment. The welder's equipment necessarily consists of the following items:

- suit - trousers and jacket;

- shoes;

- protective mask;

- mittens (or leggings);

- for gas welders - an apron and sleeves.

Clothes are made from non-flammable materials - leather, tarpaulin, canvas (after treatment with a special compound) and special thick cloth. The material used is preferably natural, not synthetic. Shoes are closed, with thick soles and without massive metal elements on the outside and nails on the sole.

The main requirement for welding PPE is protection from sparks and the relatively short-term thermal effect of the welding arc. It is recommended to store them in a dry place. Before putting on, check for the absence of grease and oil, integrity and dryness.

Eye protection

When welding, it is extremely important to protect your eyes from the ultraviolet radiation of the arc and the infrared radiation of the hot metal. The following can help with this:

- welding glasses: compact, worn on the head and protecting only the eyes, they can be equipped with filters of different degrees of darkness;

- conventional welding helmets: they are a shield that covers the face from the front and sides, and is also equipped with a viewing window into which darkened glass is installed;

- welding mask “chameleon”: this is a mask reinforced with a system of automatic darkening of the glass when the arc is ignited - it helps to save effort and time, since it is not necessary to take off and put on the mask (bring it up and away from the face).

Each such option should be fitted tightly to the head and excessive glare should not be allowed when the arc is burning.

Useful article - What is Mig mag welding

Protection of the skin of hands and face

For maximum safety, the entire body should be covered when welding: the arc emits light, infrared and ultraviolet radiation. All of them have a merciless effect on the skin, causing severe burns.

To work confidently when performing work, it is important to use a full set of PPE including gloves. It is not recommended to cook in a T-shirt - you should wear a shirt. This way your hands won’t “burn” and your skin won’t hurt.

To protect the eyes and skin of the face, as well as the neck, it is important to use a mask or even a helmet. A raised collar will simultaneously stop the light and prevent a stray spark from falling under your clothes. The work area should be fenced off to protect third parties from radiation.

To prevent excessive dry skin, regular and special creams are produced.

Respiratory protection

You can protect yourself from the negative effects of welding aerosol (blue smoke released during welding) by using a welding mask equipped with a respirator or an air supply system. A respirator will help for a short time, but the supply of clean air will ensure long-term reliable operation.

This product consists of the following components:

- a mask placed tightly on the head;

- air purification unit with batteries;

- container with gearbox – if long-term and independent operation is necessary;

- filter, fan, check valve.

This device is especially interesting for work in unventilated rooms, inside containers to be welded and for welding large-diameter pipes from the inside. Taking into account the design and materials, an autonomous breathing system can provide operation for up to tens of thousands of hours with a flow of clean air up to 200-250 liters per minute.

Actions in case of emergency

- Immediately inform management, if there are additional instructions from management, follow them.

- Notify the competent authorities (medical institution, fire service, gas service).

- Take measures, if possible, to extinguish the fire, use primary fire extinguishing means, turn off ventilation and all electrical equipment, if possible, ensure the transportation of flammable and explosive substances from the fire, inform everyone about the fire in order to begin fire evacuation. Use a fire extinguisher appropriate to the type of fire.

- Provide first aid to victims.

- Take measures to eliminate the consequences of the emergency.

- In the event of a gas leak, you must immediately stop work, eliminate the malfunction and provide ventilation.

Thus, labor protection during welding work is of primary importance in the work process of a welder. Knowledge and careful, strict observance of the Labor Safety Instructions when performing welding work, repeated instructions on labor protection, the possibility of being held accountable for non-compliance with the Labor Safety Instructions ensures the safety of the welder, increases the overall level of labor safety in production, and develops positive labor discipline.

Requirements for welding equipment and premises

For indoor tasks (or in containers where the welder enters for a short time), safety precautions during welding work, the equipment is equipped with a permanent ventilation system. It is important to ensure the flow of fresh air into a closed volume and the selection of contaminated aerosol.

It is important to provide a sufficient level of lighting - natural or artificial. You should regularly clean the work area and avoid piling up workpieces. It is important to keep the tool neat and clean.

When several welders operate in parallel, their workplaces should be protected. If it is not possible to protect other employees, the voice command “Eyes” must be given loudly and clearly before igniting the arc.

If you have any questions, you can ask them in the comments and our experts will help you.

Labor protection requirements before welding work

The welder is obliged:

- Receive an order to perform a specific welding task.

- Provide yourself with personal and collective protective equipment and check their serviceability.

- Wear clean, oil-free special clothing and shoes, avoiding exposed areas of the body and hair.

- Check the workplace directly: clean it of dust, dirt and debris. Do not block exits with debris. The floor at the welder's workplace must be clean and dry.

- Make sure that there are no gas cylinders, unwashed containers of already used flammable materials, paint, or other flammable substances nearby. If there are any, then you need to ensure that they are at least 10 meters away from the workplace.

- Make sure that the welding machine is in good working order, that the grounding is reliable, that the electrical wiring is properly insulated, that the welding circuit is intact, and that the starting device is in good working order.

- Check the reliability of fixation of the elements to be welded.

- Turn on ventilation

- Provide a partition or special protective screen.

- Clean the edges from slag and rust.

- Ensure proper functioning of the welding unit.

- Use mats that protect against moisture when welding fixed pipe joints.

- Check the presence of water, sand or a fire extinguisher at the work site.

- If tanks containing flammable substances are to be welded, they must be thoroughly washed and dried.

- If welding of car frame elements is to be done, then the body must be grounded and the fuel tank must be removed.

- The generator should be placed in a warm place if the temperature is below zero.