Related Posts

A home-made circular saw is a good way to save a lot of money and at the same time acquire fairly high-quality and reliable equipment. A correctly assembled homemade circular saw is in no way inferior to a factory saw and is also capable of sawing logs of even very large diameters.

A circular saw is used for even cutting of lumber.

In order for a circular saw to cut huge logs without any problems, you need to equip it with a truly massive electric drive. Also for this purpose, a belt drive, shaft and engine with the highest traction force are installed on its surface. Our client is left with circular saws, made independently, consisting of 2 parts: the top and one of the.

Various electrical equipment is always located at the bottom, specifically:

Circular saw design.

At the top of the circular saw install:

In the process of making a frame for the top of the saw, it is better to use an iron corner with a width of 25 mm. At the same time, the rectangle, which will represent the frame of the upper part of the homemade circular, must have dimensions of 600x400 mm. Next, four pipes are welded in the corners of this quadrangle, the diameter of which should be 17 mm, and the height should be approximately 2.5 m.

After a while, two corners need to be strengthened on the frame, where the bearings will later be fixed. The distance between these corners directly depends on the length of the shaft. To fix the bearings, you use clamps. It is best if the bearings installed on a homemade circular are closed. This way you can easily not be afraid that wood shavings will get into the space between the balls, rings and separator. Do not forget to cut the thread at the end of the shaft so that in the near future it will be possible to install a cutting disc on it.

Specifications

Before choosing a circular saw for your dacha, you need to familiarize yourself with the main technical characteristics of this tool.

Motor power

Stationary circular saws are considered the most powerful.

The performance of the saw depends on this parameter. The higher the power, the thicker the tree the circular saw can cut. Depending on the power of the electric motor, saws are divided into three types:

- Up to 1000 W. Suitable for sawing plywood.

- Up to 1500 W. With their help you can cut logs, thick boards and wooden beams.

- From 1500 W. Professional tools that can work 5-8 hours a day.

For home use, it is better to choose budget models with a power of 1000-1500 W.

Disc rotation speed

This indicator affects the speed of the circular machine. For people who plan to frequently process hardwood, it is recommended to use models with high disc rotation speeds. This will allow you to make better cuts.

The average rotation speed is about 5000 rpm. Many professional saws speed up to 6500 rpm.

Cutting depth

Angle cutting is often used when working with dense wood.

Another criterion that is taken into account when purchasing a circular saw is the cutting depth. This parameter depends on the diameter of the cutting disc used and the power of the device. For household models, the maximum cutting depth is no more than 55 mm.

If a person has to work with denser materials, it is necessary to use professional saws. With their help, it will be possible to saw wood with a thickness of more than 80 mm.

Working at an angle

Many people who choose a new circular saw for their home pay attention to whether it can be used to work at an angle. It is recommended to buy models that can be used at an angle when cutting products.

To determine that a saw can be used at an angle, you need to inspect its design. It must have a locking mechanism.

Which sole is better

Often people are confused about choosing the best circular saw blade. Many experts claim that the cast platform is the most reliable. However, such circulars are very expensive and few can afford them.

A cheaper and more accessible option is products that are equipped with forged platforms. They are quite tough and thick. The quality is practically in no way inferior to more expensive cast platforms.

Battery type

Cordless models are suitable for outdoor work.

At home, cordless models are often used. These cordless saws are very convenient and allow you to cut wood even in hard-to-reach places. There are two types of batteries that are often used in power tools:

- Lithium-ion. Modern batteries that drain slowly. The only drawback is poor frost resistance.

- Nickel-cadmium. Outdated but still in use batteries. They are rarely installed in circular machines, as they quickly discharge.

Important! It is recommended to choose models whose battery has a voltage of at least 18 V.

Do you need a level or a laser pointer?

Devices equipped with an additional laser pointer are often added to the ratings of circular saws. This device is very useful, as it indicates the direction of movement of the circular. Therefore, for beginners who have not previously used such tools, it is better to give preference to models with a laser pointer.

Is speed adjustment necessary?

The speed controller allows you to adjust the rotation speed of the disk.

When choosing a new circular saw, you need to pay attention to whether it has additional functions. It is recommended to buy models that are equipped with a speed controller. Using this device, a person will be able to manually adjust the rotation speed of the working disk. This is very convenient when you have to cut materials of different densities.

Do you need a soft start?

Another additional function that should be in a circular machine is soft start. With its help, you can gradually increase the engine speed and, accordingly, the disk rotation speed. Of course, using this function increases the cutting time. However, in this way it is possible to protect the motor from sudden voltage changes.

circular machine with a 1.5 kw motor at 1500 rpm 220 volts

At the stage of production of a pendulum circular in handicraft conditions, only very strong iron corners should be used as material for the frame. Next, on the finished metal frame it will be necessary to place, what remains for our client to do, the mechanisms necessary for the normal operation of a homemade circular saw. If you have such a design, you can personally set the flight altitude of the cutting disc without any problems, without any special effort, while avoiding unnecessary design difficulties.

For the production of similar homemade products the following will be useful:

- two iron plates;

- wooden beam;

- spindle from a bike;

- star;

- chain.

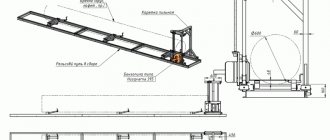

The device of a circular saw with a separate engine.

Source: auramm.ru

Design, principle of operation and use of a circular saw

At first glance, the device of a circular saw is as simple as possible - a powerful motor, on the shaft of which a cutting metal disc is mounted. In the case of stationary tools, the engine can be located separately and transmit force to the working shaft with a belt through a system of pulleys, but hand tools, of which the absolute majority among household ones, are made in one housing.

Adding to the complexity of the device is the need to use high-quality materials, strict adherence to the alignment of parts, plus maintaining serious safety measures. The saw blade rotates at high speeds, so neglecting any of the above points will, at best, lead to damage to the tool.

As a result, an impressive number of mechanical-electronic protective and blocking devices are added to the engine and cutting wheel, the purpose of which is to instantly stop and de-energize the tool if something goes wrong.

The principle of operation of a circular saw is clear from its design - a rotating disk with teeth cuts a board along which the tool itself is pulled. In the case of a stationary saw, everything happens the other way around - the board is pulled through a circle fixed to the frame and divided into two parts.

There is one important note about the use of a circular saw - it is not suitable for figure cutting and is intended to cut boards and other materials only in a straight line. There are models with additional graduation of the leading sole, which allows you to set the blade not strictly perpendicular to the surface being sawed, but at a certain angle, but at the same time the saw is also driven strictly in a straight line.

1. Upper main protective casing. 2. Power button. 3. Power lock button. 4. Laser switch activation button.

5. Support handle. 6. Housing with motor. 7. Laser pointer. 8. Adjusting the cutting angle.

9. Saw blade. 10. Lower loaded casing. 11. Support sole.

What speed is needed for a circular

Do-it-yourself circular saw – durable, convenient, inexpensive!

For any home craftsman, having your own stationary sawing machine is time saving and work safety. You can purchase a ready-made stationary circular. The price of small machines starts from 9,000 rubles, more or less reputable stationary saws are sold in the price range from 30 to 100 thousand.

Despite the apparent complexity of the design, any craftsman with simple plumbing skills can make a homemade circular saw. Moreover, during the design process it is possible to add functions not provided by the manufacturer.

The best circular saws for quality and reliability

DeWALT DWE560 is one of the best circular saws.

Among the most reliable and high-quality models are the following:

- Interskol DP-190. The saw has a power of 1600 W, the diameter of the circle is 19 cm. Allows you to make cuts 60 mm deep.

- DeWALT DWE560. The device is equipped with a 1300 W motor. This allows you to cut any tree.

- BOSCH GKS 190. Cutting depth - 70 mm. Cuts both small and dense bars.

Additional Information! All listed models are equipped with soft start.

What is a circular saw for?

Before work, you need to find the main tasks of the sawing machine. If you just need to cut firewood for the winter, or do simple carpentry work like making a fence - a fairly strong table with a slot for a saw blade. These options are popular in rural areas.

Obviously, there can be no question of any safety or functionality when using such a device.

In some similar “models” there is a shaft for securing the knives of a plane or jointer. Usually, a frame is welded from a corner or channel, an electric motor from a decommissioned factory ventilation is mounted on it, and with the help of a pulley the torque is transmitted to the disk. It makes no sense to carefully outline the production technology of such a machine.

It's a different matter if you want to create carpentry work. In this case, you need a coordinate table with guides that are fixed at different angles. Since such a stationary saw can work with small-sized workpieces, you need to take care of the operator’s safety. It is better to provide for adjusting the rotation speed and the ability to easily change disks with different diameters.

Circular saws: how to choose by power level

For a circular saw, the main characteristic is the outer diameter of the cutting blade. Manufacturers complete a specific model with this parameter in mind: in particular, as the disk size increases, it is necessary to install more and more powerful motors. Why? A weak motor will not be able to spin the blade to the required speed, which will make working with the saw extremely ineffective.

The high power of the tool means the presence of a high-tech stabilization system, which leads not only to an increase in the size and weight of the model, but also causes an increase in its price. Saws with large accessories are ideal for cutting massive and thick workpieces.

Experts traditionally advise choosing a tool with a power reserve, since thanks to it, all other things being equal, a longer period of stable continuous operation of the circular saw is ensured. For infrequent household use, it is enough to purchase a saw with a rating of 1000-1200 W, but if you are planning regular and extensive work at a professional level, then it is better to choose a model with at least 1600 W. But you need to take into account your physical capabilities. For comparison: a 1200 W model weighs about 3 kg, while a 2000 W model weighs 7 kg.

High power does not always guarantee high performance. For example, a 1600-watt Bosch 1656 saw and a 1400-watt Hitachi C8 perform the same amount of work in 27 and 22 seconds, respectively. The speed is also affected by the level of vibration and the ability of the tool to stay on the desired line.

How to make a circular, maintaining a balance between economy, functionality and safety

Bed. The frame can be made from an iron angle (channel) purchased from scrap metal collectors. If you have the means, contact a metal warehouse. The legs can be made from old water pipes, connecting them with corners.

You need to use electric welding. Be sure to strengthen the corner joints with a jib. The upper part of the frame (on which the table will rest) and the podium for the electric motor are made from a corner with a side of at least 50 mm. If the machine is equipped with wheels for movement, they must have iron rims and have locks. The higher the weight of the frame, the more stable the machine will be, and the safer the work will be.

Table. The working surface is made of iron, aluminum or silumin sheet. It is permissible to use textolite, plexiglass or moisture-resistant plywood. Zinc-coated sheet metal is placed on top of the plywood. The main condition is that the material should not burst from vibrations, have a smooth surface and not allow deflections under a weight of more than 50 kg. If the tabletop cracks or warps, the circular disk will jam.

This will lead to injury and damage to the workpiece. The introduction of popular materials OSB and chipboard is not necessary. These materials are unstable to vibrations and can collapse at the most crucial moment.

There are two options for producing a working groove for a circular disk . You can cut a groove or place two halves of the tabletop at a distance from each other. The disk should protrude above the table by no more than 1/3 of its diameter.

Which circular saw to choose: ergonomics

Convenience and quality of work depend not only on the technical characteristics of the tool, but also on the degree of its ergonomics. Manufacturers even produce circular saws specifically designed for left-handers. In general, everyone can choose a saw according to their hand; you just need to pay attention to the following parameters:

- Handles. It is best to purchase a model with adjustable handles. In this case, you can customize the circular machine to suit your own requirements. It would be good if the handles were rubberized: this ensures safe operation, since the tool can be confidently controlled throughout the entire sawing process.

- Frame. Most models are made of plastic: the safety margin of this material is enough so that the saw does not cause problems. Expensive metal circulars are heavy, which is often not very convenient.

- Additional functions:

- collection of sawdust. The saw must have special connections for connecting a dust collector or connecting a vacuum cleaner. The latter option is considered more labor-intensive, but it provides the highest quality sawdust removal;

- smooth start. The implementation of this function allows you to extend the “life” of the engine and increase the level of safety when working with a circular saw;

- laser pointer. Necessary for making precise cuts;

- immersion A very useful function that allows you to start cutting from any place, rather than from the beginning: for example, this feature is useful for cutting a hole in a solid slab;

- accidental start blocking. Protects the user from unplanned activation of the tool.

The main recommendation when buying a circular saw is to hold it in your hands until the deal is concluded. This is the only way to assess how suitable the tool is for a particular user.

A circular saw is useful to anyone who even occasionally does home repairs. The cost of purchasing a tool will pay for itself very quickly, becoming an example of the rational use of the family budget.

Circular jointer (ROM on the shafts.) Measurement with a tachometer

Measuring with a mechanical tachometer requires direct contact with the surface of the object.

Drive unit. The best option is a V-belt. You can use a poly-V-ribbed drive belt complete with pulleys from a car engine. The belt drive guarantees a certain safety when the disc becomes jammed (for example, a nail in a workpiece). Unlike a rigid gear drive, the belt will slip on the pulley, preventing the circular disk .

If the electric motor does not have a speed controller, replacement pulleys of different diameters can be made. This will make it possible to use disks of all types, at different operating speeds.

Shaft. Perhaps the most important part of a homemade circular saw . It is not safe to make handicrafts from a piece of pipe, so it is better to order it from a good turner or buy it ready-made. The same goes for mounting for bearings. To save money, you can use hub kits from your car.

Bearings must be protected from dust; for this purpose, a gasket casing is installed in the grooves between the bearing races. The shaft may have slots with fastenings for plane knives. In this case, it must be balanced. It can also be equipped with mounts for cutters. Then the machine will be able to produce paneled doors and cornices of complex shapes.

Electrical part. The starting device must match the power of the electric motor. The safest option is a push-button one, with thermal protection against overcurrent. In this case, if the disk jams, automatic shutdown is possible. The electrical panel is mounted on a dielectric material, the wiring is reliably insulated from the metal frame. The shutdown button is located in an accessible place and should be pressed without force.

Often such machines are stored outside. Therefore, the electrical part must be protected from direct moisture. When designing a homemade circular saw, it is necessary to provide for the possibility of its repair, maintenance, and replacement of worn parts.

Moving parts must be lubricated. Before practical work, drawings are made, which include every detail. Any error in manufacturing entails the purchase of new material, which will inevitably increase the cost of the structure.

Do-it-yourself stationary circular saw - according to our drawings and instructions, anyone can do it

The household often lacks a circular saw, especially if major renovations or construction are underway. Not everyone can afford industrial products - they are too expensive. But you can make a circular saw yourself, using materials that are available in the household.

A do-it-yourself stationary circular saw is created with advancement in several possible directions:

- adapting existing hand tools using the motor and circular saw for new capabilities;

- improvement of industrial products to expand functionality;

- assembly of individual parts, manufactured mainly in-house.

A stationary circular machine includes several main components: a table, a shaft, a motor and some others, the characteristics of which are not so important.

Making a workbench with a built-in saw cheap and cheerful

The table is used for fastening woodworking mechanisms. It can be assembled entirely from metal, which is preferable, especially for machines with a high-power engine. Wood also makes good circular tables. But it is necessary to take into account that the tabletop should be covered with a sheet of metal, otherwise the wood will soon wear out. Tables must be very rigid and stable, capable of withstanding considerable load during work. The surface is made perfectly flat; protective shields must be installed above the rotating parts.

For a homemade circular machine, a washing machine motor is quite suitable. Portable tools are less suitable: their commutator motors are designed only for short-term work. They have very high speeds, low efficiency, and are afraid of clogging. You can use a three-phase electric motor, but if the household does not have 380 V, you will need to purchase capacitors to make it work on 220 V.

The most critical component is the shaft. Use a ready-made one, if available, or machine it from round metal. The work on the lathe is performed in one setup, then the assembly with the working parts is checked for centering. Even minimal runout is unacceptable, otherwise during work it will become stronger, at which it is unacceptable to work. Seats are provided on the shaft: for a circular saw and for pulleys on the other side. You can also make grooves for planing knives.

The characteristics of the circular saw, the engine and the maximum thickness of lumber that can be cut are interconnected. The maximum speed for which it is designed is indicated on the purchased circular disk. The number of revolutions transmitted by the engine to the shaft should be less. The engine power affects the maximum permissible saw tooth diameter. The diameter must be at least three times the thickness of the material, otherwise sawing will be difficult. It is believed that to cut materials 100 mm thick, you need a motor of at least 1 kW of power.

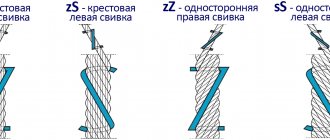

The transmission is made only by a V-belt - if foreign objects get under the saw, the material jams, the belt slips on the pulleys. Injuries in such cases are practically eliminated. It is important to choose the right gear ratio. We take into account two indicators: engine speed and the maximum permissible speed of the circular saw. We calculate the required pulley diameters. A pulley with a large diameter is installed on the engine, and a smaller one on the circular shaft to increase the number of revolutions.

The revolutions of the shaft with a circular saw are as many times greater than the engine revolutions as the diameter of its pulley is smaller than the diameter of the pulley on the engine.

To work with wood in large volumes, it is better to have a machine that allows you to cut the material, plan it, and select a quarter. A fairly powerful electric motor and a rigid table are required. We present a structure made of steel angle and sheet steel. It provides a cutting depth of 60 mm; you can plan boards 200 mm wide. A three-phase motor of 1.1 kW, 2700 rpm is used. To connect to 220 V, capacitors are required.

1 – machine frame; 2 – panel; 3 – starter; 4 – device for height adjustment; 5.7 – work table of two halves; 6 – base; 8 – engine; 9 – platform; 10 – M10 studs; 11 – circular disk; 12 – shaft; 13 – stops of the lifting mechanism; 14 – driven pulley; 15 – belt; 16 – drive pulley; 17 – switch.

The work table has dimensions of 700×300 mm. In the drawing we see that the height of the entire structure is 350 mm. The height is not sufficient for comfortable work; the circular saw will have to be installed on an additional platform; it weighs only 35 kg. You can increase the length and width, increase the height to 1200 mm. We adjust the remaining sizes to fit them, but the design features remain unchanged.

First we make the bed frame from steel corners 25x25 mm. If we are not going to increase the height, we make another similar lower frame. For a frame with a higher height, first we weld four legs from the same corners to the upper frame, and then we tie them at a height of 15–20 cm from the bottom. The lower frame has grooves for the engine platform locking bolts. Two studs are welded to the back side of the platform, which go into the holes on the back of the lower frame. By tightening the studs, we tighten the belts, then we lock the platform by tightening the nuts on the studs that go into the grooves.

To adjust the height of the table in relation to the saw, we use a simple lifting mechanism. It consists of racks, in the upper part of which we cut grooves at an angle of 45°. A total of eight racks are needed - four on each side. We weld them to the frame with grooves located in a mirror image. We attach cross members to the outer posts. We drill holes in the middle of each of them and weld nuts. Threaded shafts will move along them to regulate the lift.

Circular saw from a grinder or circular saw

If there is no need to work with massive wooden workpieces, you can make a small-sized stationary saw from a ready-made power tool. Circular Saw. A ready-made and fairly safe tool. There are two options for stationary use.

You can simply attach the saw to the bottom of the table so that the blade protrudes above the surface to the required height. The difficulty is that the switch will be inaccessible. Therefore, it is necessary to block it and duplicate the starting device or remove the standard switch from the body of the circular saw . It's effective, but not safe.

You can see how to use a circular saw as a circular saw in this video

Another option is a sliding bed. The base is mounted from two parallel metal guides. A frame with rollers and a fixed circular saw is installed on it. The workpiece is motionless, and the circular saw, moving along the guides on the carriage, makes cuts at the desired angle. This easy-to-make machine can actually work wonders on small workpieces.

Sawing speed - reference information on choosing cutting parameters

Sawing speed - reference information on choosing cutting parametersCircular saw cutting speed.

Typically, to increase stability, a circular saw blade with the smallest possible diameter is selected. At the same time, in order to achieve the highest cutting speed, it is necessary that the diameter of the circular saw be correctly selected, taking into account the number of revolutions of the machine (if the machine has an adjustable speed, recommendations are given on the operation of the machine). Carbide saw blades can be used at relatively high speeds.

You can calculate the sawing speed using the following formula:

v = (D * 3.14 * n) / (60 * 1000) where

n - number of saw revolutions per minute D - saw diameter, mm v - cutting speed, m/s

Recommendations for choosing cutting speed:

| Wood: cross cut | 50-80 |

| Longitudinal sawing - dry wood | 60-10 |

| Longitudinal sawing - raw wood | 60-100 |

| Sawmill discs | 60-100 |

| Plywood and laminated boards | 60-80 |

| Fiberboard | 70-80 |

| Drywall, particle board and decor. | 50-80 |

| plywood veneer, thin cardboard reels | 50-80 |

| Hard plastic | 50-75 |

| Plexiglas, PVC, Bakelite | 50-85 |

| Plastic laminate | 50-75 |

| Soft plastics | 15-50 |

| Aluminum | 60-80 |

| Copper | 50-70 |

| Brass | 50-70 |

| Lightweight concrete | 40-60 |

| Steel (not hardened) | 5-30 |

Feed per tooth.

To increase service life and improve cutting quality, it is important to choose the optimal feed rate per tooth. If the circular saw has a low feed speed, this can cause rapid wear on the saw. If the feed rate is too high, it may cause tooth breakage and insufficient spacing between teeth.

You can calculate the feed per tooth using the formula below:

Sz = (S * 1000) / (n * z) where:

Sz - feed per 1 tooth, mm S - feed speed, m/min n - number of revolutions per minute Z - number of teeth

Recommendations for choosing the feed rate per tooth, expressed in mm.

| Material | feed per tooth (mm) |

| Wood: cross cut | 0,10-0,35 |

| Longitudinal sawing - dry wood | 0,10-0,20 |

| Longitudinal sawing - raw wood | 0,20-0,80 |

| Sawmill discs | 0,70-1,50 |

| Sawmill discs * | 0,80-2,50 |

| Plywood and laminated boards | 0,05-0,12 |

| Fiberboard | 0,08-0,25 |

| Drywall, particle board and decor. | 0,08-0,25 |

| plywood veneer, thin cardboard reels | 0,08-0,25 |

| Hard plastic | 0,05-0,12 |

| Plexiglas, vinyl plastic, bakelite | 0,05-0,12 |

| Plastic laminate | 0,03-0,06 |

| Soft plastics | 0,05-0,08 |

| Aluminum | 0,02-0,05 |

| Copper | 0,03-0,08 |

| Brass | 0,03-0,08 |

| Steel (not hardened) | 0,01-0,03 |

| *Notes and edge processing |

Power to the saw - see picture

Homemade circular

- Go to page:

#271 Post by Ruddyu » Mon Mar 30, 2009 21:56

#272 Post by xxxxxxxxx » Tue Mar 31, 2009 9:18 am

#273 Message by Boris_B » Tue Mar 31, 2009 9:38

#274 Post by xxxxxxxxx » Tue Mar 31, 2009 10:26

#275 Post by Hedgehog » Tue Mar 31, 2009 2:51 pm

Good luck to everyone. Dmitriy.

Experts are like dirt. There are not enough modelers. Don't tell me what I'm doing wrong. Show me how you do it. Full-time school of classical ship modeling: Here, on the forum, Facebook

#276 Post by xxxxxxxxx » Tue Mar 31, 2009 15:27

#277 Post by Hedgehog » Tue Mar 31, 2009 15:41

Good luck to everyone. Dmitriy.

Experts are like dirt. There are not enough modelers. Don't tell me what I'm doing wrong. Show me how you do it. Full-time school of classical ship modeling: Here, on the forum, Facebook

#278 Message by Boris_B » Wed Apr 01, 2009 2:29

#279 Post by Sarasen » Wed Apr 01, 2009 12:06

#280 Post by Tyjn » Thu Apr 02, 2009 22:25

During the construction of the “Pallada”, the period of preparing firewood, slats for velhout, etc. began, I took out the “Skillful Hands” machine from the closet, but could not find the original table for the circular machine anywhere. I had to use my head and hands and create this version in a couple of hours. Works with the original disc and with cutters Ф40*10*06 and Ф47*16*0.8-1.5. Cuts great.

Source: www.shipmodeling.ru